Donuts

Find innovative production technology for making donuts and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Which donuts technology do you need?

Electric oven zones for snack and cookie baking

Optimize your baking line with electric oven zones designed to eliminate e...

Croissant production module for pastry make-up lines

Enhance your bakery’s product range with a versatile module de...

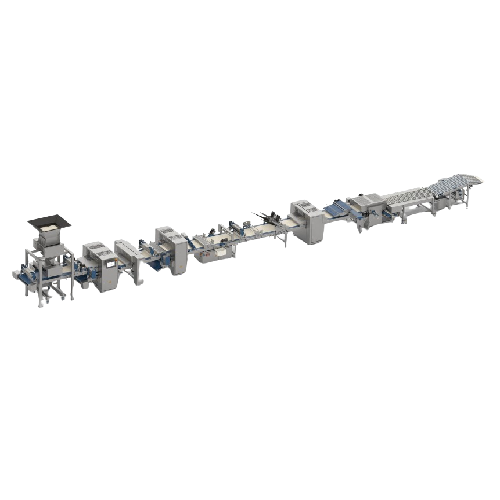

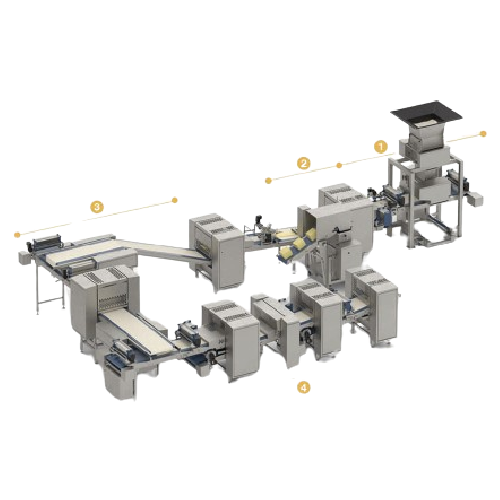

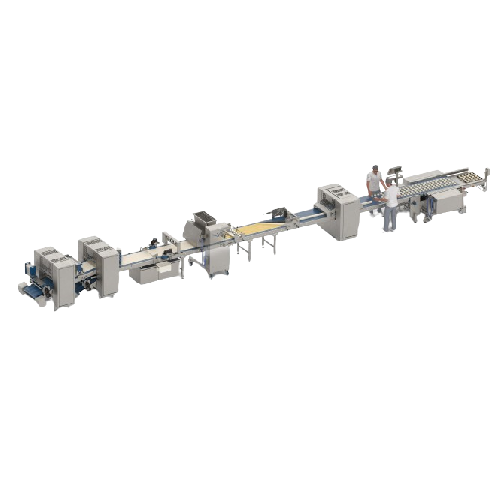

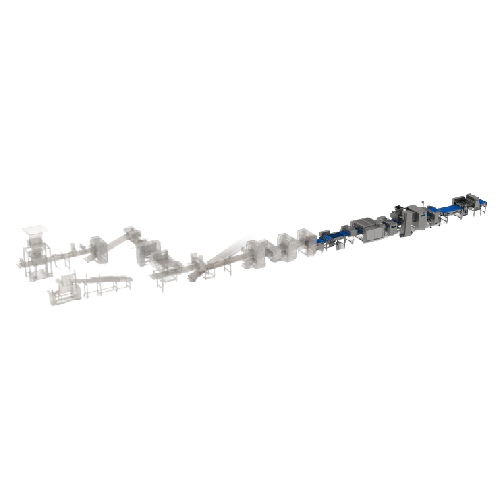

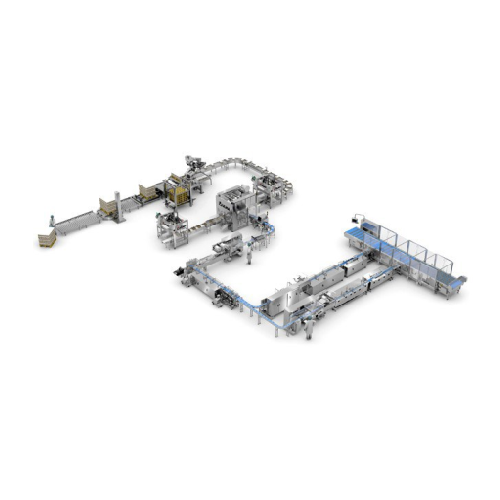

Donut production line for various shapes and sizes

Optimize your bakery’s output with precision-engineered dough pr...

