Making Lipstick

Find innovative production technology for making lipstick and connect directly with world-leading specialists

In America was estimated that $1,780 is the number that an average woman spends on lipstick during her life. Putting color on your lips apparently comes at a price and it is $1,780. Making lipstick involves pigment milling, melting of waxes, mixing of ingredients like oils and alcohol, molding and last but not least filling and packaging. Besides ingredients, what lipstick making equipment do you need?

Tell us about your production challenge

Formulation of lipstick for color, fragrance, and moisturizing effect

Each ingredient that makes up the lipstick has a job to do. Waxes, the base for its solid structure, are mixed with oils that help the lipstick last longer – did you know that oils are actually the ingredient that differentiates lipstick from crayons?

Then it is made of preservatives and antioxidants that work to inhibit oxidation and prolong its shelf life and emollients provide that moisturizing effect when applied to the lips.

Lipstick making equipment to get the right mixture

When making lipstick, ingredients are melted in separate vessels – one for waxes, one for oils, and one for the solvents. Lipstick making equipment involves first a roll mill to create the pigment mass by grinding together oils and solvents with the combination of pigments of your choice. To mix the pigment mass with the base wax you can use a steam-jacketed kettle with an agitator to remove air bubbles until you get uniform color and texture.

Once preservatives and fragrances are added, you can shape the lipstick mixture in a vertical mold at a temperature of 35 °C. After being cooled down and taken out of the mold, sticks are flamed to give the lipstick a shiny appearance before capping it and ready for packaging. Think that the cylindrical shape has existed since 1915 since Maurice Levy invented the cylindrical container while in 1923, the first swivel-up tube was patented.

Stability in organic and inorganic pigments

It’s not what you think. In this case, the term organic refers to the chemical structure of pigments and not any positive meaning related to healthy food or products. Organic pigment are based on carbon chains and carbon rings, so it means that they contain carbon atoms. They are made up of dyes and lakes. These carbon-based particles are smaller than those of inorganic pigments. This makes them more unstable and they can move around on the skin. Inorganic pigments are not carbon-based and are made up of mineral compounds such as iron oxides or titanium dioxide. The difference in the particle size is also the reason why most organic pigments are considered transparent and most inorganic pigments are considered opaque.

Inorganic pigments offer better UV protection and coverage due to their larger particle sizes. To help with stability, an inorganic pigment is usually added to the organic formulation. Pigments banned from lipstick and cosmetics, in general, are very different across the countries. For example, the EU has banned 1328 chemicals while US only 30. Several coal tar dyes are prohibited in Europe and also in Canada, but the US still allows the use of coal tar in cosmetic products and lipstick is one of them.

Where does the red lipstick color come from? Bugs. Say what?

We can’t deny that red lipstick will always be the color, even with the millions of available shades. It might surprise you that back in the 19th century, the red color used in lipstick was made from carmine dye. This natural red dye is extracted from a cochineal insect that produces carminic acid, the bright red color used in lipstick. Of course, to get the color out of the bug, you have to kill the insect, the pregnant female precisely. To produce 500g of dye, the number of cochineals you need is 70,000. This natural dye has recently reappeared as a natural alternative to other carcinogenic synthetic red dyes and is considered FDA-approved for safe use. In lipsticks that use this natural dye, it is labeled in the ingredients as “cochineal extract” or “natural red 4”.

Processing steps involved in lipstick making

Which lipstick technology do you need?

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Gas pycnometer for true density measurement of solids and powders

Achieve highly precise density measurements of solid ...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

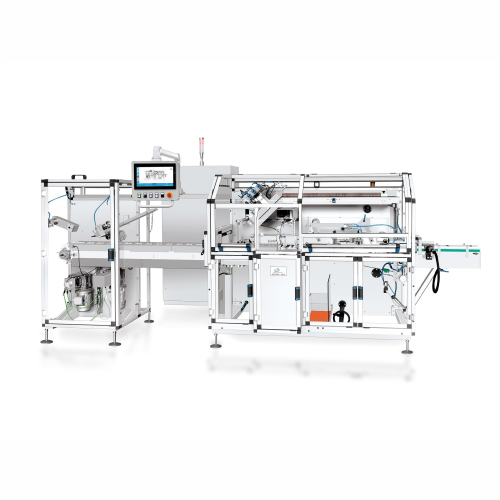

Case packer for pharmaceutical and healthcare products

Streamline your packaging line with a versatile case packer design...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Automatic carton overwrapping solution

Enhance your packaging line’s efficiency with a machine that seamlessly overwr...

