Breakfast cereals

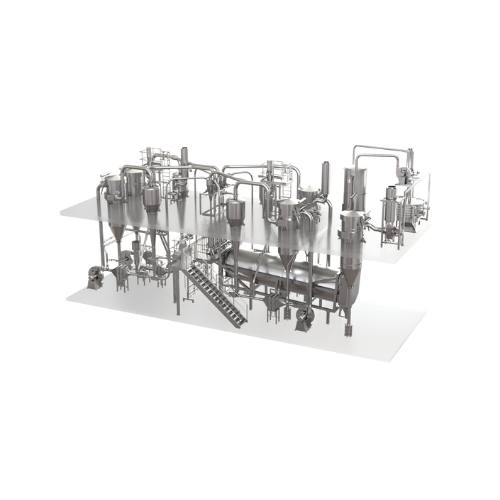

Find innovative production technology for making breakfast cereals and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Which breakfast cereals technology do you need?

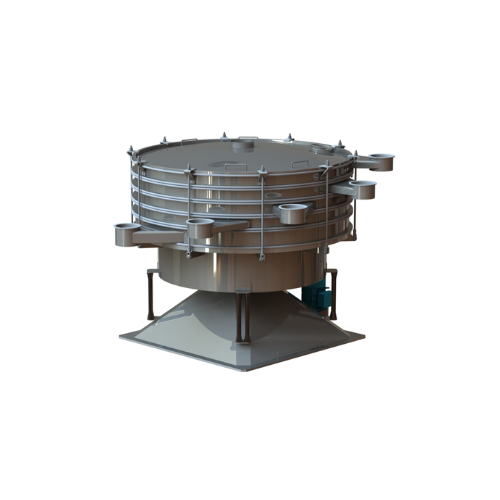

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

High infeed palletizer for varied product types

Optimize your production line with high infeed palletizers, ensuring seaml...

Sweep auger for flat bottom silos

Optimize your grain storage operations with a fully automatic sweep auger designed to eff...

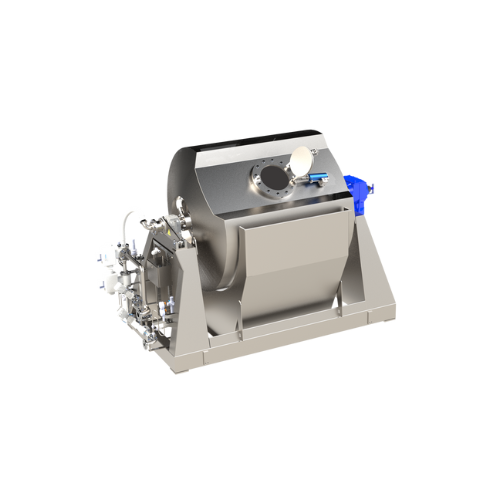

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

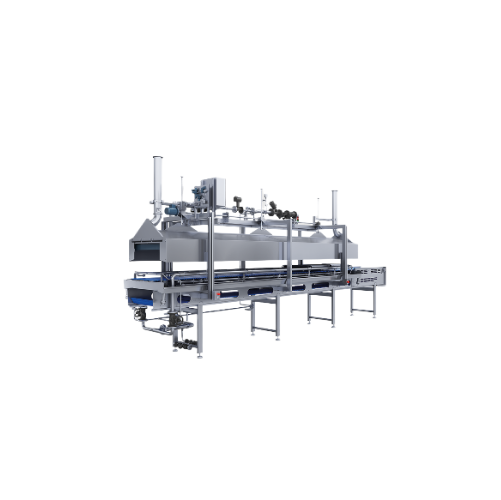

Continuous cooker for high-volume food processing

Elevate your production efficiency with a continuous cooker that ensure...

R&d scale steam cooker for small batch processing

Optimize your R&D with a steam cooker that replicates large-scale ...

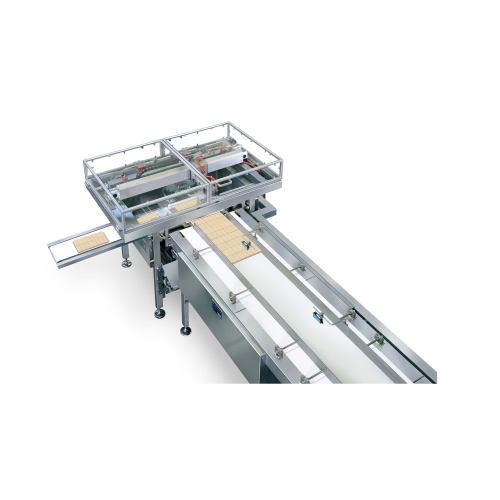

Wafer row discharge device for feeding packing machines

Efficiently automate wafer row feeding to improve packaging throu...

Wafer distribution device for chocolate coating plants

Enhance your chocolate coating operations with precision wafer dis...

Wafer sandwich cooling systems

Efficiently setting cream fillings for clean cuts, this cooling system ensures your wafer san...

