Making Pharmaceutical Cartridges

Find innovative production technology for making pharmaceutical cartridges and connect directly with world-leading specialists

Pharmaceutical cartridges are glass containers of cylindrical shape, suitable for liquid or solid pharmaceutical dosage forms. Generally, these are designed for a specific apparatus such as pre-filled syringes and autoinjectors. Drugs that can be placed in cartridges using a pharmaceutical cartridge filling equipment include insulin, dental anesthesia, and other emergency drugs for allergies.

Stories about pharmaceutical cartridges

Tell us about your production challenge

Dual-chamber cartridges as innovative packaging for freeze-dried products

In the lyophilization process, water is removed from a product after freezing and placing it under a vacuum to change ice directly to vapor without passing through the liquid phase. Vials are the most used packaging for freeze-drying products due to their simple assembly. The fact that they have a large volume facilitates heat transfer and rapid sublimation during drying.

However, more innovative packaging such as dual-chamber syringes or cartridges made their entrance as packaging forms of freeze-dried substances. Dual-chamber syringes are good for single-dose applications and filling volumes of 0.1 to 5mL.

Dual-chamber cartridges instead are meant for single and multiple doses with a filling volume of 0.1 to 1mL. The main difference with the dual-chamber syringes is their closure system in which the cartridge has an injection membrane for needles and is mostly used in applications like pen systems which require careful calibration. They are also available with special closures that can be sealed in the lyophilizer, creating a nitrogen atmosphere over the product. Advantages of dual-chamber drug delivery systems include accurate dosing, minimal reconstitution errors, and fewer steps for preparation and injection.

Pharmaceutical cartridges – the perfect match for pre-filled syringes

Pre-filled syringe cartridges have many advantages over traditional syringes. These advantages revolve around convenience, sterility and accuracy. If a patient requires a quick injection or there is an emergency, having a pre-filled syringe cartridge ready is more convenient than filling a standard syringe. This way, health workers can also be sure to provide accurate dosage to patients instead of overfilling or underfilling the barrel, which can negatively affect the treatment. An important advantage is that drugs into cartridges can remain sterile for about two or three years instead the medications in standard syringes will have a shelf life of about 12 hours.

Insulin pens make self-injection easier

Insulin pens are gaining popularity for diabetic patients that need insulin injections. Most patients prefer using insulin pens over vials and syringes because are more convenient to use through self-injection as they already contain the exact dosage needed. They are safer with less needle exposure from the environment and also less painful when injecting them to the body due to smaller needle size.

Insulin pens can be reusable and disposable. Reusable pens only need the needle and cartridge disposed of after every use. The disposable pens have a pre-filled cartridge and as the name says, the whole pen is disposed of after use. Another advantage of using insulin pens is overall cost savings from lesser medication waste due to the exact dosage filled per insulin pen.

Pharmaceutical cartridge filling equipment for safety and compliance

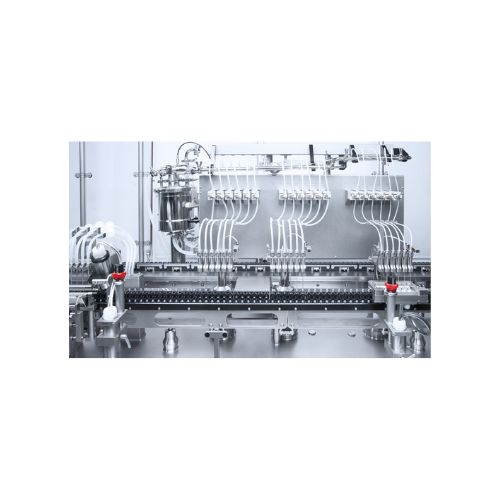

Pharmaceutical cartridges must undergo aseptic filling through a pharmaceutical cartridge filling equipment. The process involves handling medications that may be sensitive to other elements and ensuring that the substance is free from contaminants that may cause health risks once patients use it.

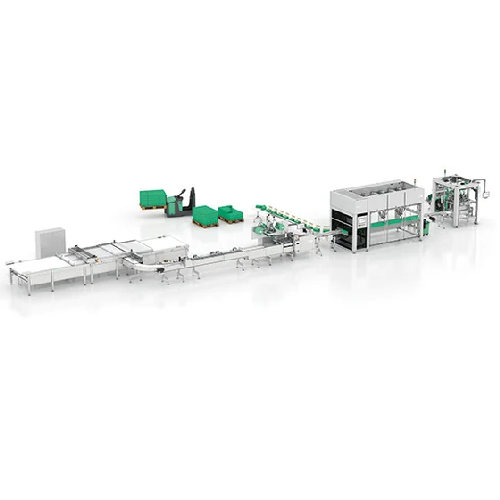

The process starts with washing the cartridges before sending them to a depyrogenation tunnel so you can remove pyrogens. Then you can fill the cartridges with the substance and seal them with a plunger or stopper. After sealing, they are sent to a labeling and coding machine for all the labels and serial coding. Then, they are loaded on a tray and ready for packaging. These should be done under a sterile environment as per pharmacopeia standards.

