What are you making?

Connect directly with innovative technology suppliers that know how to build and improve your production line

3d lollipops

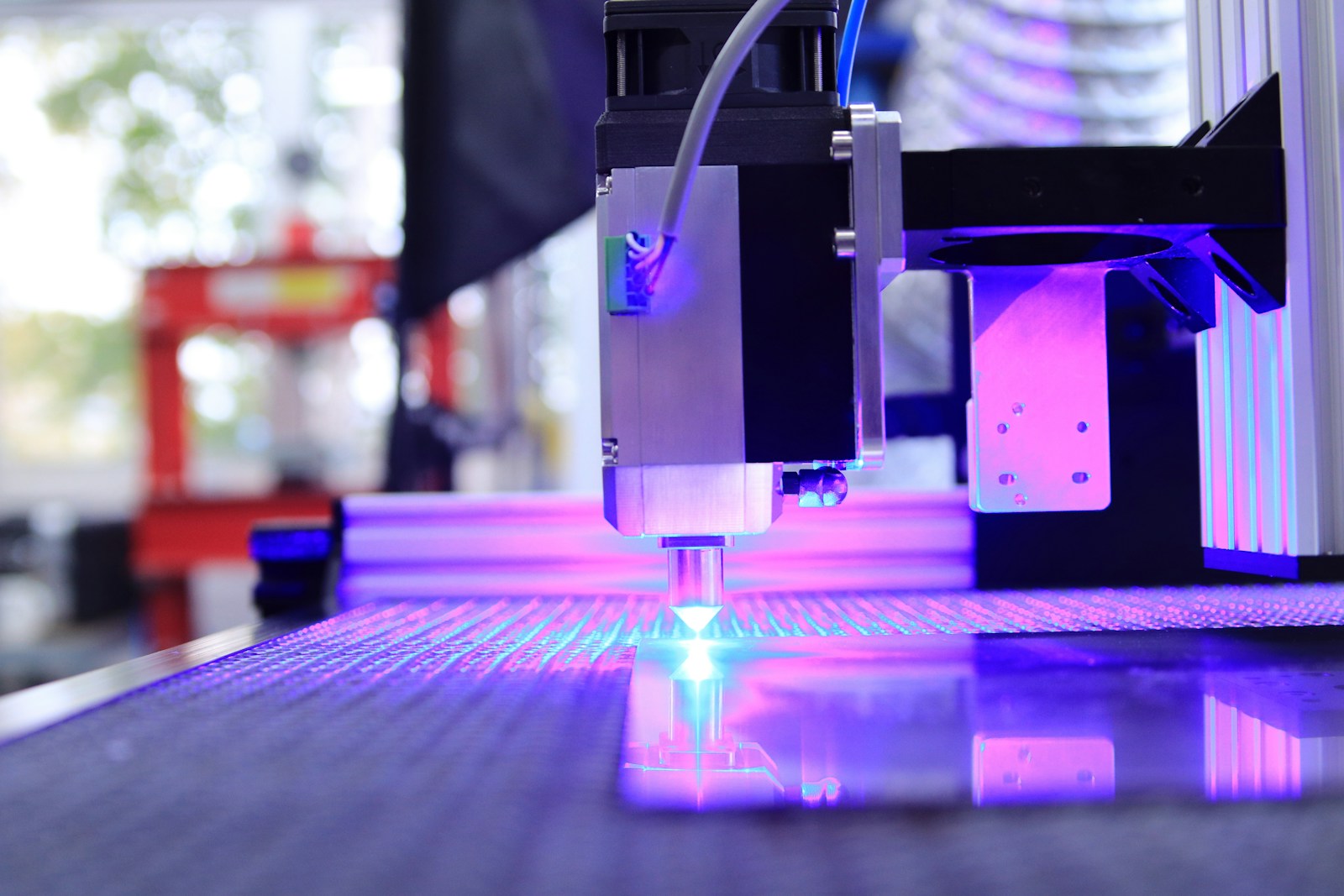

3d printing

Abrasives

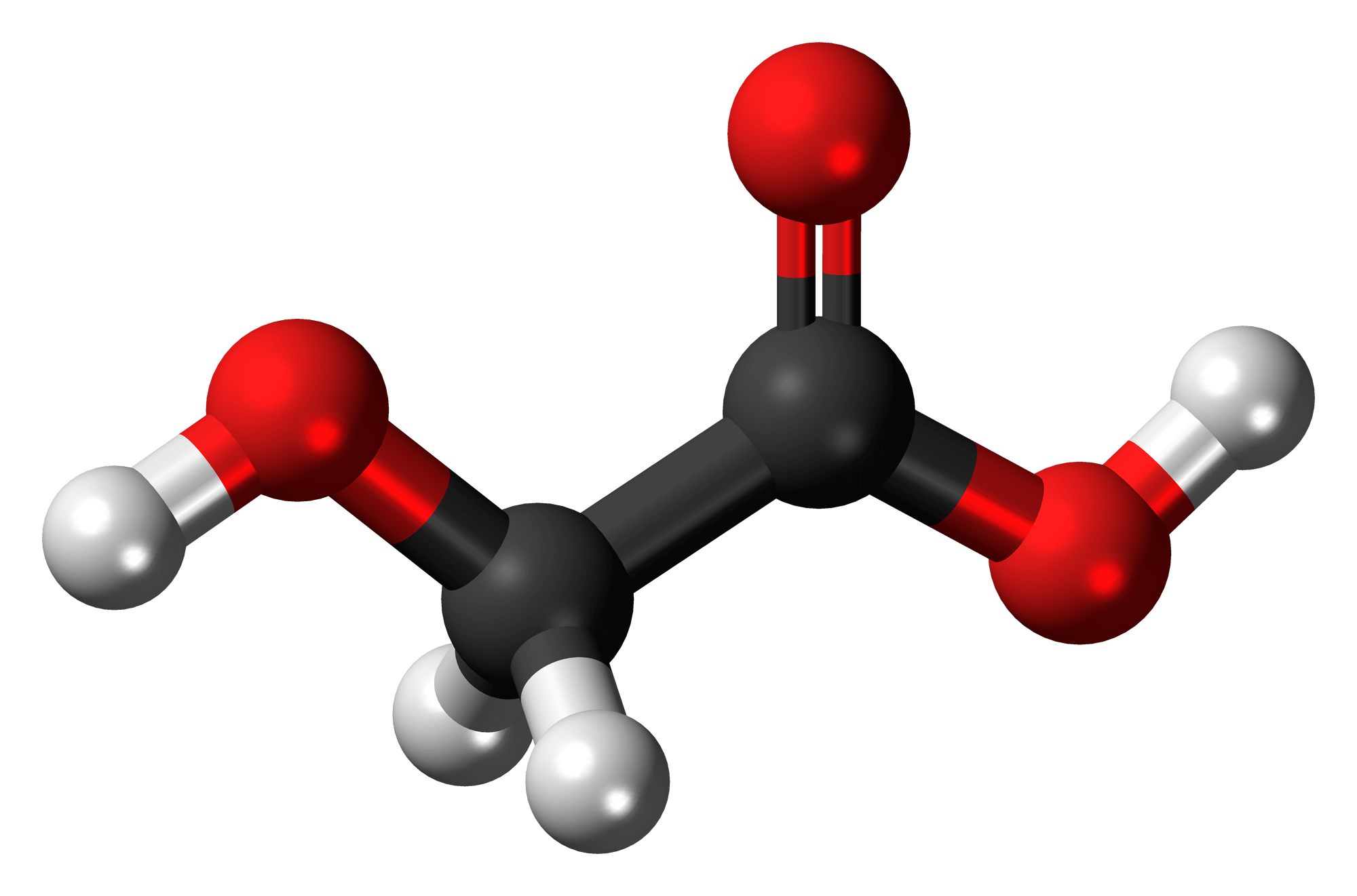

Acetic acid

Acetone

Acrylic coatings

Acrylic emulsions

Acrylic paint

Acrylic sealants

Activated carbon

Active pharmaceutical ingredients (API)

