Oat Milk Manufacturing Equipment

Find innovative production technology for making oat milk and connect directly with world-leading specialists

Although invented in the 1990s by Rickard Öste, oat milk has only recently grown to be one of the most popular milk alternatives in coffee shops, and it owes it to its smooth mouthfeel and creamy texture. Extracted the plant materials from oats with water, this non-dairy milk is high in fibers, low in saturated fats, and eco-friendly. Oat milk processing equipment helps prepare raw materials, starting with harvest over kilning and making them into flakes or flour, and mixing the prepared materials with water and enzymes.

Tell us about your production challenge

The first steps in oat milk production

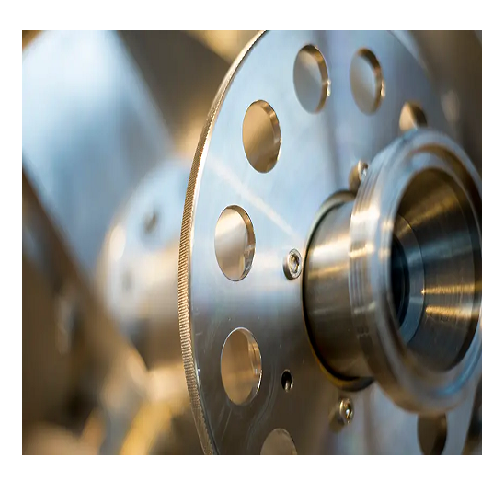

Before starting with the production of oat milk, the crucial step is to prepare the raw material – oats. Once harvested, oats are passed under a magnetic separator, as well as a series of rotating or oscillating screens, to remove foreign objects. Oats are indigestible before processing. To change that, oats must be removed from their hard husks. This process, called dehulling, happens in modern mills – oat milk processing equipment where oats fall into the center of a rotating disc and travel through a series of impact rings on the dehuller’s wall results in the separation.

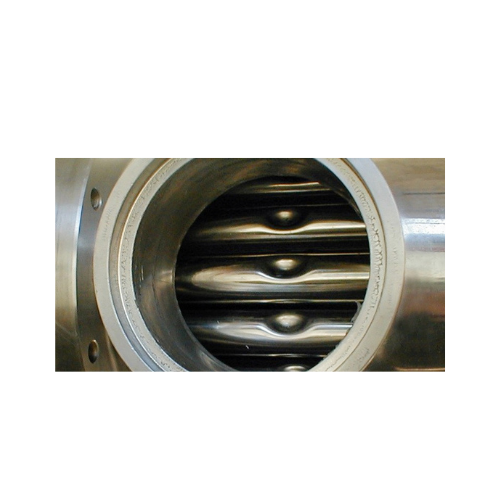

In order to control and stabilize flavors, as well as to improve food safety, oats must undergo treatments of steaming and kilning (applying heat for an extended period), which takes place in long cylinders with steam and air being injected into the columns. Finally, to make oat flakes, the grains are flattened with the help of two rotating rollers. Some manufacturers make oat milk from milk flour, which is achieved by grinding oats with a pin or hammer mill.

From oat milk processing equipment to the to-oat-lly delicious beverage

Making oat milk is a quite simple formula, mixing rolled oats with water, a ratio of 1:2.7. Soaking them in warm water causes the breakage of the hull, which results in a slurry. The critical step in the production of oat milk, especially when it comes to the beverage’s flavor, is the process of adding enzymes to the slurry. For instance, in a production process called hydrolysis, α-amylase (77.78 mg per 1 kg of oats) is added to break down the starch into simpler sugars which is the answer to why oat milk tastes sweeter than plain oats.

Furthermore, the high percentage of starch in oats requires adding enzymes to keep the texture of the milk smooth and creamy. In addition to enzymes, oil can also help the smooth texture of the drink. Other ingredients, such as salt or vitamins, can be added to enhance the taste and health benefits. After achieving the desired properties, it is crucial to sterilize the product properly – either with UHT or pasteurization – and mix it with a homogenizer in a high-pressure and high-speed blender to ensure the final velvety texture with no oat chunks.

Oat-standing sustainability metrics

Not only is the oat milk industry one of the fastest-growing plant-based milk industries, but it is also leading in the possible sustainability metrics compared to its alternatives. Firstly, compared to dairy milk, oat milk production uses 60% less energy, 80% less land, and emits 80% fewer gases. The oat milk manufacturing process emits no methane and only 0.18 kilograms of carbon dioxide for a 200-milliliter glass. Furthermore, oats require the least amount of water to grow compared to other plants.

