Making French Fries

Find innovative production technology for making french fries and connect directly with world-leading specialists

Thomas Jefferson served as the third US president, extended the country’s territory, and authored the Declaration of Independence. But his lasting impact on American society goes beyond politics. He is credited with introducing French fries after his stint as Minister to France. The tasty snack remains a global favorite, cut in all shapes and sizes and topped with imaginative condiments. But while the 19th century President had his potato chips prepared by his cook, serving the market demand today requires specialized French fry processing equipment.

Stories about french fries

Tell us about your production challenge

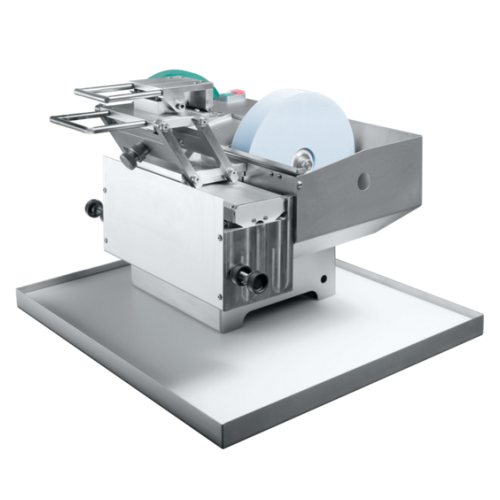

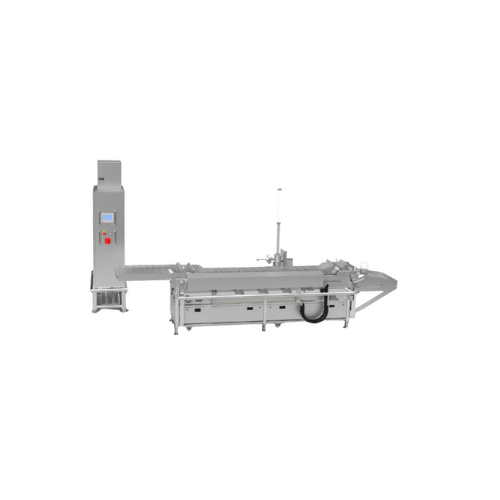

Use a steam peeling machine to skin potatoes

French fries demand 100% skinned potatoes, but the peeling process risks lowering the yield if the peeling machine cuts too deep into the flesh.

Use a steam system to loosen the tuber’s skin before peeling it away. De-stoned potatoes are sprayed with water and subjected to high-pressure steam. As soon as the steam is released, the water molecules expand and separate the peel from the flesh. The potatoes are then conveyed through a series of dry brushes that scrub them off the skin.

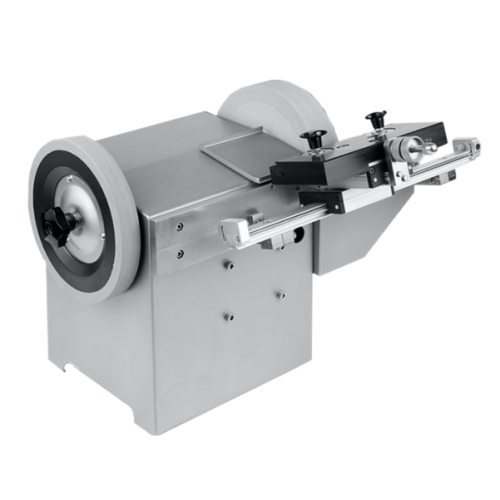

Make the cut with the right knife block system

Long strips, thick slices, or chunky wedges, the cut is a signature of the French fry. So, a critical step in the processing line is homogeneous cutting.

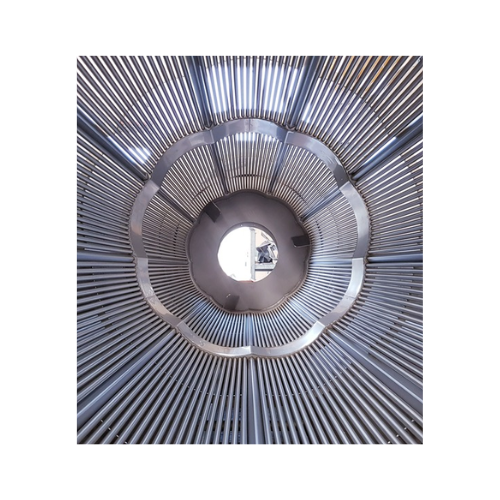

Cutting machines use sorting tubes to arrange the individual potatoes in a precise position. The potatoes then slide into the cutter head, where a knife block system cuts them down into accurate shapes and sizes.

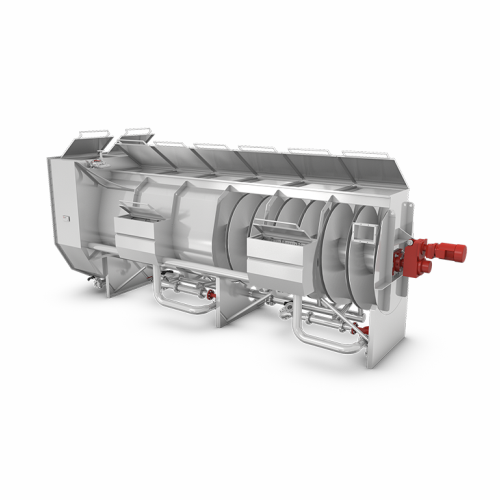

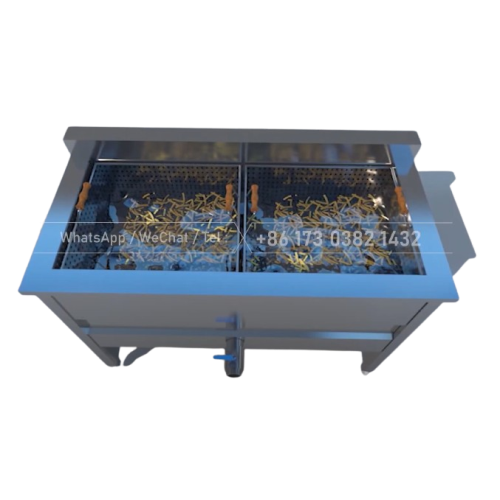

Potato blanchers are fundamental French fry processing equipment

Potatoes carry enzymes that catalyze the breakdown of the cells. This activity not only degrades the product quickly but also causes enzymatic browning. Blanching has stood the test of time as an effective method for inactivating enzymes.