Industrial dough laminator for croissants and pastries

Achieve consistently light and flaky products with precision lamin...

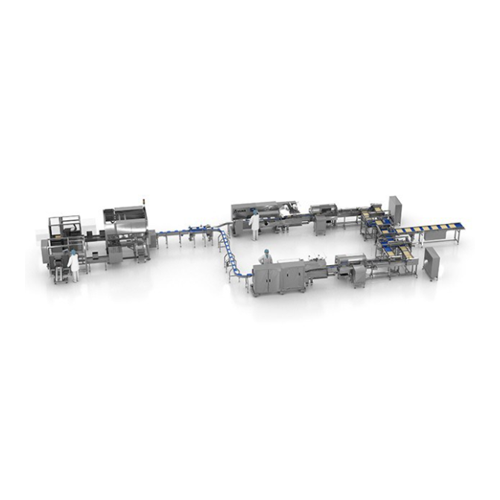

Pastry production line for large-scale bakeries

Streamline your bakery production with a versatile line designed to effici...

Dough laminating equipment for croissants and pastries

Optimize your bakery’s output with our advanced laminating e...

Industrial bread process line

Optimize your bakery operations with a versatile bread processing line, designed to handle a v...

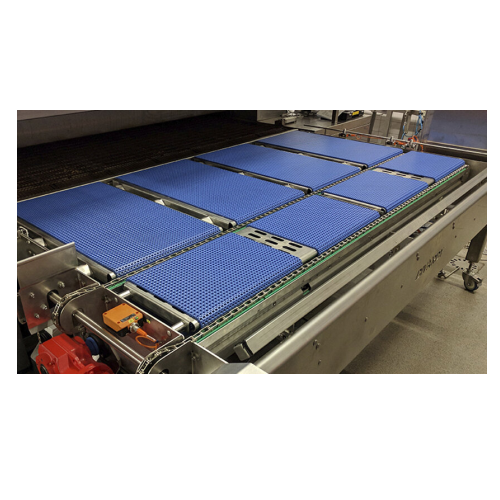

Industrial bakery conveying solutions

Ensure seamless, hygienic transport of bakery goods with precision-engineered conveyi...

Industrial croissant production line

Streamline your bakery’s operations with a versatile solution capable of produci...

Advanced bakery depanning solutions

Streamline your bakery production with cutting-edge depanning technologies designed to ...

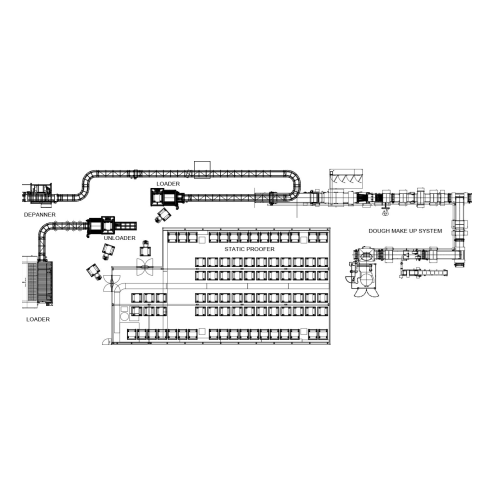

Automated bread production line

Optimize your bakery operations with precision-engineered systems that streamline every stag...

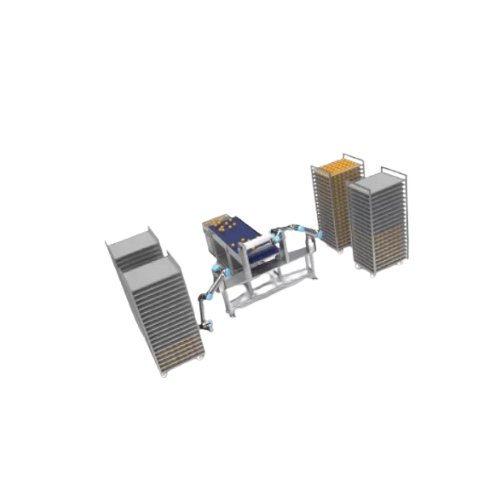

Automatic oven loading and unloading system

Streamline your bakery’s production efficiency with precise and synchron...

Chocolate decoration system for pralines and biscuits

Achieve intricate chocolate patterns and uniform coatings on confec...

Chocolate enrobing system for industrial production

Effortlessly transition between chocolate types in your high-speed pr...

Enrobers for bakery goods coating

Ensure complete and uniform coating of baked goods, snacks, and pastries, enhancing produ...

