Making Frozen Pizza

Find innovative production technology for making frozen pizza and connect directly with world-leading specialists

Let's face it. No one can resist craving pizza for more than a couple of days. And in fact, cosmonaut Yuri Usachov didn't even make it while in orbit and received a pizza delivery through a rocket. Frozen pizza making process involves first creating the dough, allowing it to rise, and cutting it into the typical pizza shapes. After choosing sauces and toppings you prefer, you can let your pizzas cool in a spiral freezer.

Stories about frozen pizza

Select your frozen pizza process

Tell us about your production challenge

It’s pizza time – How to make frozen pizza

It’s been a while since Joseph Bucci filed the first official patent for frozen pizza and was trying to figure out how to get rid of the excess moisture coming from tomato sauce. Since then, the frozen pizza market has grown more and more to be valued at USD 19.6 billion in 2019. Pizza consists of a flattened bread dough traditionally topped with tomato sauce, mozzarella, and oregano. Flour, water, sugar, salt, yeast, and olive oil are mixed together and kneaded to create the dough.

The dough is then left to rise typically for 10-15 minutes at 25-40°C. After rising, a sheeting machine flattens the dough (1 inch thick). To prevent air pockets from forming in the dough, stainless steel spikes make small holes in the dough.

A roller with round shapes cuts the dough, creating the pizzas, and the leftover dough is mixed again with fresh dough. After baking the pizzas for 5 minutes at 180 to 280°C, you can add your favorite toppings and sauces. Now, cool the pizzas for about 25 minutes below 20 degrees in a spiral freezer. All that’s left is to apply a plastic wrap using an overwrapping machine and then an arm will place the pizza in the pizza box. Enjoy!

Can pizza be your favorite vegetable?

Of course, it can! Even the frozen pizza market is paying more attention to the demand of consumers who are increasingly looking for a plant-based diet. The first step was to find an alternative to animal-based toppings, swapping meat for plant-based meat or dairy products such as mozzarella or cheese for vegan cheese. But producers didn’t stop at the toppings. They went deeper, thinking of new ways to revolutionize the pizza crust itself.

So you start with cauliflower-based pizza crust, which has less sugar and more fiber than traditional pizza, and end with hemp seed pizza crust. Hemp is considered a superfood because it is a complete source of plant-based protein; plus it can provide you with the necessary fatty acids like Omega-3 and Omega-6 that your body cannot produce from scratch on its own.

Why does frozen pizza taste different from fresh pizza?

Well, we certainly can’t expect a frozen pizza to taste the same as freshly made pizza from a pizza maker in a restaurant. But over the years, many manufacturers have tried to get as close as possible to the flavor of fresh pizza, trying to improve the frozen pizza making process. In the international patent WO2003001917A1, the inventors explain some reasons why the two pizzas taste different and provide a method for creating a frozen pizza that is more like a fresh one.

For example, one reason they explain is a difference in oil used in the two processes. Fresh pizza is baked in a tray containing a much higher oil content than frozen pizza. This causes the fresh pizza to have a crispy and gold base that tastes better. In some manufacturing processes, the ball of dough is put into the pan and pressed into it as well. This means the pan can only be lightly oiled, not allowing the frozen pizza to develop the same texture as fresh pizza.

Processing steps involved in frozen pizza making

Which frozen pizza technology do you need?

Topping depositor for pizzas and baked goods

Enhance your production line’s efficiency by uniformly adding both dry ...

Dough thickness reduction system

Achieve precise dough sheet reduction with controlled thickness to enhance consistency and ...

Industrial pizza production line for bases and toppings

Optimize your pizza production with versatile equipment designed ...

Industrial cold storage solutions

Ensure precise temperature control and optimal storage conditions for a diverse range of ...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Horizontal stretch-film wrapping system for frozen food

Optimize your packaging line with a high-speed solution that secu...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