Wafer sheet conditioning tunnel for chocolate coating

Optimize your chocolate-coated wafer production by ensuring precise...

Wafer sheet cooling system

Ensure optimal cooling and conditioning of baked wafer sheets with a system designed to maintain ...

Single-screw cooking extruder for snack production

Optimize your snack production with a versatile extruder designed to h...

Automatic wafer batter preparation system

Optimize wafer production with precision dosing and homogeneous mixing, ensuring...

Contact spreading machine for cream application on wafer sheets

Ensure precise cream application with our specialized co...

Cream preparation plant for wafer production

Achieve consistent cream texture and optimal weight for perfect wafer product...

Hollow wafer spreading machine for consistent coating

Optimize your snack production with precise spreading—achieve unifo...

Semi-automatic batter preparation plant for wafer production

Enhance your wafer production with a versatile system desig...

Automatic wafer baking machine for high-capacity production

Streamline your wafer and snack production with a high-speed...

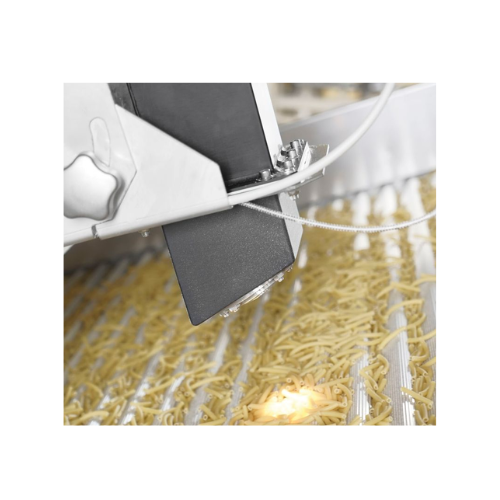

Cooling drum for seasoned extrudates

Ensure consistent texture and quality in your extruded snacks by effectively cooling s...

Cream preparation plant for homogeneous mixing

Optimize your snack production with precise mixing technology, ensuring con...

Industrial drum dryer for extruded snacks

For snack producers aiming to achieve precise moisture control, this rotating dr...

Seasoning drum for extruded snack products

Achieve consistent seasoning and mixing for extruded snacks with precision and ...

Continuous extruded snack dyeing system

Enhance the aesthetics of your extruded snacks with precise and continuous dyeing, ...

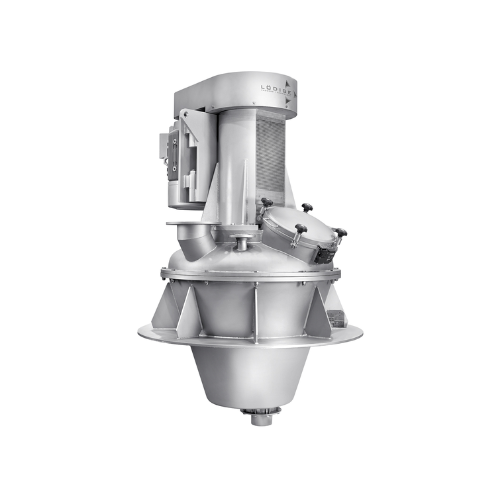

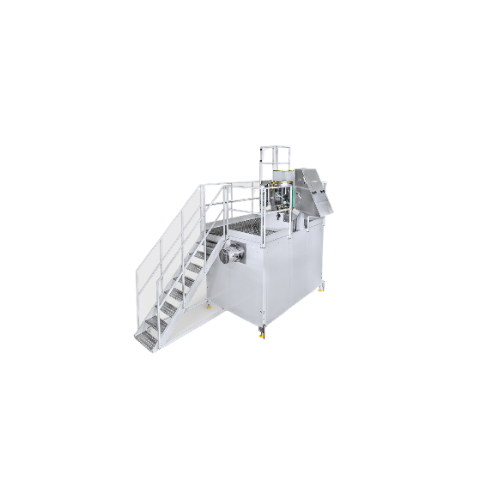

Intermediate container for raw material preparation

Streamline your snack and cereal production with this solution that e...

Intermediate cream container for snack production

Ensure consistent cream texture before extrusion with a solution design...

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

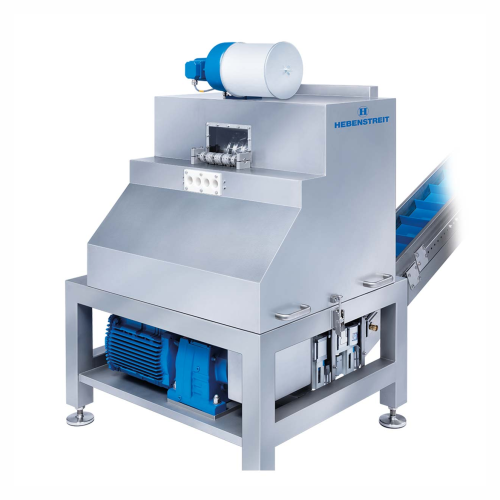

Roller embossing system for snack production

Effortlessly shape and press multiple product strands into diverse, precise f...