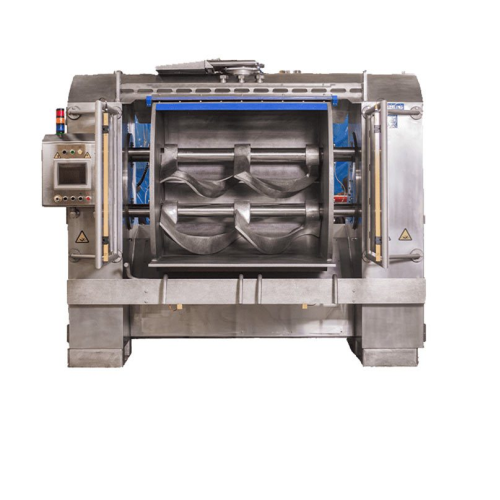

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Vision counting system for bakery products

Achieve precise and consistent product counting with this advanced system, desi...

Industrial vision robot for optimized packing

Optimize your bakery production line with a system designed to efficiently p...

Bulk box filler for bakery and pastry products

Efficiently pack fragile bakery and pastry products with gentle handling an...

Industrial bakery bag dropper for boxes or trays

Enhance your bakery line with precision-based bag dropping solutions that...

Dough divider for high-efficiency bakery production

Achieve precise dough division and high-speed production efficiency w...

Convection oven for bakery production

Optimize your baking with precise temperature and humidity control, ensuring perfect ...

Conical rounder for bakery products

Optimize your dough handling process with efficient shaping solutions, ensuring consist...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

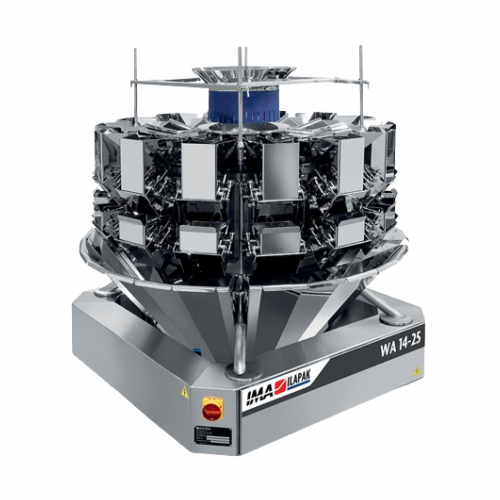

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Breaded products fryer

Achieve superior coating preservation and precise frying temperature control with this fryer, designed...

Industrial bagel boiling system

Ensure consistent bagel quality with high-capacity boiling, coupled with continuous water fi...

Dough portioning system for bakery operations

Achieve precise dough portioning with minimal waste using our advanced syste...

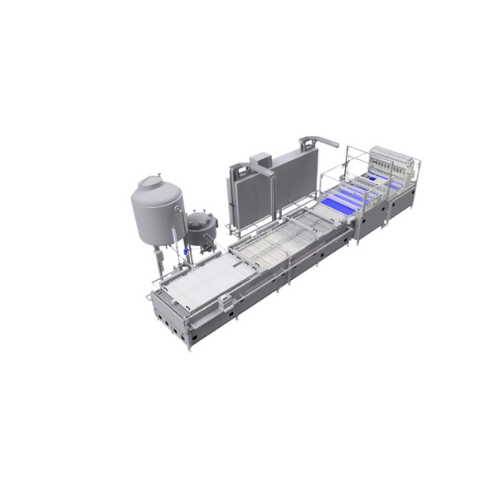

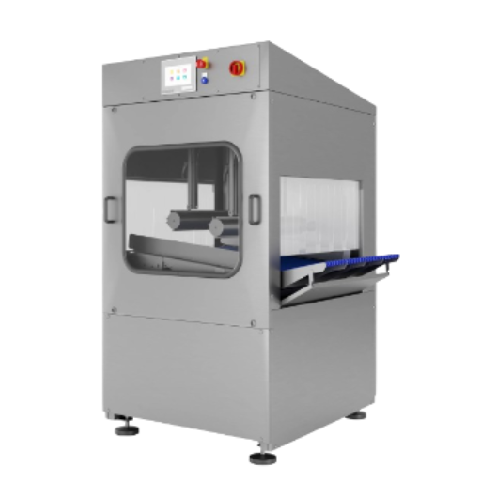

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

Automatic packaging system for preformed bags

Enhance your bakery’s efficiency with advanced preformed bag packaging...

Double jacketed mixer for dough cooling

Achieve consistent dough quality and superior gluten development with precise tempe...