Processing steps involved in pharmaceutical cartridges making

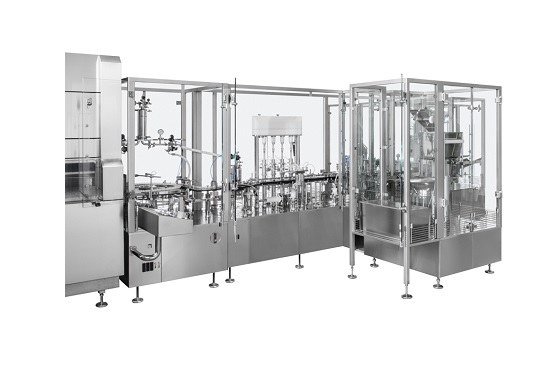

Aseptic filling equipment

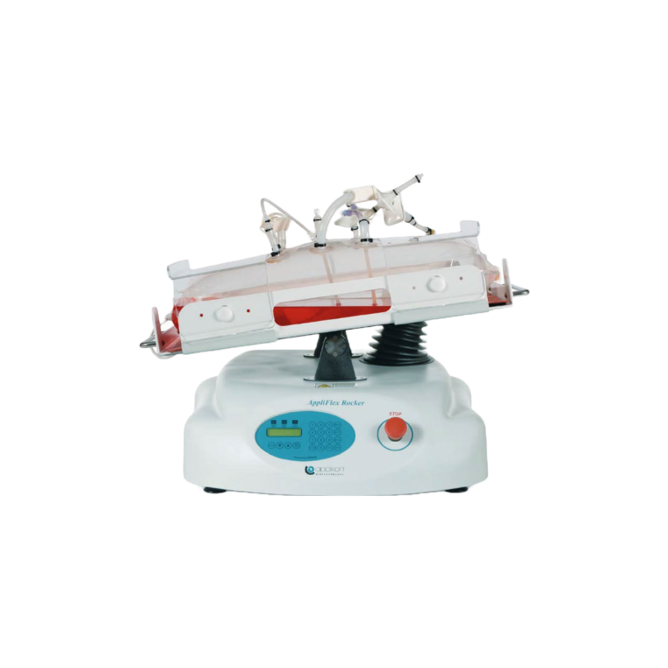

Bioreactor systems

Biosafety cabinets

Biotech

Biotech sampling and control

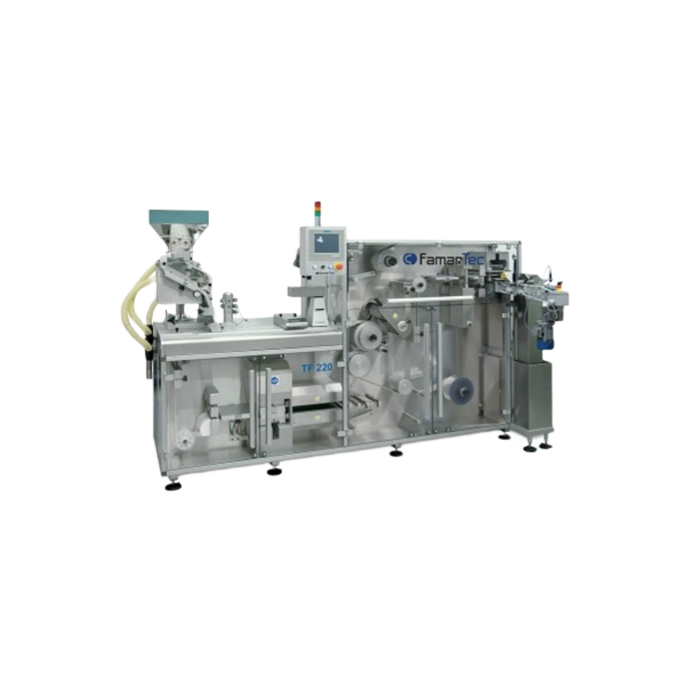

Blister Packaging Equipment

Contained transfer systems

Containment

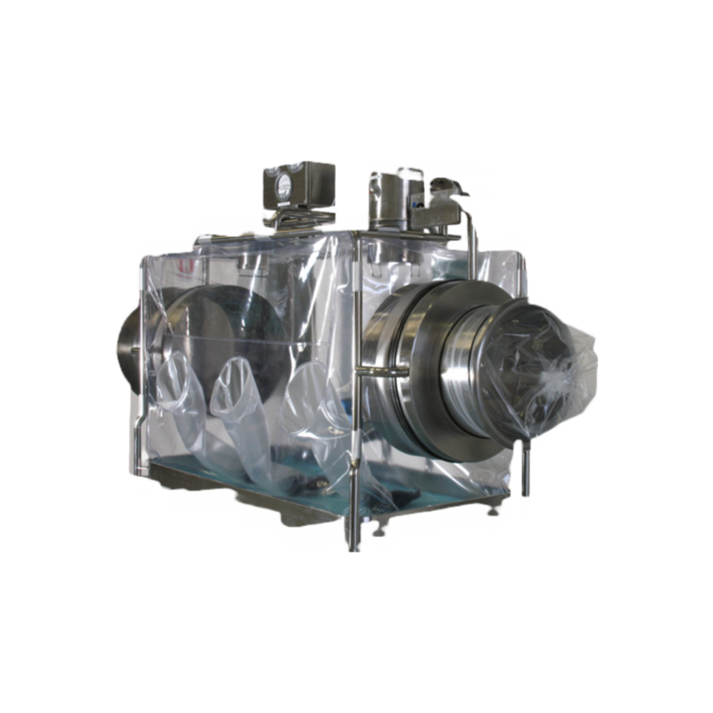

Containment isolators

Dosing

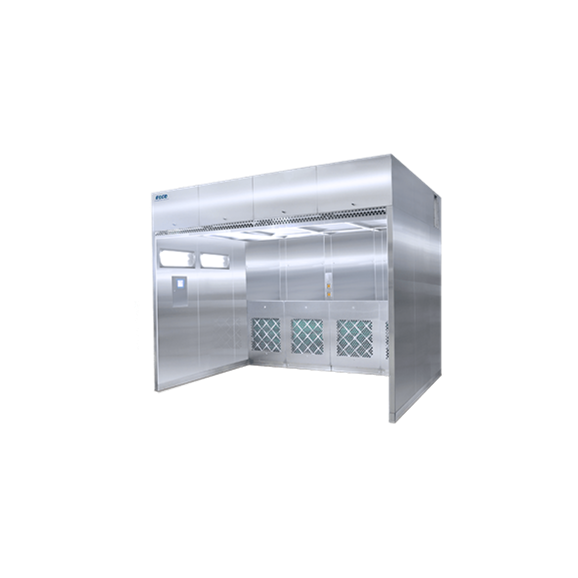

Downflow booths

Drying

Filling

Flexible containment solutions

Formulation

Freeze dryers

High pressure homogenizers

Inspection

Measurement & Control

Monolithic columns

Packing

Single use systems

Sterilization

Which pharmaceutical cartridges technology do you need?

Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powder...

Outsert application system for pharma bottles

Effortlessly enhance packaging efficiency in pharmaceutical lines with this ...