Seasoning mixing system for extruded snacks

Achieve consistent flavor profiles in your extruded snacks with this high-spee...

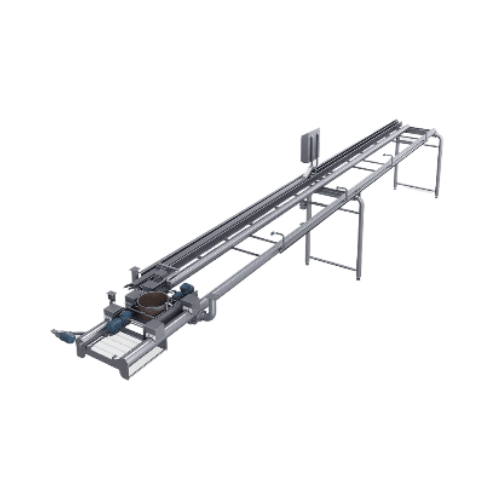

Conveyor systems for snack production

Streamline your snack production with advanced conveyor systems designed for seamless...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

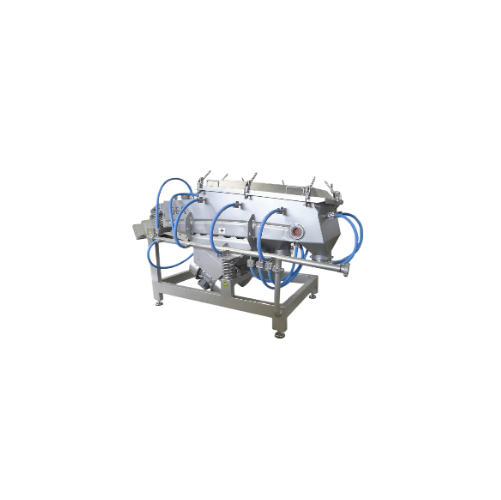

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

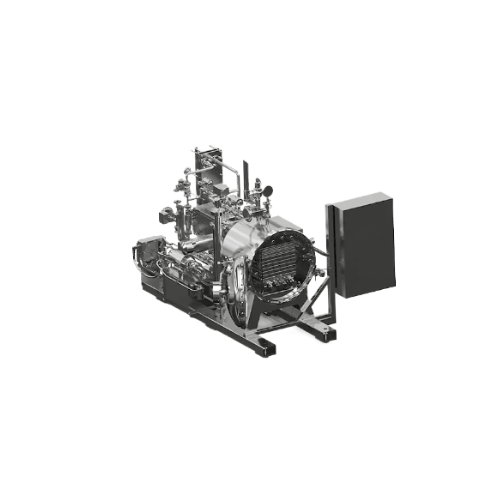

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Pellet mill for noise-reduced pelleting

Optimize production with a pellet mill designed to minimize noise and enhance lubri...

Steam chambers for grain expansion in steam-flaking

Ensure precise grain expansion with steam chambers, designed for unif...

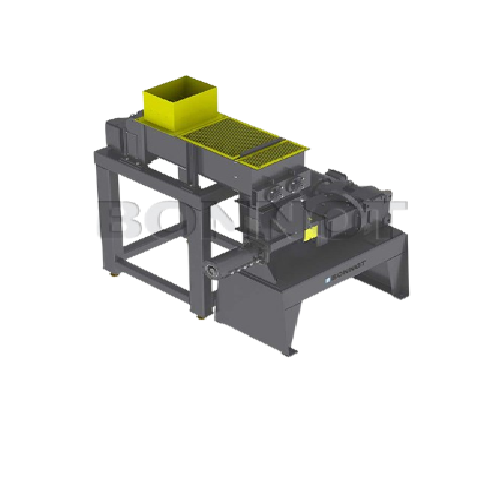

Industrial lump breaker for particle size reduction

Optimize your production line with an advanced solution for efficient...

Industrial steam systems for conditioning

Efficiently deliver optimal steam conditioning for diverse feedstock, enhancing ...

Industrial grain flaking solution

Enhance grain processing efficiency with precision-engineered flaking solutions, designed...

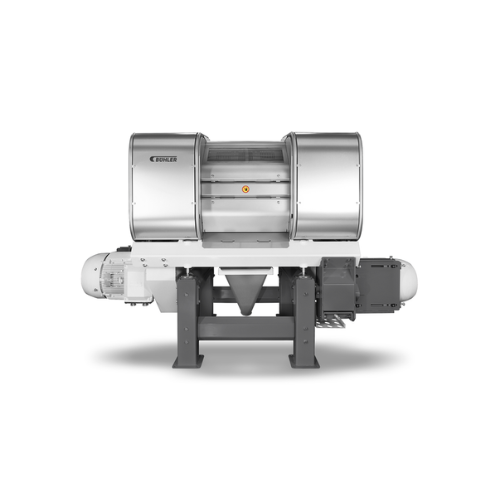

Hammermills for grinding tough products

Optimize particle size reduction with precision-designed hammermills that efficient...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