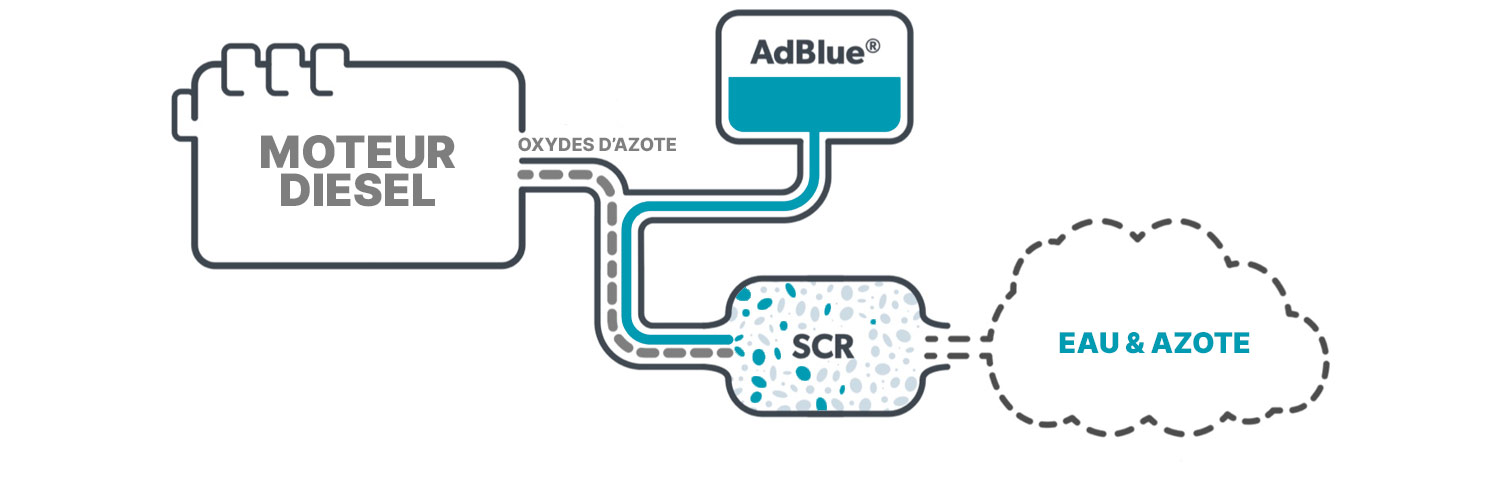

Adblue

Additive manufacturing metal

Additive manufacturing polymer

Adhesives

Advanced ceramics

Aerated chocolate

Aerosol cans

Aerosols

Aerospace coatings

Aerospace components

Agar-agar

Agglomerates

Aggregates

Agricultural by-products

Agricultural residues

Agricultural seeds

Agrochemicals

Aioli

Alcoholic beverages

Ale beer

Alfalfa meal

Alfalfa seeds

Alfredo sauce

Algae

All-purpose flour

Alloys

Almond butter

Almond flour

Almond milk

Almond milk powder

Almonds

Aloe vera gel

Alternative medicine

Alternative proteins

Alumina

Alumina ceramics

Aluminium oxide

Aluminum beverage cans

Aluminum powder

Amber ale

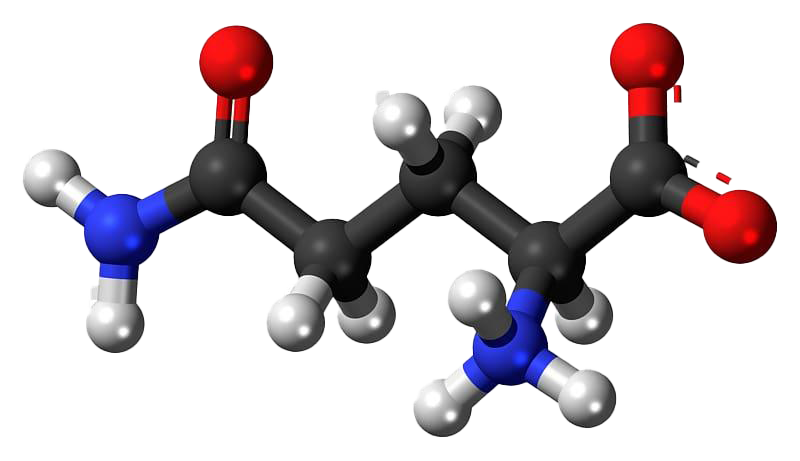

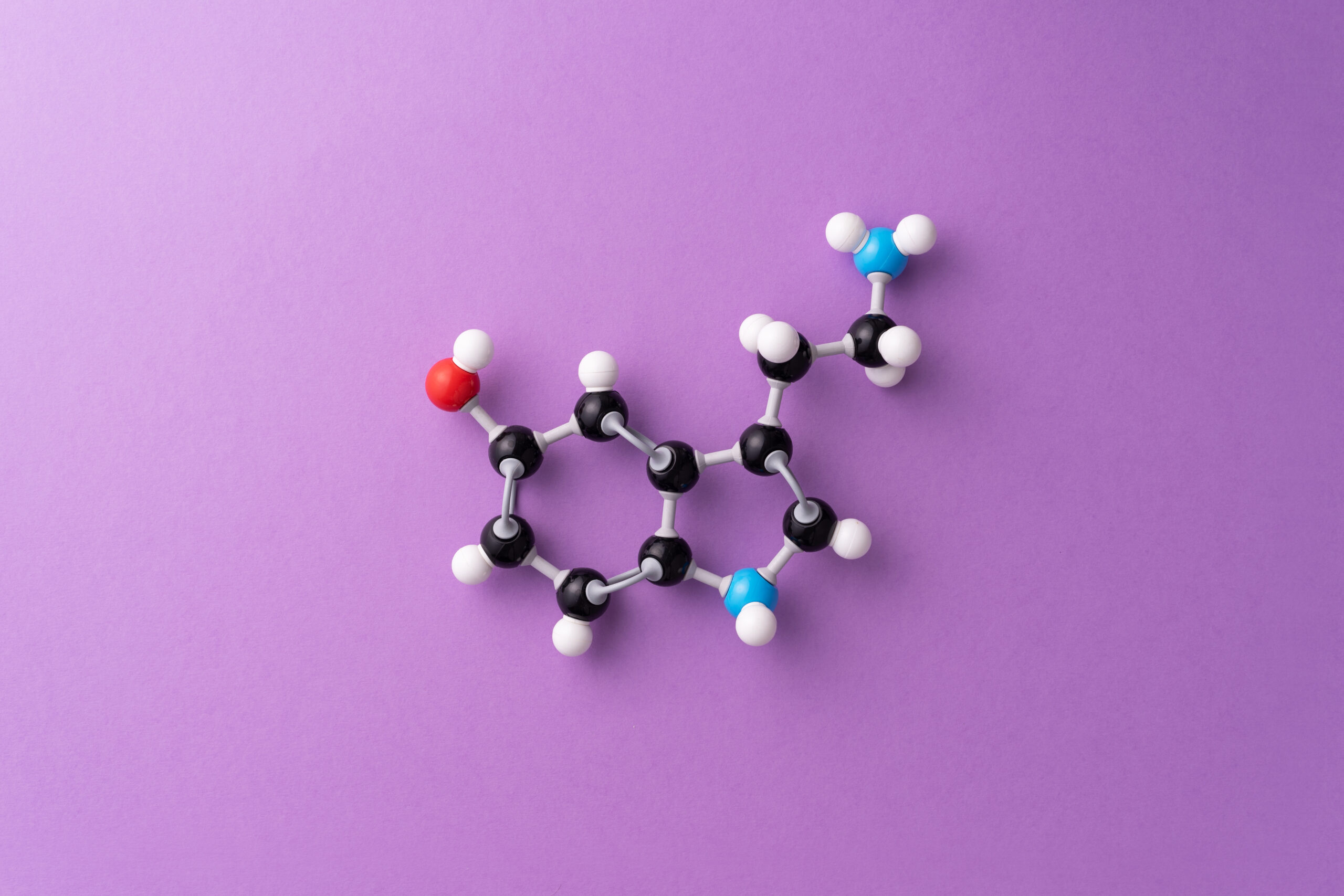

Amino acids

Ammonia

Ammonium nitrate

Ammonium nitrate fertilizer

Ammonium sulfate

Amoxicillin capsules

Ampoules

Analgesic tablets

Analogue cheese

Anhydrous pastes

Animal by-products

Animal diagnostics

Animal fats

Animal feed

Animal feed additives

Animal health products

Anode and cathode materials

Antacid tablets

Anti-aging cream

Anti-corrosion coatings

Anti-dandruff shampoo

Anti-friction coatings

Anti-reflective coated lenses

Antibacterial ointment

Antibiotic powders

Antibiotic tablets

Antibiotics

Antibodies

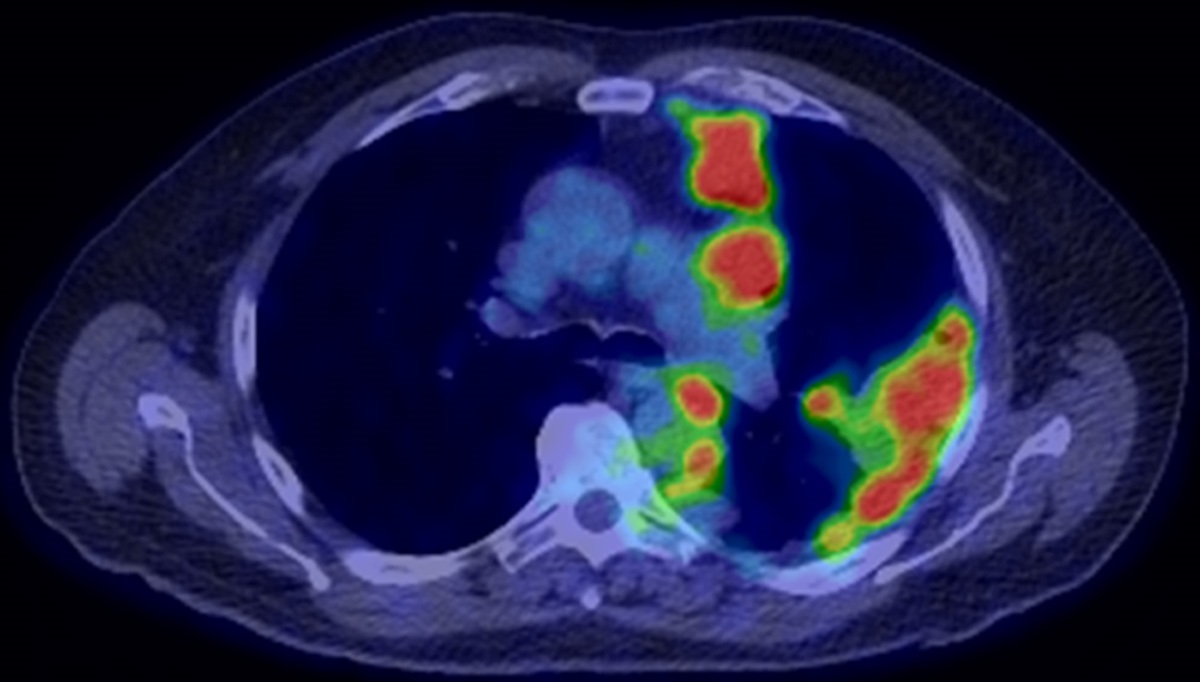

Anticancer drugs

Antihistamine tablets

Antioxidant supplements

Antiseptic solutions

Antiviral drugs

Api suspensions

Apple chips

Apple cider

Apple compote

Apple concentrate

Apple juice

Apple pies

Apple puree

Apple wedges

Apples

Apricot puree

Apricots

Aquaculture

Aquafeed

Aquafeed

Arabica coffee beans

Arborio rice

Aromas

Aromatherapy oils

Artificial sweeteners

Artisan bread

Artist colors

Arugula

Aspartame

Asphalt

Aspirin

Asthma inhalers

Automotive

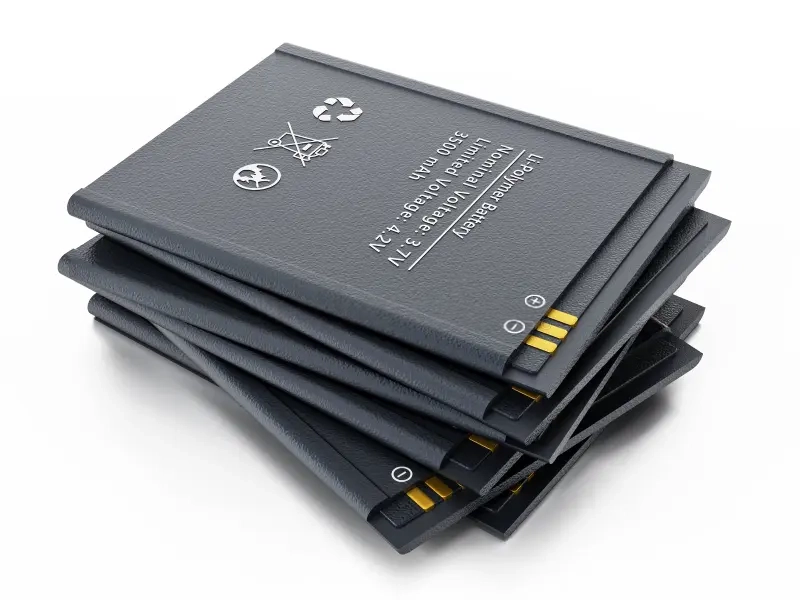

Automotive batteries

Automotive catalysts

Automotive coatings

Automotive paints

Automotive tires

Avocado oil

Avocados

Ayran

Baby Food

Baby wipes

Bacon

Bacteria

Bagels

Bags

Baguettes

Baked goods

Baker's yeast

Bakery

Bakery fillings

Bakery flour

Bakery ingredients

Bakery mixes

Baking powder

Baking soda

Ball donuts

Ball lollipops

Balsamic vinegar

Banana chips

Banana puree

Bananas

Bandages

Bao

Barbecue ribs

Barbecue sauce

Barley

Barley flakes

Barley flour

Barley malt

Basmati rice

Batter

Battered fish fillets

Battered nuts

Battered onion rings

Batteries

Battery electrodes