Automatic top load case packer for bottles and jars

Streamline your packaging process with reliable case packing for prod...

Automatic horizontal cartoning solution

Optimize your production line efficiency with a versatile cartoning system that acc...

Automatic horizontal cartoning solution for various products

Optimize your packaging line with this advanced cartoning s...

Automatic vertical cartoning solution for jars and bottles

Streamline your production line with a versatile packaging so...

Metal tube crimping system

Optimize your packaging line with this semi-automatic system designed to efficiently crimp metal ...

Versatile industrial melter for raw ingredients

Enhance your formulation capabilities with a flexible melter designed for ...

Industrial melter for cosmetic product processing

Streamline your production with this versatile melter, designed to effi...

Pre-glued case cartoning solution

Elevate your cosmetics packaging line with high-speed cartoning, ensuring seamless integr...

Mobile melting tank for hot filling lipstick

Optimize your cosmetics production with precise melting and hot filling techn...

Preparation system for lipstick production in stores

Streamline your cosmetic production by transforming raw ingredients ...

Lipstick filling solution for high output production

Achieve precision and efficiency in lipstick production with advance...

Cosmetic pencil filling system

Streamline your cosmetic production with high-speed filling and precise molding capabilities,...

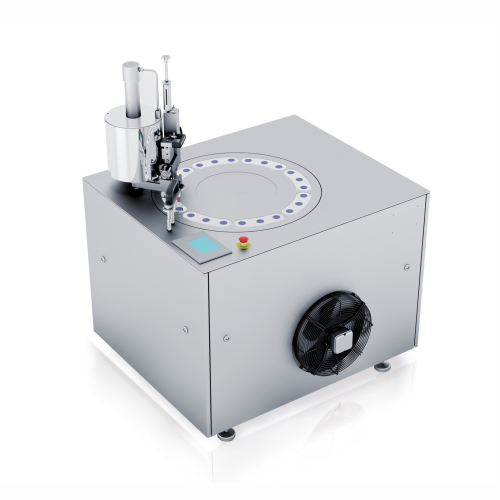

Lipstick moulding system

Achieve precision and efficiency in your cosmetic production line with advanced moulding and dosing ...

Semi-automatic lipstick moulding system

Streamline your lipstick production with a versatile system that effortlessly mould...

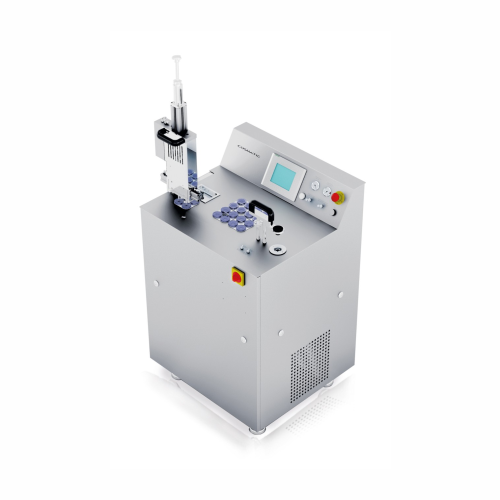

Lipstick production laboratory system

Optimize lipstick production with precise moulding and controlled temperature systems...

Lipstick packaging fit tester

Ensure precise packaging fit for lipsticks, improving product quality and decreasing return ra...

Semi-automatic screw capper for bottles and jars

Ensure your packaging line operates smoothly by seamlessly capping a wide...

High-speed rotary self-adhesive labelling system for bottles and jars

For cosmetics producers seeking precise and effic...

Laboratory demoulding unit for lipstick samples

Streamline your laboratory’s lipstick sampling process with a versat...

Continuous motion cartoning solution for diverse products

Streamline your packaging line with a versatile, high-speed ca...

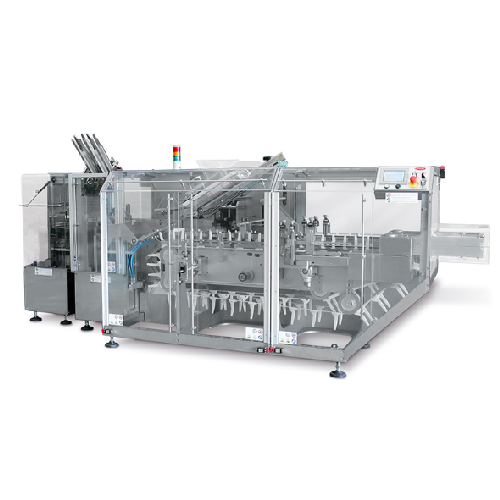

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

Automatic case packing solution for cosmetic products

Streamline your cosmetic production line with efficient case packin...

