Making Body Lotion

Find innovative production technology for making body lotion and connect directly with world-leading specialists

Every minute, your skin loses between 30,000 and 40,000 dead skin cells. This means losing millions of cells every day, which makes your skin look less glowing. Being a moisturizing agent, body lotion has the power to hydrate your skin and give the glow back to it. Production involves water and oil phases, which you then mix with an emulsifier and blend until homogeneous. Preservatives are essential for any solution containing water for the prevention of microbial growth.

Technology picks for producing bodylotion

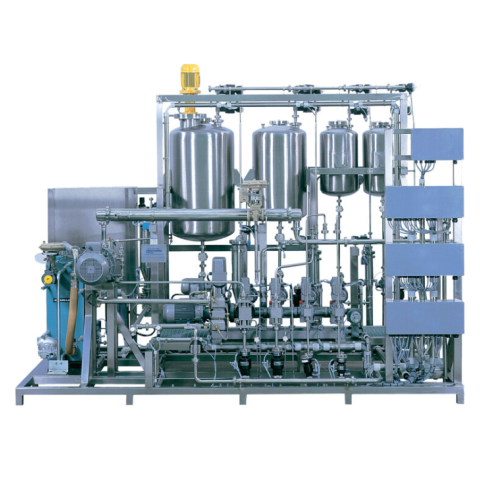

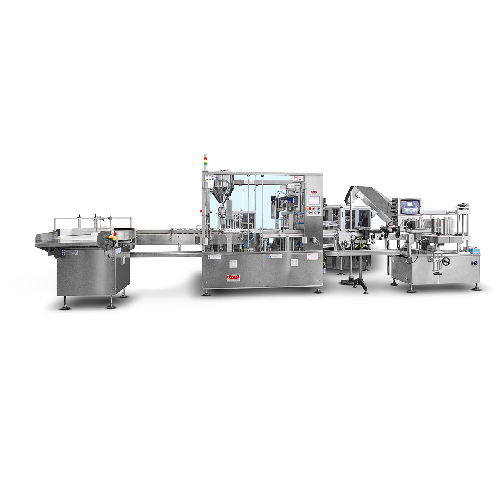

Automated body lotion blending system

Streamline your personal care product manufacturing with a seamless blending and emul...

Emulsifier for cosmetic creams

The process of making cream and lotion involves mixing of water phase and oil phase to create...