Bauxite

Bavarois

Bb cream

Beans

Beauty products

Bechamel sauce

Beef

Beef gravy

Beef jerky

Beef patties

Beef steaks

Beef stew

Beer

Beer bottles

Beer cans

Beer wort

Beetroot juice

Belgian ale

Bell peppers

Bentonite

Bentonite clay

Benzene

Berries

Beverage concentrates

Beverage ingredients

Beverages

Bfs products

Bio-pharmaceuticals

Bioactive compounds

Biochar

Biochemistry

Biocides

Biodegradable plastics

Biodegradable polymers

Biodiesel

Bioenergy

Bioethanol

Biofuel

Biofuels

Biogas

Biogas digestate

Biologic drug formulations

Biologics

Biomass

Biomass briquettes

Biomass pellets

Biomethane

Biopharmaceuticals

Bioplastics

Biopolymers

Biorefinery

Biosimilars

Biosolids

Biscotti

Biscuits

Black beans

Black pepper

Black soldier fly protein

Black tea

Blister packs

Blood glucose test strips

Blood plasma products

Blue cheese

Blueberries

Blueberry jam

Blueberry muffins

Bocconcini

Body care

Body lotion

Body wash

Boiled sausage

Bolognese sauce

Bone meal

Botanical extracts

Botanical medicine

Bottled drinks

Bottled water

Bottles

Bouillon cubes

Boxes

Bran

Bran flakes

Brandy

Bratwurst

Bread

Bread Rolls

Bread loaves

Bread mix

Bread spreads

Breadcrumbs

Breaded products

Breaded shrimp

Breadings

Breadsticks

Breakfast cereal

Breakfast cereals

Brewers grain

Brewery

Brick

Brie cheese

Brines

Brioche

Briquettes

Brittles

Broth

Broths

Brown rice

Brown sugar

Brownies

Bubble gum

Buffer solutions

Building materials

Bulk chemicals

Bundles

Buns

Burrata

Butter

Butter biscuits

Buttercream

Buttermilk

CBD gummies

CBD oil

Cabbage

Cabernet sauvignon

Caesar salad dressing

Caffeine

Cake

Cake mixes

Calcium carbonate (gcc)

Calcium phosphate

Calcium supplements

Candied fruits

Candle wax

Candy

Candy bars

Candy coatings

Cannabinoids

Cannabis candy

Cannabis distillate

Cannabis edibles

Cannabis extracts

Cannabis oil

Cannabis seeds

Canned beans

Canned beverages

Canned cat food

Canned corn

Canned dog food

Canned fish

Canned fruits

Canned peaches

Canned soft drinks

Canned soup

Canned tomatoes

Canned tuna

Canola meal

Canola oil

Cans

Caplets

Capsules

Car tires

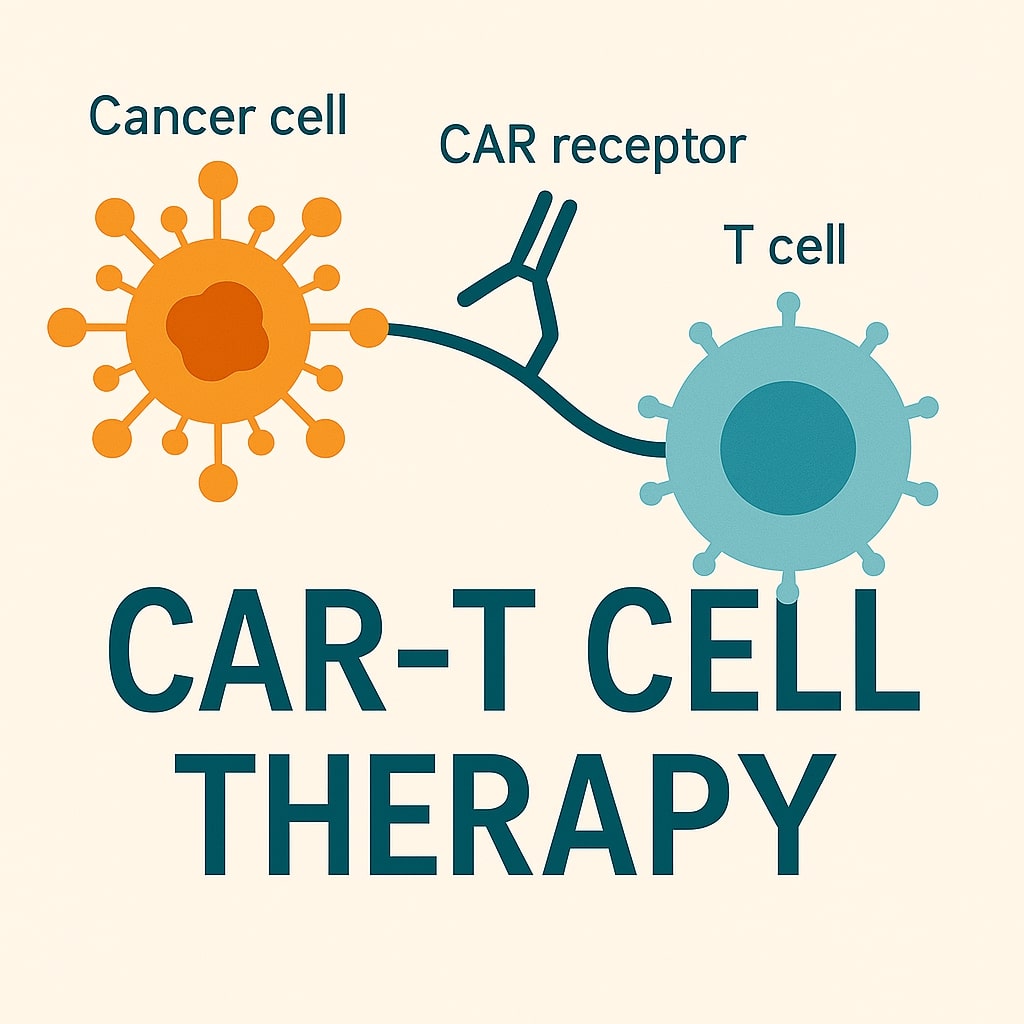

Car-t cell therapies

Caramel

Carbon black

Carbon capture

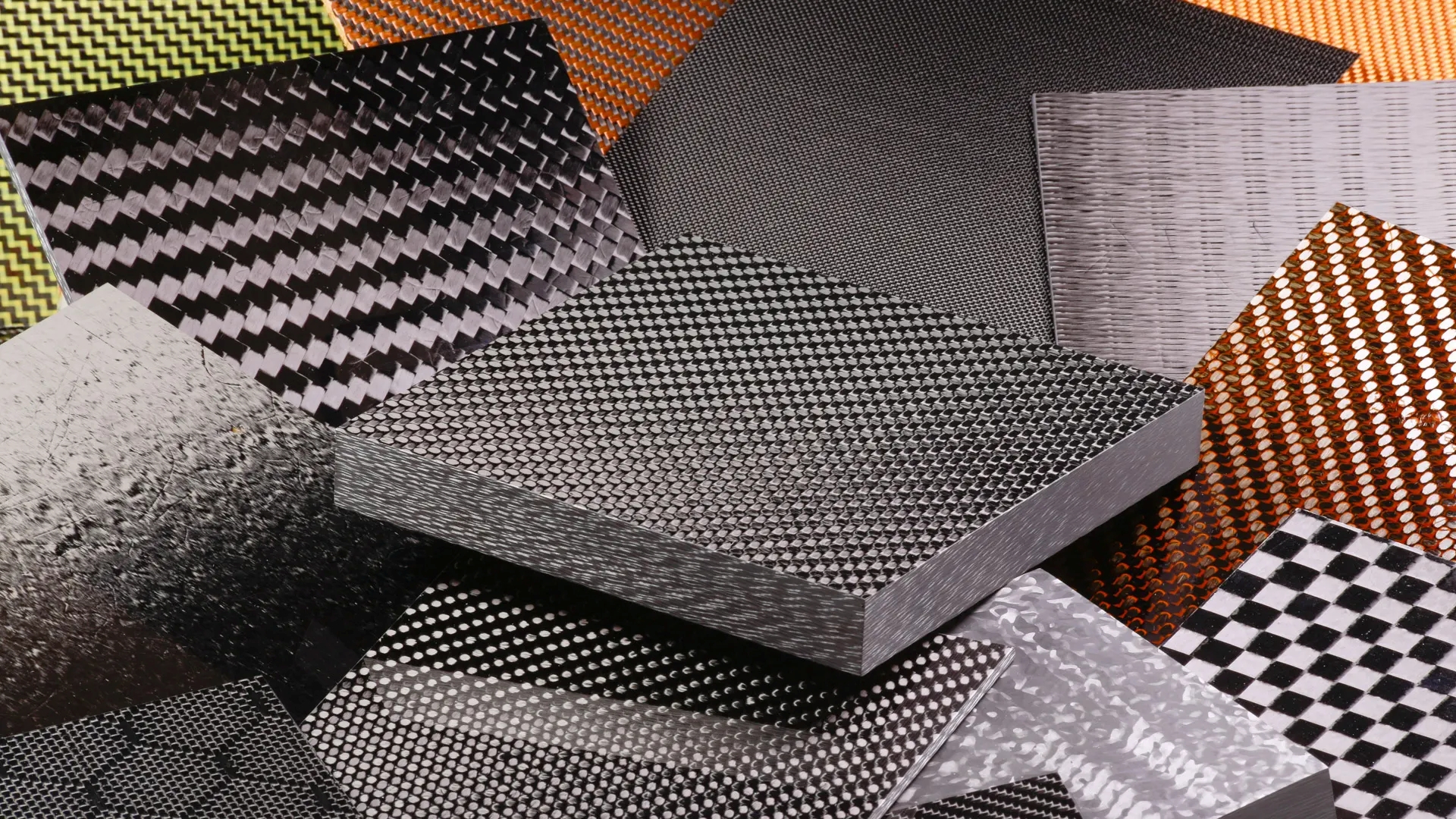

Carbon fiber composites

Carbon materials

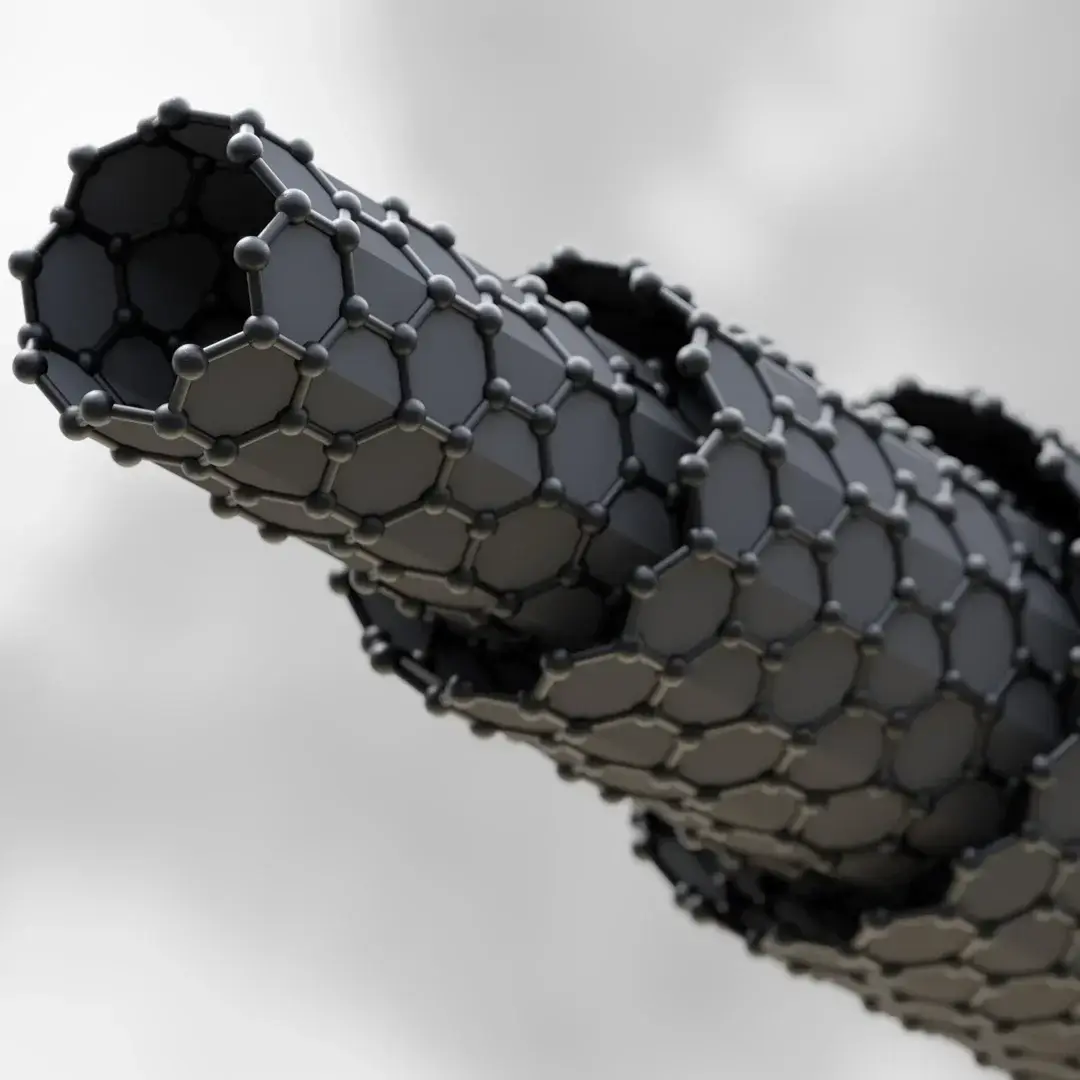

Carbon nanotubes

Carbonated beverages

Carbonated soft drinks (csd)