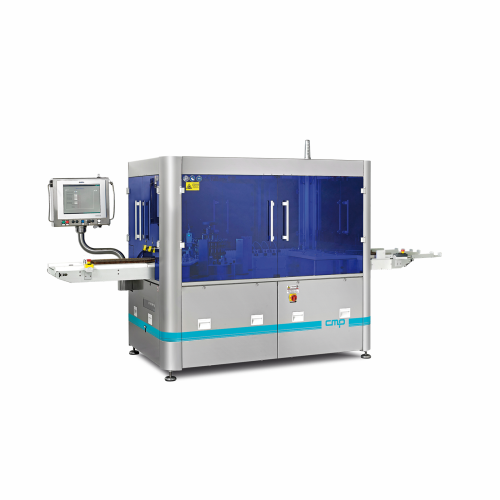

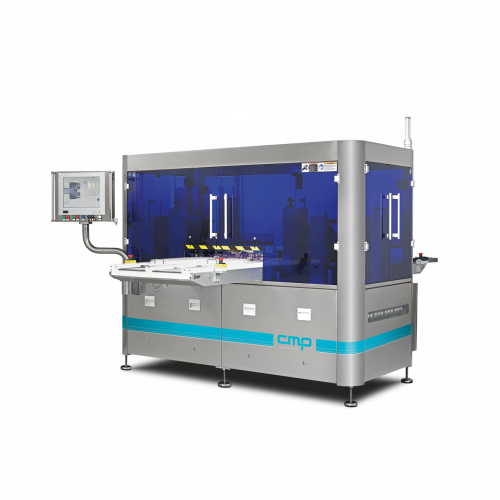

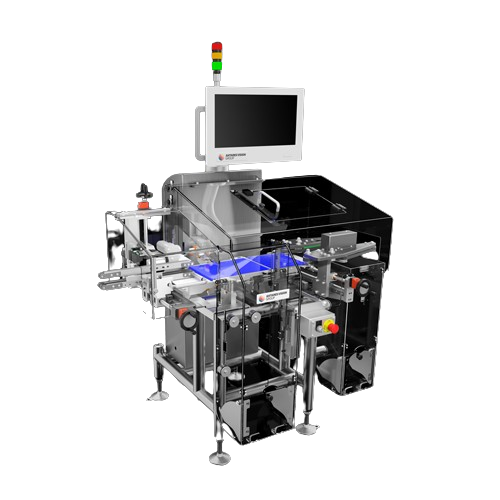

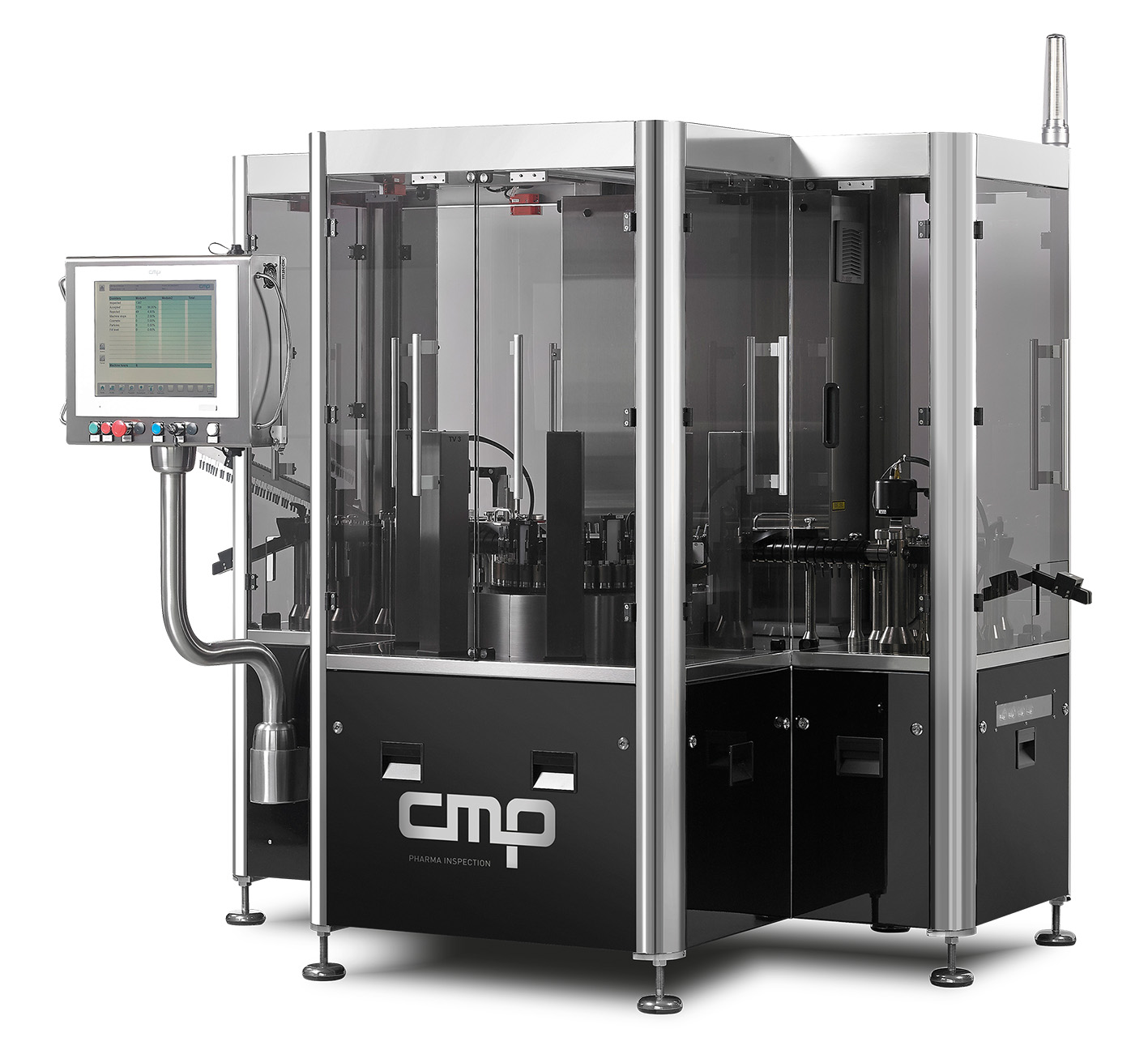

Inspection system for glass containers

Ensure precise inspection of liquid, freeze-dried, and powdered products in glass co...

Glass container Inspection line

Ensure precise quality control with a high-speed inspection line designed for glass containe...

360 and leak Inspection system for glass containers

Ensure the integrity of every glass container with a comprehensive in...

Inspection for glass containers

Ensure the integrity and quality of your liquid formulations with high-speed inspection and ...

Counter-rotating blender for cosmetic and pharmaceutical mixing

Achieve precise mixing and homogenizing of complex formu...

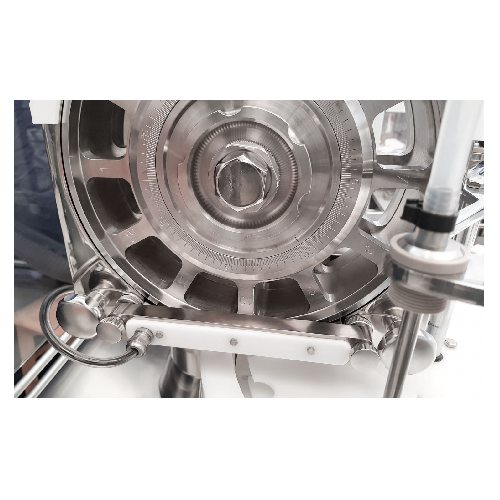

Rotary vial washers for parenteral containers