Blanching machines specialized for French fries boil the potatoes in water at around 95°C for a maximum of 4 minutes before quickly cooling them down.

Inactivate the enzymes to preserve the potatoes for longer

Blanching potatoes does more than denature their enzymes. The high temperature causes the starch in potatoes to swell and gelatinize. Meanwhile, the process also leaches out excess starches that impede cooking.

Since the surface of the potato is subjected to heat more directly, the outside of the chip forms a firmer gelatinization. This prepares the strip to produce a crispy exterior and a soft interior as they move through the French fry processing equipment.

Limit oxidation by coating a binding solution onto the French fries

One of the biggest challenges in food manufacturing is controlling free metal ions that produce oxidation and reduce shelf life.

Coat the potato strips in a sodium acid pyrophosphate (SAPP) solution to bind the ions and avoid discoloration and rancidity. The coating is performed in a dipping station where the potatoes are sprayed using a volumetric dosing system.

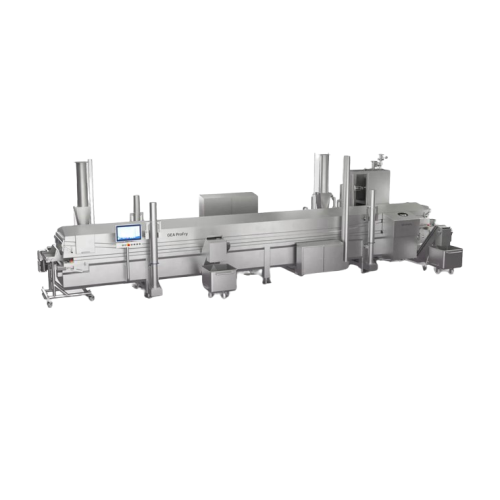

Remove moisture from the chips to allow oil absorption

The vital process for potato chips is, of course, the frying step. As the dry potato strips are immersed in hot oil, they release moisture and absorb the lipids that develop the classic texture of fries.

Higher temperatures reduce more moisture, but the impact beyond the industry standard of 180°C is negligible. The strips must not be completely dry, however. Moisture produces fracture force that gives the fries their bite.

Fry the chips a second time to cook the crust

Potato chips go through two rounds of frying: a partial fry and a finish. The first treatment reduces retained moisture and cooks the interior. The finish fry cycle is shorter and cooks the surface of the individual strips.

After the two cycles are completed, most of the oil content accumulates in a thin crust of about 1 mm, forming the crunchy exterior and soft interior.

Keep a short oil turnover rate in the fryer system

The French fry is nothing without the oil, but maintaining oil quality is a challenge, particularly for continuous processes. A short turnover rate keeps the oil fresh for longer, contributing to lower volume requirements.

The oil turnover rate refers to the time it takes for the stainless steel pans to be replenished with the starting quantity of oil.

Freeze the potatoes as quickly as possible

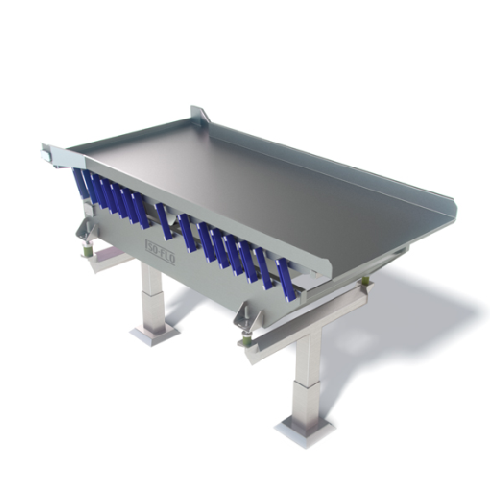

Remove the excess oil covering the fries in a de-fatter. The vibrating tray shakes the unabsorbed oil off the strips and recovers it for new frying cycles.

The chips are now ready for freezing. Bring their temperature down in a cooling chamber, then freeze to a temperature of -12°C. The power of the freezing tunnel is essential because a shorter freezing time retains the organoleptic profile of the freshly fried chip.

Processing steps involved in french fries making

Which french fries technology do you need?

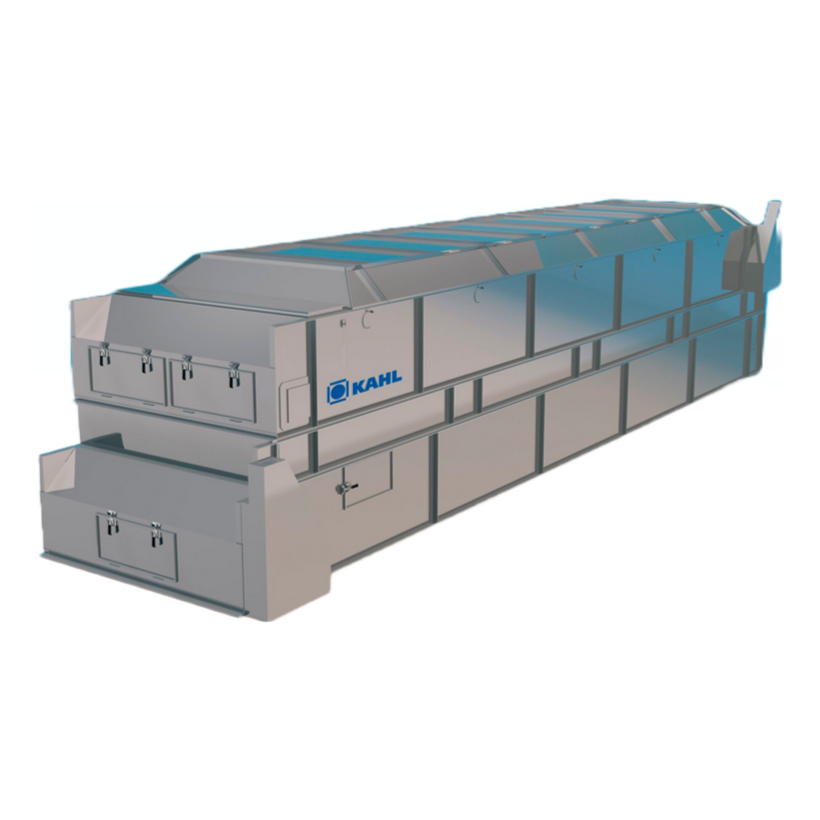

Industrial multi-pass dryer for bakery products

Ensure consistent moisture reduction and quality enhancement in your baker...