Cardboard

Cardboard boxes

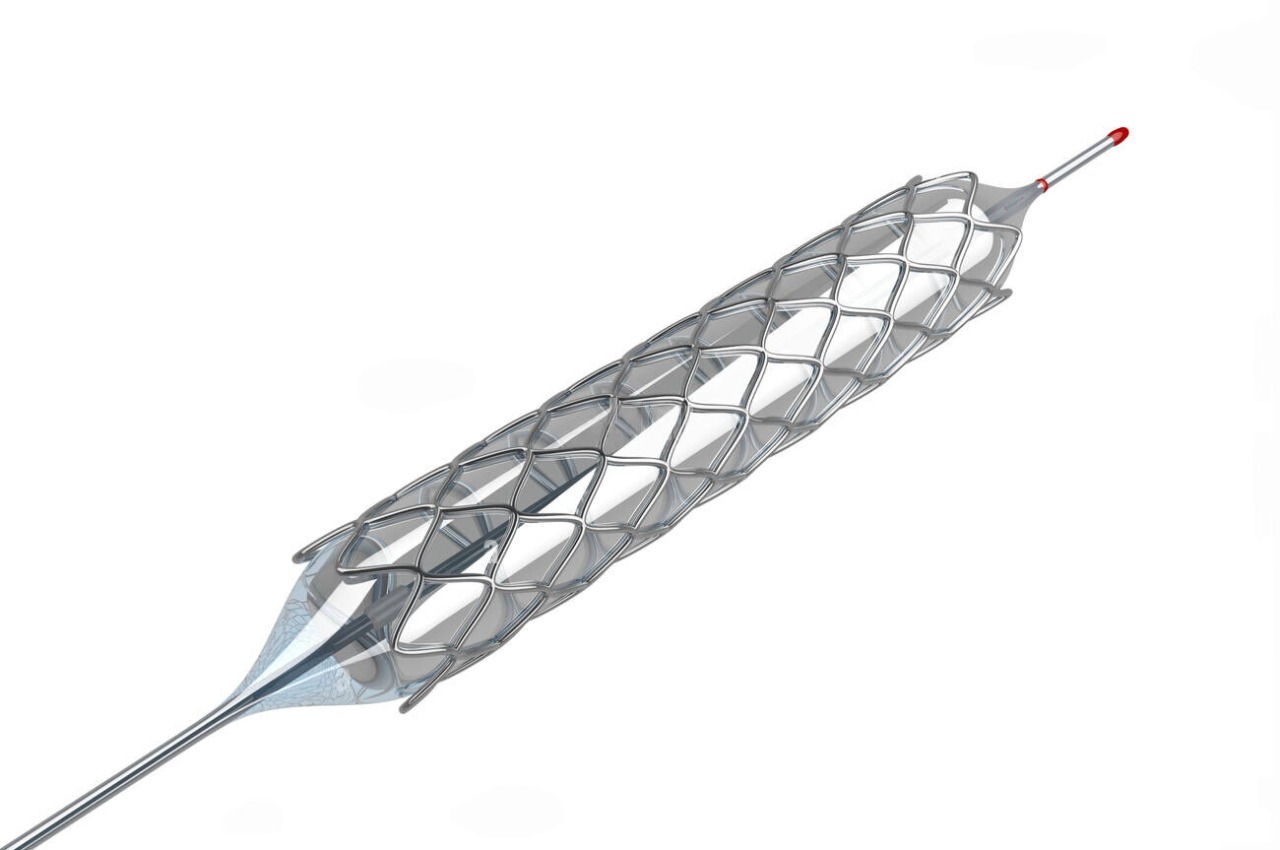

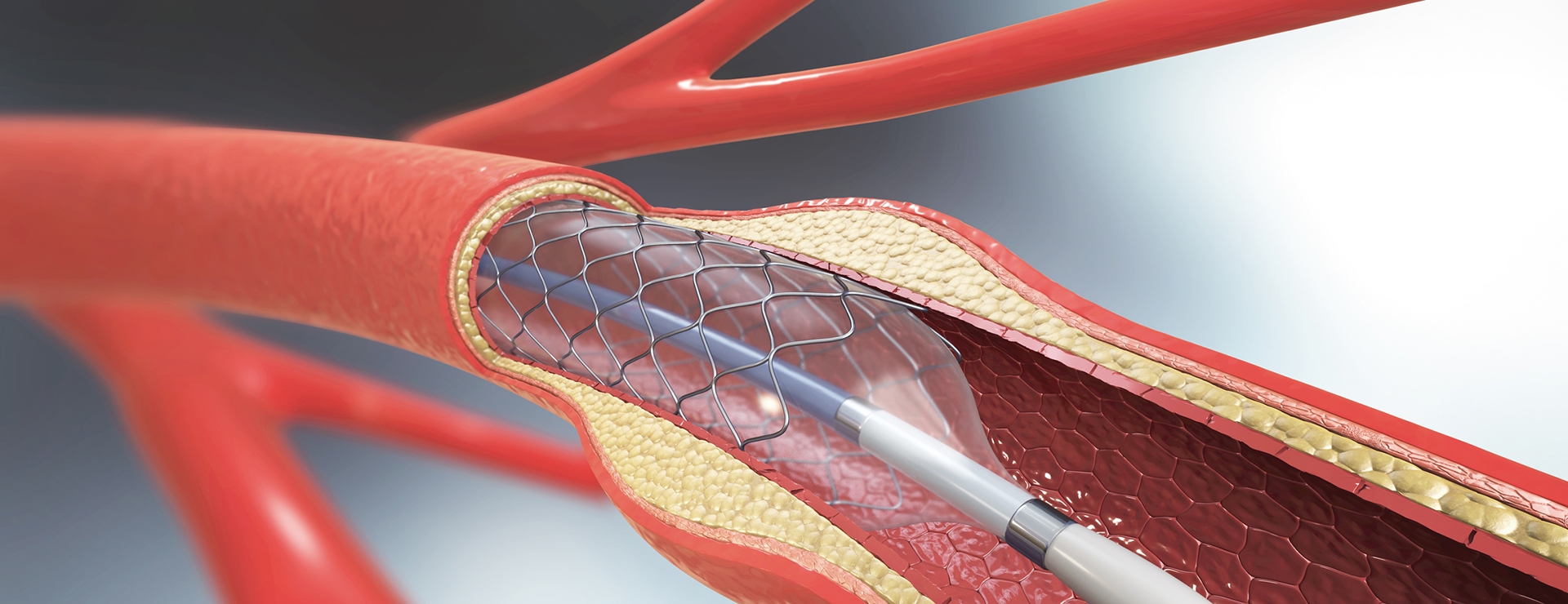

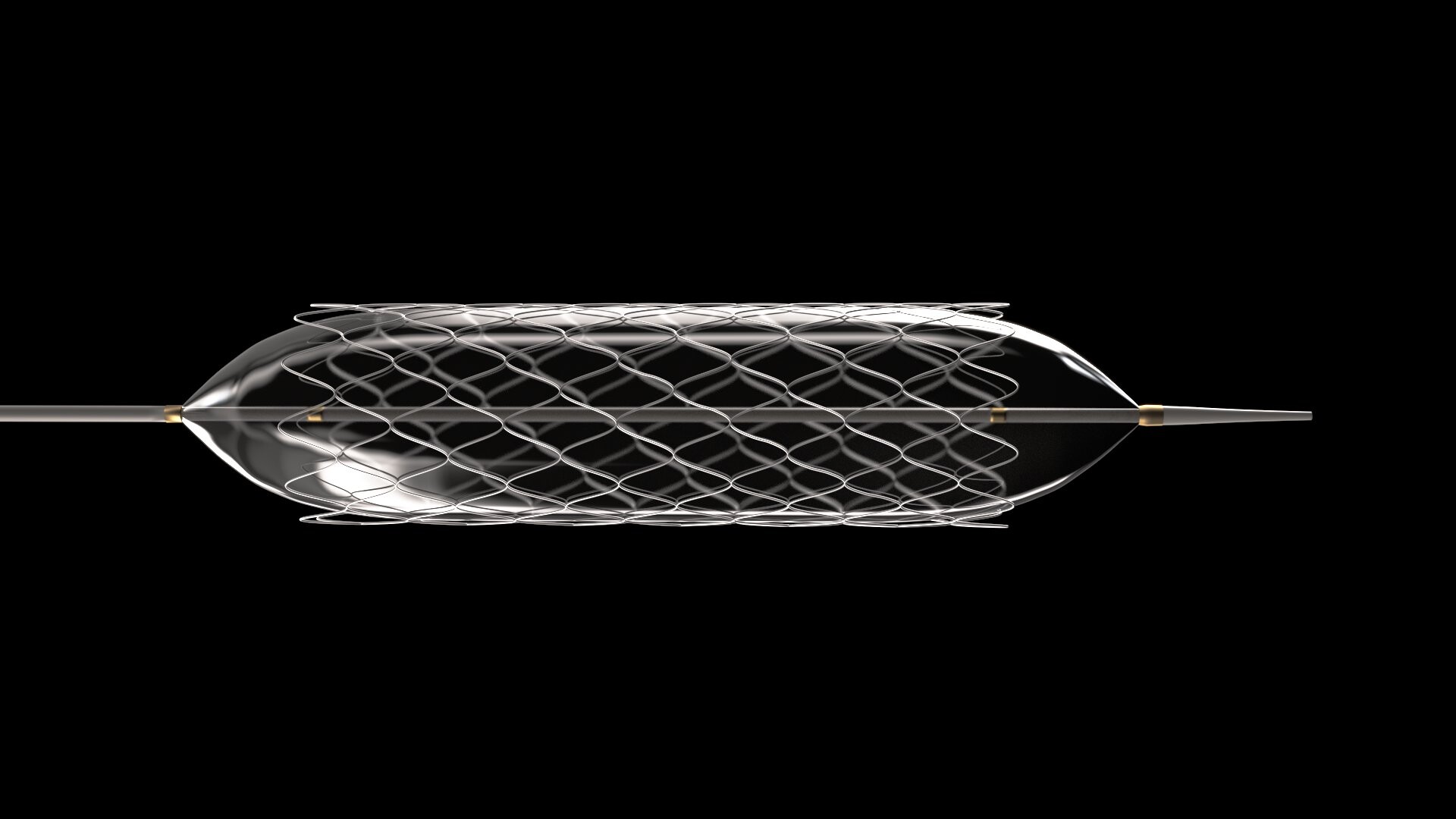

Cardiac stents

Carrot juice

Carrot puree

Carrots

Cartons

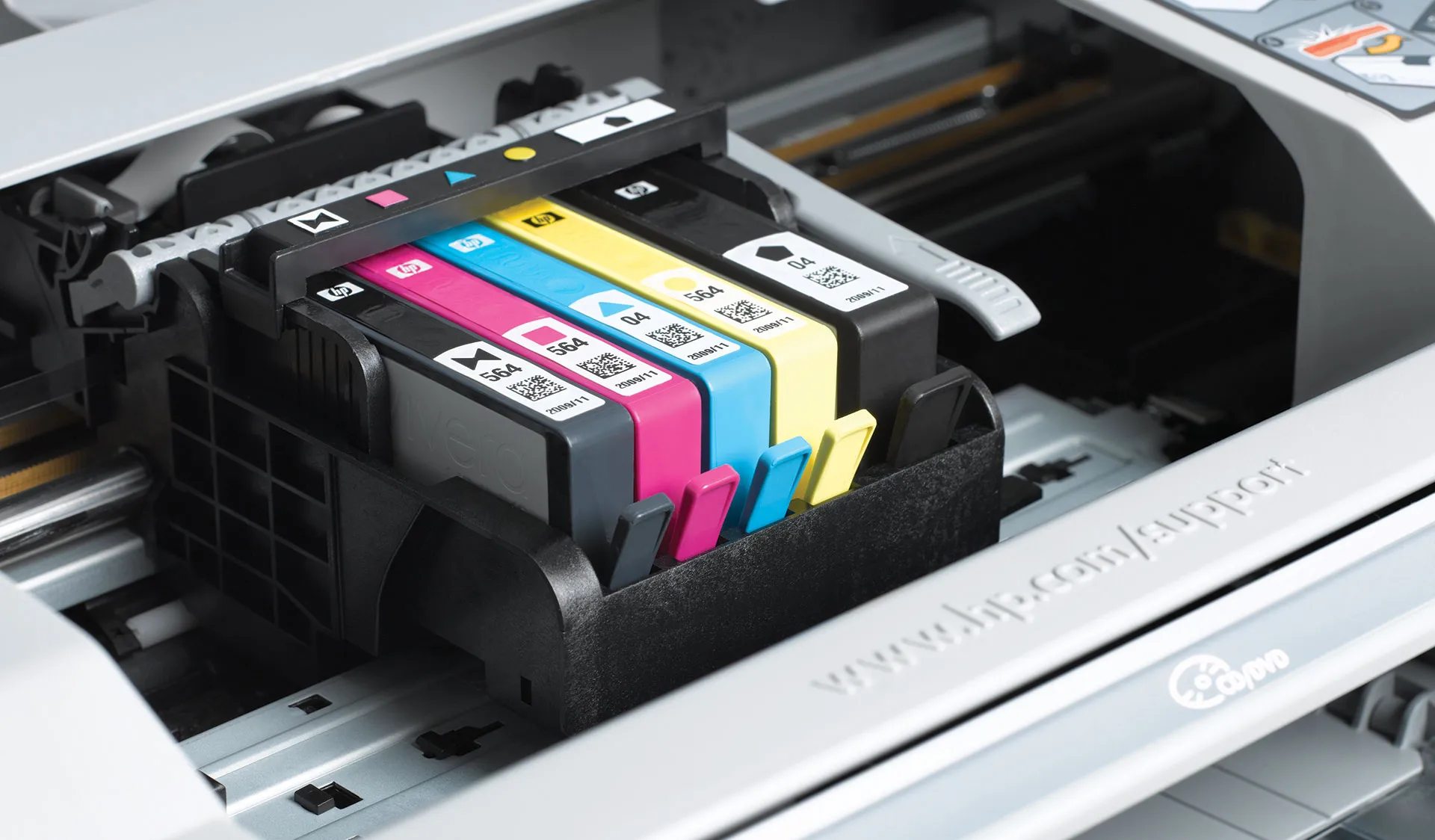

Cartridges

Casein

Cashew butter

Cashew milk

Cashews

Cassava

Cassava chips

Casting compounds

Cat biscuits

Cat food

Cat kibble

Cat treats

Catalyst powders

Catalysts

Catalytic converters

Catheters

Cathode materials

Cattle feed

Cbd distillate

Celery juice

Cell and gene therapy

Cell and tissue culture

Cell culture

Cell culture media

Cell therapy

Cellulose

Cement

Cement additives

Cement blocks

Center-filled lollipops

Ceramic glazes

Ceramic pigments

Ceramic powders

Ceramic tiles

Ceramics

Cereal bars

Cereal grains

Cereals

Chalk

Chamomile oil

Chamomile tea bags

Champagne

Chapati

Chardonnay

Cheddar cheese

Cheese

Cheese Blocks

Cheese crackers

Cheese cubes

Cheese puffs

Cheese sauce

Cheese shreds

Cheese slices

Cheese spread

Cheese spreads

Cheese sticks

Cheese wheels

Cheesecake

Chemical additives

Chemical catalysts

Chemical compounds

Chemical emulsions

Chemical granules

Chemical intermediates

Chemical powders

Chemical reagents

Chemical solvents

Chemical suspensions

Chemical waste

Chemicals

Chemistry

Chemotherapy drugs

Cherries

Cherry tomatoes

Chestnut puree

Chestnuts

Chewable tablets

Chewing gum

Chewing gum sticks

Chia seeds

Chicken breast

Chicken broth

Chicken curry

Chicken drumsticks

Chicken feed

Chicken fillets

Chicken gizzards

Chicken manure

Chicken mince

Chicken nuggets

Chicken tenders

Chicken thighs

Chicken wings

Chickpea flour

Chickpeas

Chili paste

Chili powder

Chili sauce

Chinese traditional medicine

Chips

Chlorella powder

Chocolate

Chocolate balls

Chocolate bars

Chocolate bonbons

Chocolate chip cookies

Chocolate chip muffins

Chocolate chips

Chocolate coatings

Chocolate couverture

Chocolate croissants

Chocolate decorations

Chocolate dragees

Chocolate drops

Chocolate eggs

Chocolate fillings

Chocolate ganache

Chocolate liquor

Chocolate milk

Chocolate molds

Chocolate mousse

Chocolate pralines

Chocolate spread

Chocolate spreads

Chocolate truffles

Chorizo

Chutneys

Ciabatta

Cider

Cigarettes

Cigars

Cinnamon powder

Cinnamon rolls

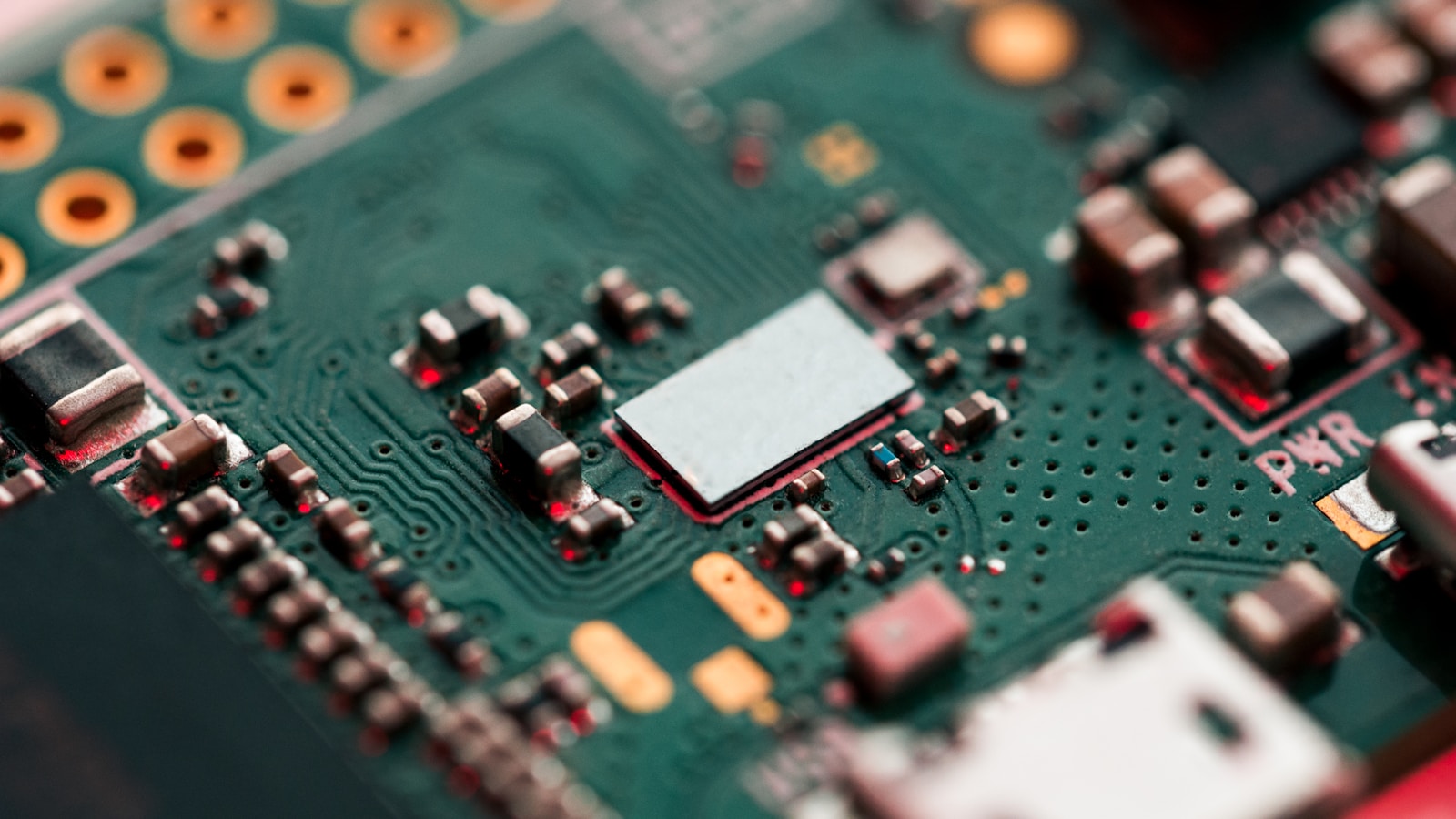

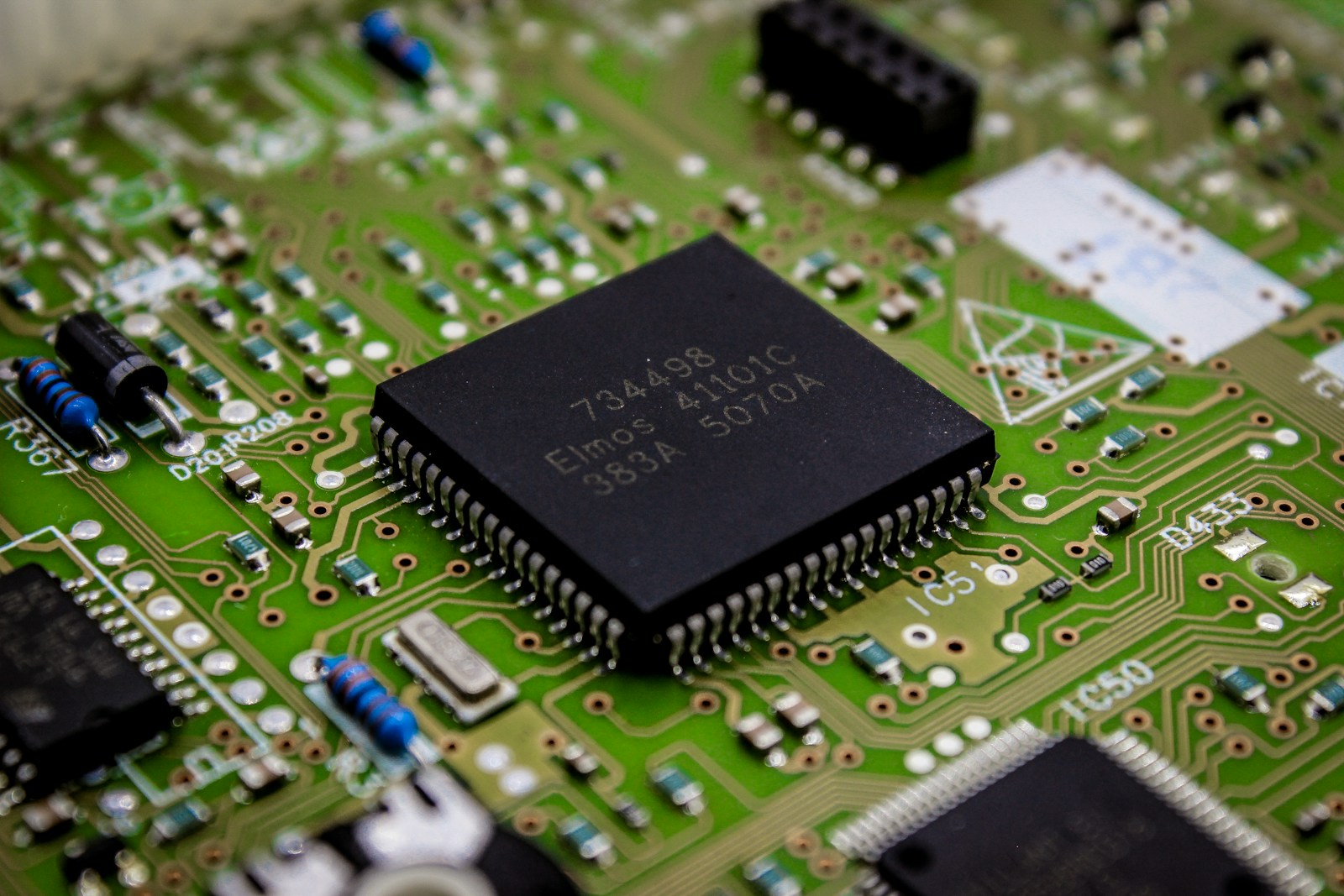

Circuit boards

Citric acid

Citrus Fruit

Clarified grape juice

Clarified wine

Clay

Clay bricks

Cleaning agents

Cleaning wipes

Clinical trials

Clinker

Club sandwiches

Coal

Coated lenses

Coated nuts

Coated seeds

Coated tablets

Coating materials

Cocktail sausages

Cocoa

Cocoa beans

Cocoa butter

Cocoa liquor

Cocoa mass

Cocoa nibs

Cocoa powder

Coconut cream

Coconut milk

Coconut oil

Coconut water

Coenzyme q10 capsules

Coffee

Coffee blends

Coffee capsules

Coffee cream

Coffee creamer

Coffee extracts

Coffee grounds

Coffee powder