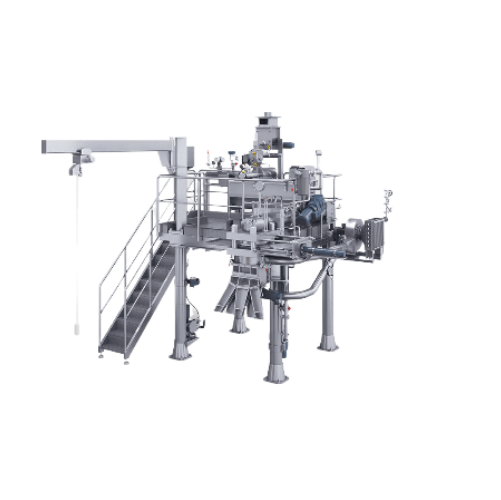

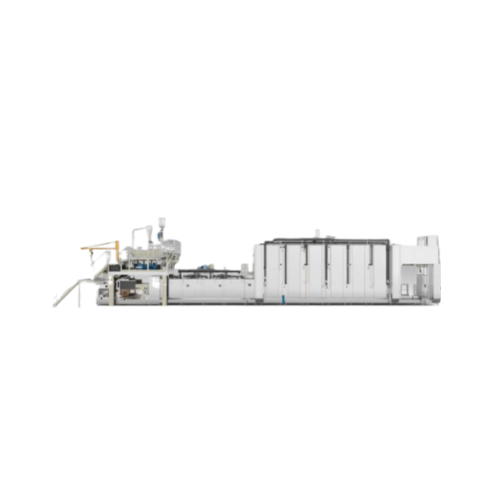

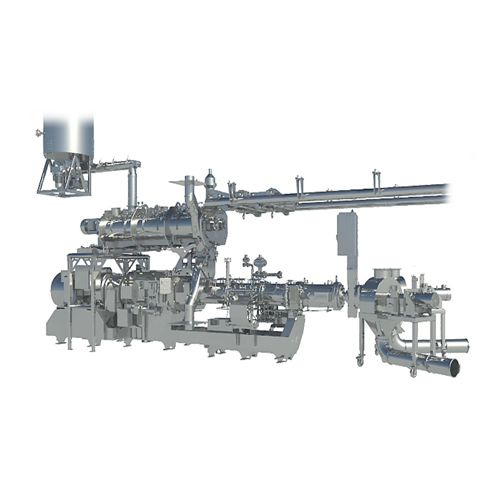

High-performance twin-screw extruder for food production

Enhance your production line efficiency and product quality with...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

Granola drying solution

Optimize your granola production with modular drying technology that ensures precise moisture control...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

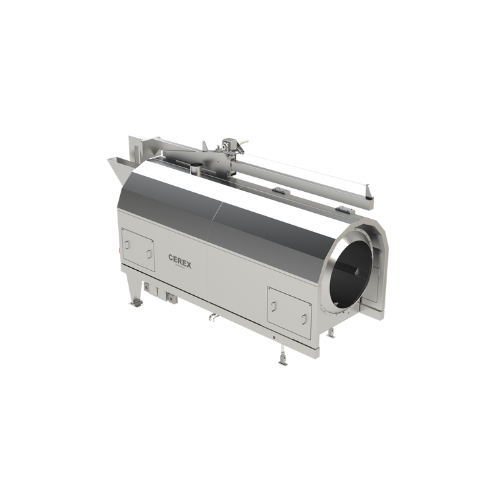

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

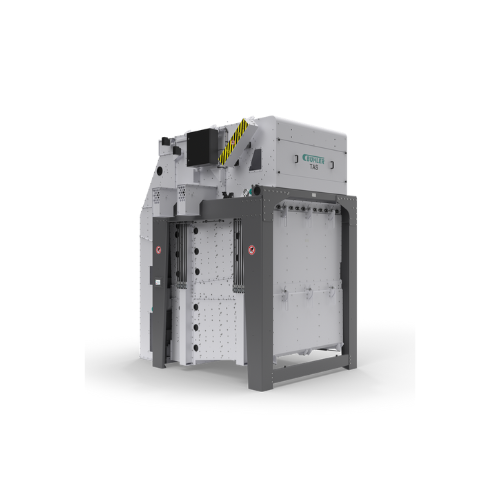

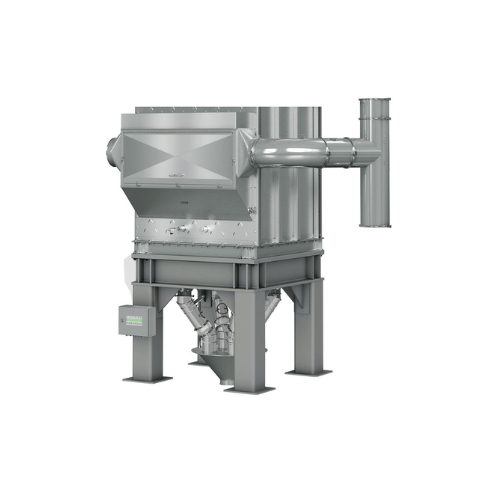

Industrial screeners for grain product processing

Optimize your cereal production line with specialized industrial screen...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