Pulsed electric field system for food preservation

Enhance your production line with technology that extends shelf life a...

Oven for high-yield cooking of prepared foods

Achieve unparalleled consistency and enhanced yield in food production with ...

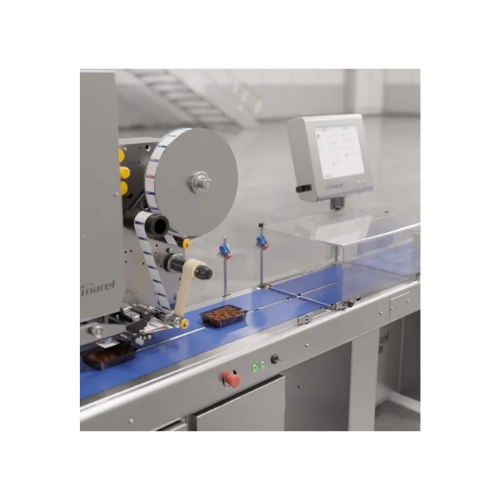

Weigh price labeler for retail food products

Achieve consistent, high-speed labeling and pricing with precision—streamlini...

Industrial fryer for uniformly cooked convenience foods

Ensure perfectly fried textures and flavors with cutting-edge oil...

Root crop peeler for high-volume processing

For efficient root crop processing, this robust peeler, washer, and scrubber e...

Potato chip production line

Achieve consistent, high-quality potato chips with a seamlessly integrated line that optimizes e...

Optical measuring and weighing instrument for peeled potatoes

Enhance your potato processing efficiency by precisely det...

Potato diameter sorter

Efficiently sort and pre-grade peeled potatoes by diameter to streamline your processing line and enha...

Industrial potato cutting system

Optimize your potato processing with precision slicing and cutting solutions designed for a...

Screw type blancher for potato products

Achieve precise temperature control and even water circulation to enhance your pota...

Steam peeling system for potatoes

Enhance your potato processing efficiency by reducing peeling time up to 25% while minimi...

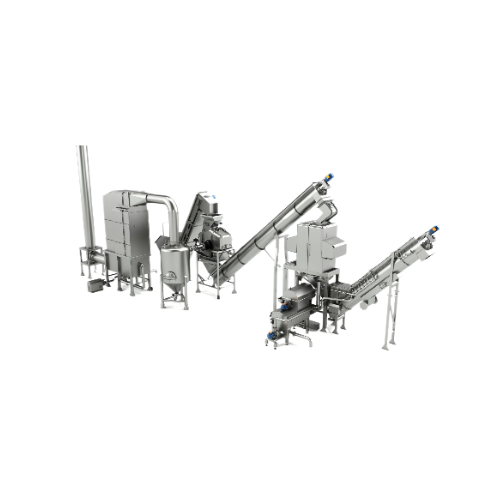

Industrial potato flake production line

Maximize yield and quality in potato processing by integrating advanced pre-cleanin...

Formed mash processing line for potato products

Optimize your potato processing with this versatile line, designed for hig...