Automatic cartoning solution for cosmetic and fragrance samples

Streamline your cosmetic and fragrance sample packaging ...

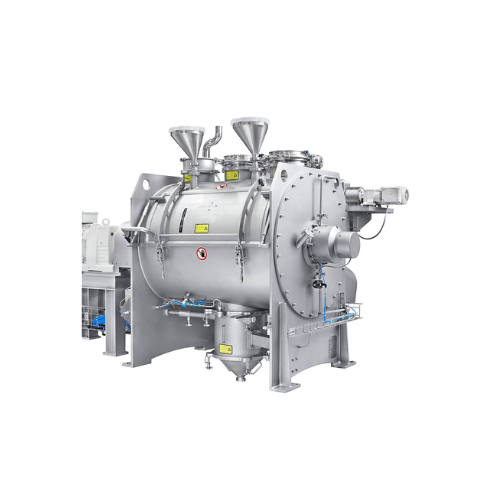

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Precision weighing tank for liquid and dry ingredient blending

Enhance your production line with precision control over ...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Volumetric filling system for cosmetic products

Streamline your production line with precise volumetric control, ensuring ...

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Pilot plant for highly viscous applications

Perfect for R&D, this pilot plant efficiently handles complex mixing and ...

Horizontal cartoner for cosmetic applications

Perfect for packaging fragile cosmetic items, this cartoner efficiently mana...

Lipstick moulding solution for cosmetics manufacturing

Streamline lipstick production with high-speed molding and flexibl...

High-speed continuous motion overwrapper for thin films

For those needing high-speed, efficient wrapping, this equipment ...

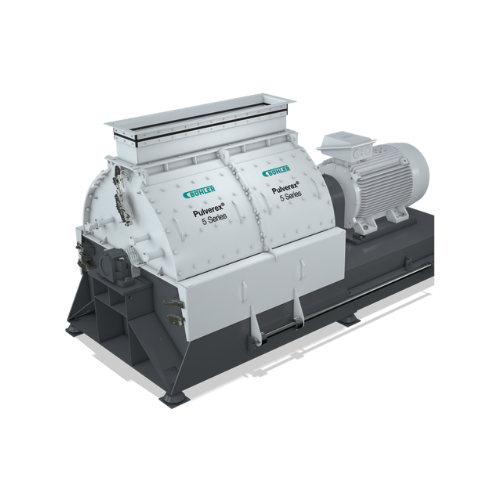

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Full-volume bead mill for wet grinding applications

Achieve superior dispersion and particle size consistency with advanc...

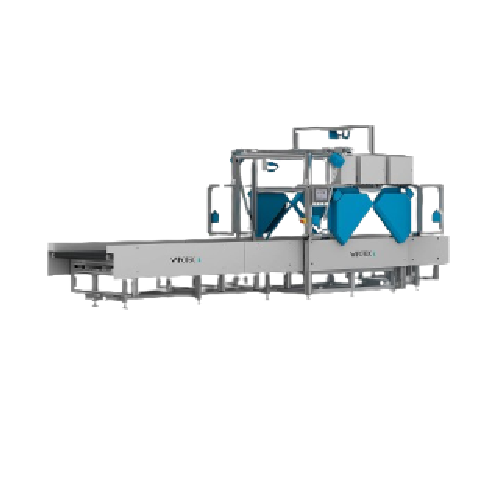

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Vertical ribbon vacuum dryer for thermosensitive products

Achieve optimal drying of thermo-sensitive materials like powd...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

High viscosity product mixer

Struggling with mixing high viscosity products like creams and gels? This co-axial mixer enhanc...

X ray inspection for unstable cosmetic products

Ensure product integrity by detecting contaminants in unstable packaging w...