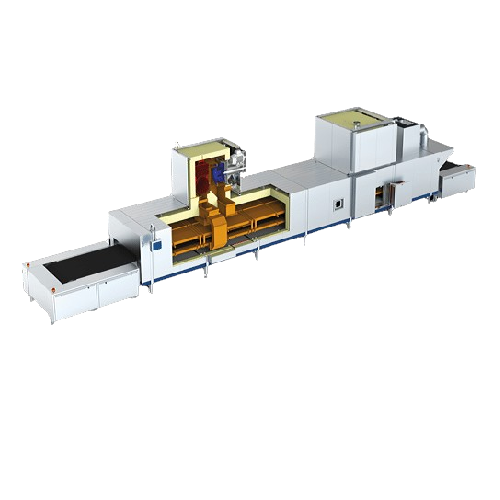

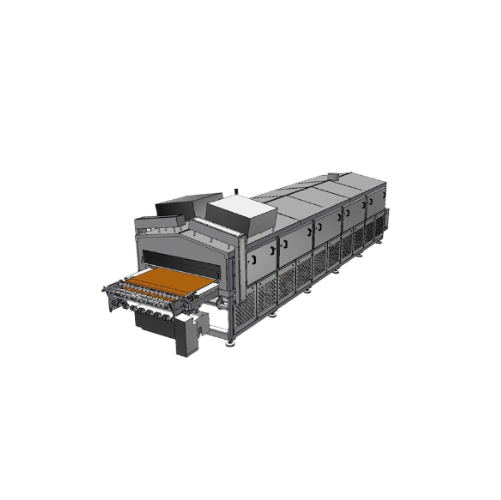

Compact tunnel oven for continuous baking

Elevate your culinary production with a tunnel oven designed for precise, contin...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic freezing systems for food processing

When you need precise and rapid freezing for diverse food products, these a...

Cryogenic food freezer

Achieve rapid and precise freezing for diverse food products, ensuring optimal texture and moisture re...

Cryogenic tunnel freezer

Achieve efficient and rapid freezing with state-of-the-art cryogenic technology, ideal for maintaini...

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Top-down inspector for food and packaging

Ensure seamless product safety and quality assurance with advanced top-down insp...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

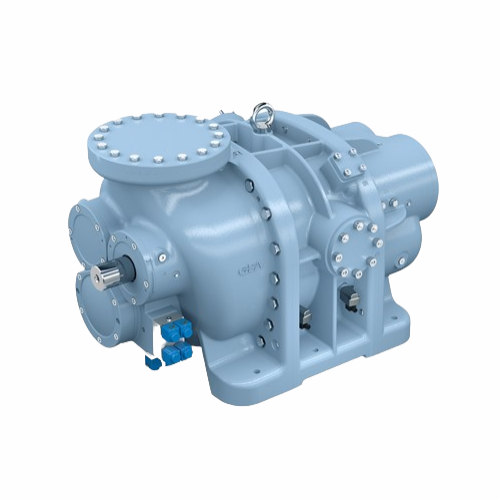

Industrial screw compressor for various refrigerants

Optimize your refrigeration systems with high-performance screw comp...