Namely, 1 liter of oat milk requires 48 liters of water, which is significantly less than dairy and other plant-based kinds of milk, especially almond which requires 8 times more water. Finally, oats can be cultivated in most parts of the world, benefiting the soil and agrobiodiversity.

Oat milk… or not?: Rules and Labels

Due to a few-year-old rule, plant-based alternatives to dairy products must not be labeled as “milk”, “yogurt” or similar as it could potentially be misleading for customers and understood as false advertising. However, each EU language has terminology exceptions, which means different labels are allowed in different countries. While this law was passed in the European Union as early as 2017, it has yet to be decided on a federal level in the United States. There were talks that such rules would soon be applied there too; however FDA still has not passed formal regulations. Therefore, while you might find “oat milk” on American shelves, in Europe you must look for “oat drink” instead. The bottom line is: it is the same product.

Processing steps involved in oat milk making

Which oat milk technology do you need?

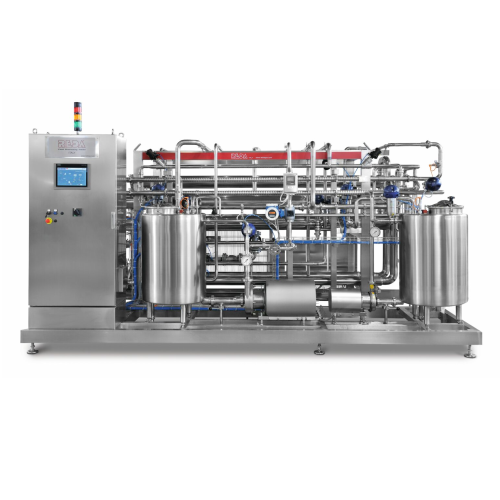

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reduc...

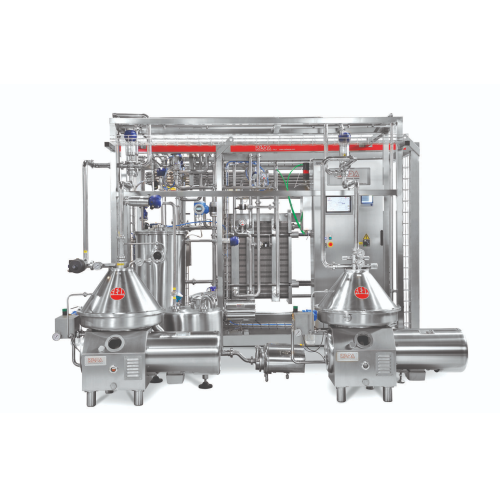

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Milk standardization system

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

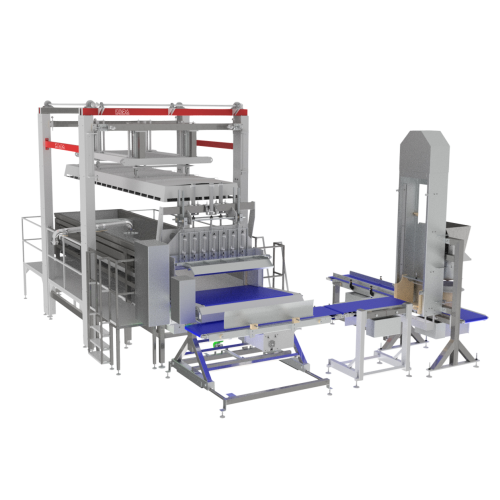

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

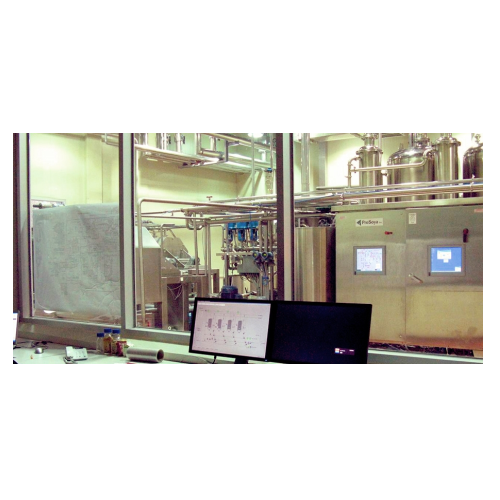

Oat milk processing plant

Transform whole oats into creamy, nutritious oat milk with precision, leveraging advanced continuo...