Ensure sterile and pyrogen-free parenteral preparations with a seamless wash...

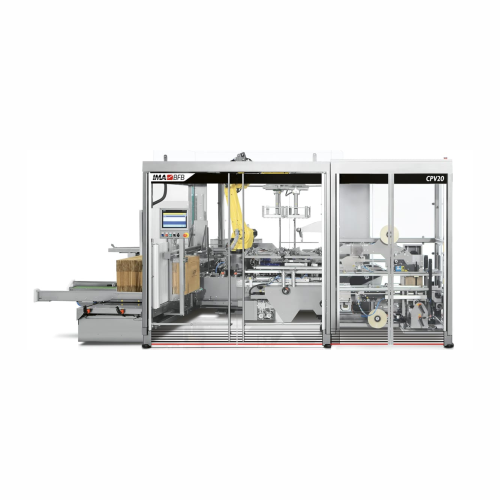

Top-loading case packer for pharmaceutical and cosmetic products

Ensure precision and flexibility in packaging with this...

Final product inspection system for pharmaceutical containers

Ensure the integrity and precision of packaged pharmaceuti...

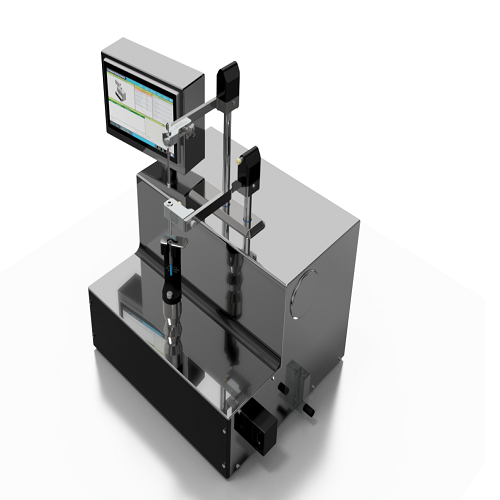

Powder dosing system for development and small batches

Streamline lab-scale pharmaceutical production with a versatile po...

Inline digital printing system for pharmaceutical packaging

Enhance packaging precision and compliance with cutting-edge...

Semi-automatic powder dosing system

Achieve precise micro-dosing for pharmaceutical powders with a flexible system ideal fo...

Digital packaging printer for blister-lidding foils

Ensure precise branding on blister packaging with high-speed digital ...