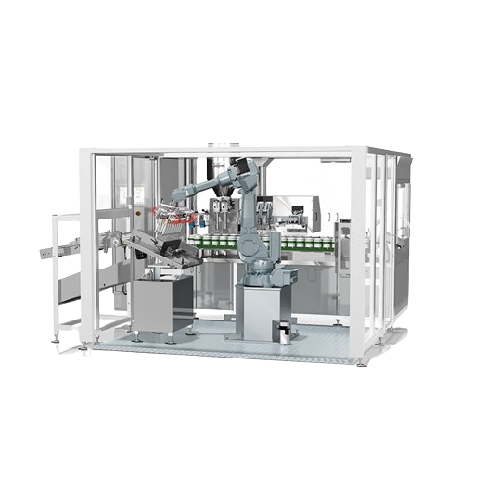

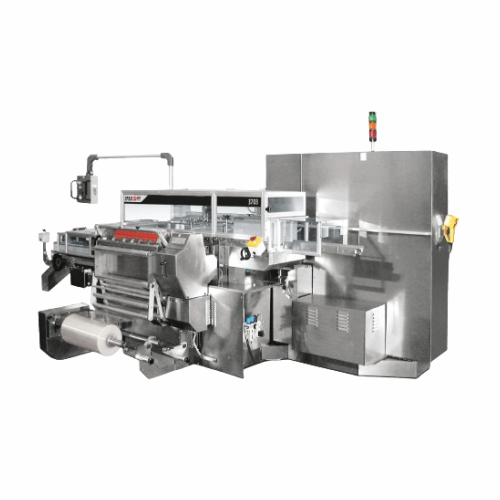

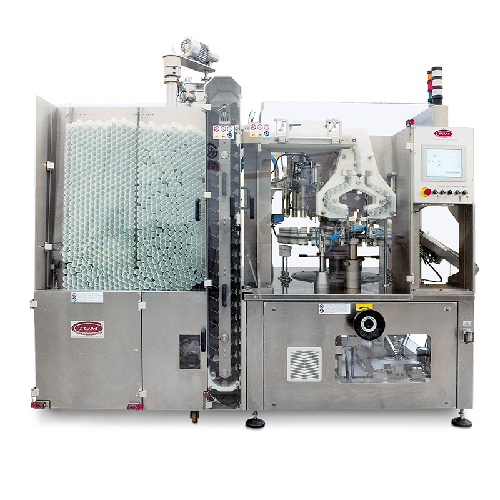

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

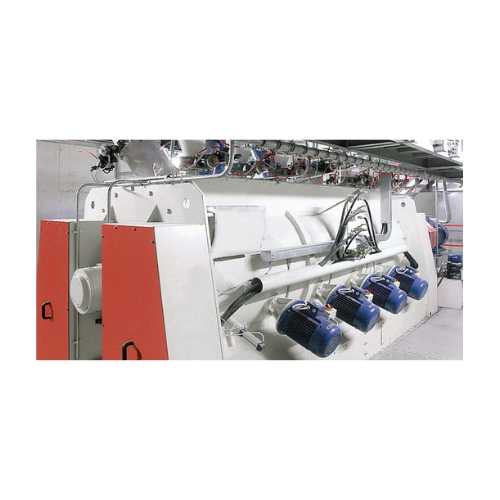

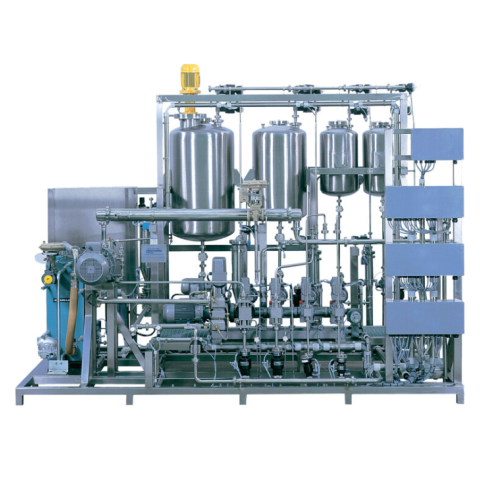

Inline system for personal care product production

Optimize your personal care production with precise mixing, heating, a...

Stories about body lotion

Select your body lotion process

Tell us about your production challenge

Transforming your production process with body lotion making equipment

In the first stage of body lotion production, you prepare and mix the oil and water-soluble ingredients separately. You start with your dry ingredients, such as cetyl alcohol in the form of flakes or powder, sometimes blended while dry. You will usually add emulsifiers and stabilizers to the water phase, while powders and flakes may mix better with your chosen oil. Some ingredients mix better when heated so that you might consider body lotion making equipment such as kneaders, dispersers, and homogenizers fitted with temperature control capabilities.

Even so, you should take care to add active ingredients after steps involving elevated temperatures to avoid degradation. Once the two phases are thoroughly mixed, you bring them together in a homogenizer machine to reduce particle size and develop an evenly distributed mixture. You will then mix this final combination until the body lotion preparation is entirely uniform.

How can you avoid the formation of agglomerates in your mixtures?

When dispersing powders into liquids in the body lotion making process, agglomerates might form – this can affect the texture and performance of the final product. Agglomerates can certainly be filtered out at the end of the process, but the best way to ensure the quality of the final product is to avoid their formation. The problem is that they can resist breakdown by conventional agitators. These clumps of ingredients will form primarily on the surfaces of your body lotion making equipment where conventional agitators are unable to exert the necessary shearing forces for reconstitution.