High-performance decanter centrifuge for dewatering

Achieve efficient and reliable dewatering by integrating a decanter c...

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Aseptic storage tanks for high efficiency applications

Ensure consistent aseptic storage and efficient handling of variou...

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

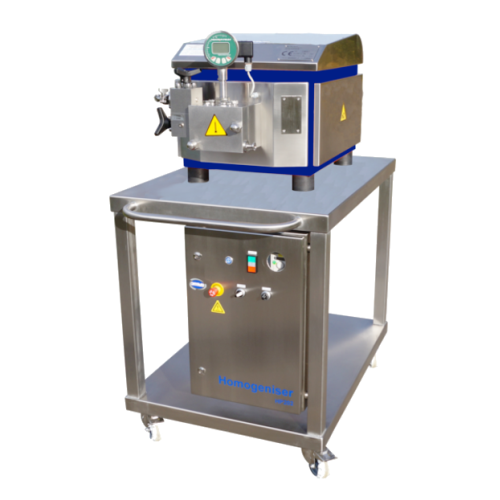

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Carbonation and can seaming solution for beverages

Optimize your beverage production with a seamless integration that sim...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

Juice product deaerator

Ensure high-quality filling without foam formation through efficient deaeration, perfect for manufact...

Uht system for milk products

Achieve optimal product safety and quality for dairy and plant-based beverages with precise UHT...

Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchan...

Crate washer for beverage manufacturers

Ensure thorough cleaning of beverage crates with an advanced washing system featuri...

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

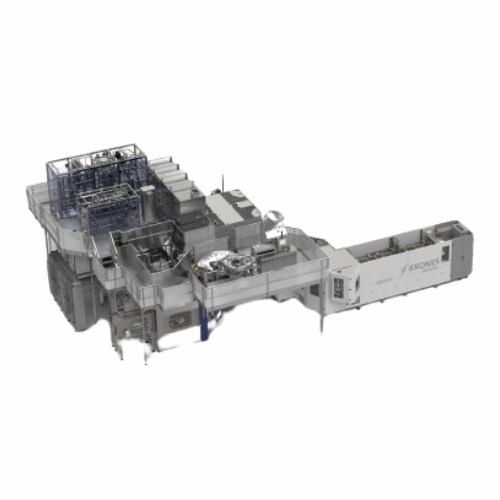

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

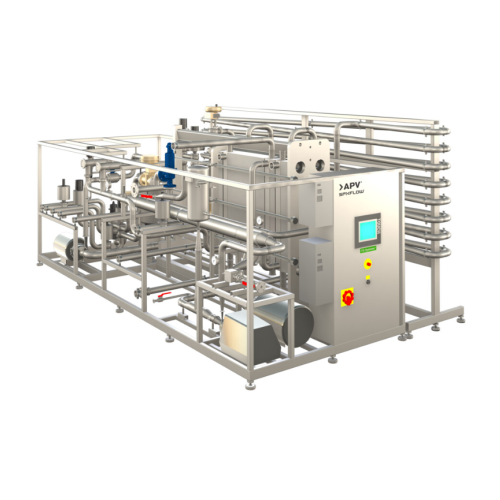

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

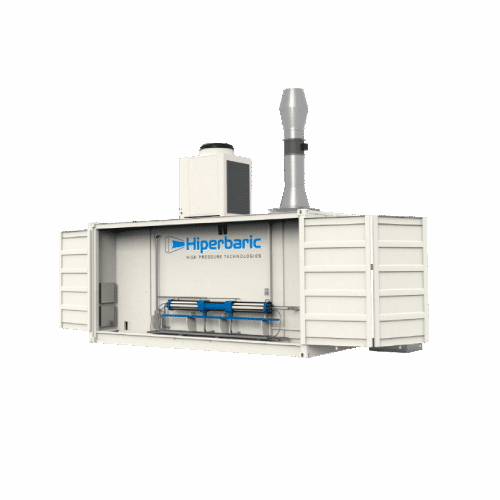

Hydrogen compression solution for refueling stations

For operations demanding efficient hydrogen compression, this modula...

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

High-capacity manual mixer for industrial applications

Optimize your mixing process with a highly efficient, manually ope...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Decanter centrifuge for food industry separation

Achieve precise separation and ensure optimum product quality with our ad...