Cognac

Coil coatings

Cola soft drink

Cold Cuts

Cold and flu tablets

Cold brew coffee

Cold-pressed juice

Cold-pressed olive oil

Coleslaw

Collagen peptides

Collagen powder

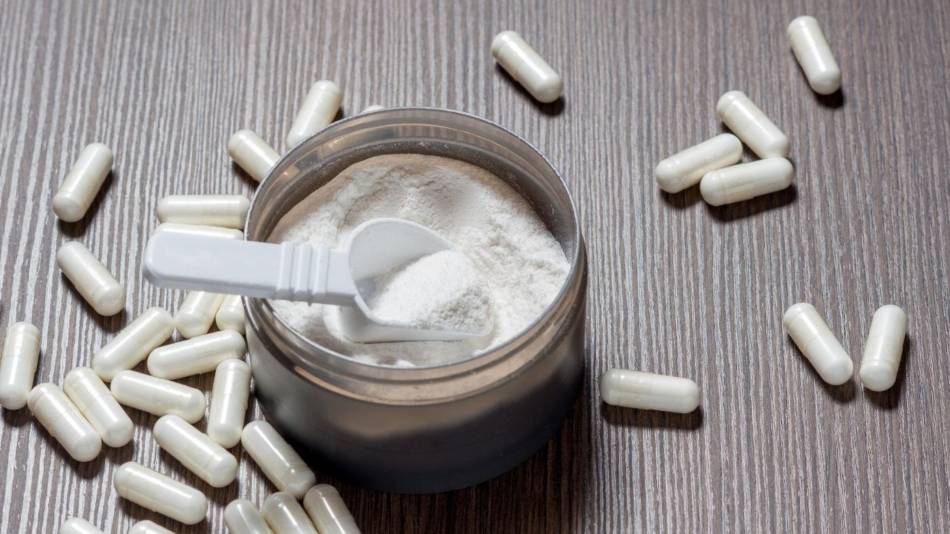

Collagen supplements

Color masterbatches

Colorants

Composite materials

Compost

Compound chocolate

Compound feed

Concrete

Concrete additives

Concrete admixtures

Concrete aggregates

Concrete mixtures

Condensed milk

Condiments

Conditioner

Conductive additives

Conductive coatings

Conductive inks

Confectionery coatings

Confectionery fillings

Construction chemicals

Construction materials

Consumer electronics

Contact Lenses

Containers

Continence care

Controlled-release tablets

Convenience foods

Cooked ham

Cooked sausages

Cookie dough

Cookies

Cooking cream

Cooking oil

Copper

Copper cathodes

Copper concentrate

Copper sulfate

Corn

Corn Chips

Corn flakes

Corn flour

Corn gluten meal

Corn grits

Corn nuts

Corn oil

Corn puffs

Corn seeds

Corn syrup

Corn tortillas

Corned beef

Cornmeal

Cornstarch

Coronary stents

Corrugated cardboard boxes

Cosmetic creams

Cosmetic emulsions

Cosmetic foundation

Cosmetic lotions

Cosmetic powders

Cosmetic serums

Cosmetics

Cottage cheese

Cottonseed meal

Cottonseed oil

Cough syrup

Couscous

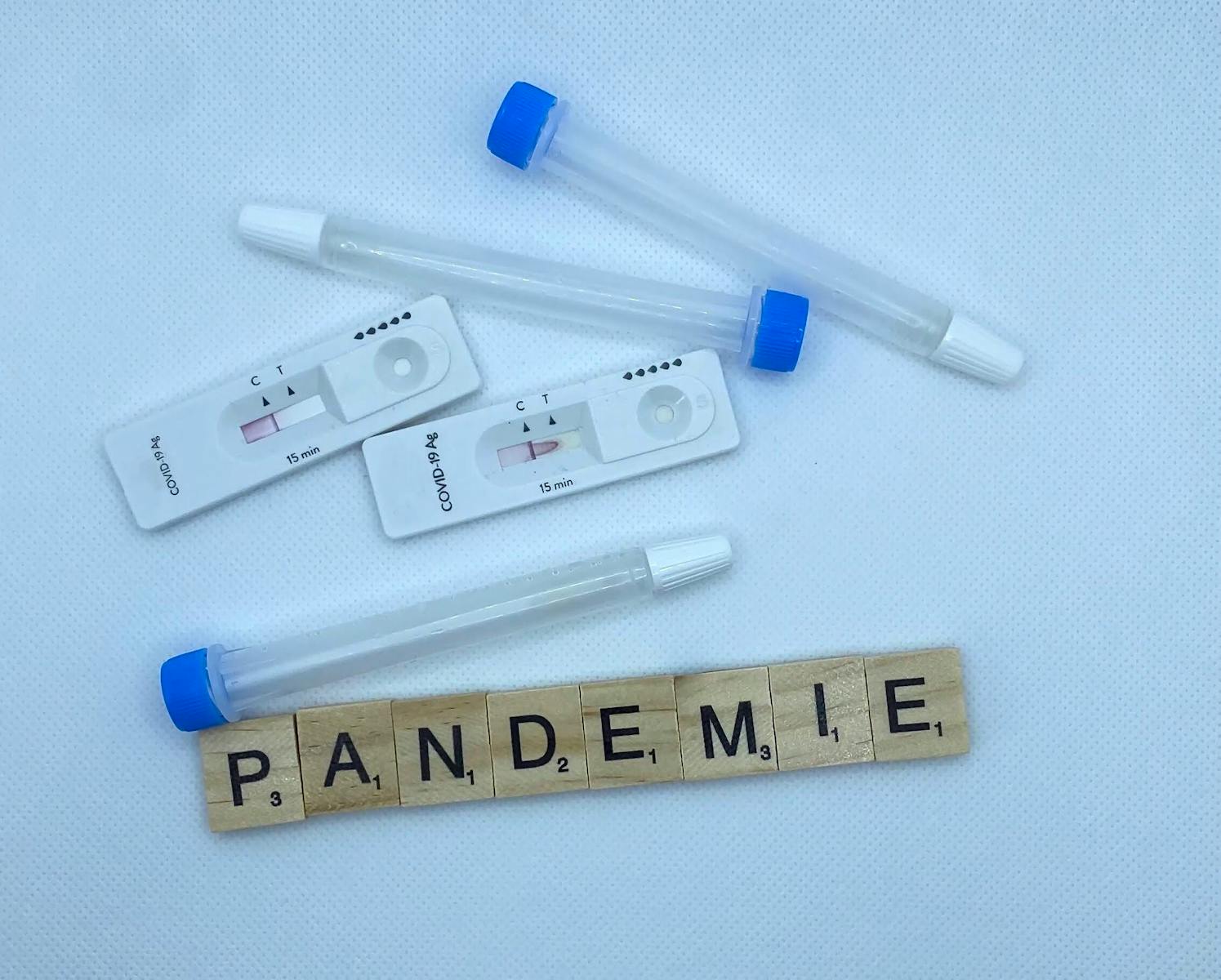

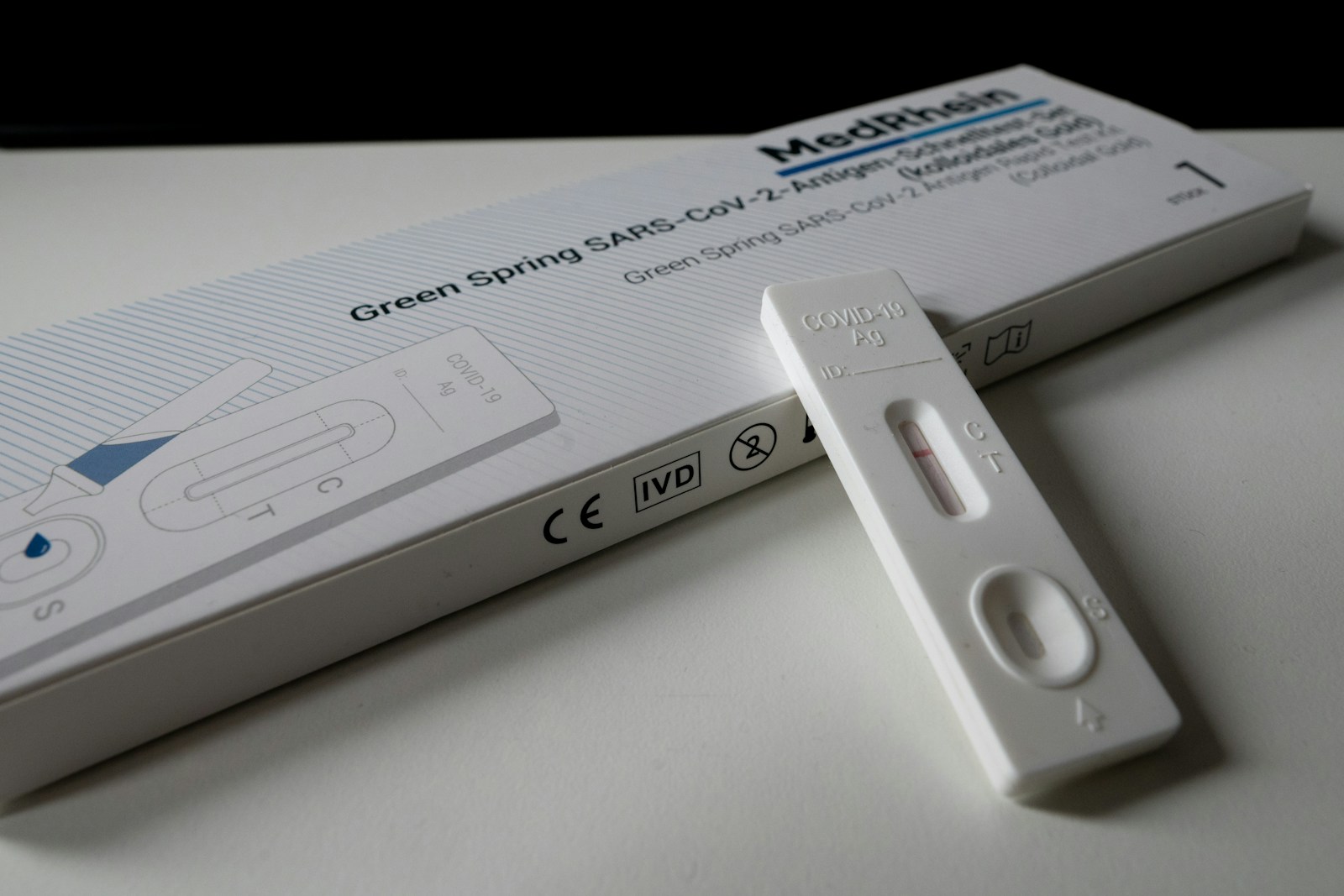

Covid-19 test kits

Covid-19 vaccines

Crab cakes

Crackers

Craft beer

Crates

Cream

Cream cheese

Cream crackers

Cream fillings

Cream puffs

Creams

Cricket flour

Cricket protein

Crinkle cut fries

Crispbread

Crispies

Crisps

Croissants

Crop protection agents

Croutons

Crude oil

Crushed stone

Cucumbers

Cultivated meat

Culture media

Cumin powder

Cupcakes

Curd

Curd cheese

Cured meats

Curly fries

Curry paste

Curry powder

Custard

Cytotoxic drugs

Dairy

Dairy alternatives

Dairy powder

Dairy protein supplements

Danish pastries

Dark chocolate

Dark roast coffee

Dates

Dealcoholized wine

Decaffeinated coffee

Dehydrated fruits

Dehydrated potato flakes

Dehydrated vegetables

Dental

Dental implants

Deoderant

Deodorants

Dessert wine

Desserts

Detergent bottles

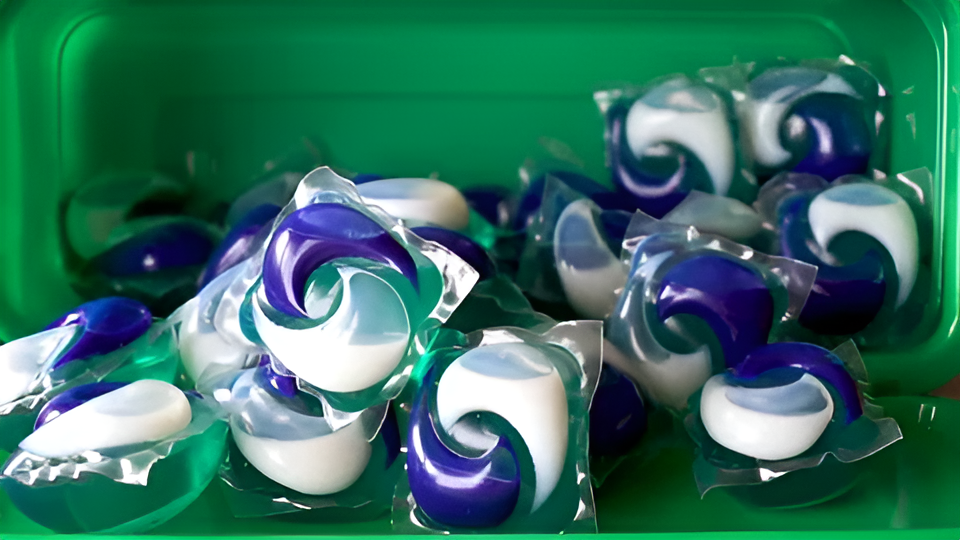

Detergent pods

Detergent powder

Detergent tablets

Detergents

Dextrose

Diagnostic devices

Diagnostic kits

Diagnostic reagents

Diagnostics

Diamonds

Diesel

Dietary supplements

Digestive biscuits

Digital printing inks

Dijon mustard

Dips

Dishwasher tablets

Dishwashing liquid

Dishwashing powder

Disinfectant wipes

Disinfectants

Dispersion paints

Disposable syringes

Distillates

Dna

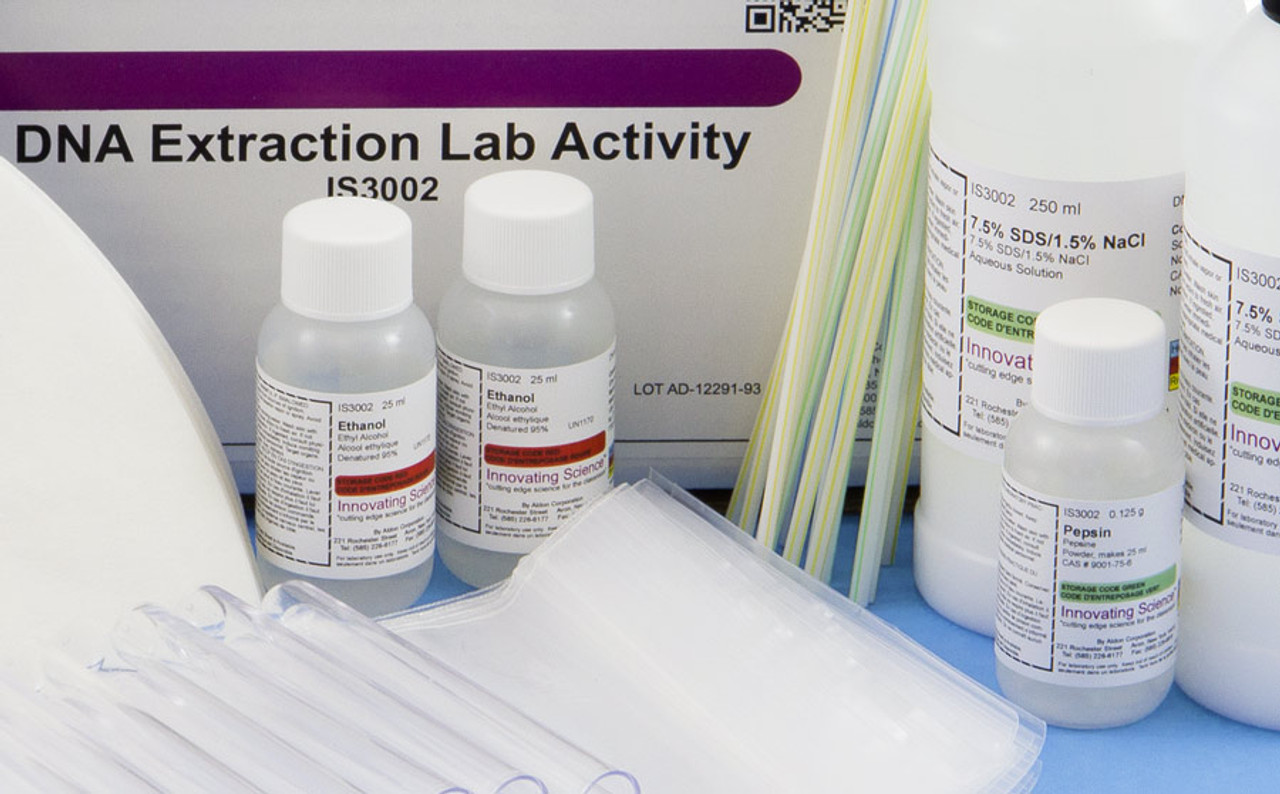

Dna extraction kits

Dog biscuits

Dog food

Dog treats

Donuts

Dough

Dragees

Dressings

Dried apples

Dried biosolids

Dried distillers grains (DDGS)

Dried foods

Dried fruit

Dried herbs

Dried meat

Dried oregano

Dried sausage

Drinks

Drug formulations

Dry beans

Dry pet food

Dry powder inhalants (dpi)

