Making Nougat

Find innovative production technology for making nougat and connect directly with world-leading specialists

Nougat is a delicious confection that contains lots of nuts and dried fruits. The word “nougat” itself derives from an old Latin word for nuts. In addition to nuts, the white variety of nougat contains egg whites, honey, and sugar. Similar ingredients make brown nougat variations, except caramelized sugar replaces egg whites as the base ingredient. Depending on your intended scale of production, there are quite a few nougat making equipment you should consider getting.

Select your nougat process

Tell us about your production challenge

What nougat making equipment do you need?

A lot of mixing and beating go into the making of nougat, and you need to homogenize the various ingredients for the sweet to turn out well. For starters, make a sugar syrup combining sugar, honey, and water. To get a smooth, even mixture for industrial scale production of nougats, a heavy-duty mixer can help.

In any case, these types of mixers are the more convenient option. An electric mixer may be better for whipping the egg whites. A heavy-duty stand mixer will also reveal its worth when the time to combine the egg mixture with the sugar syrup comes. If you decide to add nuts to your nougat, the most common type is to process almonds with the nougat. Finally, a nougat cutting machine gets the sweets ready for the market.

It’s important to get the temperature just right when cooking the syrup. Ideally, the cooking temperature should not exceed 148 °C (300 °F) . Use a candy thermometer and an industrial cooker for medium to large scale production of nougats.

How to make sure that your nougat doesn’t stick

Apart from determining the consistency of nougat, temperature also plays an important role in preventing it from getting sticky. If you’re looking to make soft nougat, you may cook the sugar syrup with temperatures approaching 118 °C (245 °F). For hard nougat, let the temperature climb up to 148 °C (300 °F) while cooking the sugar syrup.

Remember that an essential nougat making equipment at this stage is your candy thermometer. An industrial cooker will also maximize productivity and ensure that the right temperature gets used. Finally, wrap individual nougat pieces in wax paper to ensure that they don’t stick together.

Health and environmental impacts of nougat production

While nougat does not contain traces of gluten, it may still trigger allergic reactions in some consumers due to its (fairly) high content of allergens such as eggs and nuts. These reactions can be fatal, which is why it’s important for you to clearly mention these items in your list of ingredients. By extension, nougat is also not an option for vegans or vegetarians, since it contains eggs and honey. In a much broader sense, because it involves animal byproducts, which contributes to pollution and climate change, nougat production does have a negative impact on the environment.

Processing steps involved in nougat making

Which nougat technology do you need?

Chocolate enrobing system for industrial production

Effortlessly transition between chocolate types in your high-speed pr...

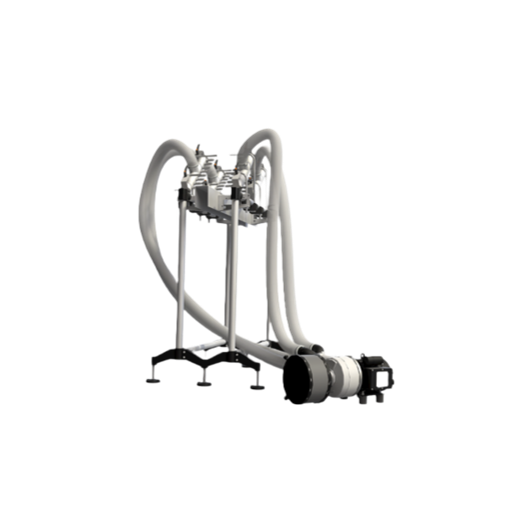

Whipping agent solution station for egg solutions

Optimize your production of delicate egg-based foams with a versatile s...

Continuous cooking unit with vacuum for candy production

Achieve precise caramelization and cooking with enhanced flavor ...

Fat melting tank for confectionery production

Melt solid fat blocks efficiently to streamline your caramel, nougat, and ch...