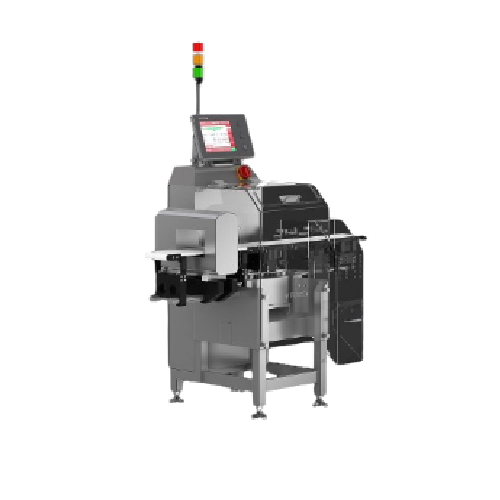

Combi x-ray inspection and checkweighing for small products

Optimize your production line’s quality control with a...

Dual lane x-ray inspection system for cosmetics

Optimize your production line with dual-lane x-ray technology that ensures...

X-ray inspection for contaminants in horizontal products

Ensure your packaged and unpackaged products are contaminant-fre...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

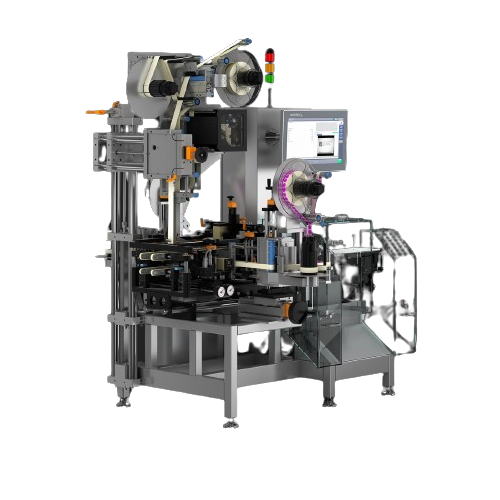

Tabletop labeler with integrated thermal printer for round containers

Efficiently label and print variable data on roun...

Compact serialisation system with tamper-evident and vignette labeler

Streamline your packaging operations with a high-...

Labeling system for shipping cases

Streamline your packaging operations with this modular system, enhancing precision and e...

Compact x-ray scanner for foreign body detection

Ensure product quality with a space-saving x-ray scanner designed for hig...

Dimensioning and weighing system for package handling

Optimize your package handling operations with a system that precis...

Checkweigher with integrated metal detector for food industry

Ensure comprehensive quality control in your production li...

High-efficiency disperser for viscous products

Achieve precise control over the mixing and dispersing of high-viscosity ma...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

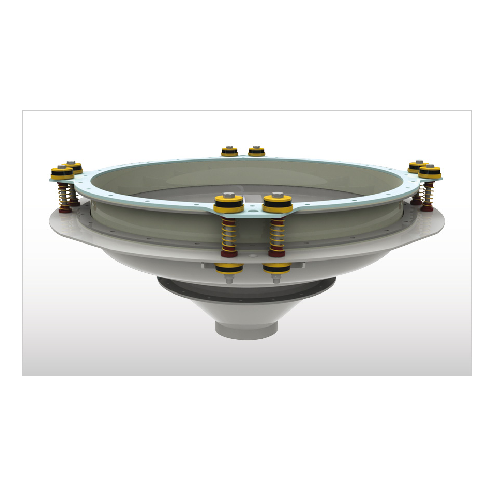

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Explosion-proof dissolver for production applications

Ensure safety and efficiency in volatile environments with a robust...

Explosion-proof dissolver for chemical processing

Ensure safe and efficient dispersion in volatile environments with this...

Adjustable industrial mixers for thick product blending

Experience precise blending and control for thick and high-viscos...

Vacuum homogenizers for cosmeto-pharma and fine chemistry

Bring precision and efficiency to your formulation processes w...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

Explosion-proof vacuum dissolver for high viscosity applications

For operations requiring precise control in high-viscos...

Miniature sensor for pressure and temperature monitoring

Enhance production reliability with a compact sensor that ensure...

Homogenizer for high viscosity liquids and solid suspensions

Struggling with homogenizing high-viscosity ingredients and...

Industrial tank mixer for high-volume containers

Optimize your mixing processes with a robust solution designed for high-v...

Industrial container mixing system for high viscosity media

Effortlessly blend high-viscosity liquids and slurries with ...