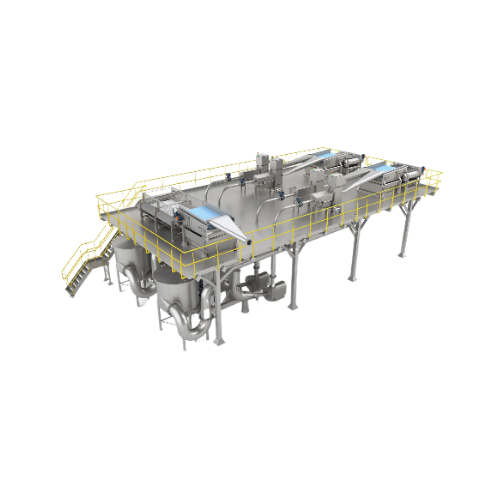

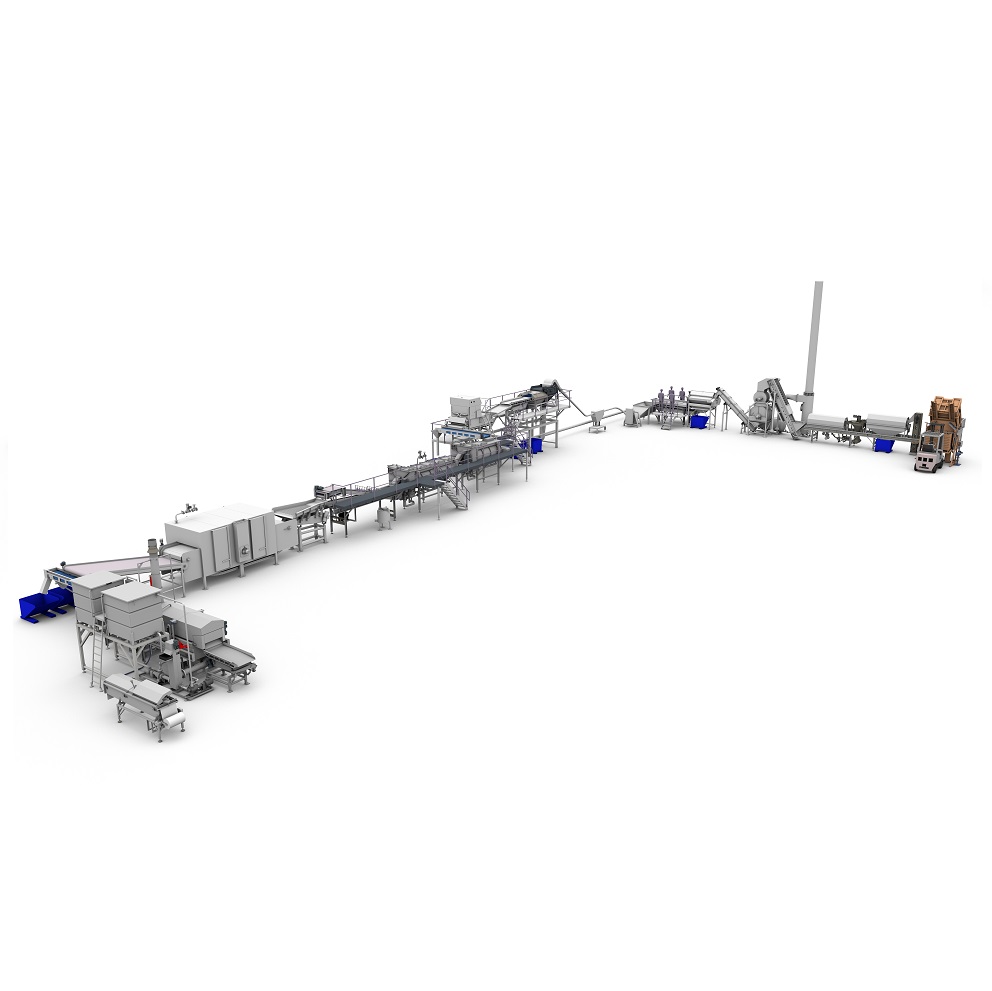

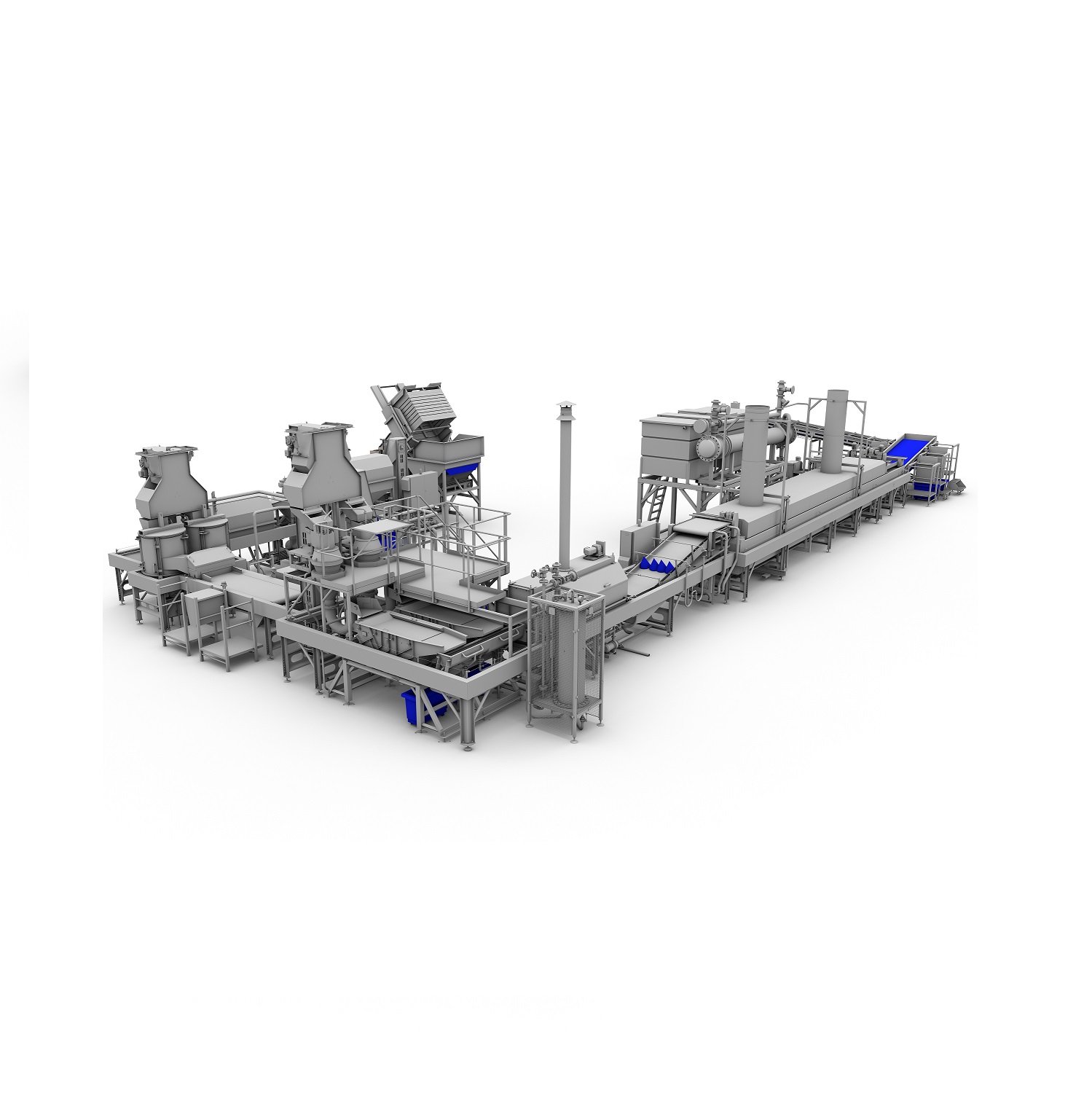

French fry and coated french fry processing line

Optimize every potato’s potential from pre-cleaning to frying with ...

Hash brown production line for formed potato products

Optimize potato processing with this advanced production line, tran...

Industrial cutting solution for potato products

Optimize your potato and vegetable processing with a versatile cutting mac...

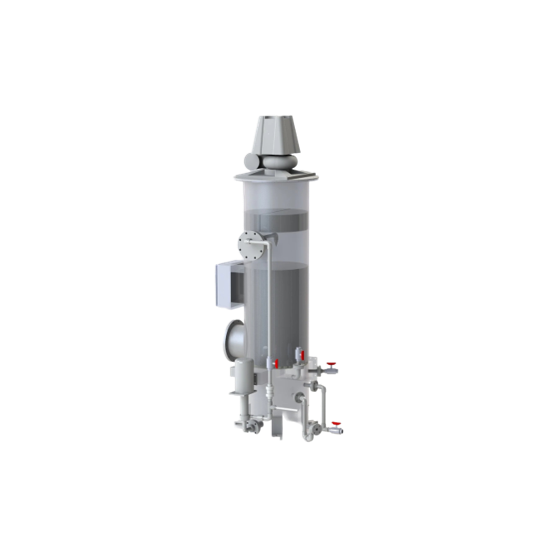

Cyclone destoner for removing stones and clods

Ensure optimal pre-cleaning by removing stones and clods from potatoes effi...

