Ready-to-use denesting equipment for pharmaceutical fill-finish

Ensure sterility and precision in your fill-finish workflow with advanced denesting and renesting technology, designed for seamless integration and minimal operator intervention.

Denests and Renests Sterile Containers Efficiently

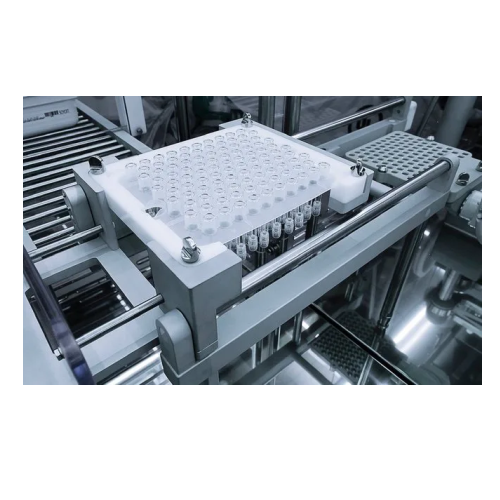

The Hull i-Dositecno Ready-To-Use (RTU) Denesting Equipment is designed for precision handling of sterile products in the pharmaceutical and life sciences industries. This semi-automatic system employs a Stäubli TX2 robot with a CS9 controller to ensure precise denesting and renesting of syringes, vials, and cartridges. Ideal for biopharmaceuticals and diagnostic kits, it efficiently processes up to 2,400 units per hour, maintaining sterility and enhancing production workflow.

With Siemens or Allen Bradley PLC-controlled servo motors, the equipment allows for precise control over the rate and height settings, ensuring seamless integration into existing production lines. Its cleanroom-ready design is constructed from premium steel to meet GMP Grade A/ISO 5 standards, providing full resistance to hydrogene peroxide (H2O2) decontamination.

The Hull i-Dositecno equipment supports aseptic processing within isolators or restricted access barrier systems (RABs) and complies with Annex 1, 21CFR part 11, and GAMP5. It features a compact, modular design with minimal operator intervention, offering efficient and reliable operation. Additionally, Hull i-Dositecno provides customization support and validation packages for compliance, ensuring the equipment meets specific operational needs.

Benefits

- Enhances production efficiency with high-speed processing of up to 2,400 units per hour.

- Maintains stringent sterility, reducing contamination risks in critical environments.

- Integrates seamlessly into existing lines, minimizing setup and transition times.

- Reduces manual handling and labor costs with automated robotic denesting.

- Ensures regulatory compliance with GMP, Annex 1, and 21CFR part 11 standards.

- Applications

- Injectable products, Biopharmaceuticals, Pharmaceutical packaging, Diagnostic kits, Sterile liquids

- End products

- Insulin syringes, Ophthalmic injection cartridges, Pre-filled vaccine vials, Monoclonal antibody injectables, Covid-19 test kits

- Steps before

- Nest filling, Pre-sterilization, Cleaning and preparation

- Steps after

- Renesting, Aseptic processing, Fill-finish assembly, Packaging

- Input ingredients

- nested packaging, pre-sterilized containers, SCF components, syringes, vials, cartridges

- Output ingredients

- denested components, renested components, separated SCF components, assembled SCF components

- Market info

- Automation

- PLC-controlled

- Capacity

- Up to 2, 400 units per hour

- Cleanroom Compatibility

- Engineered from premium steel, Cleanroom ready

- Compliance

- 21 CFR Part 11, cGMP, Annex 1, GAMP5

- Container type

- Syringes, Vials, Cartridges

- Robot type

- Stäubli TX2 with CS9 controller

- Servo Motor Control

- Siemens or Allen Bradley

- Resistance to decontamination

- Resistance to vaporous and fluid hydrogen peroxide (H₂O₂)

- Semi-automatic Operation

- Semi-automatic with servo driven robotic transport

- Automation level

- Semi-automatic / PLC

- Batch vs. continuous operation

- Batch

- Cleanroom readiness

- ISO 5 / GMP Grade A

- CIP/SIP

- Not specified

- Corrosive resistance (e.g. acids)

- Hydrogen peroxide (H2O2) resistant

- Cleanability

- H2O2 decontamination process

- GMP Compliance

- cGMP

- ISO Cleanroom Standards

- ISO 5

- Compact footprint

- Yes

- Control panel type

- Siemens or Allen Bradley PLC

- Discharge method

- Semi-automatic with servo driven robotic transport

- Machine production rate

- Up to 2, 400 units per hour

- Control panel type

- Siemens or Allen Bradley PLC-controlled servo motors

- Integration possibilities

- Can be assembled in isolator or RABs

- Modular system

- Modular and scalable system with small footprint

- Configuration options

- Configurable for syringes, vials, or cartridges