Invert sugar and glucose storage tank

Optimize your sweet and confectionery production by efficiently storing and resting g...

Pressurized buffer tank for aerated products storage

Ensure consistent aeration and product quality with this pressurized...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Chocolate storage tank

Optimize your chocolate production with seamless storage solutions that ensure consistent quality and ...

Conching solution for chocolate processing

Achieve optimal chocolate texture and flavor by ensuring efficient conching, cr...

Continuous chocolate mill

Enhance the texture and quality of your chocolate products with this high-speed milling solution, ...

Industrial fat melting tank for bakery and chocolate production

Efficiently melt solid fats to precise temperatures with...

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Chocolate moulding press for coco mass

Enhance your production line with precise chocolate moulding capabilities, shaping e...

Chocolate cooling tunnel

Enhance your confectionery production with efficient cooling and precise crystallization, critical f...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

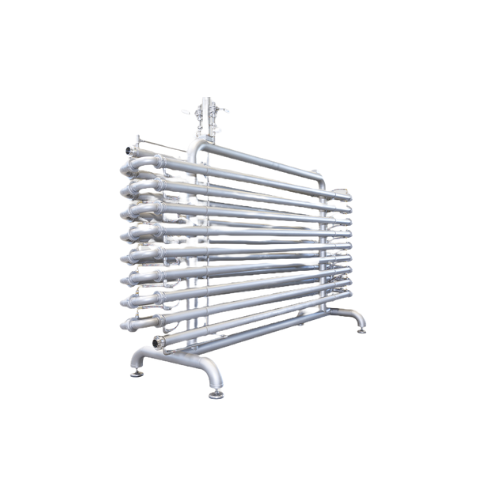

Cooling system for heat-treated products

Efficiently reduce temperatures of high-heat products to protect quality and textu...

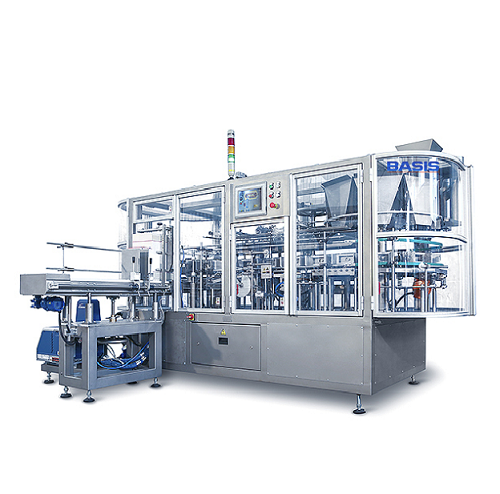

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

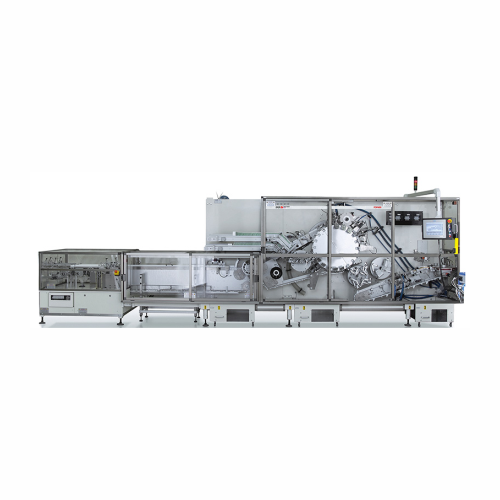

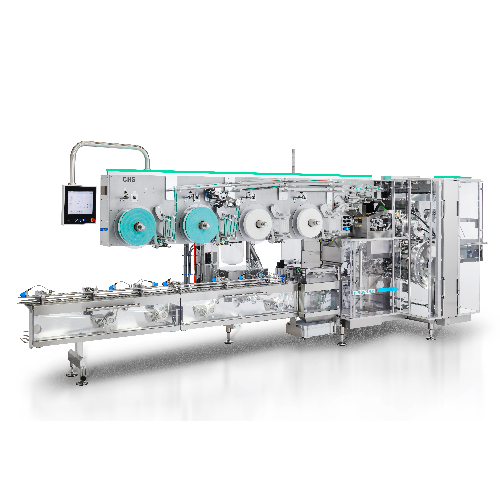

Horizontal cartoning solution for pharmaceutical packaging

Streamline your confectionery packaging with high-speed, cont...