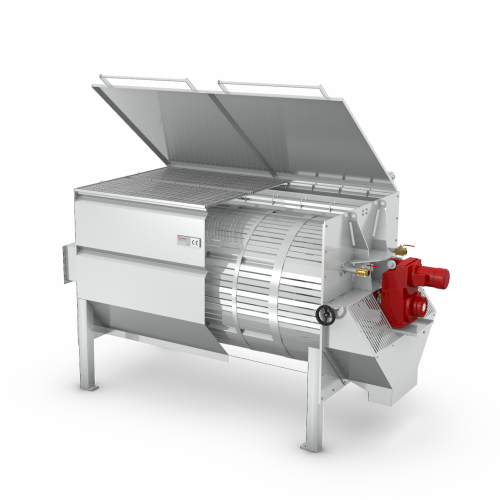

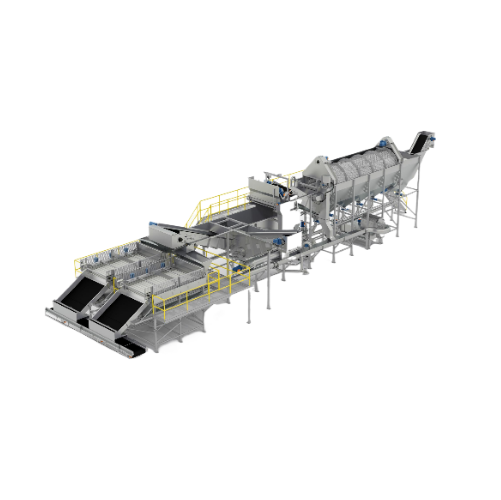

Potato drum washer for soil, clay, and sand removal

Ensure your potato processing line efficiently removes soil, clay, an...

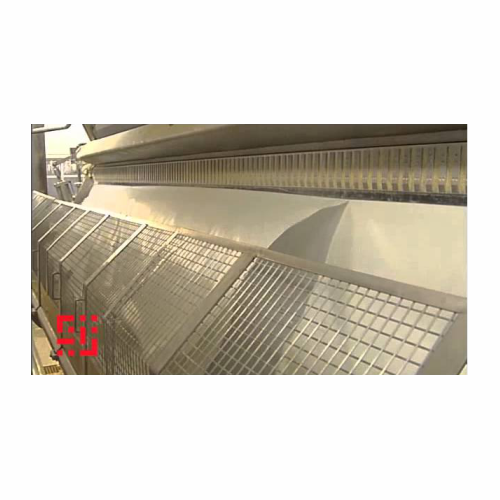

Dry brush system for potatoes after steam peeling

Optimize your potato processing by ensuring consistent peel removal aft...

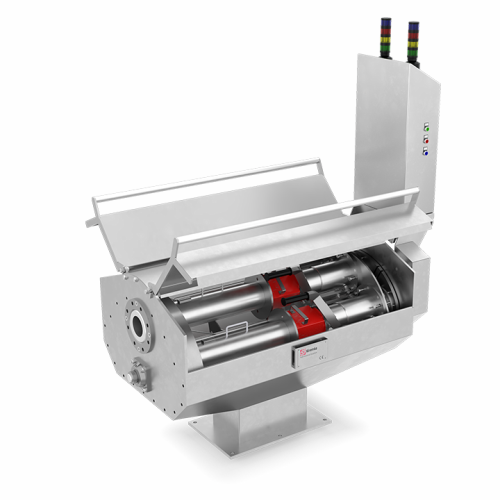

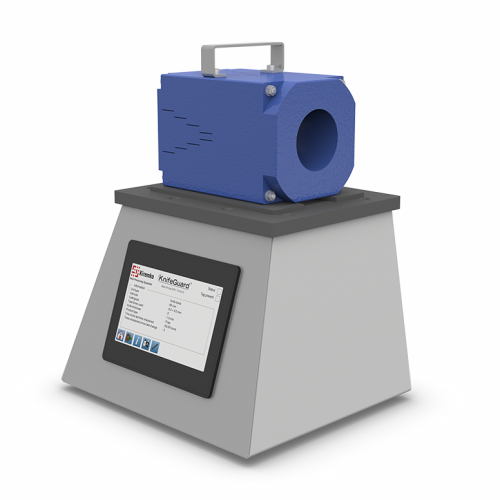

Innovative knife identification system for quadraflow hydro cutter

Ensure optimal cutting performance and minimize prod...

French fry length grader

Efficiently sort and standardize your potato products by length, optimizing your french fry producti...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

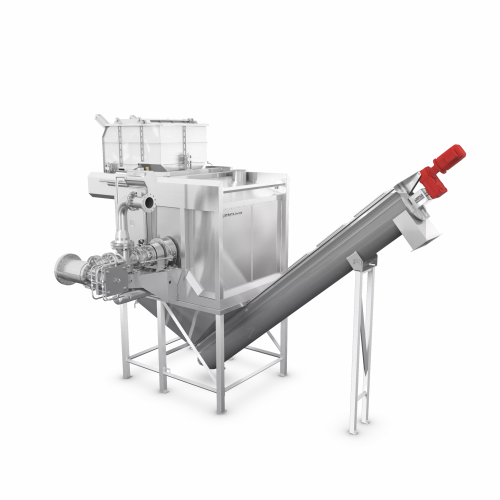

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

Industrial transfer conveyor system

Efficiently transport and sort diverse food products with precision, ensuring seamless ...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

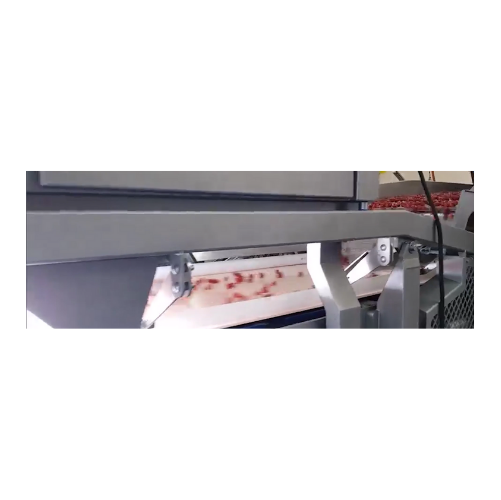

Automatic defect removal for french fries

Maximize yield and enhance quality in potato strip production with precision cut...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

Vertical packaging for leafy greens

Optimize your packaging line with high-speed vertical systems designed for precise pack...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

Compact continuous fryer for food service applications

Streamline your frying operations with a compact continuous soluti...