Dry powders

Drymix building materials

Drywall

Duck breasts

Dulce de leche

Dumplings

Durum wheat semolina

Dyes

Eardrops

Echinacea extract

Eclairs

Edible Oil

Edible fats

Effervescent granules

Effervescent tablets

Egg cartons

Egg noodles

Egg rolls

Eggs

Elastomers

Elderberry extract

Electrical waste

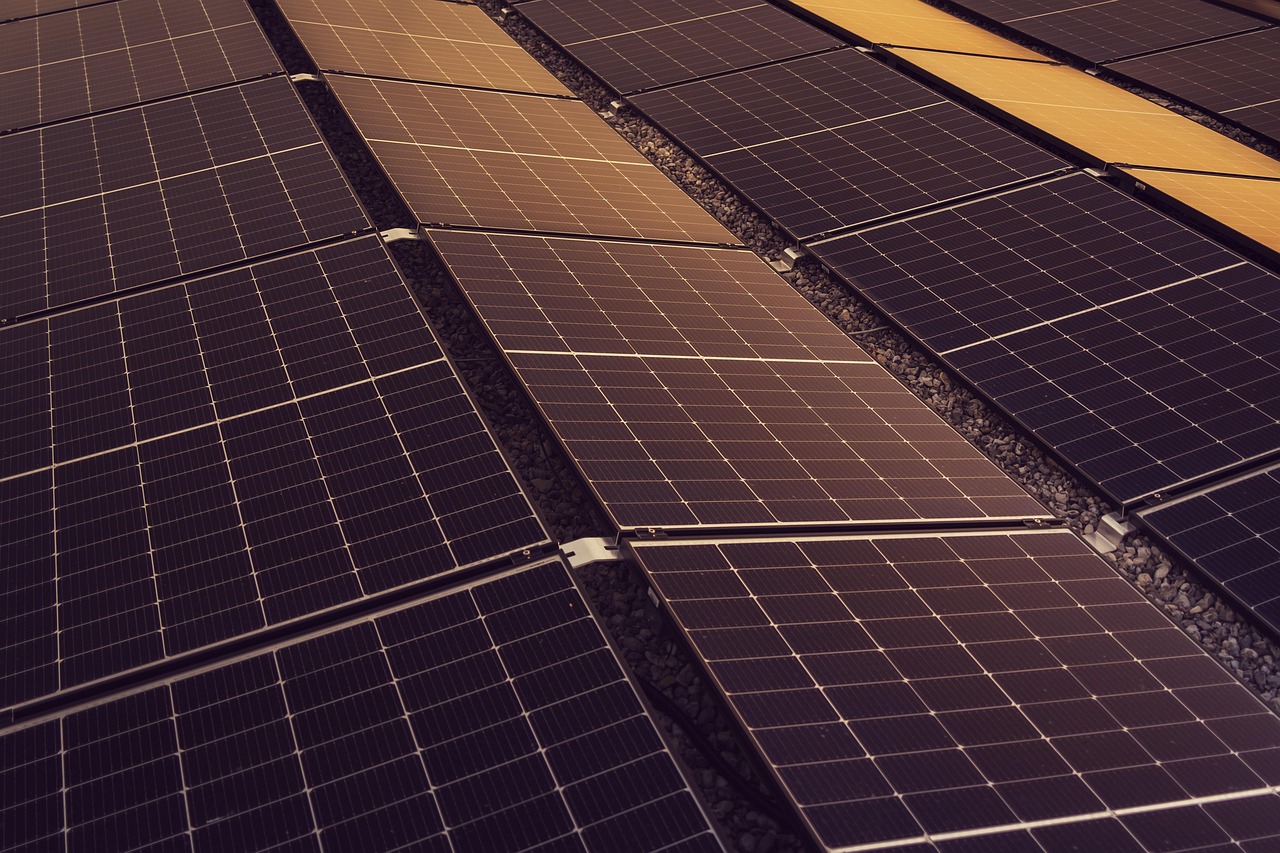

Electricity

Electrochemistry

Electrolyte drinks

Electrolyte solutions

Electronic materials

Electronics

Emulsifiers

Emulsion paints

Emulsions

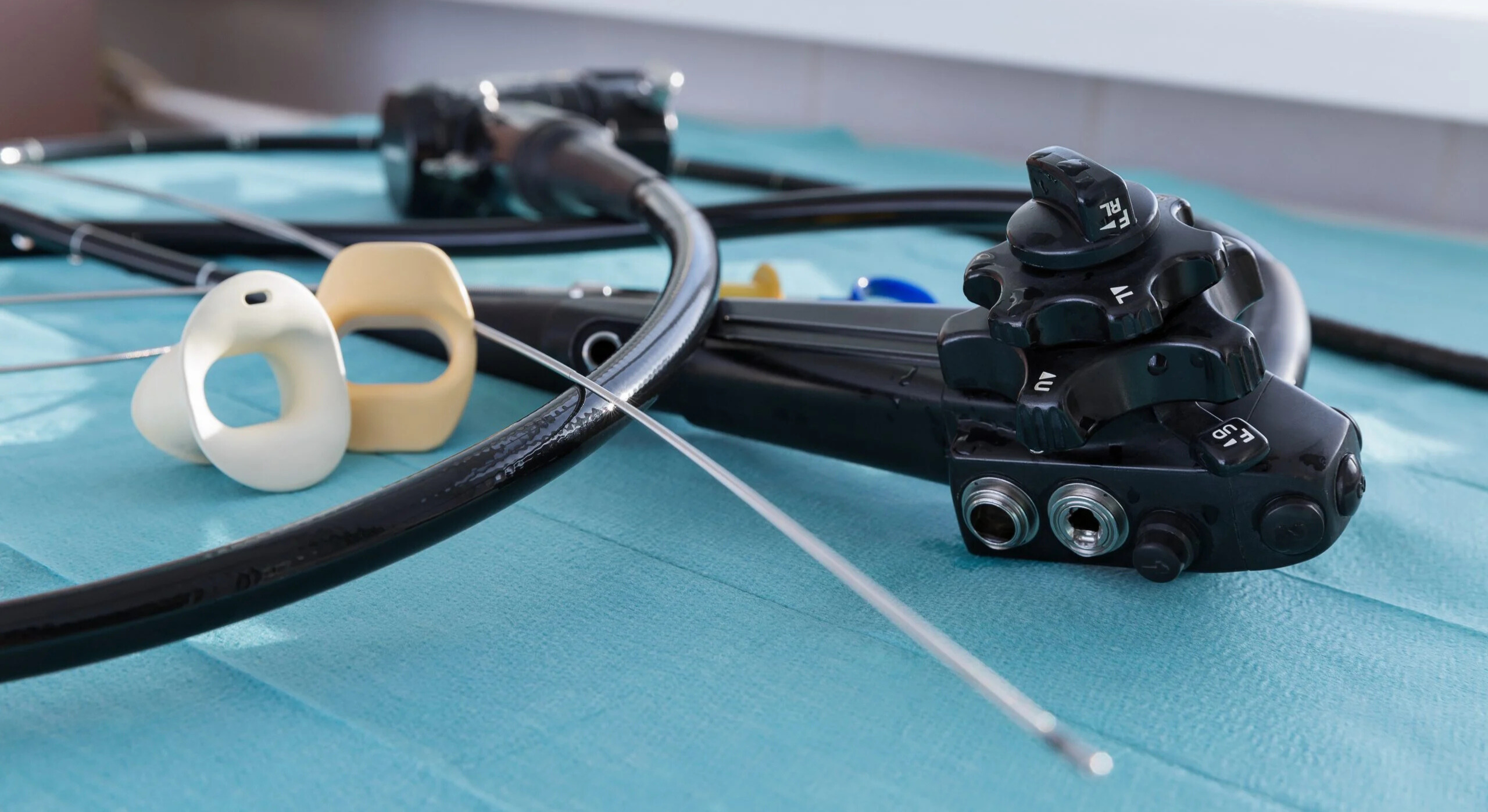

Endoscopes

Energy

Energy bars

Energy drinks

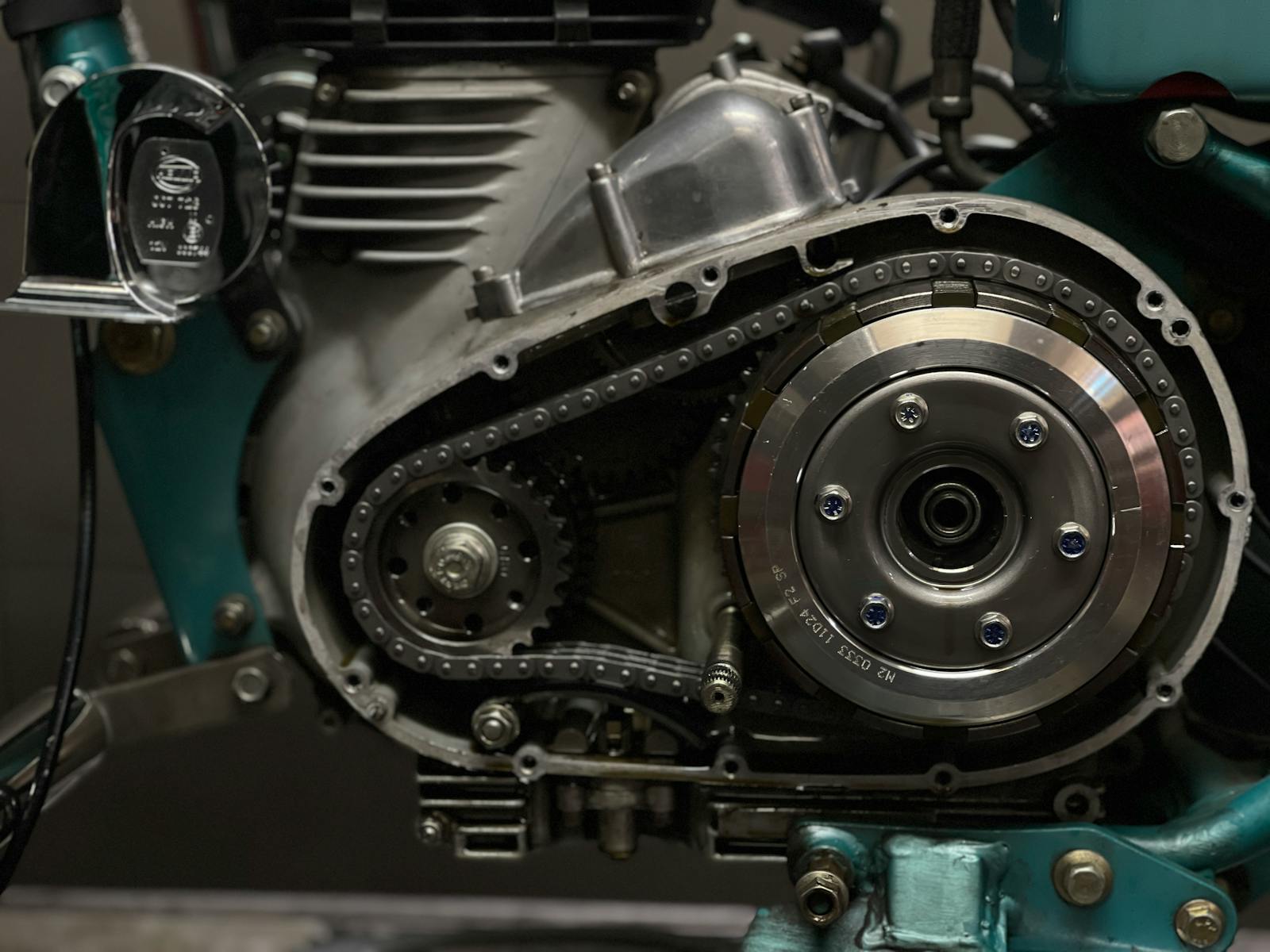

Engine components

Engine oils

Engineering materials

Engineering plastics

Enteric Coated Tablets

Environmental applications

Enzyme catalysts

Enzyme replacement therapies

Enzymes

Epoxy adhesives

Epoxy coatings

Epoxy resin

Er tablets

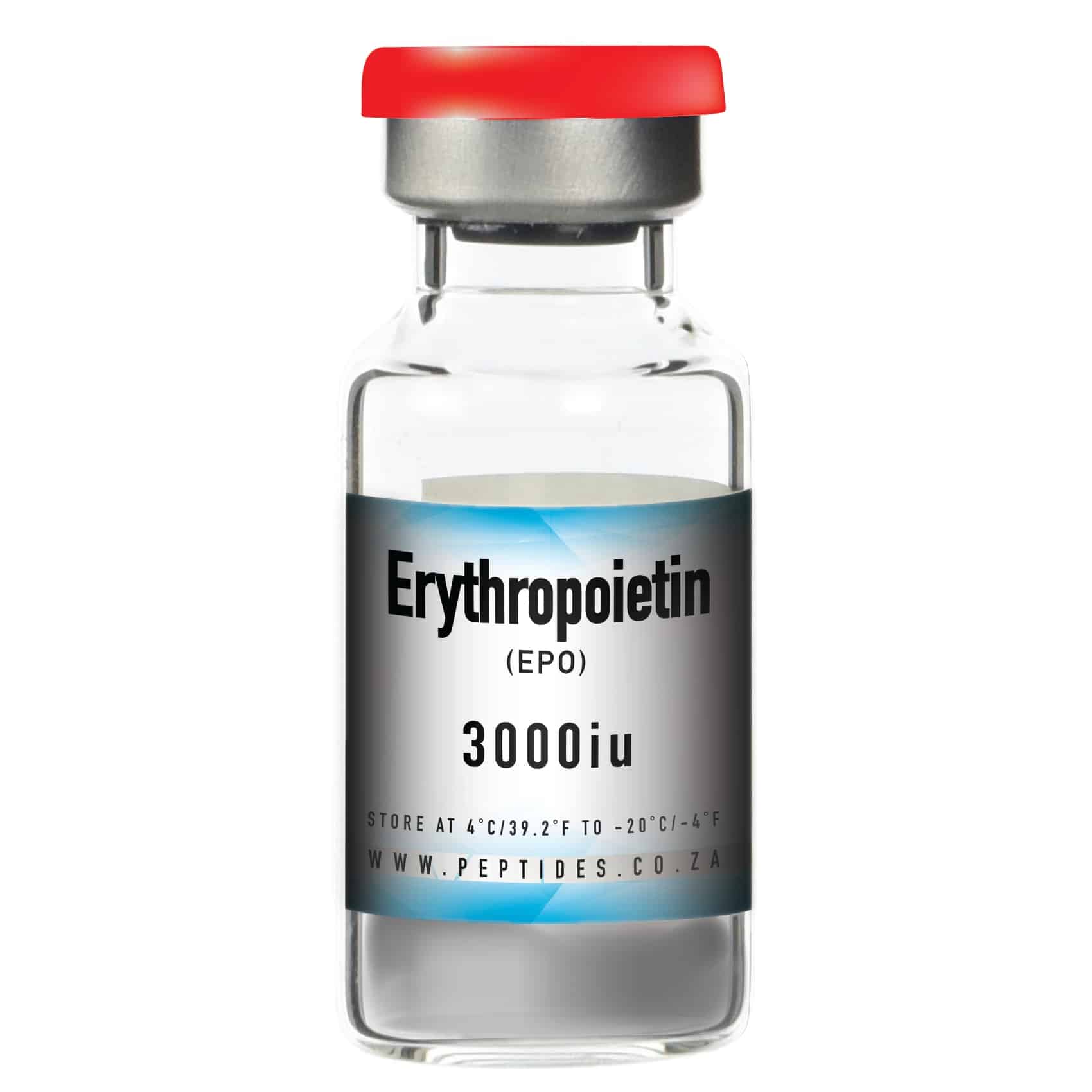

Erythropoietin

Esl milk

Espresso coffee

Essential oil blends

Essential oil extracts

Essential oils

Ethanol

Ethylene

Ethylene glycol

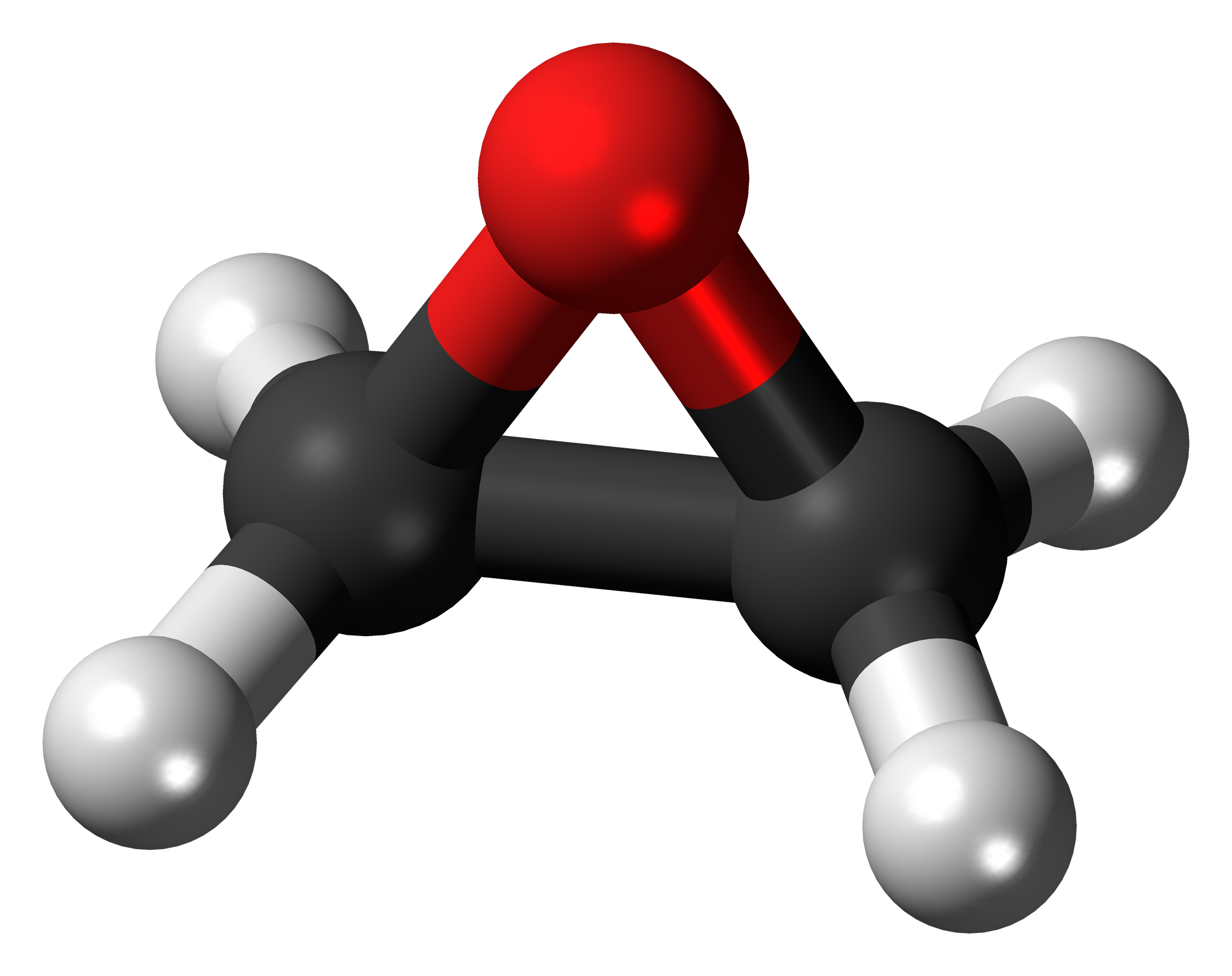

Ethylene oxide

Eucalyptus oil

Evaporated milk

Excipients

Extended-release tablets

Extra virgin olive oil

Extracts

Extrudates

Extruded aquafeed

Extruded cereal

Extruded snacks

Eye care products

Eyedrops

Eyeshadow

Fabric softener

Fabricated chips

Face cream

Face masks

Face powder

Facial Tissues

Facial moisturizers

Fast food

Fat-based compounds

Fats

Fatty acids

Feed

Feed additives

Feed concentrates

Feed ingredients

Feed premixes

Fermentation broths

Fermented beverages

Fermented dairy products

Fermented products

Fertilizer pellets

Feta cheese

Fettuccine

Fiberglass

Fibers

Filled croissants

Fillings

Film

Film-coated tablets

Filter coffee

Fine ceramics

Fine chemicals

Firebricks

Fish

Fish by-products

Fish cakes

Fish feed

Fish fillets

Fish fingers

Fish oil

Fish oil capsules

Fish oil supplements

Fish sticks

Fishmeal

Fishmeal powder

Flakes

Flame retardants

Flatbread

Flavor enhancers

Flavor extracts

Flavored mineral water

Flavoring agents

Flavors

Flavoured milk

Flax seeds

Floating pellets

Flour

Flower extract

Flower seeds

Fludeoxyglucose (fdg)

Fluoride toothpaste

Fluorodeoxyglucose (fdg)

Fly ash

Foam

Foam kisses

Focaccia

Fodder

Fondant

Fondant icing

Food

Food additives

Food colorants

Food flavorings

Food ingredients

Food powders

Food preservatives

Food supplements

Food-to-go

Forestry

Formulated dairy products

Fortified wine

Foundation cream

Fragrance compounds

Fragrance oils

Fragrances

Frankfurters

Free-flowing powders

Freeze dried berries

Freeze-dried fruits

Freeze-dried pharmaceuticals

Freeze-dried plasma

French fries

Fresh produce

Fried chicken

Frosting

Frozen beef patties

Frozen berries

Frozen cakes

Frozen croissants

Frozen desserts

Frozen dinners

Frozen dough

Frozen fish fillets

Frozen food

Frozen fruit

Frozen mixed vegetables

Frozen peas

Frozen pizza

Frozen shrimp

Frozen yogurt

Fruit

Fruit bars

Fruit chews

Fruit compote

Fruit concentrate

Fruit jam

Fruit jellies

Fruit juice

Fruit juice concentrate

Fruit leather

Fruit nectars

Fruit pastes

Fruit pies

Fruit powder

Fruit preserves

Fruit pulp

Fruit punch

Fruit puree

Fruit salad

Fruit syrups

Fruit yogurt

Fudge

Fuel

Functional drinks

Functional flours

Functional foods

Fungi

Fungicides

Fusilli pasta

Ganache

Garlic

Garlic paste

Garlic powder

Gas

Gas and energy

Gasoline

Gel capsules

Gel nail polish

Gelatin capsules

Gelatin desserts

Gelatin powder

Gelatin sheets

Gelatine

Gels

Gene therapy

Geology

Gin

Ginger ale

Ginger paste

Gingerbread biscuits

Ginkgo extract

Ginseng extract

Glass

Glass beads

Glass bottles

Glass cleaner

Glass fibers

Glass sheets

Gloss varnish

Glucose syrup

Glue

Gluten

Gluten-free bread

Gluten-free flour

Glycerin suppositories

Glycerine

Glycerol

Glyphosate

Glyphosate herbicides

Gmp radiopharmacy

Gouda cheese

Grains

Grana padano cheese

Granola

Granola bars

Granules

Grape Juice

Grape must

Grapefruit juice

Grapefruits

Grapes

Graphite

Graphite anodes

Graphite electrodes

Grass seeds

Grated cheese

Gravel

Gravy

Grease

Greek yoghurt

Green beans

Green chemistry

Green coffee beans

Green tea

Ground cinnamon

Ground coffee

Guacamole

Gummies

Gummy Bears

Gypsum

Gypsum board

Gypsum powder

HPMC capsules

Hair care products

Hair conditioner

Hair dye kits

Hair gel

Halloumi

Halva

Ham

Hamburger buns

Hamburgers

Hand cream

Hand sanitizer

Hand soap

Hard Candy

Hard cheese

Hard gelatin capsules

Hard lemonade

Hard minerals

Hard seltzer

Hash Browns

Hazelnut spread

Hazelnuts

Healthcare products

Healthy snacks

Hemp

Hemp seed oil

Hemp seeds

Hepatitis b vaccines

Herbal Extracts

Herbal infusions

Herbal medicines

Herbal supplements

Herbal tea

Herbal tinctures

Herbicides

Herbs

High potent drugs

High-fructose corn syrup

High-potency active pharmaceutical ingredients (hpapis)