Horizontal cartoning machine for medium to high-speed production

Optimize your cartoning process with precise loading an...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Entry-level texture analysis system for Qc applications

Perfect for quality control labs, this portable system streamline...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

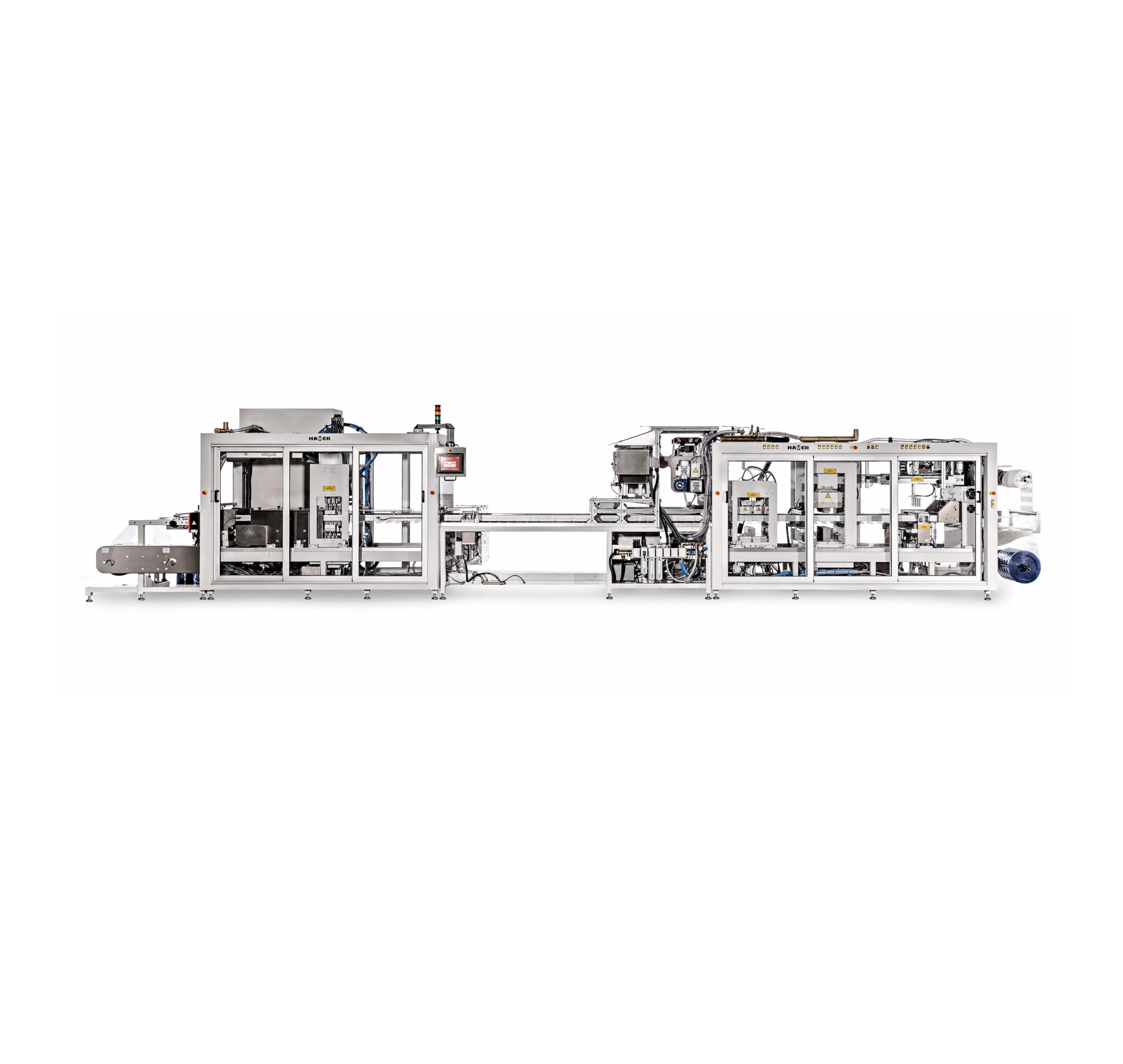

Process integration for pharma industry

Enhance your production line with seamless process integration, ensuring accurate l...

Ultra-compact case packer for consumer goods

Maximize efficiency on your production floor with a compact case packer desig...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Automatic blister sealing machine for retail products

Blister packages for retail are usually designed with a paperboard ...

Industrial blister packaging machine for retail products

A blister can be simply defined as a type of packaging that cons...

Automatic lipstick filling machine

Lipsticks, lip balms and lip glosses are very popular cosmetic products that require hig...

Automatic blister packaging machine

Automated blister packaging is a popular choice for pharmaceutical production thanks to...