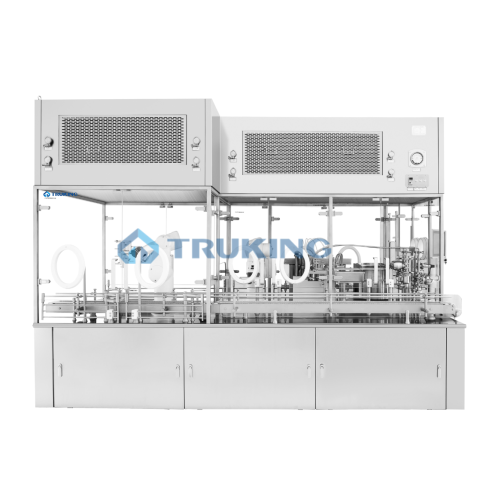

Aseptic filling solutions for Rtu vials, cartridges, and syringes

Optimize your aseptic filling processes with a system...

Vial and syringe filling system for pharmaceuticals

Ensure aseptic precision in liquid formulation filling with a modular...

Aseptic syringe filling solution for Rtu containers

Streamline your pharmaceutical liquid filling operations with precise...

Gloveless robotic filling cell for aseptic pharmaceutical processing

Eliminate human intervention in aseptic filling wi...

Industrial manipulator for sterile and nonsterile filling

Maintain the integrity of high-value pharmaceuticals with a hi...

Rotary washer for pharmaceutical containers

Ensure optimal preparation of pharmaceutical containers with advanced rotary w...

Vial filling system for sterile and nonsterile pharmaceuticals

Enhance precision in injectable drug preparation with a s...

Optical inspection for ampoules, vials, cartridges, and syringes

Ensure product integrity and safety with this advanced ...

Cartridge assembler and filler for next generation tobacco products

Boost your production line’s efficiency with ...

Aseptic filling isolator for vial / Pfs / cartridge

Ensure sterile and contamination-free filling of vials, pre-filled sy...

Linear tamper evident labeler

Secure product integrity with high-speed labeling that ensures tamper evidence, while seamless...

Syringe dispensing system for nuclear medicine

Optimize your radiopharmaceutical workflows with a system designed to preci...

Modular sterility testing isolator for pharmaceuticals

Achieve uncompromised sterility with modular isolators designed fo...

High quality sterile filling system

Experience unparalleled precision in aseptic filling with this advanced system, designe...

Bottle cleaning station for controlled environments

Ensure high-level decontamination of passive units and containers wit...

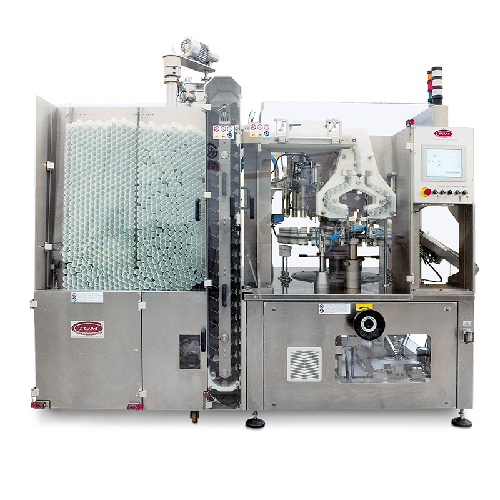

High-speed syringe assembler and labeller

Streamline your syringe production with a high-speed solution that assembles and...

Filling and closing solution for nested containers

Streamline your vial, cartridge, and syringe production with precise d...

Filling and closing system for nested containers

Optimize liquid formulation packaging with a high-speed system designed f...

Bin and feed unit for closures

Ensure seamless closure feeding with quantity-controlled precision to prevent production stop...

Tub sealing solution for pharmaceutical packaging

Achieve precision sealing for nested pharmaceutical containers with an ...

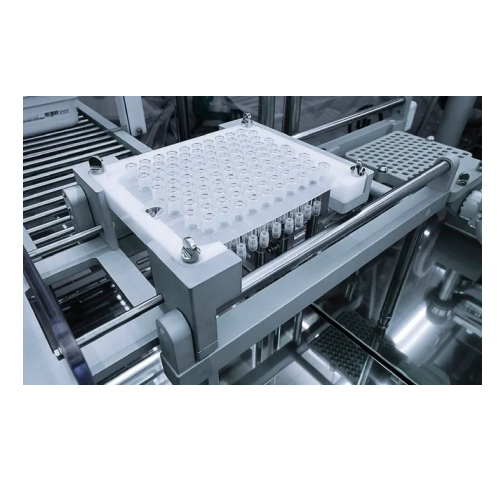

Tray loader for pharmaceutical containers

Maximize efficiency in aseptic fill-finish lines with precise and rapid tray loa...