Various agitators exist to address mixtures of different viscosities and formulations prone to the formation of such aggregations. As a result, you may require specialized bladed agitators such as high shear mixers for mixtures that are prone to the formation of such agglomerates.

How water forms the distinction between creams and lotions

In essence, the question of cream or lotion is one of water content, as water directly affects the viscosity of the formulation. Lotions will consist of more water, while creams contain more oil. Practically, this means that dry skin will benefit more from creams, while lotions are better suited to oily skin. A thinner formula is less likely to clog pores, while a thicker formula provides a protective barrier to lock in moisture. Body lotions will generally be easier to homogenize, while creams are more likely to require specialized equipment. Of course, this will depend heavily upon your chosen formula and the properties of its ingredients.

Hurdles to homogenization and how emulsifiers can help

By nature, oil and water are an unlikely pair. Mixing the two is virtually impossible without an intermediary to bridge the gap. For this reason, emulsifiers are essential to the production of body lotion. These amphipathic molecules have both polar and nonpolar aspects, allowing them to bind to both. It’s this property that facilitates the mixture of two otherwise immiscible liquids. If you’ve tried to wash oil from your hands with water alone, you’ve seen this principle in action. The addition of soap, a very common emulsifier, will mix with the oil and wash right off.

Processing steps involved in body lotion making

Which body lotion technology do you need?

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

Industrial melter for cosmetic product processing

Streamline your production with this versatile melter, designed to effi...

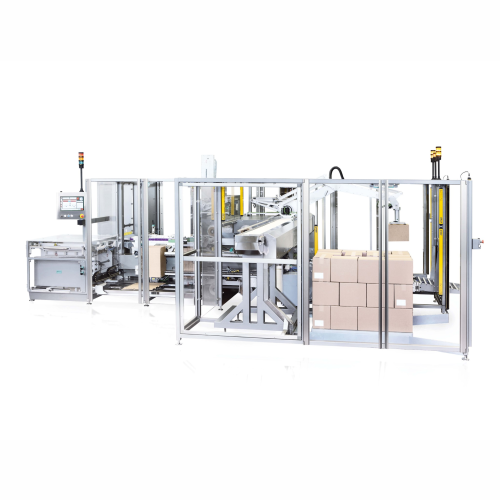

Automatic vertical case packer and palletizer for cosmetic sector

Optimize your packaging process with a compact soluti...

Automatic sachet filling and sealing system for liquids and creams

Optimize your cosmetic and personal care production ...

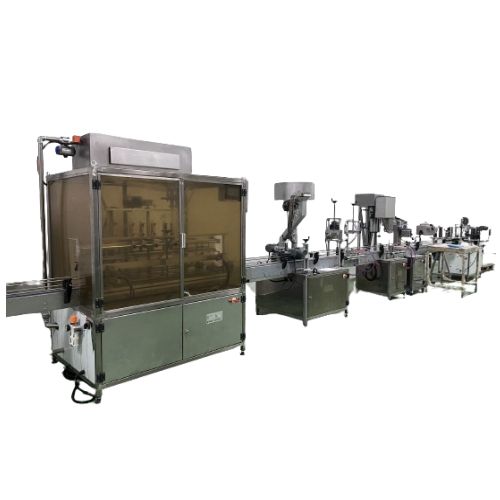

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

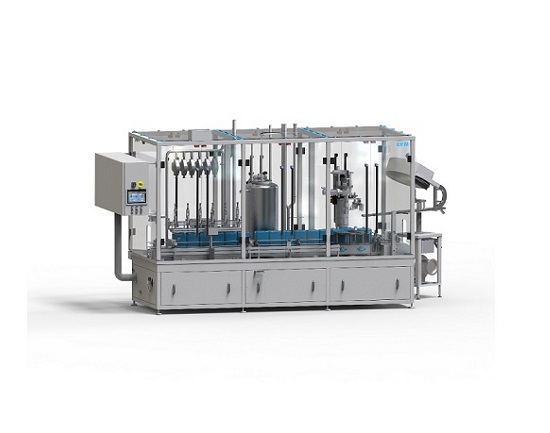

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Paste filling system for high viscosity products

Efficiently fill high viscosity products with precision and speed, reduci...