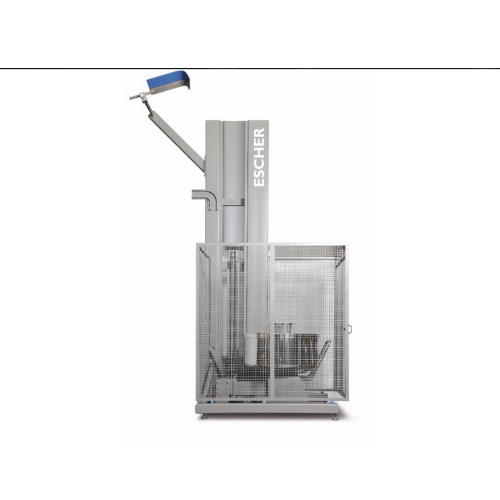

Industrial bowl lifter-tipper

Streamline your bakery production with a solution that simplifies dough handling by seamlessly...

Food counting system for hygienic applications

For food processors needing precise quantity control, this counting system ...

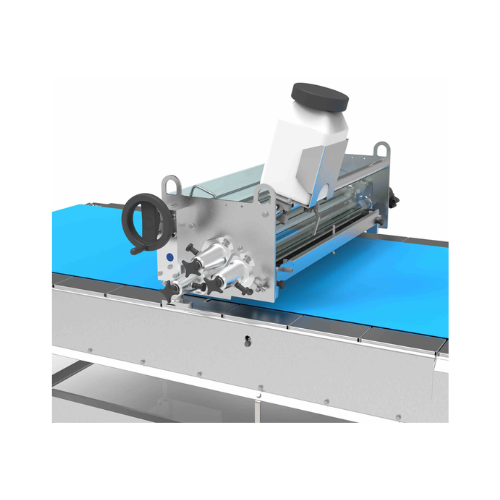

Washover unit for baked goods

Maximize production efficiency with quick-changeover washover units designed for seamless liqu...