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

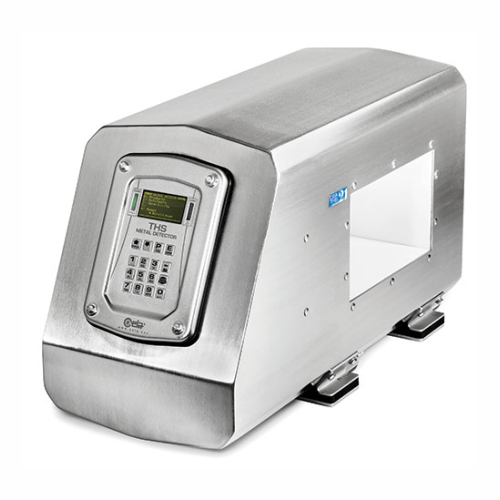

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Truck dumping system for unloading bulk potatoes

Optimize unloading with precision-tilted truck dumping, reducing product ...

Vertical screw elevator for potato processing

Efficiently elevate and separate your produce while minimizing space with ou...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Potato chip production slicer feeder

Ensure optimal slicing and consistent chip quality with a feeder that delivers a stead...

Batter applicator for poultry and seafood

Achieve consistent, even coating of batters and marinades for a variety of food ...

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

Potato product surface oil removal system

Efficiently remove excess surface oil from fried potato products, enhancing prod...

Potato slice washer conditioner

Ensure consistent texture and color in your potato chips by precisely controlling washing an...

Continuous fryer for prepared foods

Effortlessly achieve uniform frying with precise temperature and conveyor speed control...

Thermal fluid heated fryer for prepared foods

Achieve precise, uniform frying with thermal fluid technology, ensuring each...

Oil cooling module for industrial fryers

Quickly cool frying oil to prevent thermal shock and maintain oil quality, allowin...

Industrial oil mist eliminator

Optimize your frying operations with efficient oil mist control, minimizing emissions and vir...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Gentle-flo storage and handling system for fresh produce

Ensure gentle handling and precise control of fresh produce stor...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Inspection conveyor for potatoes and vegetables

Streamline your defect removal and trimming process with a conveyor system...

High-efficiency heat exchanger for fryer systems

Optimize your frying line’s efficiency and environmental impact by ...

Crate dumper for potatoes and fresh produce

Ensure consistent produce flow with a robust hydraulic tilt system that stream...

Electroporation system for potato products

Optimize your potato and snack food production with an electroporation system t...

Slicer infeed conveyor for potato products

Enhance slicing efficiency by smoothly feeding potatoes into multiple slicers, ...

Multihead weigher for precise bulk product weighing

Optimize your weighing operations with highly accurate multihead tech...

Multihead weigher for food processing

Enhance production efficiency and accuracy with multihead weighing technology, offeri...

Ambient air cooling system for food products

Achieve precise cooling control with high-speed ambient air cooling systems, ...

Batch frying system for kettle-style potato chips

Achieve consistent, high-quality kettle-style potato chips with a syste...

Batch peeler for potatoes and root vegetables

Optimize your vegetable processing with precise peeling and polishing, ensur...

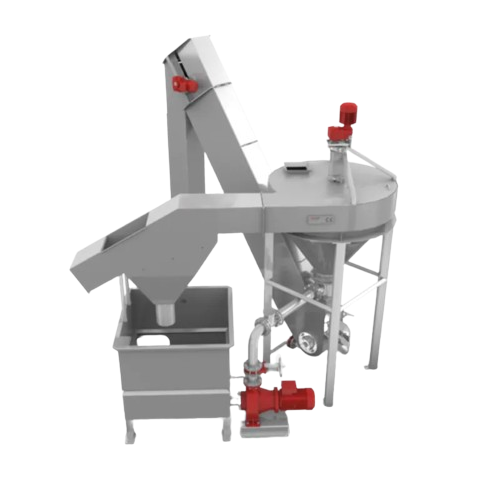

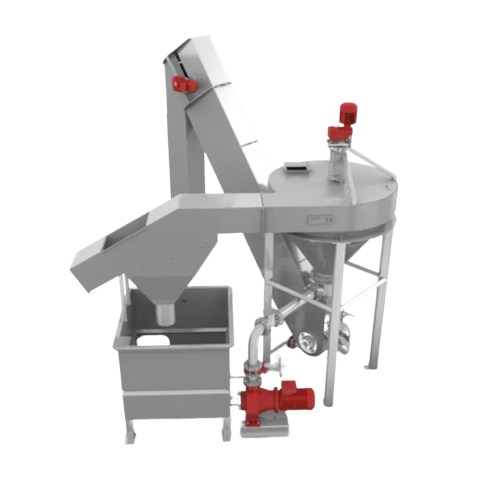

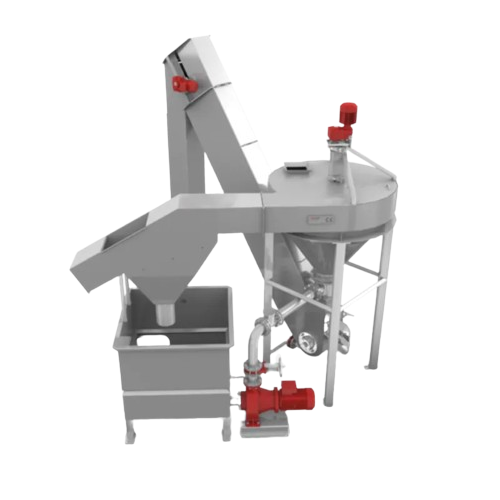

Batter coating preparation system for potato products

Achieve consistent batter quality with a high-capacity, continuous ...