Plant-based protein extraction technology

Achieve optimal purity in plant-based milk, yogurt, and cheese production with c...

Rising film evaporator for concentration of viscous liquids

Effortlessly concentrate low-to-medium fouling and highly vi...

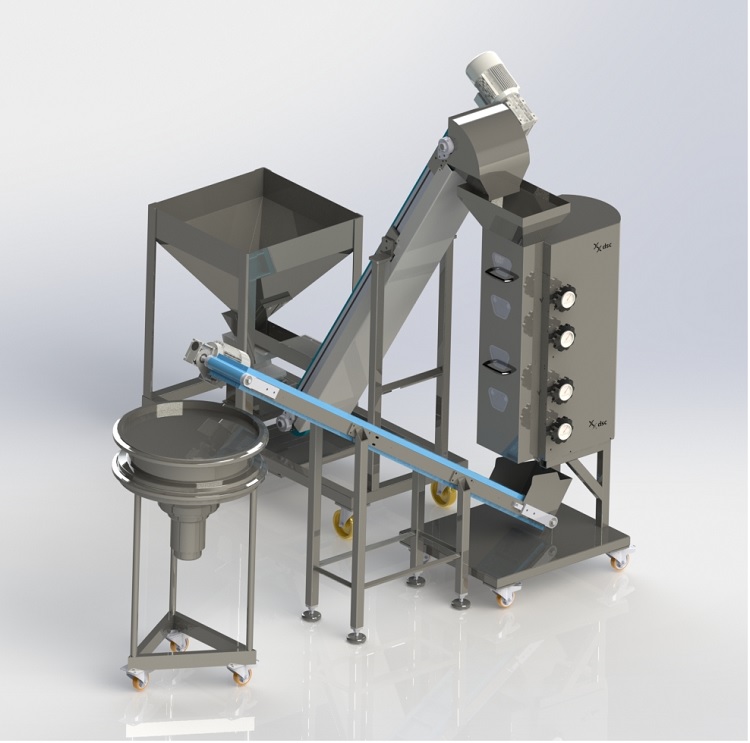

Ingredient management system for beverage production

Efficiently manage a diverse range of solid and liquid ingredients t...

Balance tank for pasteurization systems

Ensure consistent product quality with precise liquid holding and heating capabilit...

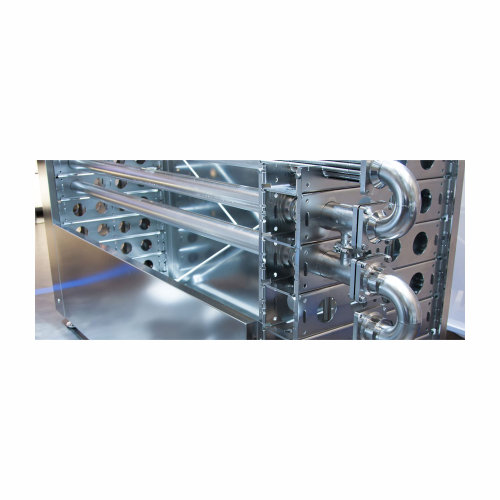

Tube-in-shell heat exchanger for low viscosity products

Enhance your beverage and food processing efficiency with a cutti...

Heat exchanger for dairy and beverage applications

Optimize your liquid product thermal processing by directly regenerati...

Deaerator for juices and dairy processing

Ensure the quality and shelf-life of liquid foods by effectively removing entrap...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Hygienic filling system for short shelf life milk

Optimize your cold-chain distribution with a filling system engineered ...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

Reverse osmosis beer dealcoholization technology

Achieve precise alcohol removal from beer while preserving flavor integri...

Aseptic filling system for sensitive beverages

Optimize your beverage production with an aseptic filling system that ensur...

Aseptic filling system for milk-based drinks

Ensure sterile bottling of milk-based and sensitive beverages with this syste...

Decanter for plant-based beverage extraction

Ensure high-yield extraction and optimal purity from plant-based ingredients ...

Fermentation and storage solutions for breweries

Enhance your brewing process with robust fermentation and storage tanks d...