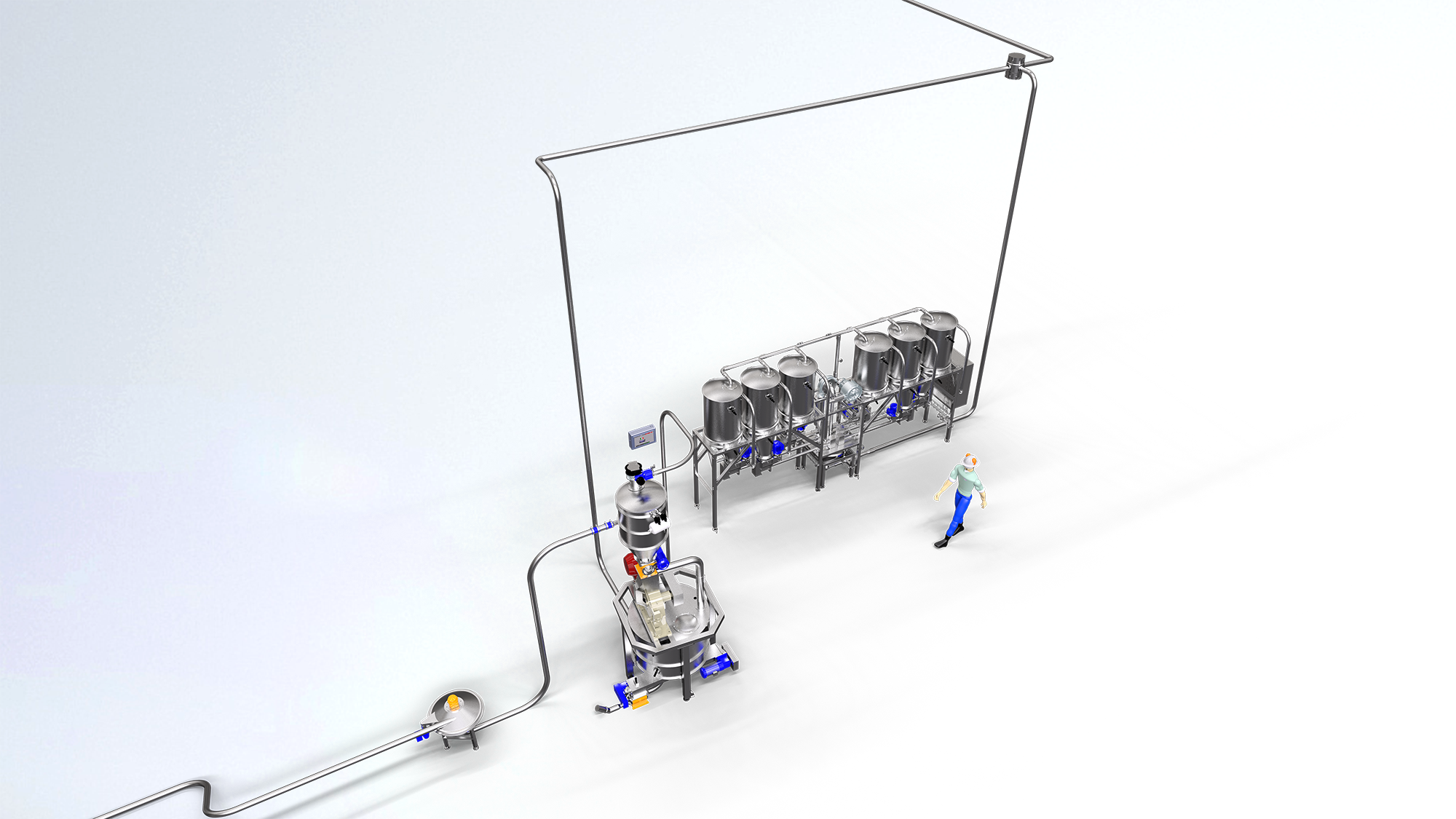

Hydration solutions for baked goods

Achieve consistent dough quality faster with a system that precisely hydrates and mixes...

Cooling conveyor for baked goods

Efficiently adapt your baked and confectionery goods to ambient conditions, ensuring optima...

High-speed mixer for dough production

Achieve consistent dough quality and streamline your production process with this ver...

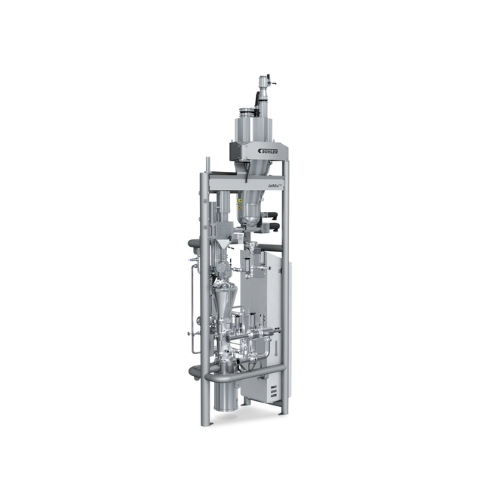

Weighing and receiving container for floury products

Achieve precise and consistent ingredient proportions with this syst...

Glaze spraying system for bakery products

Achieve perfect glaze and finish on your bakery products with precision spraying...

Release agent sprayer for baking trays and moulds

Achieve perfect results in baking by ensuring efficient and uniform gre...

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

Production line for round and square cakes

Streamline your bakery operations with a modular cake production line designed ...

Industrial glazing line for high-volume production

Elevate your production efficiency with this robust glazing line, opti...

Ultrasonic cutting line for bakery products

Experience precise slicing and cutting efficiency with our high-capacity ultra...

High-volume spraying system for glazes and marmelades

Streamline your glazing process with a system designed to minimize ...

Chocolate spraying system for bakery decoration

Achieve precision chocolate coatings and intricate dessert decorations eff...

Industrial glaze sprayer for high-volume bakery production

Enhance product appeal and extend shelf life with precise gla...

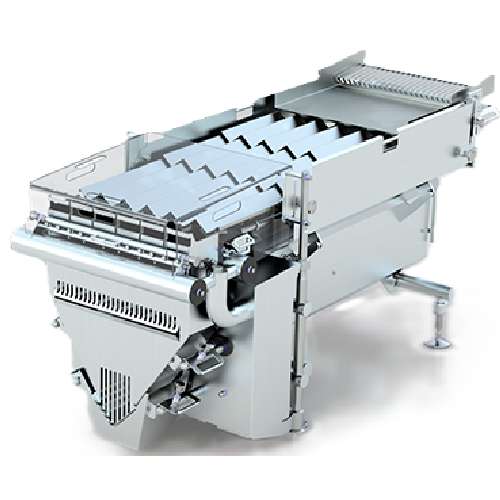

Efficient topping strewer for bakery production lines

Enhance your product’s appeal and streamline topping applicat...

Cake batter depositing line

Streamline your production with precise batter depositing and greasing, minimizing waste and opt...

Full production line with depositing and ultrasonic cutting

Streamline your baked goods and dessert production with this...