Drum dicer for french fry processors

Achieve precision in cutting fresh and frozen produce, maintaining optimal shape and s...

High-capacity tomato dicer

Achieve high-capacity precision dicing of tomatoes and minimize juice loss with cutting technolog...

V-belt slicer for meat and fish

Achieve uniform, high-quality slices with minimal waste for any long- or oblong-shaped produ...

High-capacity belt dicer for meat and poultry

Enhance your processing line’s versatility with a solution engineered ...

Belt-fed dicer for meat and poultry products

Maximize your production efficiency with a high-capacity, belt-fed dicer idea...

Vegetable and fruit dicer

Achieve uniform cuts and reduce waste in your food processing line with a versatile dicer designed...

Cheese dicer for precision cuts

Streamline your cheese processing with unparalleled precision and versatility, ensuring clea...

Knife honing equipment for industrial use

Enhance blade precision with minimal effort and cost, ensuring your cutting tool...

Flat-belt slicer for fruits and vegetables

Optimize your slicing process with a solution that delivers precision cuts whil...

Strip cutter for recovering defective fries

Enhance your potato processing line efficiency by transforming rejected strips...

Honing tool for hydrocutting blades

Maintain the sharpness and precision of your hydrocutting blades effortlessly with this...

High-capacity cheese dicer with sanitary design

For high-volume cheese producers, achieving consistent cube cuts without p...

V-belt slicer for larger diameter leafy vegetables

Optimize your slicing operations with high-speed, precision cutting fo...

Potato slicer with dual rotation technology

Revolutionize your slicing process with dual rotation technology, ensuring gen...

High-capacity dicer for frozen and large fresh vegetables

Optimize your vegetable and protein cutting processes with thi...

Centrifugal shredder and slicer for vegetables and fruits

Achieve precise slicing and shredding with reduced waste and e...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

High-capacity shredder for cheese processing

Achieve impeccable cut accuracy and consistent shred dimensions for high-volu...

Cheese shredder for high-volume applications

Streamline your cheese processing with a high-capacity shredder designed to d...

Full block cheese shredder

Maximize your production line’s efficiency with a versatile shredder that seamlessly proces...

Compact pulsed electric field treatment for french fries

Reduce oil absorption and enhance product texture with this inno...

Pulsed electric field treatment for roots, tubers, and fruits

Enhance your production line with advanced pulsed electric...

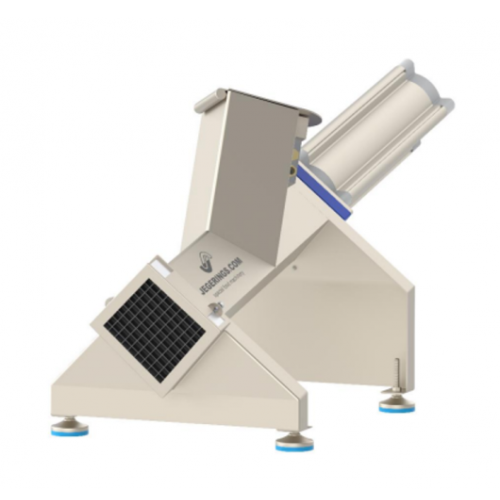

Cell disintegration measurement tool for food products

Ensure precise measurement of cell disintegration across food prod...

Modular pulsed electric field system for food processing

Enhance your food processing efficiency with a modular system th...

Precision quality control for potato and vegetable cutting

Optimize cutting precision and improve product quality by ins...

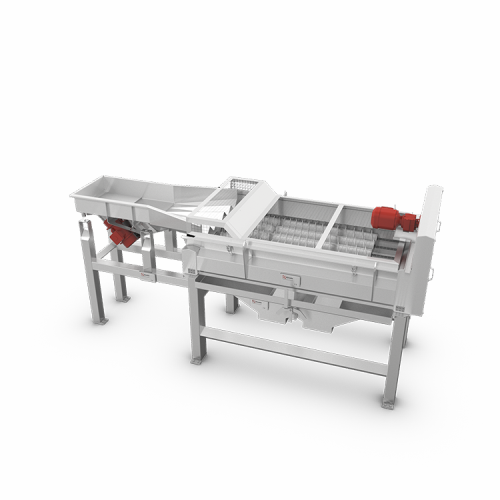

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Gravitational destoner for potatoes

Efficiently remove unwanted stones and debris from your potato and vegetable processing...

Drum washing system for tubers and roots

Ensure thorough cleaning and desoiling of tubers and root vegetables with a high-e...

Abrasive peeler for potatoes

Efficiently remove peels from potatoes and vegetables with abrasive rollers designed to enhance...

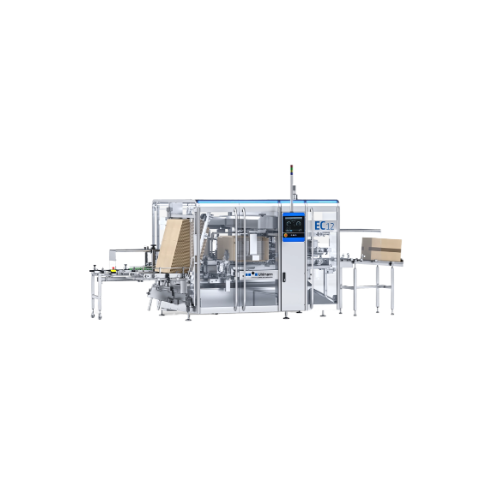

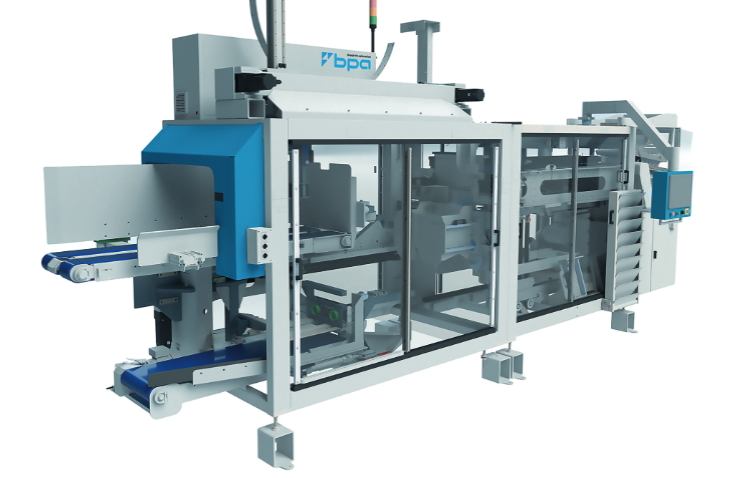

Automatic case packer for frozen potato products

Efficiently pack frozen and delicate products with precision side-loading...