Highly Active Pharmaceutical Ingredients

Hip implants

Hoagie rolls

Hollandaise sauce

Hollow chocolate figures

Home care products

Homeopathy

Honey

Hops

Hormonal injections

Hormone therapies

Hormones

Horticulture

Hot dogs

Hot melt adhesives

Hot melt glue sticks

Hot sauce

Household appliances

Household detergents

Hummus

Hyaluronic acid

Hyaluronic acid serums

Hydrated lime

Hydraulic oil

Hydrocarbons

Hydrochloric acid

Hydrocolloids

Hydrocortisone cream

Hydrogen

Hydrogen peroxide

Hydrometallurgy

Hygiene products

Hygroscopic products

Ibuprofen

Ice cream

Ice cream bars

Ice cream cakes

Ice cream cones

Ice cream cups

Ice cream sandwiches

Ice cream tubs

Iced coffee

Icing

Immediate-release tablets

Immunochemistry

Implantable medical devices

Implants

In-vitro diagnostics

Industrial products

Industrial waste

Industrial waste water

Infant formula

Infant nutrition

Influenza vaccines

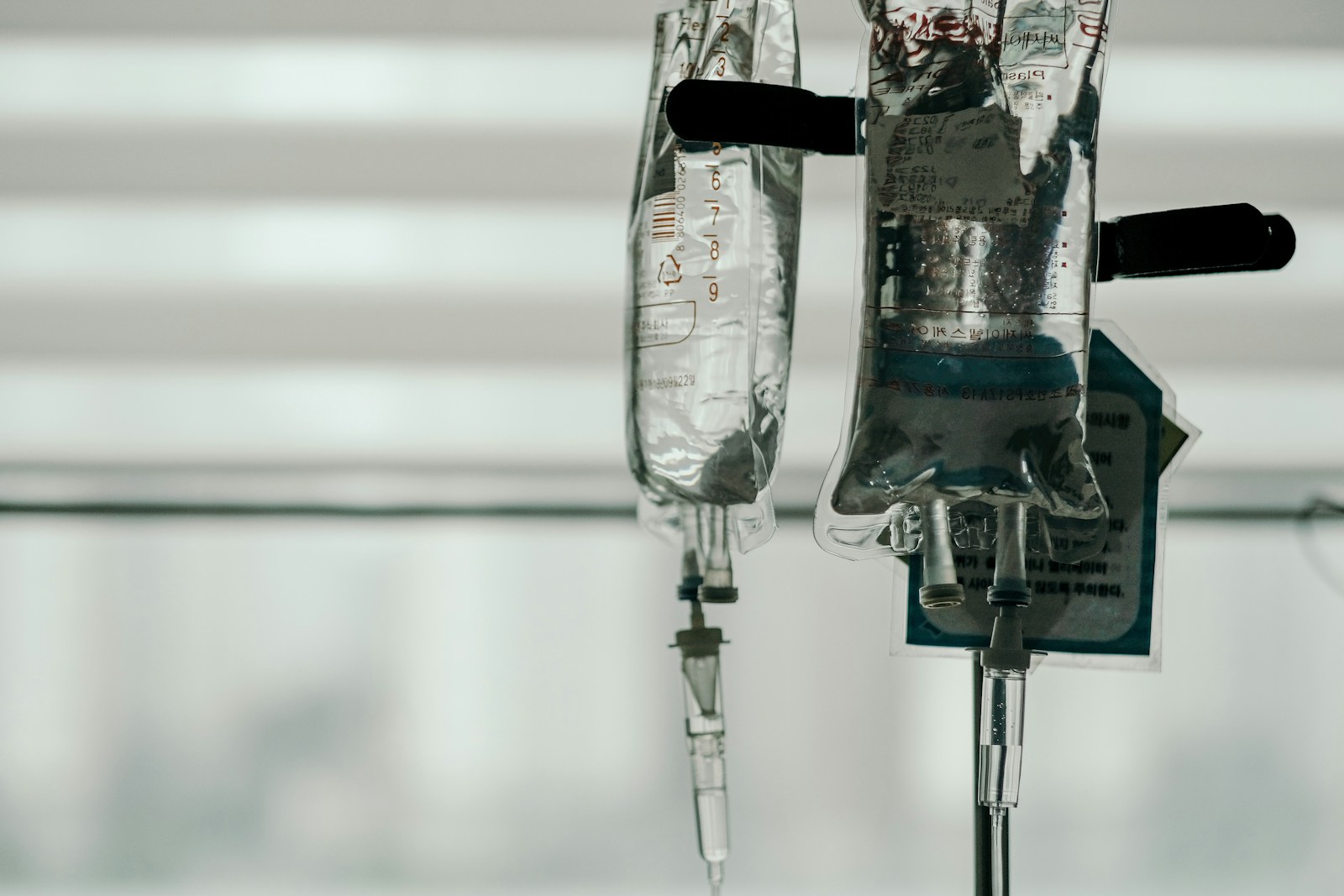

Infusions

Inhaler blisters

Inhalers

Injectable biologics

Injectables

Injection molding

Ink

Inkjet printer cartridges

Inorganic chemicals

Insect protein

Insect technology

Insecticides

Instant coffee

Instant drink powders

Instant noodles

Instant soup

Insulin

Insulin injections

Insulin pens

Intermediates

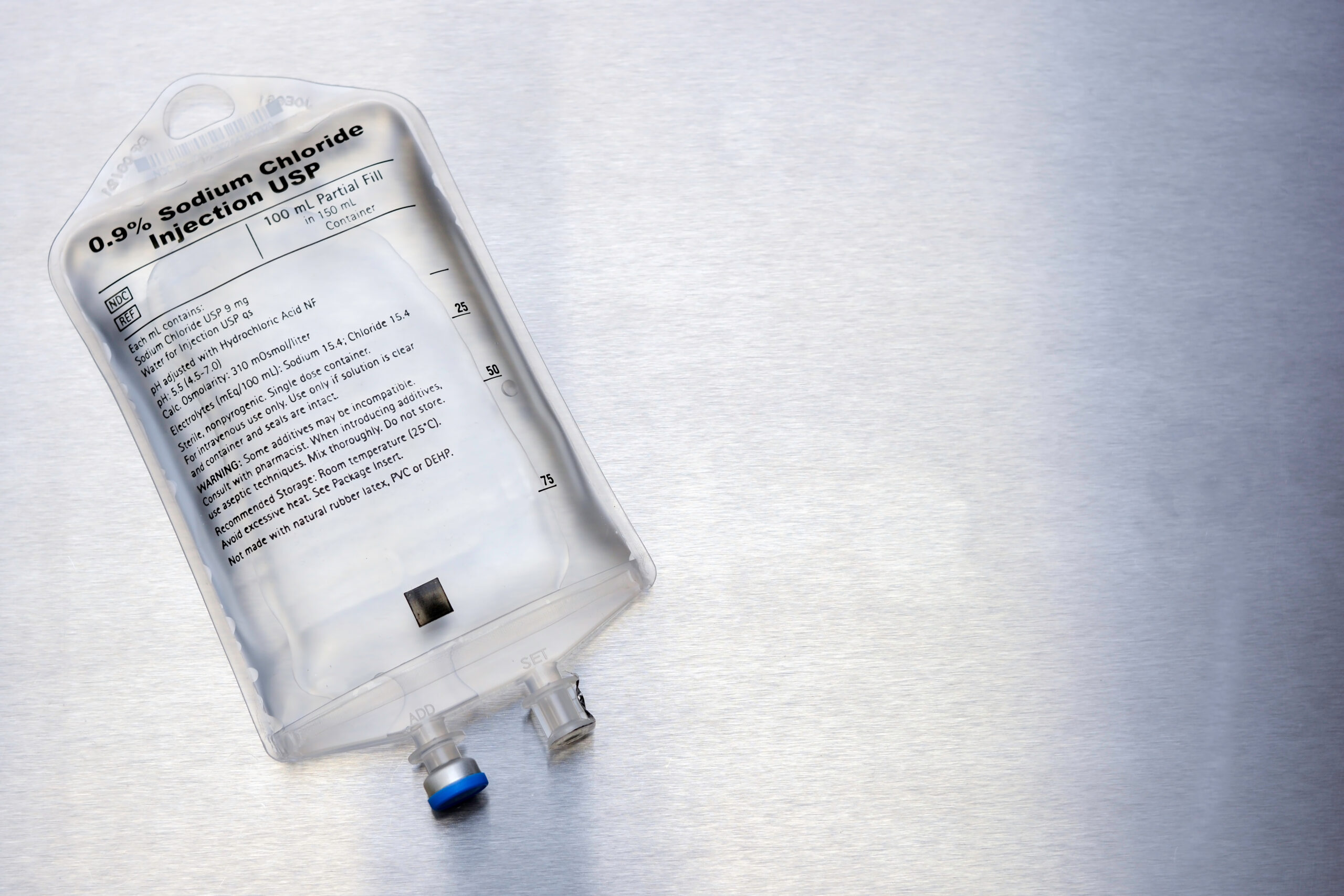

Intravenous solutions

Iodine-131

Iqf vegetables

Iron

Iron ore

Iron ore concentrate

Iron oxide pigments

Iron supplements

Isotonic drinks

Italian dressing

Jam

Japanese peanuts

Jars

Jasmine rice

Jellies

Jelly

Jelly beans

Juice cartons

Juice concentrate

Kaiser rolls

Kale

Kaolin

Kashkaval

Kebap

Kefir

Ketchup

Kettle chips

Kibble

Kidney beans

Kielbasa

Kimchi

Kiwis

Kombucha

Kraft paper

Lacquers

Lactic acid

Lactose

Lactose-free milk

Lager beer

Laminated dough

Lard

Large volume parenterals

Lasagna

Laser printer toner

Latex

Laundry detergent

Lavender oil

Layered cakes

Lead-acid batteries

Leafy vegetables

Leather

Lecithin

Legume snacks

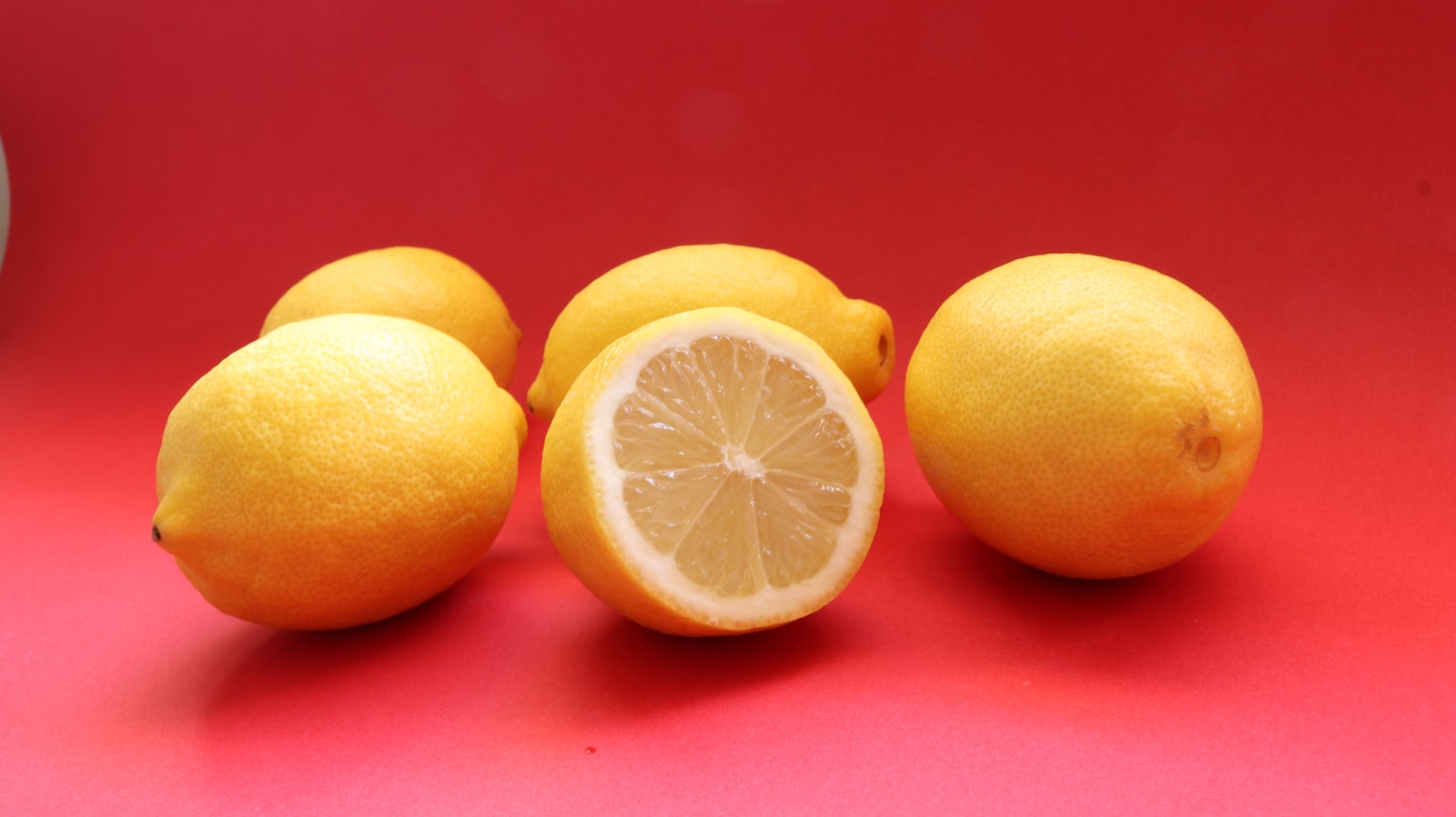

Lemon concentrate

Lemon curd

Lemon essential oil

Lemon juice

Lemonade

Lemons

Lentil chips

Lentil flour

Lentils

Lettuce

Licorice

Life science

Lignin

Limes

Limestone

Linguine

Lip balm

Lip gloss

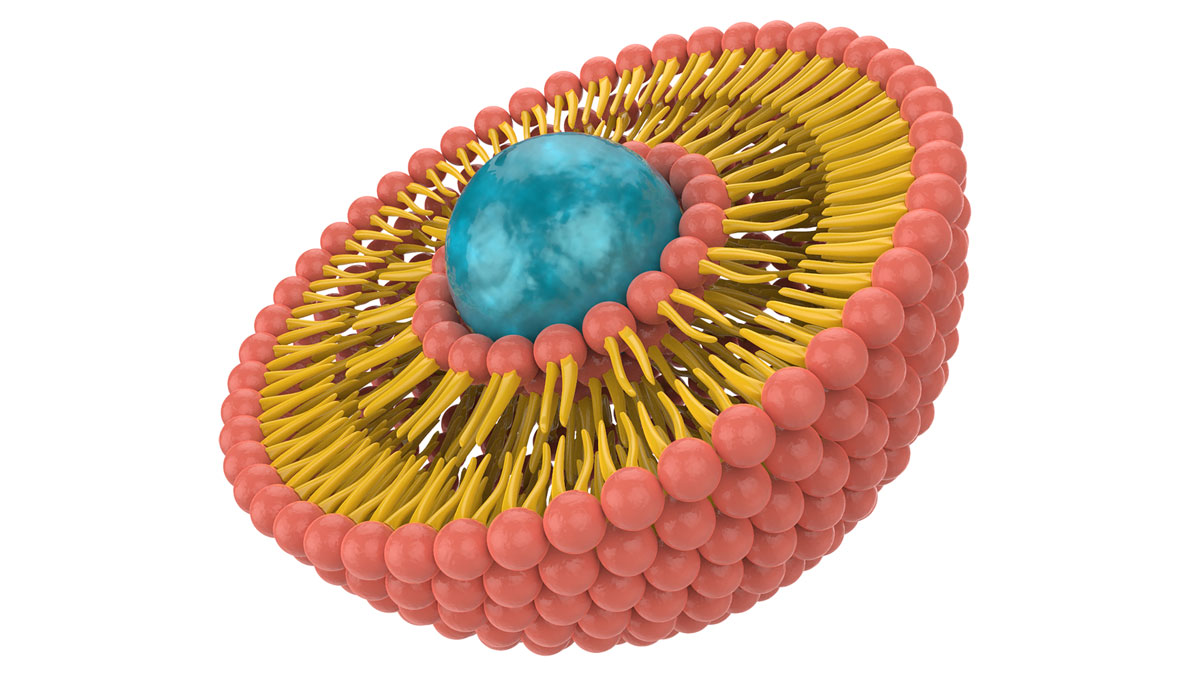

Liposomes

Lipstick

Liqueurs

Liquid

Liquid Formulations

Liquid crystal displays

Liquid detergents

Liquid dosage forms

Liquid egg products

Liquid foods

Liquid nutritional supplements

Liquid soap

Liquid supplements

Liquid sweeteners

Lithium-ion batteries

Lithium-ion battery anodes

Lithium-ion battery cathodes

Livestock feed

Livestock manure

Loaves of bread

Lollipops

Longmoulded rolls

Lotions

Lubricants

Luncheon meat

Lutetium-177

Lyophilized drugs

Lyophilized enzymes

Macaroni

Macaroni and cheese

Macarons

Machine parts

Mackerel fillets

Maize

Makeup

Malt

Malt extract

Malt rings

Malted barley

Maltodextrin

Mango chutney

Mango juice

Mango pulp

Mango sorbet

Manure

Maple syrup

Marble

Margarine

Margerine

Margherita pizza

Marinades

Marinara sauce

Marine algae

Marine applications

Marmalade

Marshmallows

Marzipan

Masa

Mascara

Mascarpone

Mash

Masterbatches

Mayonnaise

Mdf boards

Mealworm protein

Meat

Meat alternatives

Meat analogs

Meat and bone meal

Meatballs

Meatloaf

Medical devices

Medical gummies

Medical packaging

Medical testing kits

Medicinal cannabis

Medicinal herbs

Medicine

Melons

Merlot wine

Metal

Metal alloy powders

Metal ores

Metal oxides

Metal powder

Metal powders

Metal recycling

Metal salts

Metallic powders

Metallography

Metallurgy

Metals

Methanol

Micro organisms

Micro-tablets

Microbial cultures

Microbiology

Microchips

Microcrispies

Microcrystalline cellulose

Microneedles

Microspheres

Microtablets

Milk

Milk chocolate

Milk powder

Milk protein isolate

Milkshakes

Minced meat

Mineral fillers

Mineral oils

Mineral slurries

Mineral supplements

Mineral water

Minerals

Minestrone soup

Mining

Mixed nuts

Mixed salad bags

Mixed vegetable packs

Mochi

Modified starches

Moisturizers

Molasses

Molecular biology

Monoclonal antibodies

Monomers

Moped tires

Mortadella

Mortar mix

Mosquito repellent

Motor oil

Mousses

Mouthwash

Mozzarella

Mozzarella sticks

Mrna vaccines

Muesli

Muesli bars

Muffins

Mulch

Multi-fruit solutions

Multi-layer tablets

Multigrain bread

Multivitamin supplements

Mushrooms

Must

Mustard

Naan bread

Nacho chips

Nail polish

Nano suspensions

Nanoemulsions

Nanoparticles

Nasal spray

Natural food colorants

Natural paints

Nectar

Next generation biologics

Nicotine patches

Nitric acid

Nitrogen

Nitrogen fertilizer

Non-alcoholic beer

Non-carbonated beverages

Non-dairy creamer

Nonwovens

Noodles

Nougat

Npk fertilizers

Nuclear

Nuclear medicine

Nuggets

Nut bars

Nut brittle

Nut butter

Nut oil

Nut paste

Nutraceuticals

Nutritional drinks

Nutritional formula

Nutritional shakes

Nutritional supplements

Nutritional yeast

Nuts

Nylon fibers

Nylon pellets

Oat bran

Oat flakes

Oat flour

Oat milk

Oatmeal

Oatmeal cookies

Oats

Oil

Oil and gas

Oil sludge

Oilseeds

Ointment

Oled screens

Oleochemicals

Olive oil

Olive paste

Olives

Omega 3 oil

Omega-3 capsules

Oncology drugs

Onion powder

Onion rings

Onions

Ophthalmics

Optical lenses

Oral care

Oral liquid formulations

Oral solid dosage forms

Oral vaccines

Orange juice

Orange marmalade

Oranges

Ores

Organic acids

Organic chemicals

Organic fertilizer

Organic pigments

Orphan drugs

Orthopedic implants

Osb boards

Ostomy

PET

Packaging Formats

Packaging materials

Paint

Paint cans

Pancakes

Paneer

Panettone

Panna cotta

Paper

Paper pulp

Paper towels

Paprika

Paracetamol

Paraffin wax

Paratha

Parenteral drugs

Parenterals

Parmesan cheese

Passion fruit juice

Pasta

Pasta filata cheese

Pasta sauce

Pasta sheets

Pastes

Pasteurized juice

Pasteurized milk

Pastrami

Pastries

Pastry cream

Pastry fillings

Patties

Pcr reagents

Pea protein isolate

Peaches

Peanut butter

Peanuts

Pears

Peas

Peat

Pectin

Pectin jellies

Pellet fuel

Pellet snacks

Pelleted feed

Pelleted seeds

Pellets

Penicillin

Penne pasta

Pepperoni

Peptides

Perfume

Personal care products

Personalized medicine

Pesticide

Pesto

Pet care

Pet food

Petrochemicals

Petroleum coke

Pharmaceutical bottles

Pharmaceutical capsules

Pharmaceutical cartridges

Pharmaceutical creams

Pharmaceutical emulsions

Pharmaceutical excipients

Pharmaceutical granules

Pharmaceutical intermediates

Pharmaceutical ointments

Pharmaceutical packaging

Pharmaceutical pills

Pharmaceutical powder

Pharmaceutical powders

Pharmaceutical suspensions

Pharmaceutical syrups

Pharmaceutical vials

Pharmaceuticals

Phosphates

Phosphoric acid

Phosphorus fertilizer

Pickled vegetables

Pickles

Pie

Pigment

Pilsner beer

Pineapples

Pinot noir

Pipettes

Pistachios

Pita bread

Pizza

Pizza dough

Plant extracts

Plant waste

Plant-based beverages

Plant-based cheese

Plant-based meat

Plant-based milk

Plant-based protein

Plant-based yogurt

Plasmid dna

Plaster

Plaster of paris

Plasterboard

Plasters

Plastic containers

Plastic intermediates

Plastic packaging

Plastic resins

Plasticizers

Plastics

Plastics recycling

Platinum catalysts

Polenta

Polishing agents

Polyester resin

Polyethylene

Polyethylene film

Polyethylene granules

Polyethylene pellets

Polyethylene powder

Polymer dispersions

Polymer emulsions

Polymer granules

Polymer pellets

Polymer powders

Polymer resins

Polymers

Polyolefins

Polypropylene

Polypropylene containers

Polypropylene films

Polypropylene granules

Polypropylene pellets

Polysaccharides

Polystyrene beads

Polyurethane adhesives

Polyurethane coatings

Polyurethane foam

Polyurethane sealants

Polyurethane varnish

Pome fruits

Pomegranate juice

Popcorn

Porcelain

Pork

Pork chops

Port silos

Portland cement

Potash

Potato chips

Potato co-products

Potato croquettes

Potato starch

Potato wedges

Potatoes

Potting soil

Pouches

Poultry

Poultry feed

Pound cake

Powder

Powder Metallurgy

Powder coating

Powder detergent

Powder dissolving

Powder for suspensions (PFS)