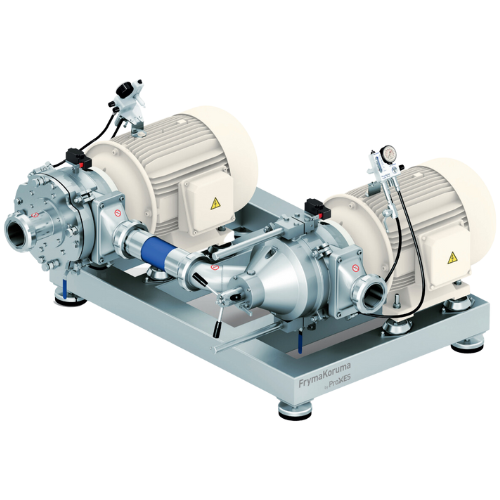

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

High performance industrial pasteurizers

Enhance your liquid processing with fully autonomous pasteurizers that ensure opti...

Direct Uht treatment for liquid foods

Optimize aseptic production with advanced UHT technology to preserve nutritional valu...

Milk skimming separator

Achieve superior separation efficiency and reduced energy consumption in dairy processing with seamle...

Plate heat exchanger for food products

Achieve precise temperature control in your processing line with this plate heat exc...

Double decanter for plant-based beverages

Optimize your plant-based beverage production by achieving high protein yield an...

Industrial grinder for plant-based beverages production

Achieve optimal particle size for seamless integration with your ...

Hydrolysation tank for plant-based beverage production

Ensure optimal hydrolysis conditions for plant-based beverages wit...

Continuous soya extraction unit

Enhance your plant-based beverage production with a unit that maximizes protein yield and re...

Thermal deactivation unit for plant-based base creation

Efficiently deactivate enzymes in plant-based beverages with prec...

High-precision decanter for plant-based beverages

Enhance your plant-based beverage production with a decanter engineered...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

In-line blender for beverage production

Enhance beverage production with a versatile solution that offers precise blending,...

Water treatment system for aseptic blending in Jnsd production

Ensure a reliable aseptic blending process for your bever...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

High capacity milk separator with polynode technology

Achieve unprecedented milk skimming efficiency and reduced environm...

Clarifiers for dairy and plant-based beverages

Ensure optimal product purity and versatility by efficiently removing impur...

High shear mixer for emulsification and powder dissolving

Achieve seamless mixing and emulsification for high and low vi...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Mid-range capacity homogenizer for dairy and beverage

For operations demanding consistent product quality and high uptime...

Ingredient dissolver for small batches

Efficiently dissolve water-soluble powders and concentrates up to 200 cP with precis...

Double decanter for plant-based beverage extraction

Maximize protein yield and enhance extraction efficiency in your plan...

Industrial grinder for plant-based beverages

Ensure optimal particle size for hydrolysis in plant-based beverage productio...

Hydrolysation tank for plant-based beverages

Optimize your plant-based beverage production with a hydrolysation tank that ...

Continuous soya protein extraction system

Optimize plant-based milk yield and reduce waste with a versatile extraction sys...

Thermal deactivation unit for plant-based beverages

Enhance your plant-based beverage production by effectively reducing ...

Coiled heat exchanger for viscous and particulate products

Optimize heat treatment of viscous and particulate foods with...

Plant-based beverage extraction system

Maximize yield and product quality in plant-based and dairy beverages with high-effi...

Dual-line filler for tetra top packages

Maximize your production flexibility with a high-speed, dual-line filling solution ...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Ultrafiltration for dairy and plant-based protein concentration

Optimize your production capacity and increase yield wit...

Medium torque top entering mixer for high fluid forces

Equip your production line with a robust mixer that transforms cha...

Soymilk processing plant

Enhance your plant-based production with our tailored soymilk processing plants, designed to efficie...

Milk pasteurizer system

Ensure your dairy and plant-based beverages achieve optimal safety and quality with precise temperatu...

Multipurpose ultra high temperature (uht) pilot plants

Optimize liquid food production with a versatile pilot unit design...

Plate juice pasteurizer system

Ensure optimal pasteurization with precise temperature control and high heat recovery, reduci...

Hygienic tanks for various processing needs

Achieve optimal processing and storage with customizable hygienic tanks, desig...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Aseptic storage tank for aseptic products

Ensure uninterrupted aseptic product storage with this advanced tank system, des...

Chilled water milk can cooler for small farms

Ensure milk quality and safety with rapid cooling from 35°C to 8°C in under ...

Energy efficient grinder for plant-based milk

Buying pre-processed materials, such as flour, and handling and dispersing t...