Dicing solution for fruits and vegetables

Optimize your ready-prepared food production line with a versatile cutting solut...

Force flow hot oil filter for food processing

Upgrade your frying oil filtration with a system that removes particulates d...

Industrial fryer for pork, poultry, and seafood

Enhance your production line with a fryer that ensures consistent, high-qu...

Industrial food processing fryer

Ensure consistent frying quality and enhanced sediment removal for high-volume food product...

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

Vertical form-fill-seal packer for frozen vegetables

Efficiently streamline your packaging line with a versatile solution...

Industrial tunnel freezers for french fries

Ensure optimal freezing performance for high-capacity potato products, minimiz...

Continuous deep fryer for industrial production

Optimize your fried product line with precise control over frying time and...

Segment cutter for potatoes and carrots

Achieve precise cuts on vegetables like carrots and potatoes with minimal featherin...

Watergun cutting head for high-volume operations

Optimize your processing line with this precision watergun cutting head, ...

Potato cutting line for high-quality potato products

Achieve precise cuts and optimized yields in potato processing with ...

Potato peeling line

Optimize your peeling process with precision steam technology that reduces peel loss and enhances product...

Industrial potato washing line

Optimize your potato processing with a versatile washing line that ensures thorough cleaning,...

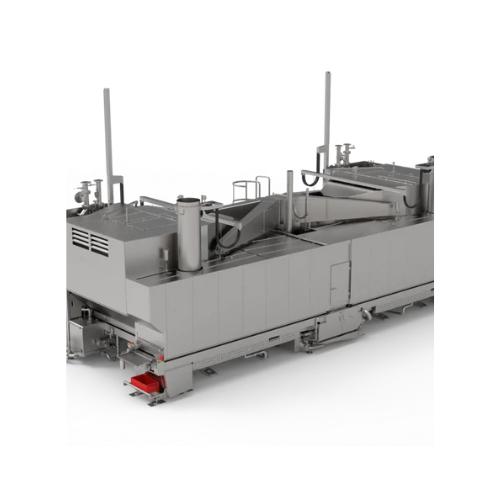

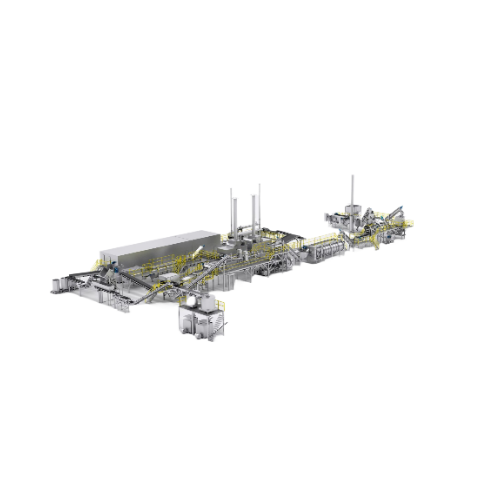

French fry production line

Optimize your French fry production with a seamless line that ensures precise cutting, consistent...

Pneumatic potato cutter for precise slicing

Achieve consistent and precise cuts for high-volume potato processing with pne...

Belt sorter for potatoes and leafy vegetables

Enhance the precision and efficiency of your sorting process with a system d...

Steam peeler for vegetables and fruits

Optimize your food processing with a versatile steam peeling solution that efficient...

Advanced food sorter for tomatoes and peaches

Achieve precise sorting and defect removal for a variety of food products, e...

French fries cutter for root vegetables

Achieve precise and uniform cuts for potatoes and other root vegetables with this p...

Small fryer for fried food processing

Enhance your frying efficiency with an advanced water-oil mixing system that reduces ...

Fast potato slicer for cutting potato chips

Optimize your potato chip production with this high-speed slicer, designed for...

Small scale potato chips production line

Optimize your small-scale snack production with a versatile solution that seamless...

Industrial food freezer for instant freezing

Experience rapid and reliable food preservation with our industrial food free...

Multifunctional fruit slicer for apples, bananas, and pineapples

Enhance your food processing capabilities with a versat...

Fully automatic electric heating frying system

Streamline your frying operations with a versatile system that not only sav...

Fried food production line

Achieve consistent quality in fried snacks with this integrated production line, streamlining pro...

Semi-automatic frozen french fries production line

Improve efficiency in your production line with a semi-automatic syste...

Small deoiling machine for potato chips production

Enhance your snack production line with rapid deoiling and dewatering,...

Storage bunker for potatoes and onions

Optimize storage and feeding efficiency for potatoes, onions, and carrots, while ens...

Root crop screw destoner

Efficiently remove stones from root crops with this screw destoner, ensuring clean produce while min...

Spiral roller grader for peeled potatoes

Achieve precise size grading for peeled potatoes with a spiral roller system that ...

Root crop submersion system

Achieve precise control over submersion times for root crops and vegetables, ensuring uniform so...

Energy recovery unit for potato chips production line

Manufacturers of French fries and potato chips require a lot of ene...

French fries processing line

Mass-producing french fries from raw potatoes requires a series of steps and various equipment ...

Flavouring system for healthy rice cakes and snacks

Being active on the market for healthy popped snacks asks for a flexi...

Potato chips production line

The key to making a flavorful and crispy bag of potato chips is the frying temperature within t...

Frozen food automatic case packer

Adequately packaged frozen fries retain their original color, taste, and texture. And bec...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Industrial potato washer

Washing potatoes or other vegetables can be a time consuming task for large restaurants or other foo...