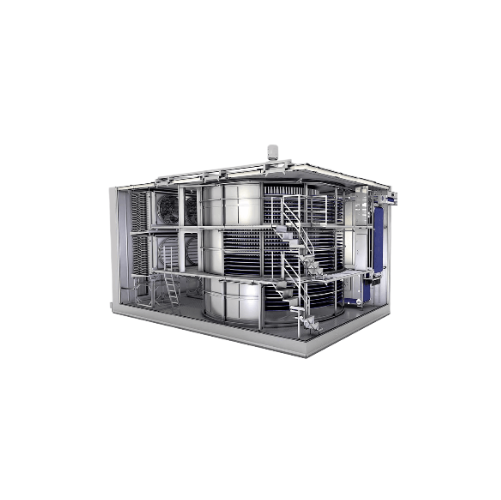

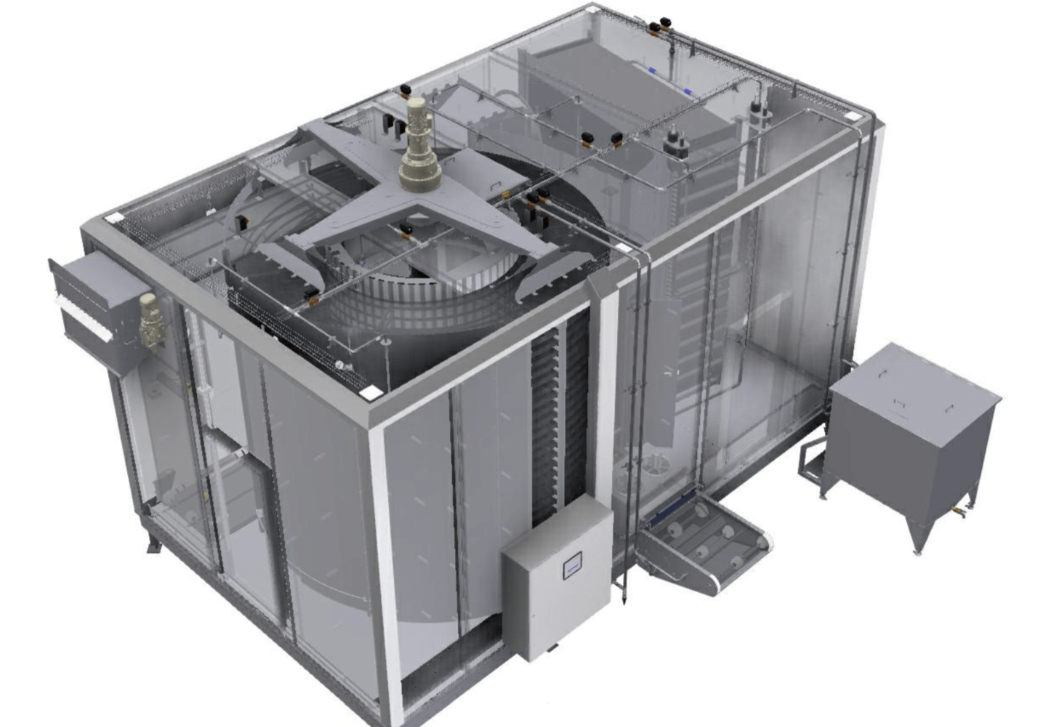

Large capacity cryogenic spiral freezer

Ensure consistent freezing quality and high yield in your continuous production lin...

Cryogenic tunnel freezer for continuous cooling

Achieve precise and efficient cryogenic freezing for continuous production...

Rotating cabinet for homogeneous cryogenic cooling

Achieve uniform and efficient cooling or freezing for diverse food pro...

Pallet lift for food processing handling

Enhance your food processing efficiency with a robust pallet lift designed for sea...

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products...

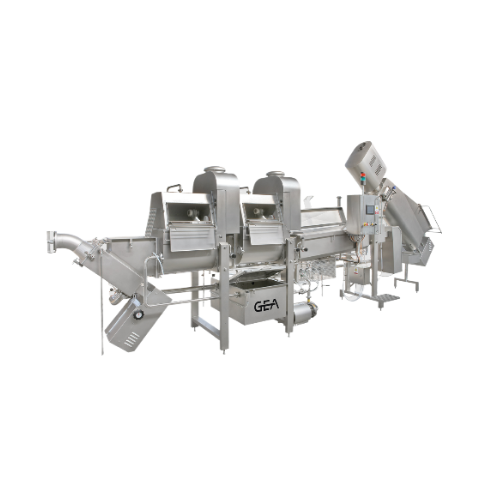

Frozen product cleaning and sizing system

Achieve precise cleaning and sizing of frozen goods effortlessly, enhancing prod...

Drum blancher for continuous cooking and blanching

Optimize your production line with a continuous drum blancher, designe...

Ultrasonic slicer for cakes and pastries

Achieve precision cuts and superior presentation with this ultrasonic slicer, desi...

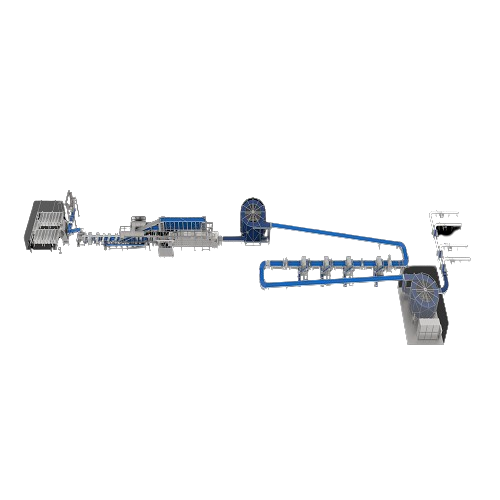

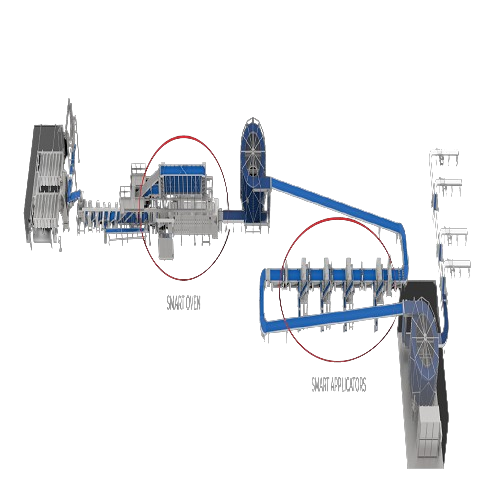

Pressed pan pizza production system

Elevate your pizza production with a system that enhances flexibility and consistency, ...

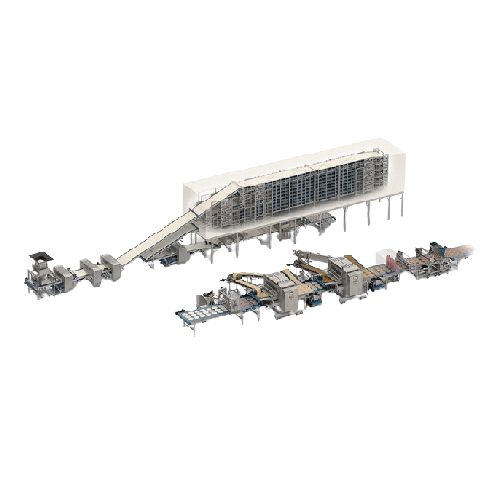

Sheeted pizza and flatbread production system

Achieve seamless integration and high-volume production of diverse baked goo...