Hydrocolloid powder dispersion unit

Achieve seamless dispersion of hydrocolloid powders in liquids, eliminating common issu...

Manual Cip system for food processing hygiene

Designed for small-scale hygiene needs, this mobile clean-in-place system en...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

Counter-rotating agitator for high viscosity products

Achieve seamless heat transfer and precise mixing with a counter-ro...

Water treatment and lotion preparation for wet wipes

Ensure the integrity of your wet wipe production by implementing con...

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

High-speed overwrapping for bar soaps

Streamline your packaging line by efficiently overwrapping various product configurat...

Positive displacement gear pump liquid filler

Optimize your liquid filling operations with precision gear pump technology,...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

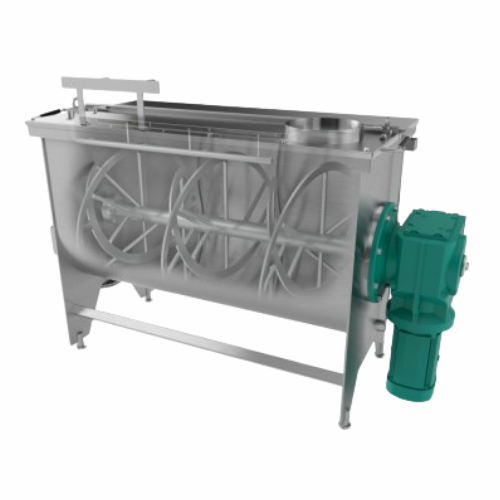

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

Horizontal flat pouching system for liquid soaps

Optimize your liquid packaging with high-speed, continuous operations tha...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Horizontal flat pouching line for liquid soaps

Streamline your liquid product packaging with a dual-lane flat pouching lin...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Vertical cartoning solution for fragrance and skincare products

Effortlessly carton even the most delicate cosmetics wit...

Tube filling solution for health and beauty applications

Achieve consistent quality and efficiency in tube filling operat...

Tube filling solution for health and beauty products

Achieve rapid production with precision in tube filling for personal...

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Rotary jet head tank cleaning system for food and beverage industry

Reduce your tank cleaning costs by up to 70% with a...

Cleaning nozzle for pharmaceutical tank cleaning

Ensure complete tank hygiene with innovative cleaning technology that tar...

Rotary filler capper for personal care products

Ensure consistent filling and capping of liquid products with high-speed p...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Tabletop labeler with integrated thermal printer for round containers

Efficiently label and print variable data on roun...

Indexed stomp capper for continuous bottle capping

Solve the challenge of manual snap cap placement with a seamless, cont...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Ergonomic melt systems for solid food and personal care products

Eliminate manual lifting and enhance safety by integrat...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Adjustable industrial mixers for thick product blending

Experience precise blending and control for thick and high-viscos...

Vacuum homogenizers for cosmeto-pharma and fine chemistry

Bring precision and efficiency to your formulation processes w...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

1-component industrial dispenser for precision dosing

Achieve unparalleled precision in microdispensing across diverse ap...

Automated precision spraying dispenser for high viscosity materials

Achieve precise spraying and consistent coating res...

Dual or triple lane food depositor

Enhance your production efficiency with a depositor that seamlessly handles a variety of...

Medium volume bottle and jar filling system

Efficiently manage filling operations for diverse liquid and semi-dense produc...

Automatic tube filling for coextruded products

Maximize efficiency in high-volume production with precision co-extruding c...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Semi-automatic capping solution for beverage and cosmetic bottles

Streamline your bottling process with versatile bench...