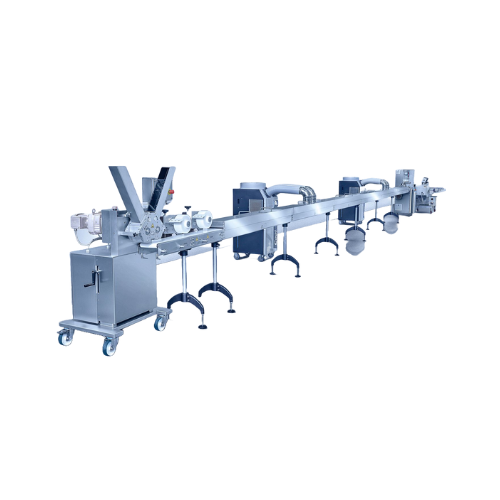

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrati...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Moisture control system for grain milling

Optimize moisture levels precisely within your grain milling process, ensuring c...

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Automatic silo scale for grain processing

Enhance your grain handling operations with precision weighing and dosing, ensur...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

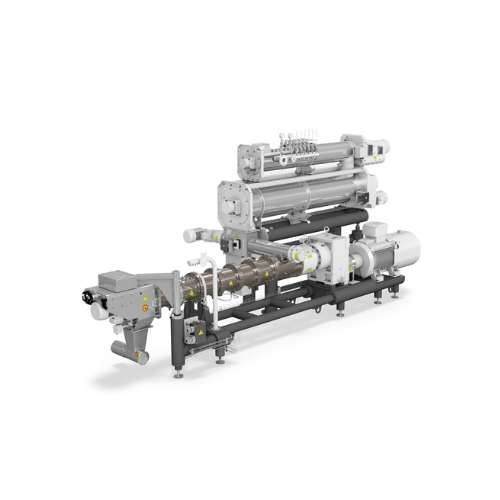

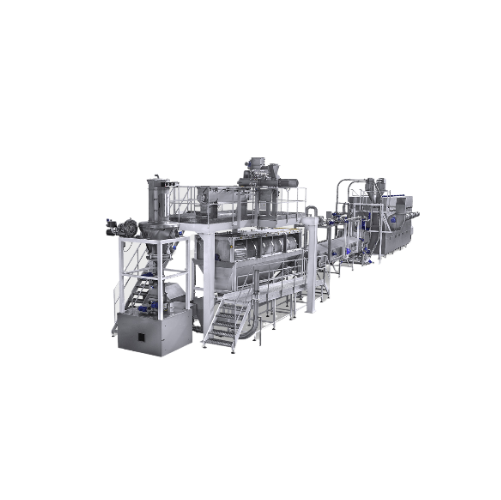

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Bran finisher for efficient flour and bran separation

Optimize your grain processing efficiency with a solution designed ...

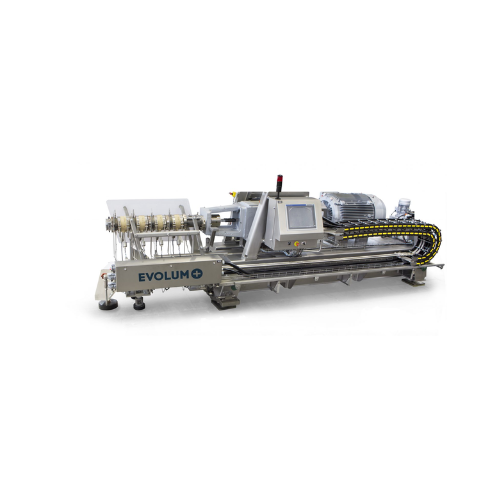

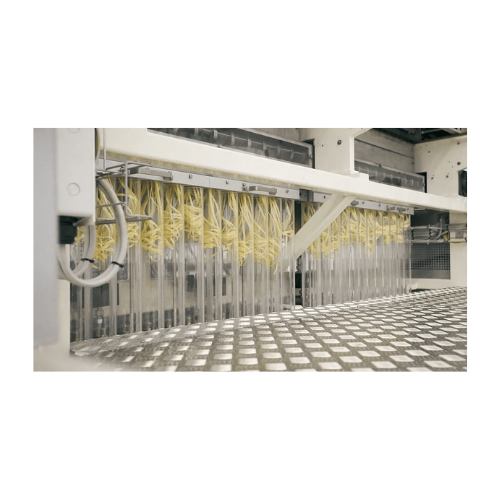

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Compound rolling unit for dough sheets

Achieve unparalleled precision in dough formation with our high-speed compound rolli...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Standard starch viscometer for gelatinization analysis

Ensure precise gelatinization property measurement with real-time ...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Loading box for granular products in production lines

Optimize your production line with a manual-to-continuous loading b...