Powdered drink mixes

Powdered sugar

Pralines

Pre-cooked meals

Pre-dough

Pre-filled Syringes

Pre-packaged meals

Pre-packaged salads

Precast concrete

Precious metals

Precision gears

Preserves

Pretzels

Primers

Pringles

Printed circuit boards

Printer ink

Probiotic cultures

Probiotic drinks

Probiotic supplements

Probiotic yogurt

Probiotics

Processed animal by-products

Processed cheese

Processed minerals

Processed vegetables

Produce

Propylene

Prosciutto

Prosecco

Protective coatings

Protein

Protein assays

Protein bars

Protein powder

Protein supplements

Protein therapeutics

Protein-based drugs

Provolone

Pudding

Puff pastry

Puffed rice

Pulp

Pulses

Pulverized coal

Pumpkin seeds

Puree

Purified water

Pvc pellets

Pvc pipes

Quark

Quartz

Quiche lorraine

Quiches

Quicklime

Quinoa

Radiochemistry

Radiopharmaceuticals

Raisin rolls

Raisins

Ramen noodles

Ranch dressing

Rapeseed oil

Ravioli

Raw pet food

Reaction flavors

Ready meals

Reagents

Reclaimed water

Recombinant proteins

Recombined milk

Recycled aggregates

Recycled aluminum

Recycled glass cullet

Recycled paper

Recycled plastic

Red velvet cakes

Refill tablets

Refined sugar

Refined vegetable oils

Refractory products

Refrigerants

Regenerative medicine

Rehydration solutions

Renewable energy

Resin

Rice

Rice Crispies

Rice bran

Rice cakes

Rice crackers

Rice flour

Rice milk

Rice noodles

Rice pudding

Ricotta

Rigid containers

Rituximab

Road marking paints

Roasted nuts

Rodenticides

Root beer

Root vegetables

Rose oil

Rte cereals

Rubber

Rubber seals

Rubber tires

Rum

Rye

Rye bread

Sachets

Salad dressing

Salads

Salami

Saline solutions

Salmon fillets

Salsa

Salt

Salted butter

Saltine crackers

Samosas

Sand

Sandwich cookies

Sandwiches

Sauce

Sauerkraut

Saurkraut

Sausages

Savoury snacks

Sawdust

Scamorza

Schnitzels

Scones

Sea buckthorn oil

Sea salt

Seafood

Sealants

Seasonings

Seaweed

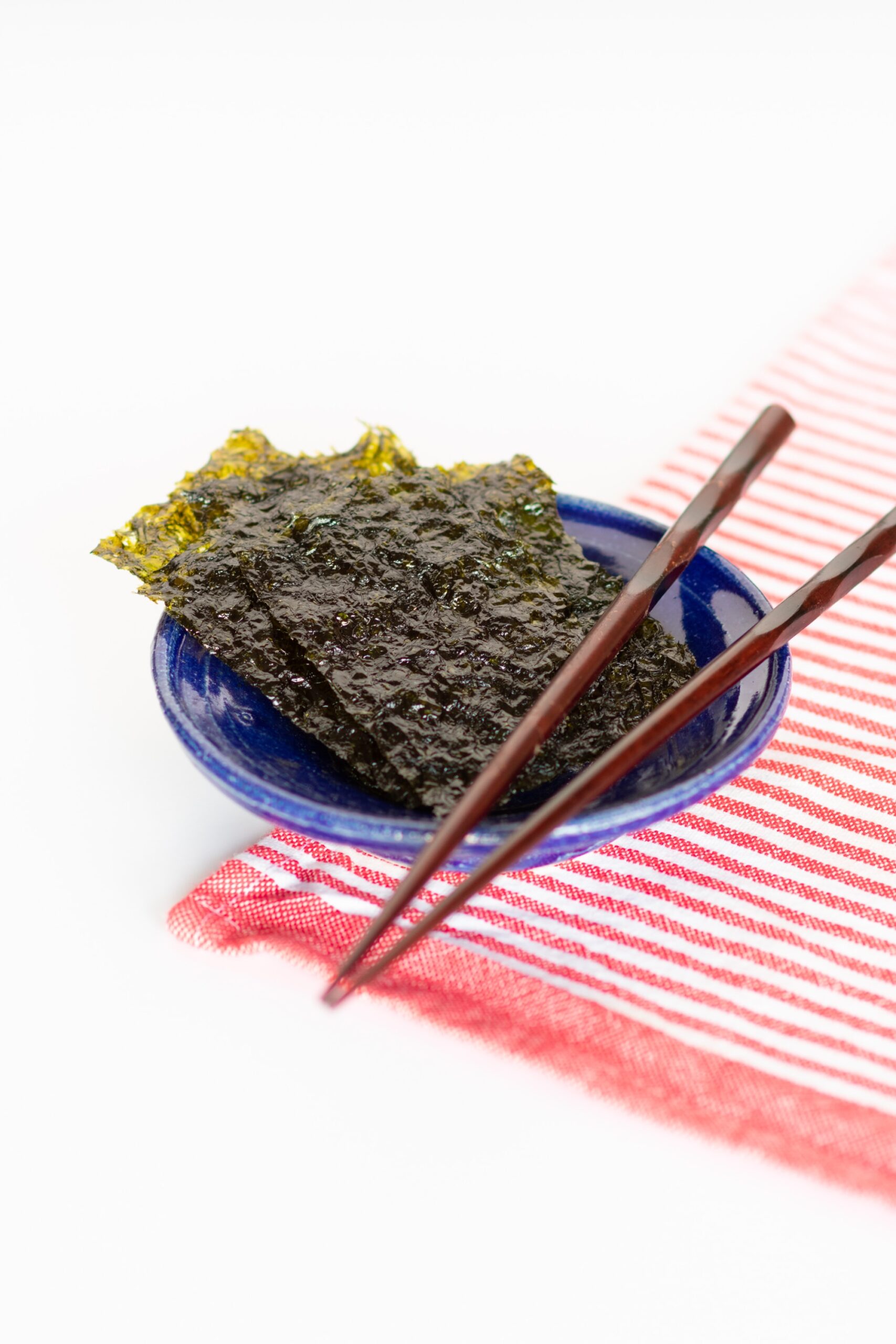

Seaweed snacks

Seed coatings

Seed oils

Seeds

Semi-solids

Semiconductors

Semolina

Serums

Sesame oil

Sesame seeds

Sewage

Shampoo

Sheet cakes

Ship paints

Shortbread

Shower gel

Shredded cheese

Shrimp

Shrimp crackers

Shrimp feed

Shumai

Silica

Silica gel

Silica sand

Silicone

Single-use bags

Sinking pellets

Skimmed milk

Skin care

Skyr

Slag

Slit rolls

Slow sinking pellets

Sludge

Slurry

Slurry

Small molecule drugs

Small volume parenterals

Smoked ham

Smoked salmon

Snack bars

Snack packaging

Snacks

Soap

Soap bars

Soap dispensers

Soda

Sodium bicarbonate

Sodium carbonate

Sodium chloride

Sodium sulfate

Soft Candy

Soft bread

Soft caramels

Soft drink bottles

Soft drink cans

Soft drinks

Softgel capsules

Soil

Solid dosage forms

Solid waste

Solid-state batteries

Solids

Soluble coffee

Solvents

Sorbet

Sorbitol

Sorghum

Soup

Soup cans

Soup liquids

Sour beer

Sour cream

Sour gas

Sourdough bread

Soy flour

Soy milk

Soy protein isolate

Soy protein powder

Soy sauce

Soy yogurt

Soybean meal

Soybean oil

Soybeans

Spaghetti

Sparkling water

Sparkling wine

Specialty chemicals

Spelt bread

Spice blends

Spice pastes

Spices

Spinach

Spirits

Spirulina powder

Split peas

Sponge cake

Sport drinks

Sports nutrition

Spreads

Spring rolls

Starch

Starch derivatives

Stearic acid

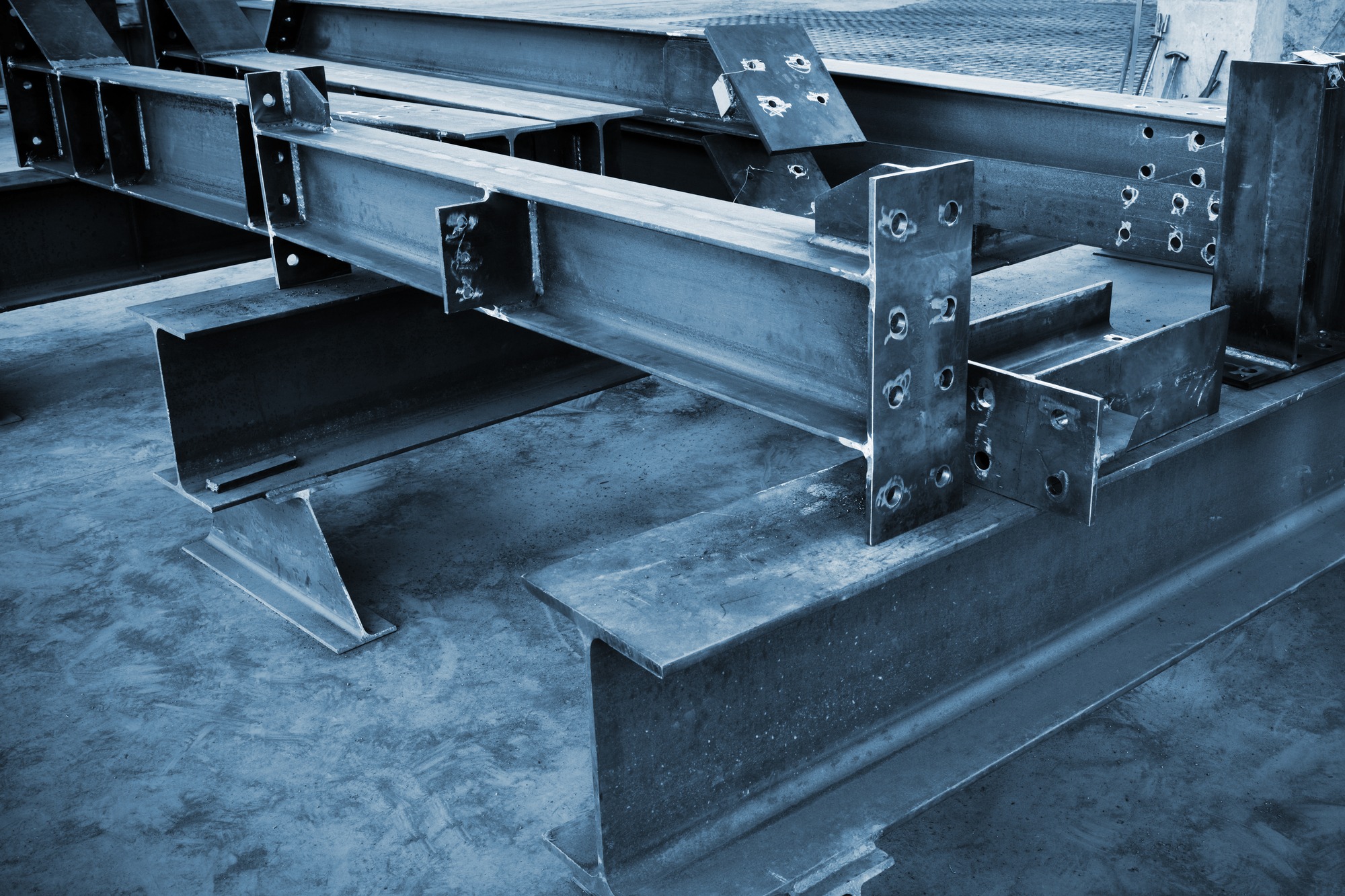

Steel

Steel beams

Steel rods

Steel sheets

Stem cell therapies

Stem cells

Stents

Sterile injectables

Sterile saline solutions

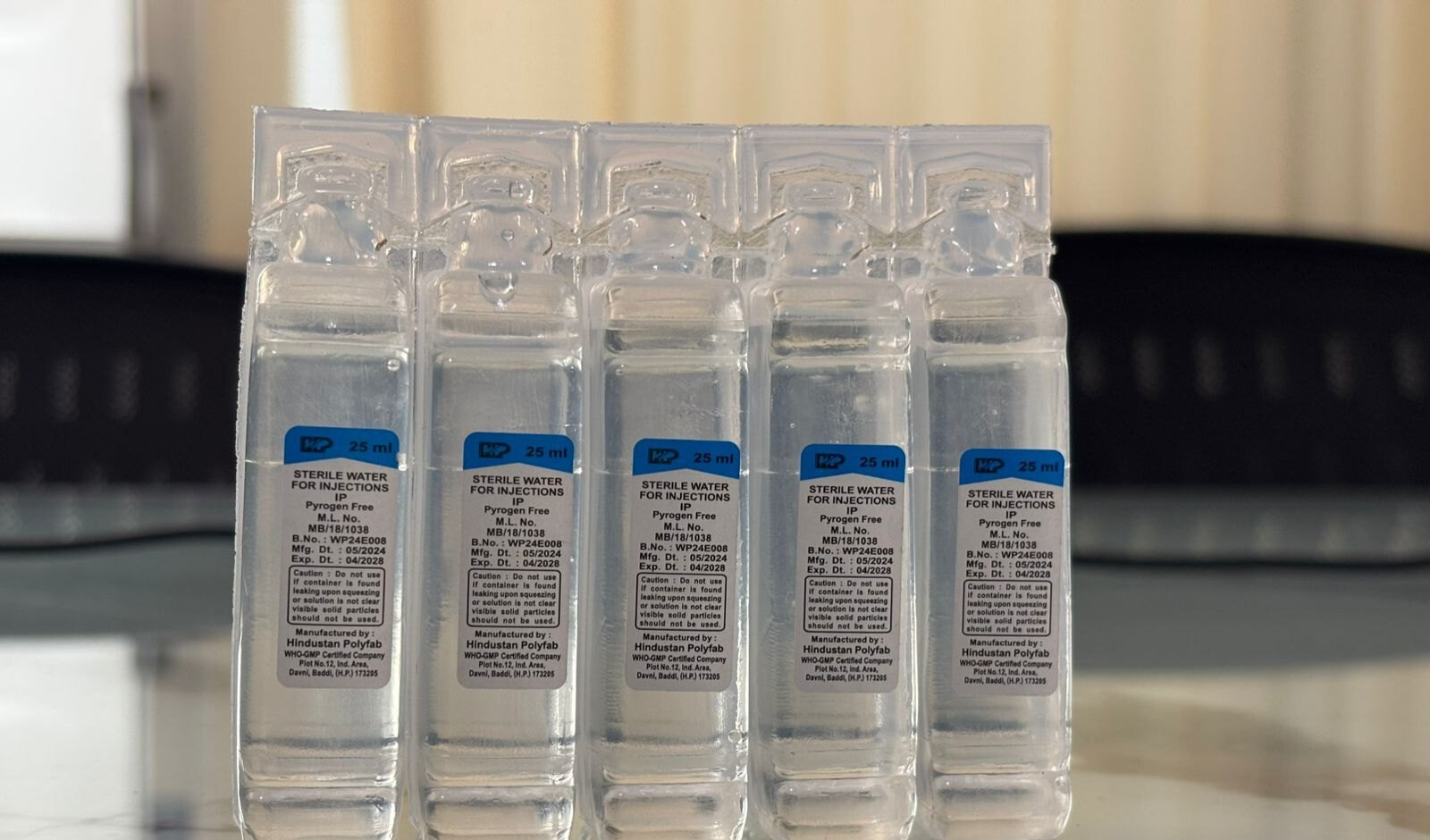

Sterile water for injection

Sterilized milk

Stews

Stick ice-cream

Stock cubes

Stout beer

Straw

Strawberries

Structural adhesives

Sublingual spray

Sugar

Sugar beet seeds

Sugar coated nuts

Sugar crystals

Sugar solutions

Sugar substitutes

Sugar syrup

Sugar-coated sweets

Sugar-coated tablets

Sugar-free gummies

Sulfuric acid

Sulphur

Sun care

Sunflower oil

Sunflower seeds

Sunscreen

Superabsorbents

Supplements

Suppositories

Surface coating

Surfactants

Surgical gloves

Surgical instruments

Surgical masks

Surgical scissors

Surimi

Sushi rice

Suspensions

Sustained-release capsules

Sustained-release tablets

Sweet potato chips

Sweet potato fries

Sweet potatoes

Sweeteners

Sweets

Swiss cheese

Swiss rolls

Synthetic fibers

Synthetic pigments

Synthetic polymers

Synthetic resin

Synthetic rubber

Syringes

Syrup

THC

Tablet coatings

Tablets

Taco shells

Tagliatelle

Tahini

Talc

Talc powder

Tallow

Tangerine juice

Tapenades

Tapioca pearls

Tapioca starch

Tartar sauce

Tarts

Tea

Tea bags

Tea extracts

Tea sachets

Tea tree oil

Technetium-99m

Technetium-99m radiopharmaceuticals

Technical ceramic

Tempeh

Terpenes

Test kits

Textile

Textile dyes

Textile fibers

Textured Vegetable Protein

Thc distillate

Thc gummies

Thc oil

Therapeutic proteins

Thermoformed packs

Thermoplastics

Thickening agents

Thin film coatings

Thinners

Timber

Tin bread

Tinctures

Tins

Tire treads

Tissue boxes

Titanium dioxide

Toast

Tobacco

Toffees

Tofu

Tofu burgers

Toluene

Tomato concentrate

Tomato juice

Tomato paste

Tomato sauce

Tomato seeds

Tomato soup

Tomatoes

Toner

Tonic water

Toothpaste

Topical creams

Toppings

Torrone

Tortellini

Tortilla Chips

Tortillas

Tostadas

Traditional chinese medicine

Trail mix

Transdermal patches

Trays

Treated effluent

Treats

Truffle balls

Truffle cream

Truffles

Tubers

Tubes

Turbine blades

Udon noodles

Uht milk

Uncoated tablets

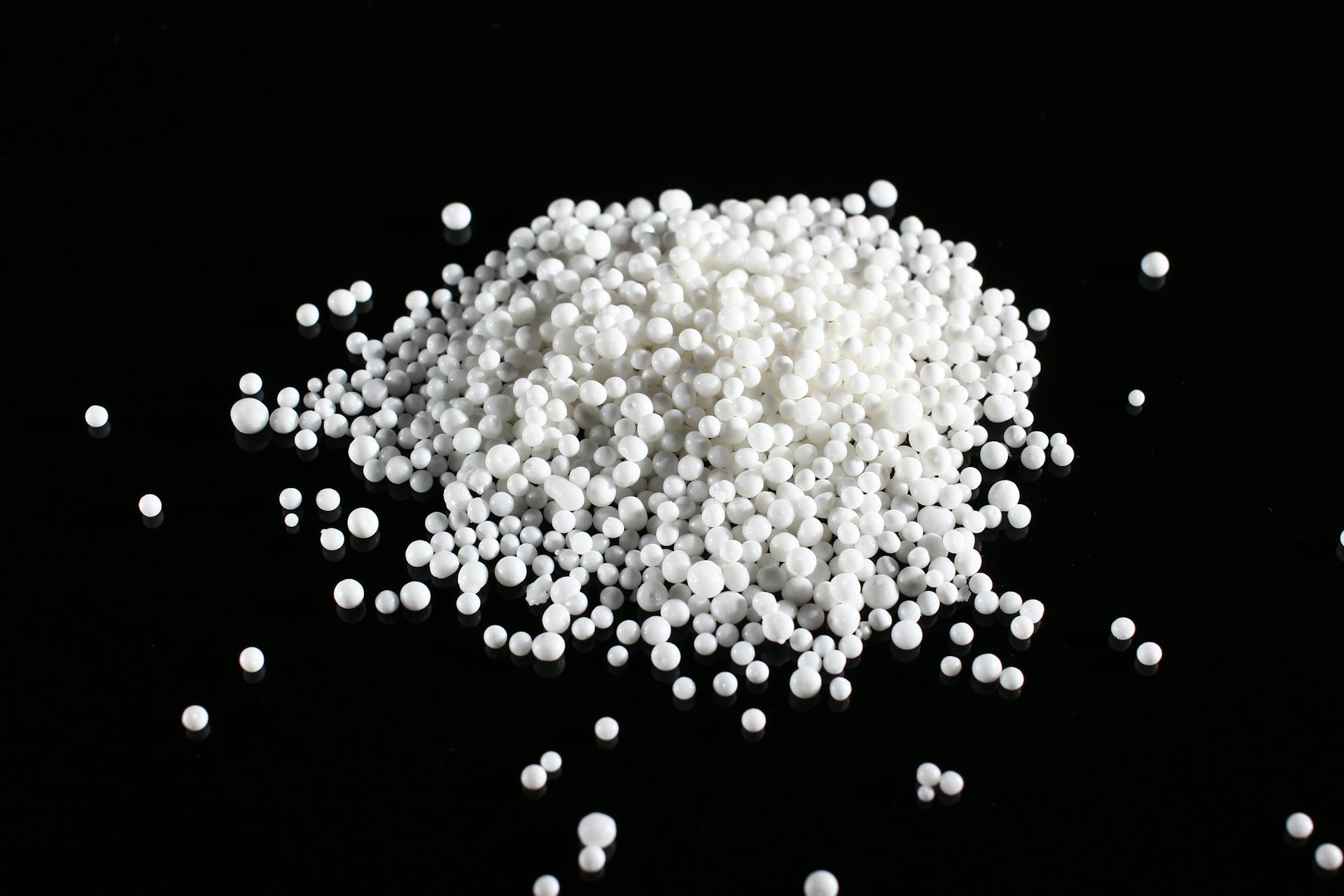

Urea

Uv-curable inks

Vaccine adjuvants

Vaccine vials

Vaccines

Vacuum packaging

Vanilla extract

Varnishes

Vegan burgers

Vegan cheese

Vegan ice cream

Vegan mayonnaise

Vegan meatballs

Vegan nuggets

Vegan sausage

Vegan sausages

Vegetable Puree

Vegetable broth

Vegetable chips

Vegetable concentrates

Vegetable juice

Vegetable oil

Vegetable patties

Vegetable powder

Vegetable proteins

Vegetable seeds

Vegetable soup

Vegetables

Vegetarian sausages

Veggie chips

Vermicelli

Veterinary

Veterinary antibiotics

Veterinary tablets

Veterinary vaccines

Vials

Vinaigrette dressing

Vinegar

Viral vector vaccines

Virgin olive oil

Vitamin C

Vitamin c supplements

Vitamin d supplements

Vitamin d3 supplements

Vitamin e supplements

Vitamin gummies

Vitamin premixes

Vitamin water

Vitamin-enriched beverages

Vitamins

Vodka

Wafer biscuits

Wafer cups

Wafer rolls

Wafer sheets

Wafer sticks

Wafers

Waffles

Wall paint

Walnuts

Waste

Wastewater

Water

Water for injection

Water-based paints

Water-ice lolly

Water-ice push-up

Watermelons

Waterproof mascara

Wax

Wax emulsions

Wet pet food

Wet wipes

Wheat

Wheat beer

Wheat bran

Wheat germ

Wheat gluten

Wheat grains

Wheat seeds

Wheat starch

Whey

Whey protein

Whey protein isolate

Whey protein powder

Whipped butter

Whipped cream

Whiskey

Whisky

White cheese

White chocolate

White rice

White wine

Whitening toothpaste

Whole grain products

Whole milk

Wine

Wine bottles

Wine concentrate

Wipes

Wood

Wood chips

Wood coatings

Wood pellets

Wood pulp

Wood varnish

Wort

Wound care products

Wraps

Xanthan gum

Yeast

Yeast extract

Yoghurt

Yogurt

Yogurt cultures

Yogurt cups

Yogurt drink

Yogurt parfaits

Yogurt powder

Yogurt tubs

Yttrium-90 microspheres

Zeolite catalysts

Zinc concentrate

Zinfandel

Zirconia dental crowns

All your data is kept confidential