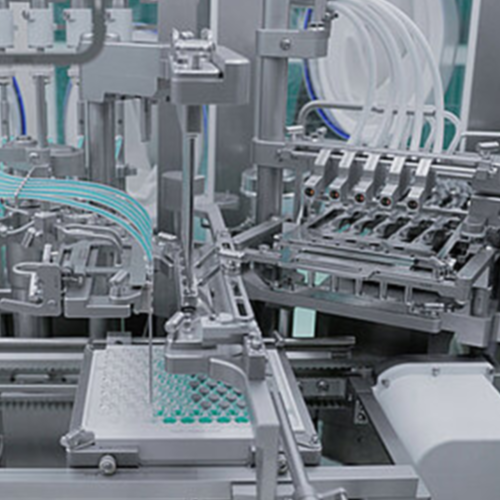

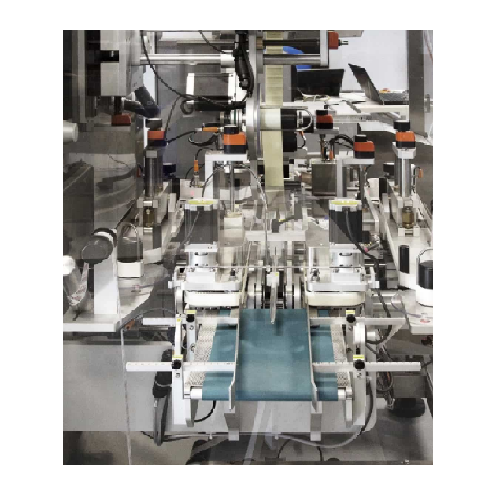

Filling and closing system for cartridges

Enhance your cartridge production with precise filling and closing technology de...

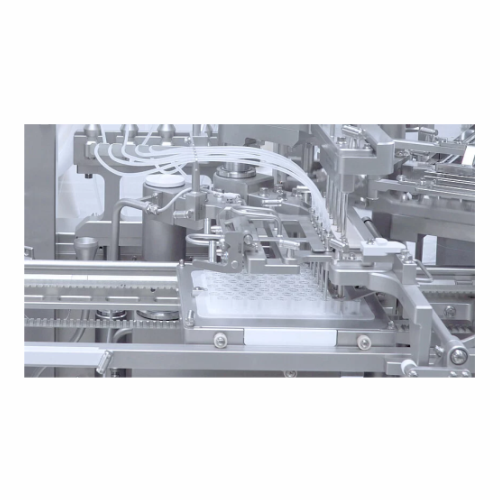

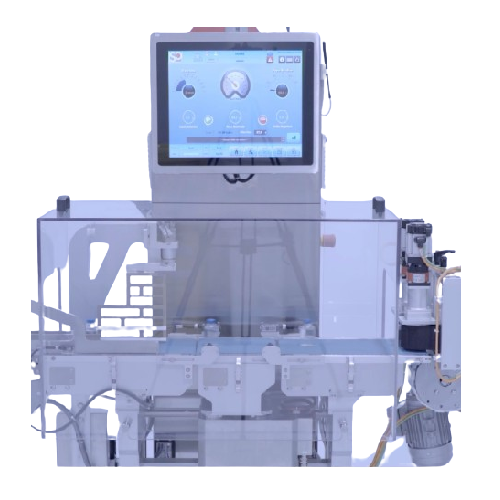

Wet cleaning system for pharmaceutical cartridges

For optimal sterile product outcomes, this system ensures precise and e...

Filling and closing system for vials, syringes, and cartridges

Optimize your aseptic fill-finish operations with a versa...

Vial and cartridge filling and closing system

Optimize your aseptic fill-finish process with high-speed, continuous operat...

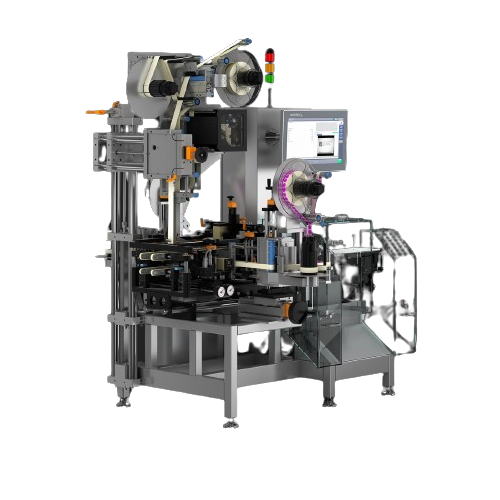

Automatic labeling system for pharmaceutical containers

Streamline your pharmaceutical packaging with precision labeling,...

Automatic vial labeling system

Achieve precise labeling at high speeds with a system designed for seamless integration into ...

Fully automatic linear labeling system for bottles

Optimize your bottle labeling process with precision and speed, ensuri...

Rotary washing system for pharmaceutical containers

Achieve superior cleanliness and efficiency with a high-speed rotary ...

Automated washing system for vials, syringes, cartridges, and ampoules

Achieve sterile conditions with this high-speed ...

Semi-automatic washer for pharmaceutical containers

Achieve precise cleaning for pharmaceutical containers with a semi-au...

High-speed washing system for ampoules and vials

Ensure contamination-free ampoules and syringes with this advanced washin...