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

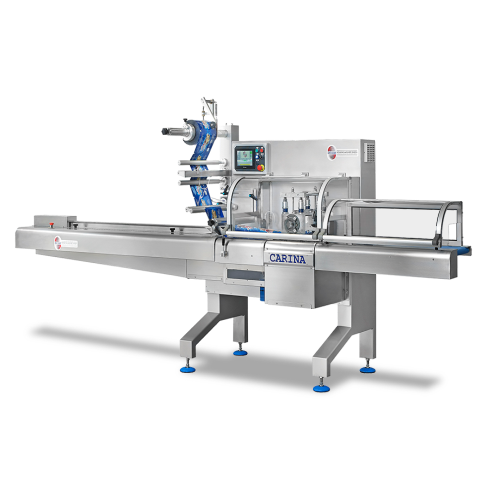

Flow wrapper for high-speed confectionery packaging

Achieve gentle, high-speed packaging for delicate confectionery items...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Batch cooker for confectionery production

Achieve consistent confectionery texture and flavor with a flexible cooking solu...

Chocolate refining five-roll refiner

Achieve optimal chocolate texture with high-efficiency refining, reducing energy usage...

Pre-cooking and final cooking for candy production

Optimize your candy production with a versatile cooker designed to han...

Continuous production fondant beater

Achieve consistent fondant quality by gently controlling crystallization and temperatu...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Batch-wise cooking and aerating system for aerated candies

When producing aerated candies, achieving uniform texture and...

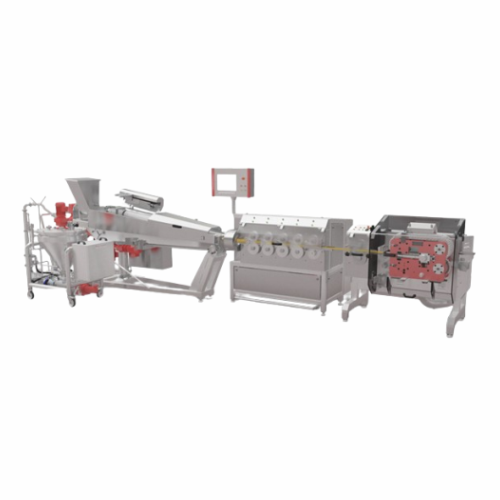

Hard candy forming line for manufacturing

Experience seamless candy production with advanced forming technology, ensuring ...

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Compact biscuit depositor for small bakeries

For artisanal producers seeking precision and versatility, this compact equip...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Cooker for nougat and hard mixtures

Optimize the production of high-density mixtures like nougat and meat sauces with this ...

Planetary cooker for medium-high density mixtures

Achieve smooth, consistent textures with a planetary cooker designed fo...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Static cooler for jelly and foam manufacturing

Ensure the integrity of your confectionery with a cooling system designed f...

Forming line for croquant, hard candy, and chewy candies

Optimize your candy production with precision forming and emboss...

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

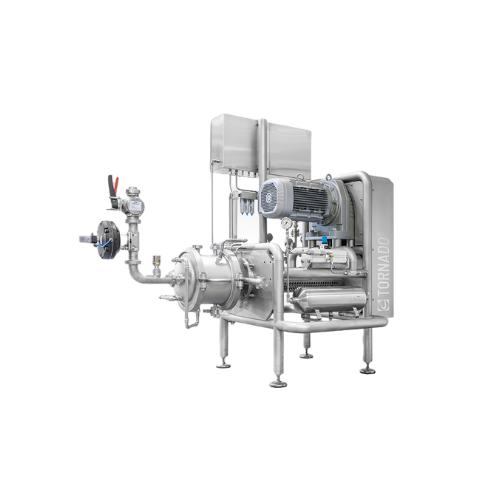

Aerator for candy masses

Enhance your candy production with precise and efficient aeration, transforming textures and creatin...

Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed ...

Aeration system for sugar masses

Optimize your production of aerated confectioneries with a two-step aeration system designe...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

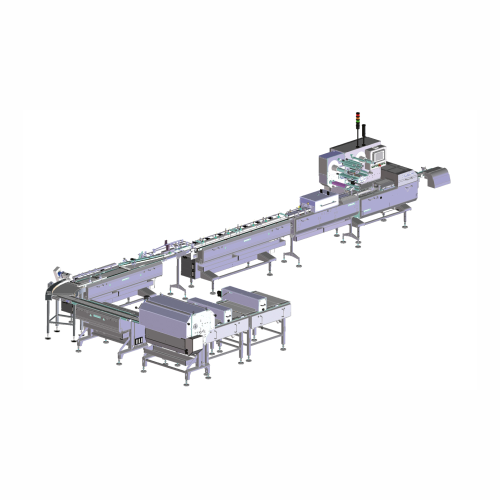

Cut and flow pack system for cylindrical and rectangular pieces

Enhance your confectionery production with a high-speed ...

Double sigma kneader for viscous product mixing

Optimize the mixing and kneading of high-viscosity products with our doubl...

Laboratory batch chocolate processing unit

Achieve precision in developing chocolate recipes with a compact 3-in-1 unit th...

Transversal cutting for confectionery production

Achieve precise and customizable cuts in high-speed confectionery and bak...

One-shot chocolate depositing system

Enhance your confectionery line with precise, high-speed depositing technology designe...

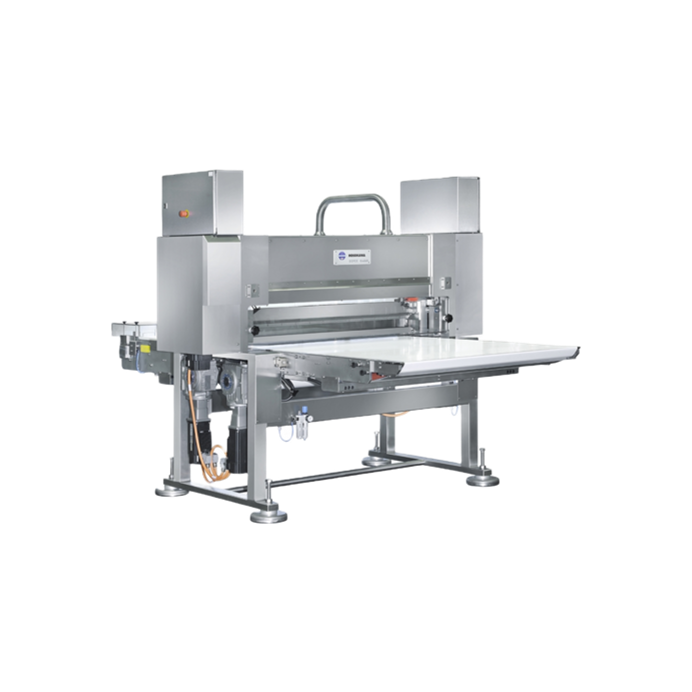

Dough sheeter for rotary-cut biscuits

Achieve consistently smooth dough bands essential for high-quality biscuits and confe...