Full production greasing and depositing line for bakery products

Elevate your production process with a greasing and dep...

Energy efficient chocolate tempering solution

Enhance your chocolate products with precise temperature control, reducing e...

Bottom enrober for chocolate and confectionery products

Optimize your production line with precise bottom enrobing, ensur...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Industrial food processing fryer

Ensure consistent frying quality and enhanced sediment removal for high-volume food product...

Oxygen and leakage detection in Map packaging

Ensure enhanced food safety and reduce waste with precise oxygen and leak de...

Robotic pick and place system for bakery products

Enhance your bakery production line with advanced robotic systems that ...

Donut glazing system for rapid production

Streamline your bakery operations with a compact system that thaws and glazes do...

Robotic tray handling for baking production lines

Enhance production efficiency by seamlessly integrating advanced roboti...

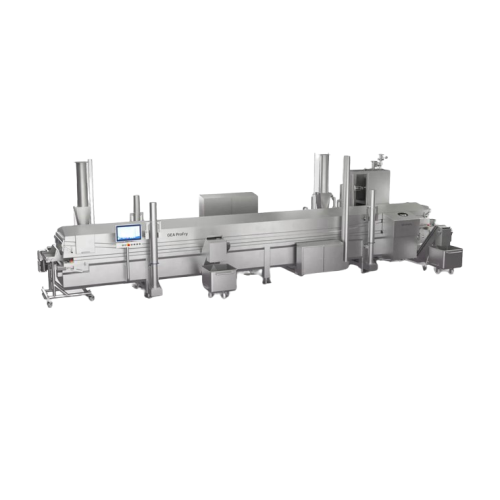

Industrial continuous frying system for donuts and pastries

Achieve artisanal-quality frying with high-volume efficiency...

Custom deep frying system for unique product requirements

For bakeries tackling specialized frying needs, this customiza...

Small batch deep fryer for bakery demonstrations

Achieve consistently low fat absorption and perfect results for small bat...

Industrial deep fryer for high-volume donuts

Streamline your high-volume pastry production with an advanced fryer system d...

Industrial donut fryer for high output and customization

Enhance your donut and pastry production efficiency with a custo...

Infrared oven for fast thawing and glazing

Streamline your donut production by seamlessly integrating rapid thawing and gl...

High performance spiral mixer for dough preparation

Achieve consistent dough quality with ease by integrating a high-perf...

Modular roll line for high-capacity bakery production

Streamline your bakery’s production process with high-speed, ...

Continuous deep fryer for consistent and efficient frying

Streamline your frying processes with this innovative continuo...

Continuous open kettle fryer for donut production

Effortlessly produce high-quality donuts with precise temperature contr...