Pneumatic syringe dosing system

Streamline your liquid dosing process with precision and efficiency, ensuring each applicati...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Automated body lotion blending system

Streamline your personal care product manufacturing with a seamless blending and emul...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

Bottom entry mixers for high viscosity products

Optimize your production line with mixers designed to handle both high and...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Manual plastic tube sealing equipment

Working in labs or with small batch production lines where you have to seal plastic o...

Semi-automatic filler

When you are a small or a medium-sized manufacturer the manual filling processes might often lead to in...

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

Up to four head automatic filling machine

When your consumer demand is increasing you will need new and more effective pac...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Hot air tunnel for shrink sleeve labels

Sleeves are very popular in food, beverage, Chemical and pharmaceutical industry be...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Filling machine for creams

Liquid cosmetics have particular requirements when it comes to filling and capping containers. Mo...

Homogenizer for creams

Homogenization (or pharmaceutical micronization) is the process of reducing particle sizes, and is a v...

Vacuum mixer for suspensions

The production of high quality pharmaceuticals often requires mixing of suspensions and similar...

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Tube unloader and feeder

The pharmaceutical and cosmetic industries utilise high speed tube fillers on large-scale production...

Tube feeding unit for high volume and high speed tube filler

High performance tube-filling machines are used for large s...

Loading cassette for a tube filler

High performance tube-filling machines are used in the pharmaceutical and cosmetic indus...

Tube feeder for a small scale production tube filler

Low speed tube-filling machines are used for small scale production ...

High speed automatic tube filler

For high-volume lines filling pharmaceutical, cosmetic or food products into tube container...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

Vertical cartoner for pharmaceutical applications

Many pharmaceutical and cosmetic products are sold in protective and de...

Medium speed tube filler and sealer

For scale-up filling of tube packaging for pharmaceuticals, cosmetics and food products...

Medium and high speed range automatic tube filler

When scaling up production of pharmaceutical, food or cosmetic products...

Low speed tube filler

Increasing numbers of products in the pharmaceutical, cosmetic and food industries are delivered in fle...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Multi-head capper

For the stand-alone capping of bottles of up to 2.5litre capacity you need a robust and flexible machine wi...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Electric shrink tunnel solution

Adapting shrink sleeve heating tunnels for different applications can be a lengthy and expen...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Laboratory size auto-steam shrink system

When managing sleeving projects, fast prototyping and testing can gain massive com...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

In-line tamper evident applicator head

Integrating tamper protection equipment into an existing production line means addit...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Advanced auto-steam shrink system

Design and development of shrink sleeves could be made much easier if small batches of sa...

Premium steam tunnel for sleeve application

Maximum flexibility in terms of pressure, temperature and ramp setting and adj...

Shrink tunnel for applying sleeves to different containers

Maximum flexibility is required when setting pressure and dir...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Dispersing machine for emulsions and suspensions

Equipment operating under the rotor/stator principal is often employed wh...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Dispersing machine for very fine emulsions and suspensions

For continuous high performance mixing of solid and liquid ra...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

High accuracy homogenizing system

When extremely high accuracy is required in your recipe or formulation traditional mixing...

Horizontal kneader

For high viscosity products, better results and reduced process times can be achieved with kneading type r...

Vertical kneader

Production of highly viscous products with high solid content often benefits from kneading processes rather t...

Continuous kneader

Effective mixing of highly viscous products with extremely high solids content can be difficult and the re...

Batch dispersing machine

Equipment operating under the rotor/stator principal is often employed when more traditional methods...

Batch dispersing machine for abrasive products

For mixing and dispersing tasks that cannot be completed by conventional st...

Batch dispersing machine for bottom entry into vessels

When your process requires high performance mixing or dispersion b...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

Agitator for low viscosity media

Reliably agitating fluids in open or pressure-less vessels in a laboratory or small scale p...

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...