Microbial cell clarification solution

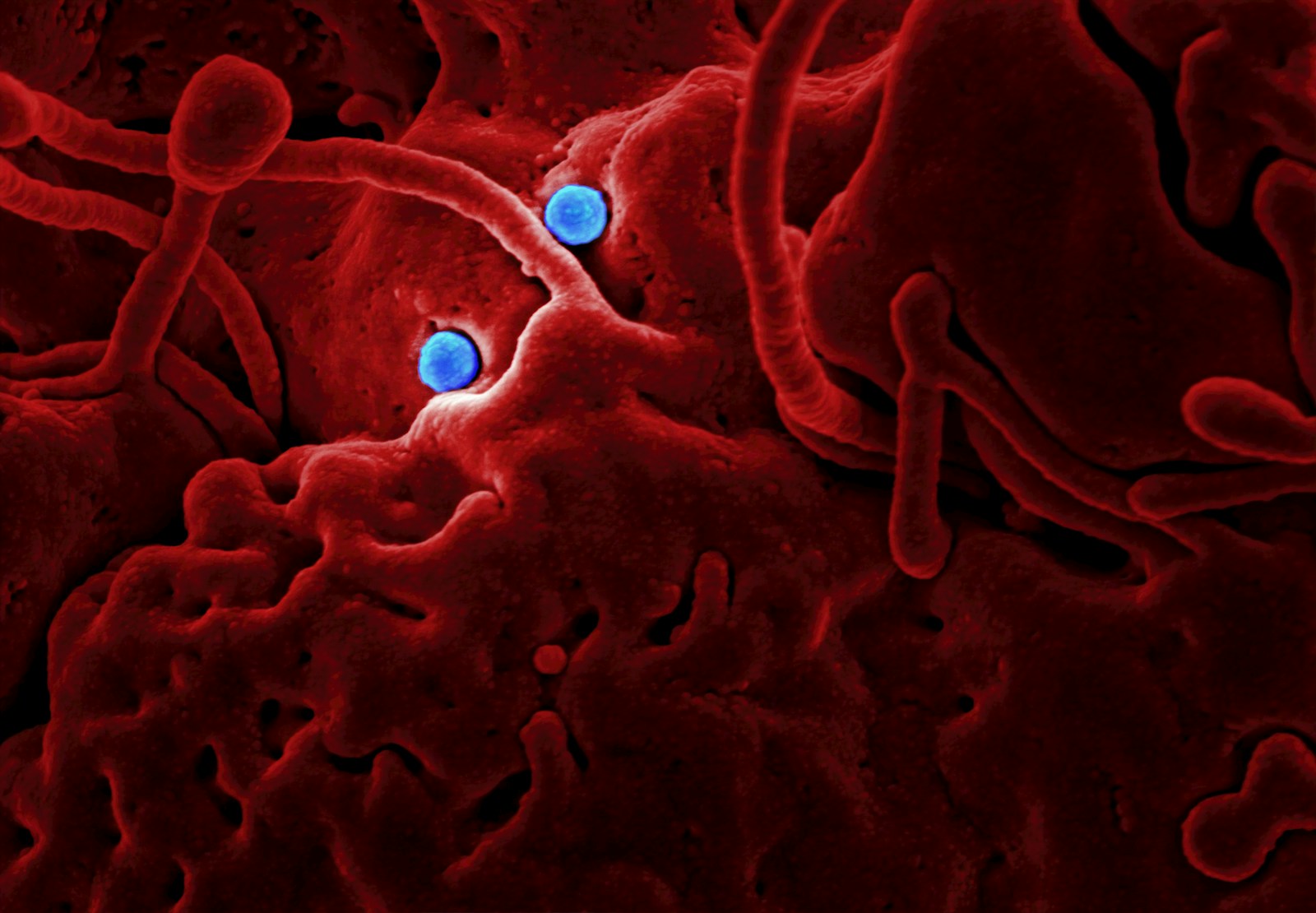

Achieve high-yield, foam-free microbial cell clarification with minimal shear stress in pharmaceutical processes, enhancing product purity and ensuring seamless integration into your production line.

Separates and Clarifies Biopharmaceutical Products

The MBPX pharma centrifuges from Alfa Laval are specialized hermetic disc stack separators designed for seamless integration in the pharmaceutical and biotech industries. They address the challenge of efficient microbiological separation with minimal product loss and shear stress. Featuring a unique hermetic design, these centrifuges ensure foam-free processing ideal for sensitive applications such as vaccine production, monoclonal antibodies, and cell-based therapies.

The MBPX system excels in clarification processes, capable of handling diverse materials from microbial cells to precipitated proteins. Skid-mounted and modular for easy installation, these separators are fully automated for continuous operation and equipped with PLC controls for precise function and remote monitoring.

These centrifuges are designed with energy efficiency in mind, utilizing optimized motor control to reduce power consumption. Constructed from materials that meet ASME BPE standards, CFR part 11, and USP class VI for product-contact polymers, they ensure compliance with stringent pharmaceutical regulations. With integrated CIP systems, the MBPX separators offer cleanliness and minimal maintenance downtime, further enhanced by factory-verified reliability before dispatch.

Benefits

- Ensures high product yield and minimal losses through gentle hermetic design.

- Reduces fouling and maintenance intervals with high separation efficiency.

- Lowers operational costs with reduced power consumption and noise levels.

- Simplifies cleaning and compliance with integrated CIP system.

- Facilitates rapid deployment and integration with customizable skid-mounted or modular systems.

- Applications

- Vaccines, Cell cultures, Microbial cells, Microbiological separation applications, Biopharmaceuticals, Precipitated proteins

- End products

- Insulin, Monoclonal antibodies, Cell-based therapy products, Enzyme preparations, Therapeutic proteins, Probiotics

- Steps before

- Fermentation, Culturing, Cell Cultivation, Protein Precipitation

- Steps after

- Polishing Filtration, Purification, Formulation, CIP (Cleaning in Place)

- Input ingredients

- microbial cells, cell cultures, precipitated proteins, suspended particles

- Output ingredients

- clarified microbial cells, clarified cell cultures, clarified precipitated proteins, vaccines, biopharmaceutical products

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Particle size range

- 0.5–500 µm

- Separation efficiency

- High

- Power consumption

- Low

- Noise level

- Low

- Shear stress

- Minimal

- Automation

- Fully automated

- Hermetic design

- Yes

- Batch capacity

- Flexible (small and large scale)

- CIP compatibility

- Yes

- Piping standard

- ASME BPE

- Polymer and seal ring standard

- USP class VI

- Control system

- PLC

- Working mechanism

- Disc stack separation

- Integrated steps

- Fully automated systems

- CIP principles

- Fully wetted contact areas

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Automatic / PLC

- Minimal shear stress

- Yes

- Absence of oxygen

- Hermetic design

- Noise level

- Low

- Energy efficiency

- Low power consumption

- High product yield

- Yes

- Foam control

- Foam free processing

- Biological compatibility

- USP Class VI

- Cleanability

- CIP compatible

- Corrosive resistance (e.g. acids)

- ASME BPE standard materials

- Density/particle size

- 0.5–500 µm

- Batch size

- Small batches to large scale

- Compact footprint

- Skid mounted solutions for small sizes

- Discharge method

- Continuous discharge of solids

- Control panel type

- PLC-controlled

- System customization

- Customized, fully automated systems

- Modular system design

- Modular system for large systems, skid mounted for smaller sizes

- Control panel integration

- Includes PLC

- System testing

- Factory tested before shipping

- Piping and component integration

- Including piping and components for service and process liquids