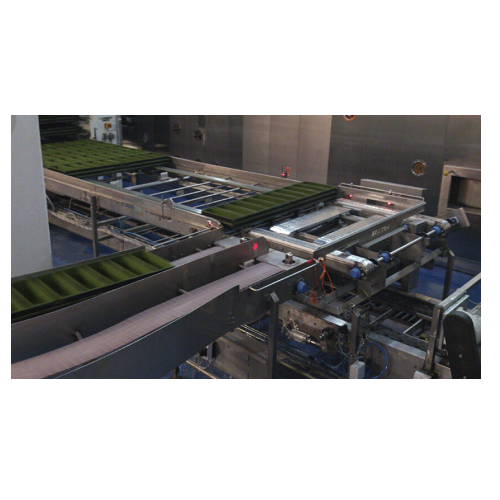

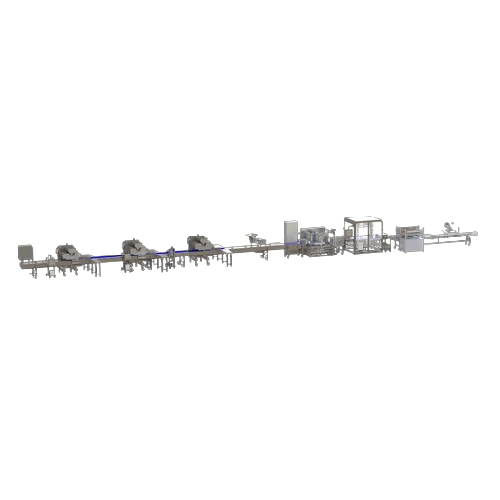

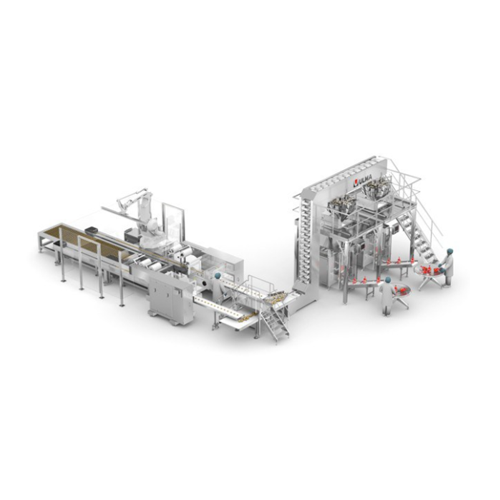

High-performance donut and ball donut production line

Efficiently produce a wide variety of donuts with precise shape and...

Industrial fryer for donuts and ball donuts

Maximize your deep-fried pastry output with precise control over frying condit...

Automatic fryer for producing donuts and ball donuts

Achieve consistent quality in donut production with this compact fry...

Industrial spiral mixer for dough production

Achieve precise control in dough consistency and quality with this spiral mix...

Weight accurate dough divider for various dough types

Achieve high-speed, precise dough portioning with adjustable pressu...

High-precision checkweigher for dough processing

Ensure consistent dough quality and reduce waste with precise weight corr...

Vertical mixing solution for bakery and snacking industry

Streamline your dough processing with robust and reliable spir...

Spiral mixers for bakery dough

Transform your bakery production with precise and consistent dough mixing, ensuring every bat...

Industrial depositor for bakeries

Enhance your bakery production with precision depositing and filling, designed to handle ...

Industrial servo-based depositor for cake production

Effortlessly manage diverse depositing tasks across high-speed baker...

Portable table top bakery depositor

Optimize your baked goods production with precise portioning and rapid depositing, all ...

Multi piston depositor for automated bakery filling

Optimize your bakery production with precise portioning and filling, ...

Servo deposition system for industrial cake production

Effortlessly streamline your food production process with precise ...

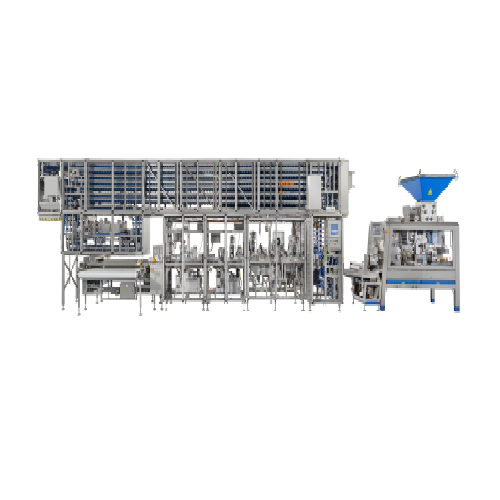

Complete solution for packaging of bakery products

Streamline your bakery’s packaging process with a fully automate...

Sweet baked goods packaging solution

Optimize your sweet baked goods packaging process with a fully automated solution desi...

Automated packaging line for wafers

Optimize your wafer production with high-speed, fully automated packaging and versatile...

Buffer tank for consistent product temperature control

Ensure consistent product temperatures and streamline your product...

Industrial conical dough rounder

Streamline your dough production with a high-capacity rounder designed to optimize dough sh...

High-capacity dough cup elevator for industrial bakeries

Enhance your bakery’s efficiency with a dough cup elevator...

Stainless steel drying tunnel for packaging lines

Optimize your packaging line efficiency by ensuring products are thorou...

Dough mixer for high-volume bakery production

Effortlessly handle diverse dough varieties with precision using this mixer,...

Efficient jam and marmalade production line

Optimize your fruit and bakery product lines with equipment designed for high-...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

Industrial washer for plastic crates

In the food production sector, hygiene regulations are getting stringent by the day. E...

Cream filling machine for bakery industry

Cream and other fillings in bakery products must be injected in the right volume...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Mixer for aeration of confectionery and bakery products

Aerated products can be difficult to mix thoroughly without reduc...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

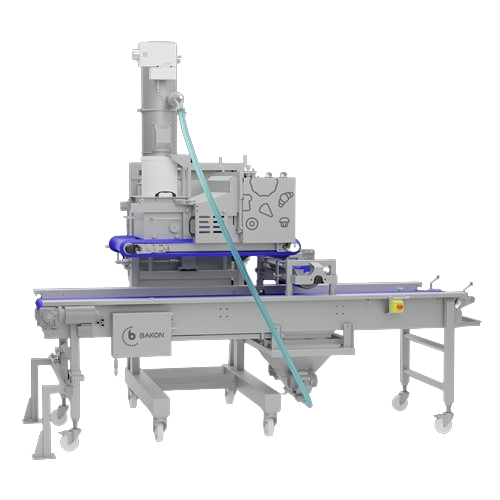

High speed decorator for donuts

Donuts quite simply need decorations. The added value through unique and visually appealing ...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