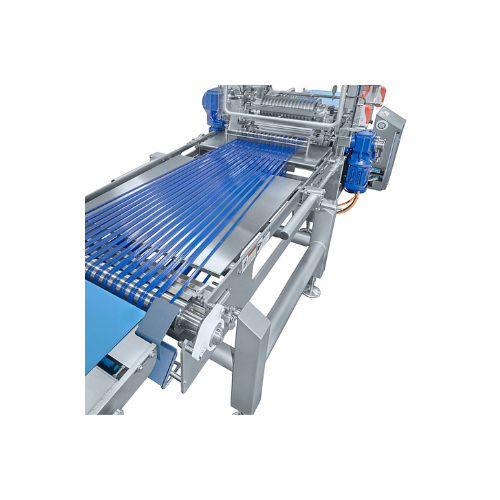

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Loose mould line for chocolate production

Streamline your chocolate production with a high-throughput line that seamlessly...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

Advanced chocolate tempering system

Achieve flawless chocolate and confectionery products with precision tempering, ensurin...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

High-speed dough depositor and extruder

Streamline your high-speed dough processing with precise dosing and gentle handling...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Robotic pick and place system for cookies

Streamline your bakery production with a flexible robotic system that seamlessly...

Product spreader for cooling conveyor

Optimize the cooling process of cream-filled products by gently spreading sandwiches ...

Automatic hamburger packaging solution

Streamline your hamburger production with a fully automated packaging system that en...

Automated packaging and case packing for snack bars

Optimize your snack bar production line with this high-speed solution...

High-speed wrapping system for chocolate bars

Ensure quick and precise packaging for chocolate bars with a high-speed syst...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Static mixer for homogeneous blending of ingredients in bakery and confectionary

Achieve consistent flavor and color i...

Batch cooker for pectin jelly and caramel production

Achieve precise temperature control and uniform cooking with steam-h...

Thermosyphon cooker for marshmallow and confectionery production

Achieve precise and consistent cooking of confectionery...

Compact continuous aerator for bakery production

Optimize your bakery production with a compact aerator that delivers prec...

Ultrasonic food cutting system

Effortlessly achieve precise, clean slices on sticky and fragile foods with ultrasonic techno...

Nougat tempering system for consistent viscosity

Achieve consistent quality and precision in praline centers and nougat ba...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Refiner for spreadable cream and chocolate

Achieve optimal texture and consistency for your spreadable creams and chocolat...

High precision dosing system for liquid media

Producing confectionery and bakery products implies mixing large amounts of ...

Large capacity confectionary mixer

The foaming process determines the quality of various confectionery products, from marsh...

Compact & pumpable food media mixer

The process of mixing ingredients for confectionery products like marshmallows and meri...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Mixer for aeration of confectionery and bakery products

Aerated products can be difficult to mix thoroughly without reduc...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Automatic pastry dough sheeter

Industrial dough sheeters turn raw dough into sheets that match recipe thickness. This includ...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

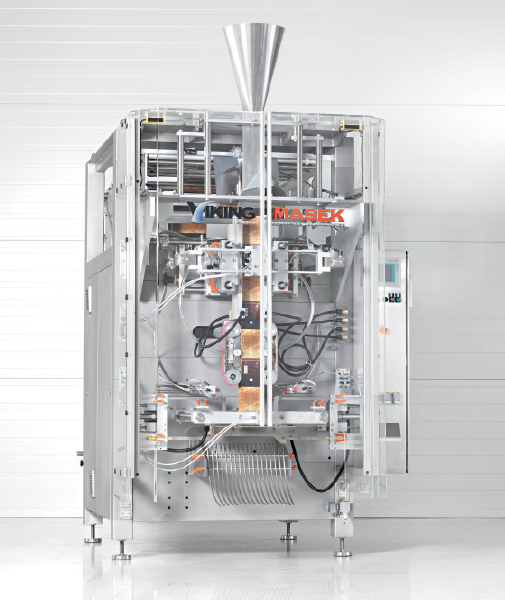

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Whipping machine for soft candy

Prepare your ingredients for any whipped or aerated product component. This is a pressurized...