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

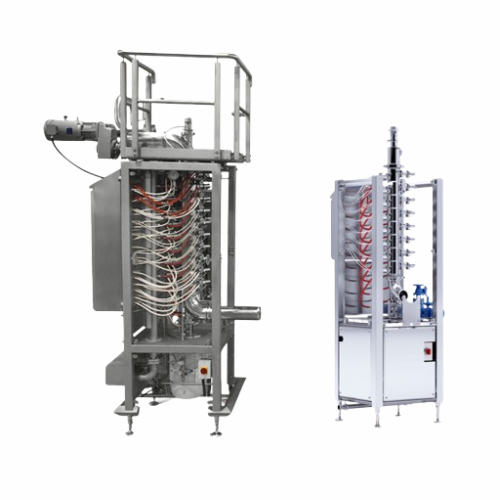

Vertical packaging system for short-cut pasta and dry granular food

Streamline your packaging operations with a high-sp...

Intermittent motion bulk packaging for pasta and granular products

Optimize your production line with precision packagi...

Packaging system for short-cut pasta and dry granular food

Streamline your packaging process with a versatile system des...

Eco-friendly vertical packaging for pasta

Reduce plastic waste and enhance sustainability in pasta packaging with high-spe...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Industrial predryer for humidity reduction in food processing

Ensure optimal shelf life and prevent product sticking wit...

Industrial cooling system for packaging temperature control

Achieve precise temperature control and maximize energy effi...

Industrial pasteurizer for efficient bacterial reduction

Ensure your food products are safe with an industrial pasteurize...

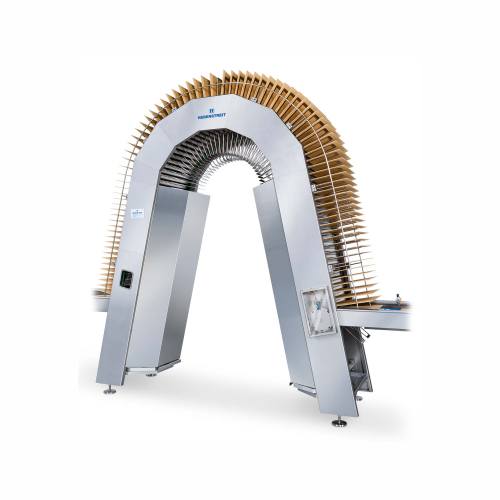

Industrial spiral cooler for thermal treatment

Improve your final conditioning and packaging process with a spiral cooler ...

Bulk packaging system for long cut pasta

Optimize your bulk packaging of long cut pasta with a high-speed, customizable sol...

High-speed pasta packaging system

Streamline your pasta packaging process with an advanced system that combines precise wei...

Long cut pasta packaging solution

Optimize your pasta production line with seamless, high-speed packaging tailored for long...

High-speed packaging system for long-cut pasta

Achieve seamless high-speed packaging with enhanced accuracy and minimized ...

High-accuracy package weigher for pasta and granular products

Optimize your packaging line with precision weighing and i...

Double sheet forming system for ravioli production

Streamline your production with high-speed forming and sealing, achiev...

Tagliatelle cutting system for pasta production

Enhance your pasta production with efficient, high-speed cutting systems d...

Extruder for short-cut pasta and lasagna production

Achieve seamless pasta and snack production with an extruder designed...

Calibrating rollers for pasta sheet thickness control

Achieve precise pasta sheet thickness control with advanced calibra...

Mixer kneader sheeter for fresh pasta processing

Streamline your pasta and dough production with a single machine that eff...

Kneader sheeter for single sheet pasta production

Achieve consistent and precise dough sheeting with advanced kneader she...

Double sheet kneader sheeter for fresh pasta processing

Efficiently transform dough into consistent sheets with our machi...

Continuous automatic pasta extruder

This state-of-the-art extruder simplifies your pasta production by seamlessly integrati...

Surface drying system for pasta production

Ensure optimal surface drying of pasta and snacks post-pasteurization, preventi...

Batch standing mixer for dough preparation

Enhance your mixing precision with a batch standing mixer that optimizes paddle...

Dough distribution system for multiple mixing points

Ensure precise dough allocation across multiple production stages wi...

Industrial screw pump for dosing hard fillings

Enhance precision and efficiency in dosing hard fillings with a robust scre...

Lobe pump for soft fillings

Efficiently dose and feed soft fillings for food products with precision, ensuring smooth integr...

Creamy filling dosing system

Effortlessly dose creamy fillings into your production line with precision, ensuring chunk size...

Pasta folding system for cannelloni production

Streamline your production by precisely folding pasta around filling to cre...

Single sheet former for fresh pasta production

Optimize your production line with a versatile machine designed to precisel...

Pasta sheet forming machine for ravioli and cappelletti

Achieve precision pasta forming with consistent thickness and hig...

Tortellini forming machine

Optimize your tortellini production with a high-speed forming machine that ensures precise thickn...

Long-cut pasta production line

Optimize your long-cut pasta production with a single-tier system designed for precise moistu...