Fluidized bed drier/cooler for grains

Processed grains absorb moisture throughout the production line. Lowering that water ...

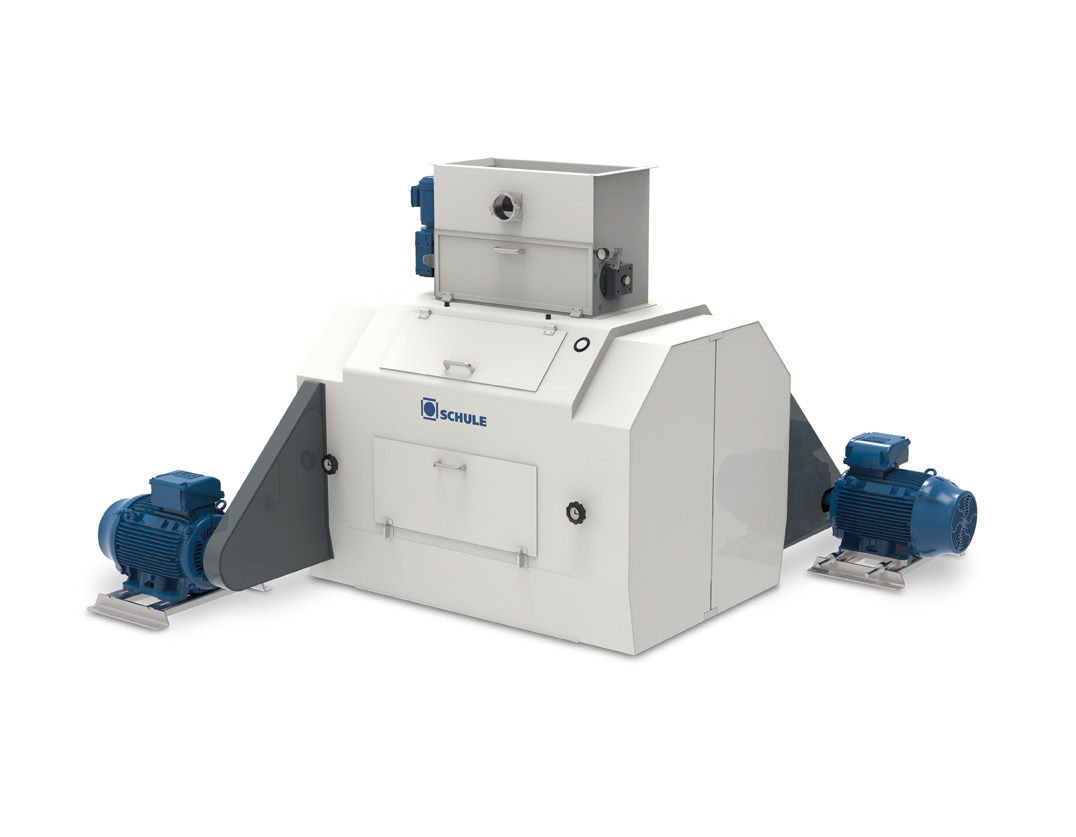

Flaking roller mill for oats

Consistent flake size is one of the main contributors to processed oat quality. But producing a...

Drum groat cutter for baby oats

Used as food thickeners and toppings, baby oat flakes must adhere to a consistent size. But ...

Color sorting machine for grains

Detecting impurities in processed grain becomes more challenging as the output increases. B...

Kiln and cooler for oats and fatty cereals

Grains such as oats and parboiled rice have a high fat content and must be stab...

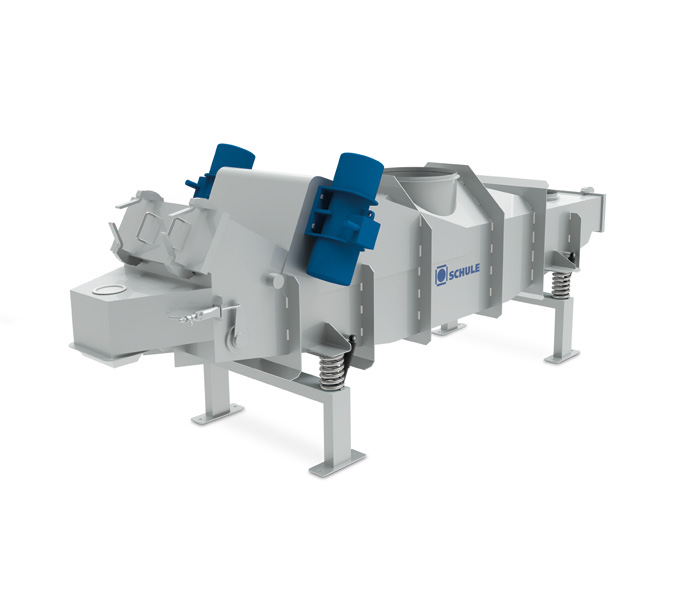

Table separator for grains

Imprecise sorting of oats and other grains brings down the yield. To avoid wastage, hulled and un...