High capacity spiral proofer for pastry

Proofing is a phase in the baking production line that can’t be rushed. It’s an ess...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Food crates washer

With the increasing demand of food production sectors for cutting costs, while increasing quality of produ...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Semi-automatic dough sheeter

There is a wide range of commercial dough sheeters available, many of which are purpose-built f...

Automatic pastry dough sheeter

Industrial dough sheeters turn raw dough into sheets that match recipe thickness. This includ...

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Automatic rework system for biscuit and bread scrap

Scraps are an inevitable byproduct of biscuit and bread production. W...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

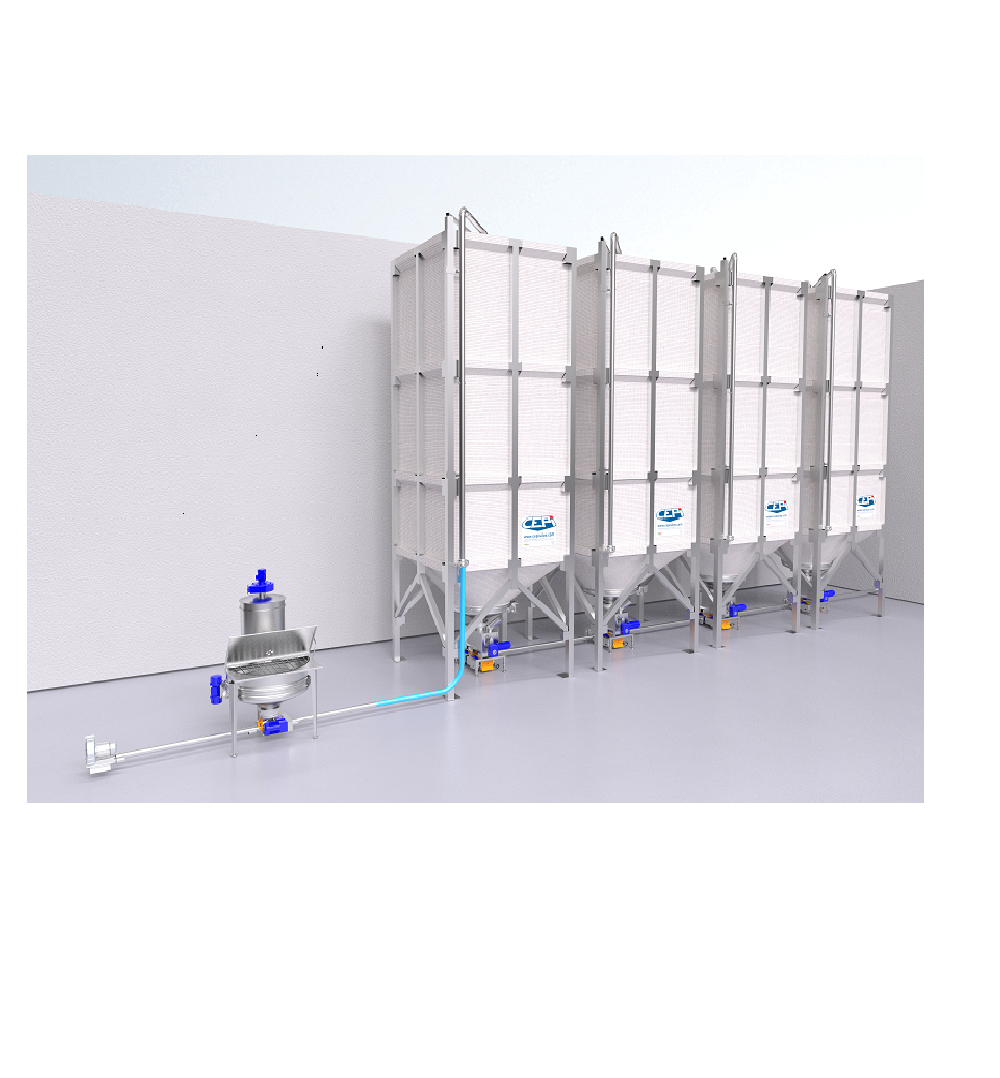

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...