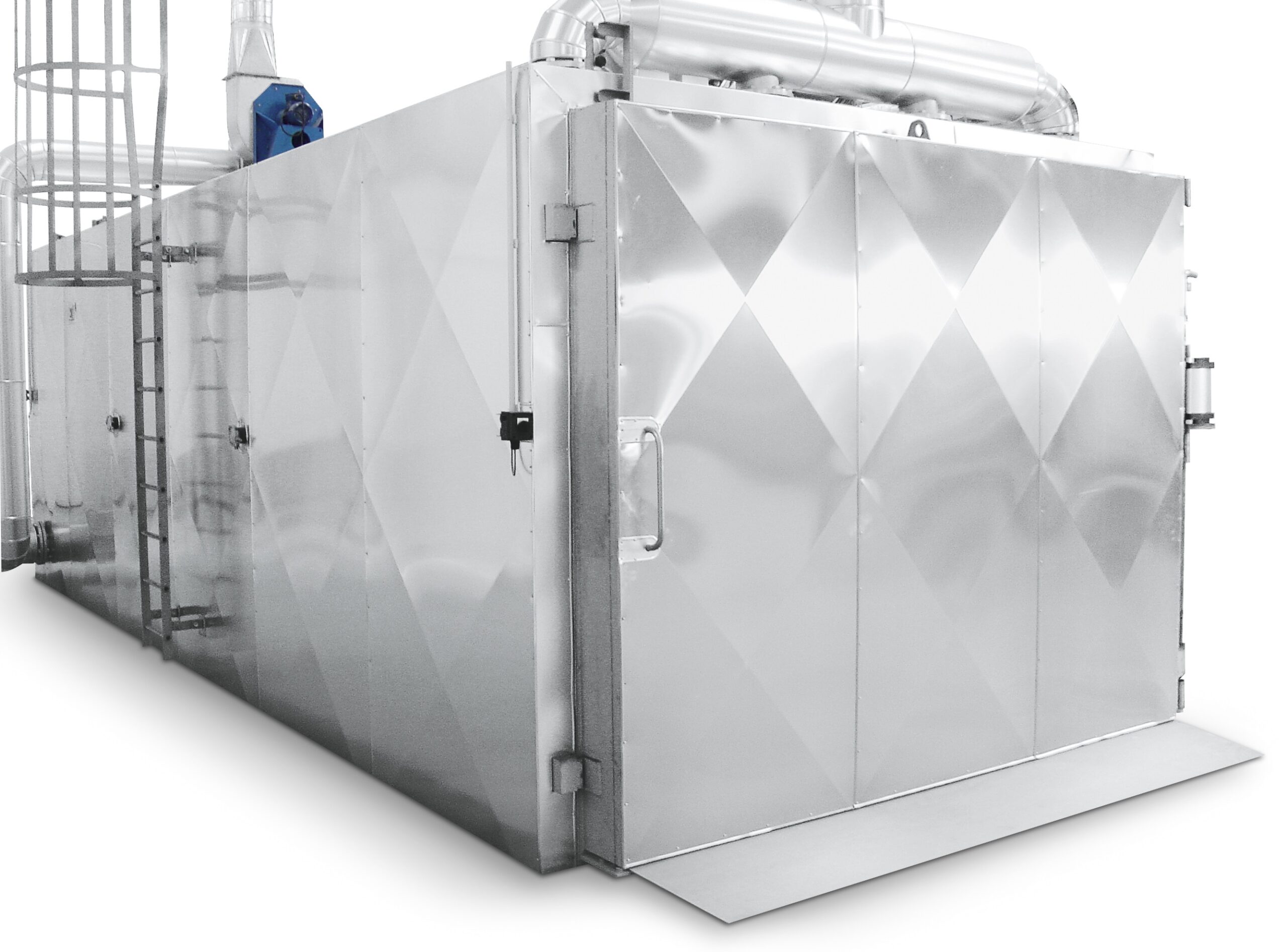

Hot air sterilization for glass containers

Ensure precise and uniform sterilization of glass ampoules, vials, and syringes...

Robotic filler for aseptic pharmaceutical packaging

Effortlessly manage complex aseptic filling tasks with a system desig...

Bench-top syringe & cartridge closing system

Ensure precise and repeatable syringe and cartridge closure with this versati...

Automated aseptic filling and closing system for vials and syringes

Optimize small-batch production with precision fill...

Aseptic small batch filling and closing system

Optimize your small-batch aseptic processing with this versatile system, de...

Aseptic small / medium batch filling and closing system

Ensure sterility in drug production by seamlessly integrating a v...

Pharmaceutical checkweigher for milligram-level accuracy

Ensure precision and compliance in your pharmaceutical packaging...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Pharmaceutical large freeze dryer with vacuum pump

Preserve the integrity and potency of sensitive compounds with precisi...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Compact serialisation system with tamper-evident and vignette labeler

Streamline your packaging operations with a high-...

Automated container closure integrity tester

Ensure the integrity of your sterile pharmaceutical containers with high-spee...

Automated Cci tester for primary packaging containers

Ensure the integrity of pharmaceutical packaging with precise and n...

Precision 2k dispenser for automated systems

Achieve precise mixing and dispensing of two-component materials with minimal...

Nested fillers for vials, pre-filled syringes, and cartridges

Optimize your aseptic filling processes with precision dos...

Superheated water sterilizer for pharmaceutical applications

Ensure precise sterilization with real-time monitoring and ...

Vertical ultrasonic washing for pharmaceutical containers

Ensure immaculate cleanliness and sterilization of pharmaceuti...

X-ray inspection for pharmaceutical vials

Ensure product purity by detecting contaminants in pharmaceutical vials with adv...

Secondary packaging cartoner for ampoules and vials

Optimize your aseptic production with efficient high-capacity carton ...

Automatic tube filling for coextruded products

Maximize efficiency in high-volume production with precision co-extruding c...

Automated visual inspection for pharmaceutical products

Ensure the integrity and safety of your parenteral products with ...

Biodecontamination system for small pharmaceutical enclosures

Achieve reliable sterilization in compact settings with th...

Robotic filler for aseptic pharmaceutical production

Streamline your aseptic filling process with high-speed robotic prec...

Pharmaceutical labeling for syringes and cartridges

Ensure precision and sterility in your labeling process with advanced...

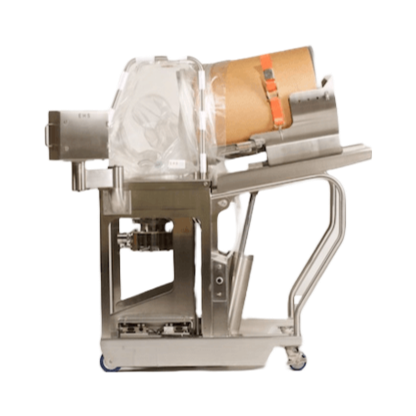

Rtu debagging system for pharmaceutical sterile environments

Designed to streamline your fill-finish process, this syste...