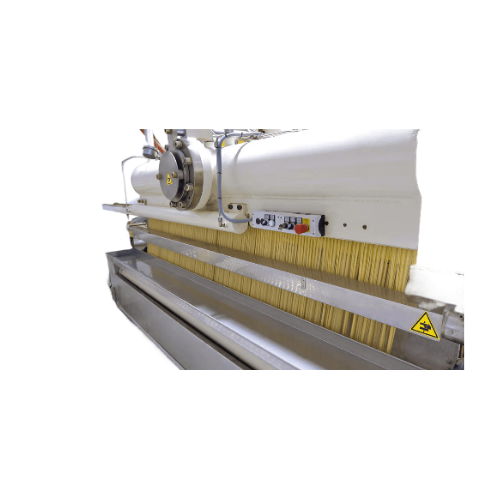

Industrial Long-cut pasta production line

Achieve superior long pasta quality with energy reductions up to 30%, featuring ...

Nest-shaped pasta production line

Streamline your pasta production with a solution designed to retain the integrity of nest...

Couscous production line

Enhance your couscous production with a seamlessly integrated line that ensures precise granule sizi...

Water cooker for fresh pasta processing

Enhance cooking precision and product quality with this water cooker, designed to c...

Industrial water cooker for pasta processing

Enhance your pasta production with precise water cooking, ensuring consistent...

Industrial water cooling system for food products

Efficiently cool and convey food products with a system designed for un...

Conveyor cleaning and cooling system for pasta

Efficiently halt cooking processes and eliminate surface starch with a stre...

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing ...

Round die washer for pasta and snack production

Ensure impeccable hygiene with a specialized washer that streamlines die m...

Industrial die washing solution for pasta production

Enhance efficiency in pasta and snack production with a robust die w...

Mini die-washer for pasta industry

Enhance the efficiency of your production line by ensuring thorough cleaning and debris ...

Pasta cutter for short pasta production

Streamline your short pasta production with a versatile cutter designed for rapid f...

Rotating cutter for short pasta production

Optimize your short pasta production line with a versatile rotating cutter desi...

Nest-shaped short pasta production line

Optimize your pasta production with a streamlined process that enhances drying effi...

Long-cut multi tier pasta line

Optimize your pasta production with high-speed, multi-tier drying and precise compression, en...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Short base skirt silo for bulk material storage

Optimize your bulk material handling with adaptable discharge and rapid lo...

Extruder for aquatic feed production

Efficiently produce a wide range of aquatic and pet feed with precise control over pel...

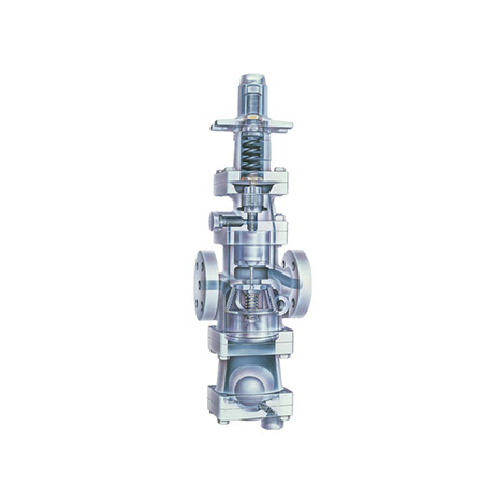

Pneumatic actuators for industrial valves

Optimize valve control in your production line with precision-engineered actuato...

Vibro bran finisher for milling operations

Optimize your grain processing with an advanced vibratory system designed to en...

Screw conveyor for grain or finished products

Optimize your production line with a space-efficient screw conveyor designed...

Double deck roller mill for grain milling

Achieve superior milling results with increased efficiency and hygiene in proces...

Industrial semolina purifier

Enhance your grain processing with high-capacity semolina purification, ensuring efficient clea...

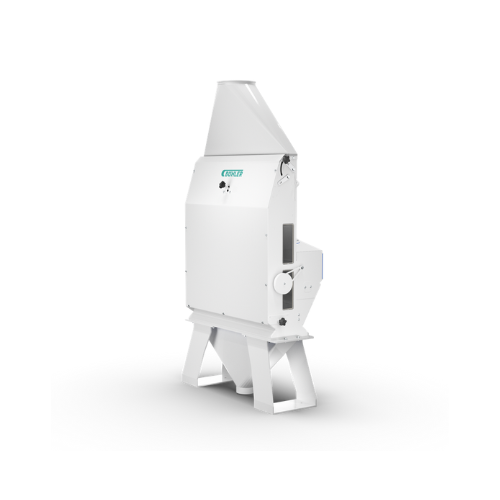

Separation system for low-density materials from grains

Efficiently separate lightweight impurities from dense grains to ...

Industrial extraction scale for accurate material weighing

Ensure precise ingredient proportions in your milling operati...

Grain separator for removing foreign materials

Ensure high-quality grain processing by efficiently removing foreign materi...

Automatic dampening system for wheat moisture regulation

Enhance your milling efficiency by precisely controlling wheat m...

Industrial grain control plansifter

Ensure precise grain quality control with an advanced plansifter, essential for guarant...