Gentle polisher for oats

The fine fluff covering oat grains complicates the cleaning of processing equipment. The hair-like f...

Impact huller for oats

Hulling technology risks breaking oat grains if the system is not adjustable to fragile materials. Agg...

Gentle de-awner for grains

Husking is a fundamental step in grain processing, but it lowers the yield if it’s not carefully ...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Sugar dissolving system for beverages

In the beverage industry, production of sweet drinks requires the addition of sugar s...

Pasteurizer machine for sensitive beverages

When you want to expand your beverage production line, following a new global ...

Water treatment for beverage preparation

Water is one of the main ingredients in producing juices and other beverages. If i...

Continuous sterilizer for milk beverages

An important goal of heat processing in the manufacturing of milk beverages is to ...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

Metal detector for bottles

For metal contamination detection in finished products that are bottled, traditional solutions re...

Air knife dryer for bottles

When filling glass bottles during beverage production, the cleaning and filling processes often ...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Vibrating sieve for liquid solid separation

Many industrial processes require the efficient separation of solids from a sl...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

High-precision X-ray fill level controller

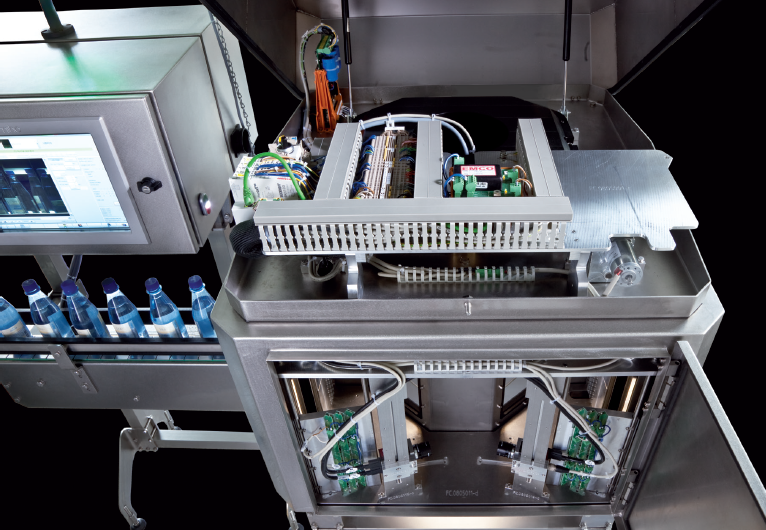

High-speed, high precision X-ray system to inspect containers that are difficul...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

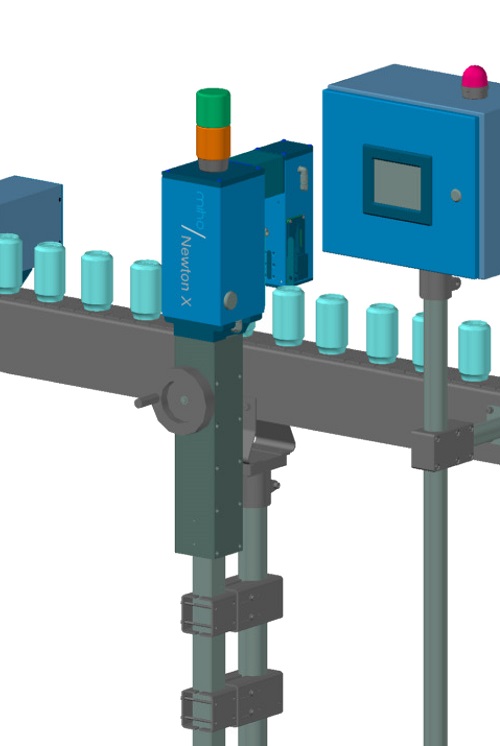

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...