Ready-to-use denesting equipment for pharmaceutical fill-finish

Ensure sterility and precision in your fill-finish workf...

Robotic syringe filling system for sterile pharmaceutical production

For high-precision liquid dosing in sterile enviro...

Pharmaceutical liquid and powder filling solution

Achieve precise filling and capping of diverse formulations with a vers...

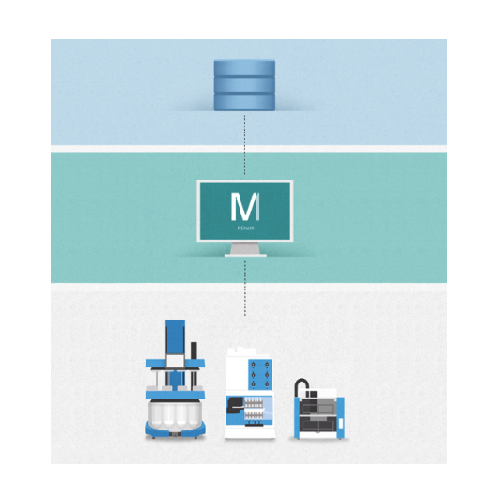

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Vial washing system for internal and external cleaning

Streamline vial preparation with comprehensive washing, sterilizin...

Nested syringe filling and stoppering system

Optimize your syringe production with precise filling and stoppering, ensurin...

Automatic tamper-evident seal applicator

Ensure your product integrity and traceability in packaging lines with this soluti...

High precision pharmaceutical checkweigher

Ensure precise weight compliance in high-speed production lines with this advan...

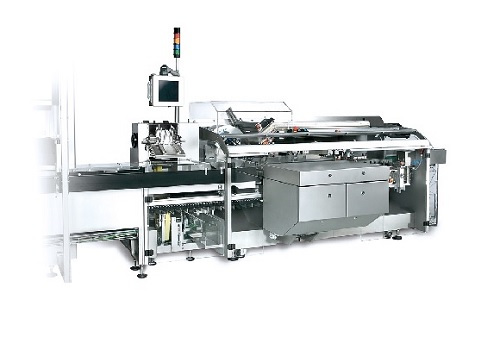

Automatic cartoning system for pharmaceuticals

Simplify your cartoning process with high-speed, continuous motion that boo...

Aseptic handling and fill-finish platform for Rtu syringes, vials, and cartridges

Ensure aseptic precision and high t...

Semi-automatic filling solution for syringes and vials in isolators

Achieve precise aseptic fill-finish operations for ...

Ethylene oxide sterilizer

When medical devices like syringes, catheters, dialysis cartridges, plastic dressings and sutures ...

Continuous pack cartoner

High volume automatic cartoning is vital for large scale production of cosmetic or pharmaceutical pr...

Horizontal cartoner for pharmaceutical applications

Automatic cartoning for cosmetic or pharmaceutical products is a requ...

Start-up sterile filling line for injectables

For smaller-scale production of vials and syringes for the injectables marke...

Table top sterile filling line for injectables

Where a compact solution is required for filling vials for the injectables ...

Cleaning and sterilization systems

An increasingly vital part of high quality pharmaceutical production is a dedicated Clea...

Industrial vial capping machine

The high capacity production of pharmaceuticals delivered in vials and cartridges requires a...

External vial washing machine

Exterior washing solutions for vials often suffer from high water consumption and low throughp...

Vial filling machine

The volume filling of vials, cartridges and syringes is a vital part of the production of a wide range o...

Nested syringe filling machine

Increasingly, pre-sterilized Ready To Use (RTU) nested vials, cartridges and syringes are the...

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

High capacity cartoner for pharmaceutical applications

Many pharmaceutical products are packed in protective and decorati...

Vertical cartoner for pharmaceutical applications

Many pharmaceutical and cosmetic products are sold in protective and de...

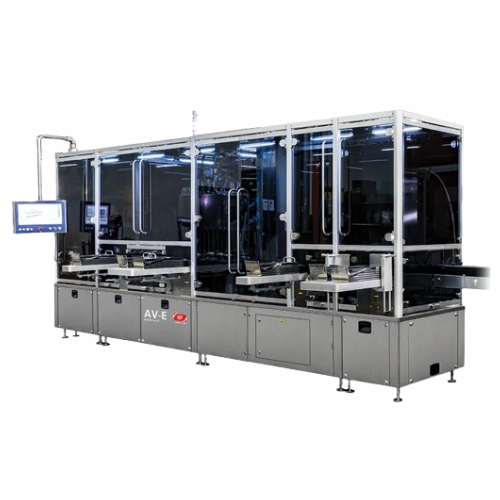

Flexible automatic inspection machine for ampoules, vials, cartridges

If you are looking to improve the efficiency of y...

Flexible automatic inspection machine for syringes

Manufacture of pre-filled syringes requires the highest quality inspec...

Small automatic inspector for ampoules, vials, or cartridges

Inspect small batch production of ampoules, vials, or cartr...

Semi-automatic inspection machine for ampoules, vials or cartridges

If you need to increase the efficiency of your manu...

Visual and HVLD inspection for ampoules, vials and cartridges

Do you need to improve the efficiency and capability of yo...

Sterile filling line for injectables

Sterile filling of liquids and powders for the pharmaceutical and cosmetic industries ...

GMP autoclave

When sterilizing and dealing non-thermolabile products, you will want to get a hold of those resistant to the te...