Industrial heavy particle separator for wheat cleaning

Optimize the performance of your filtration systems by interceptin...

Industrial impact detacher for semolina processing

Optimize your grain processing line with a solution designed to enhanc...

Flow meter for wheat dampening process

Ensure precise water control in grain processing with advanced flow measurement, ess...

Inclined intensive dampener for grain processing

Ensure consistent moisture levels for optimal grain processing and enhanc...

Intensive dampening system for flour mills

Enhance grain quality and moisture control with a high-speed solution that mini...

Twin shaft feeder for optimized material feeding

Achieve precise material flow and optimize downstream processing with adv...

Cold forming extruder for food manufacturing

Achieve precise shape and density control in cereal and snack production by i...

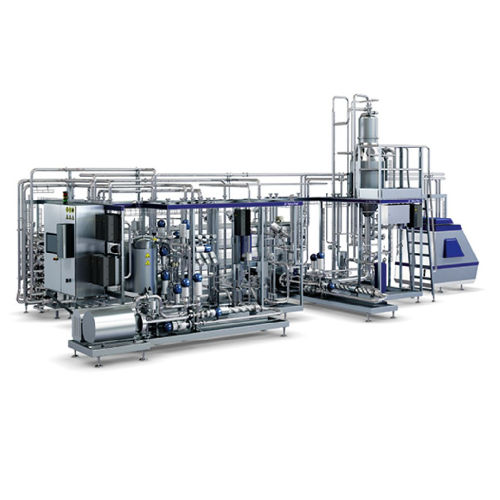

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with cont...

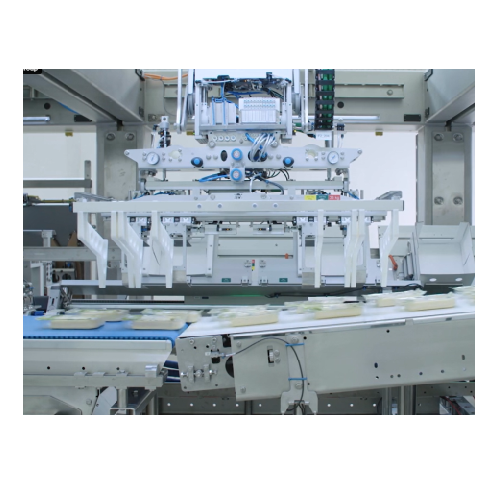

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Pellet mill conditioner for optimal granulation

Enhance pellet quality and efficiency by seamlessly integrating steam mixi...

Batch powder mixer for circulatory dispersion

Optimize your batch production with a powder mixer designed for efficient di...

Electrostatic drum flavouring for uniform coating

Achieve precise and uniform flavor distribution on snack products with ...

Case packer for diverse packaging needs

Optimize your production line with this modular case packer, designed to handle div...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

Industrial breadchips cutting solution

Achieve precise, high-speed slicing of bread-based strands into thin, uniform chips ...

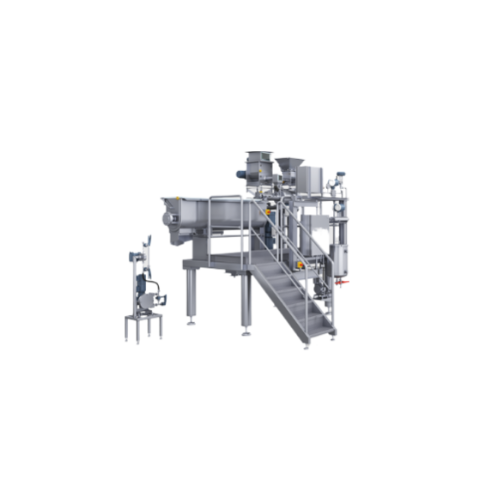

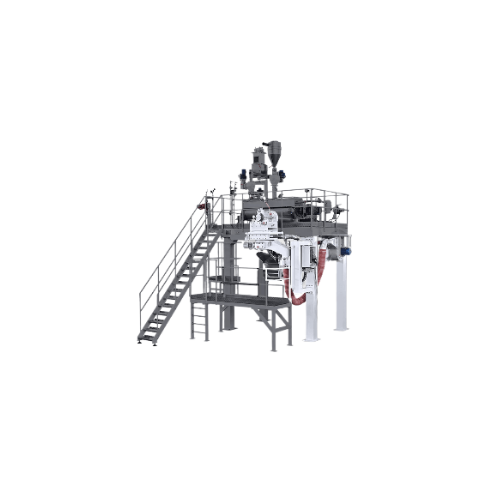

Batch mixers for raw material preparation in extrusion processes

Optimize your extrusion process with precise raw materi...

Cooling drum for breakfast cereals production

Ensure even cooling and product separation with optimized airflow for higher...

Infrared dryer for breakfast cereals

Optimize your snack production with precise moisture control, energy-efficient infrare...

Food product extruder for low to high capacity production

Optimize your snack production with versatile extruders that e...

Flavouring system for snacks and breakfast cereals

Ensure consistent and homogeneous flavouring in your snack and breakfa...

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...