Industrial tunnel oven for baking and step proofing

Optimize your production line with modular tunnel ovens and step proo...

Precision dough dividing equipment for bread production

Achieve unmatched precision and speed in your bakery operations w...

Industrial sheeting and laminating systems for baked goods

Elevate your bakery’s production line with cutting-edge...

Ai solutions for pizza production in bakeries

Bring unparalleled precision and efficiency to your bakery with intelligent ...

Automatic top sealing for frozen food packaging

Streamline your food packaging operations with a top sealing machine desig...

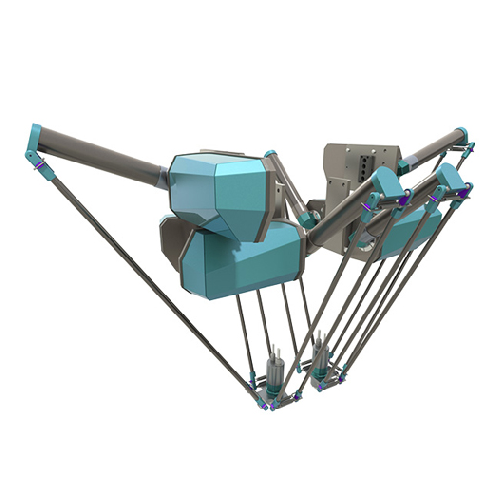

Dual-axis delta robot for high-capacity packaging lines

Enhance your production line’s efficiency with a dual-axis ...

Convection oven for uniform baking

Achieve precise, energy-efficient baking with this convection oven, offering fast heatin...

Continuous contact cooker for bottom crust treatment

Enhance dough product integrity with precise bottom heating, ensurin...

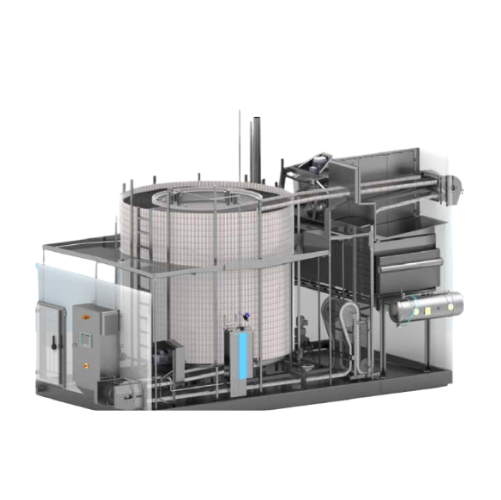

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, o...

Spiral freezer for frozen food production

Optimize your product’s shelf life and quality with advanced freezing tech...

Impingement freezer for thin product freezing

Optimize your freezing process with advanced airflow, ensuring quick and uni...

Hot water stretching and molding unit for cheese production

Revolutionize your cheese manufacturing process with a compa...

Molding and pre-hardening unit for pizza cheese

Achieve precise molding and effective pre-hardening of pizza cheeses with ...

Steam stretching equipment for mozzarella production

Optimize cheese production with advanced steam stretching equipment,...

Steam stretching system for pasta filata cheese

Optimize your cheese production with a system that seamlessly integrates s...

Customizable self-stacking solution for spiral freezers

Enhance your freezing process with a customizable self-stacking s...

Customized spiral freezer solution for food industry

Designed to enhance your freezing efficiency, our spiral solution ha...

Frozen food products control system

Ensure optimal freezing precision with a system that continuously monitors product crys...

Infrared baking oven for frozen bakery products

Accelerate your baking process by up to 70% with cutting-edge infrared tec...

High-speed infrared oven for baking frozen snacks

Enhance your bakery’s efficiency with a high-speed oven that redu...

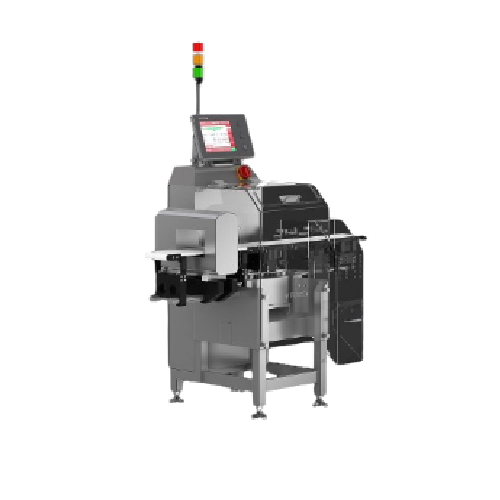

Checkweigher with integrated metal detection system

Ensure the quality and safety of your packaged foods with precise wei...

Checkweigher with integrated metal detector for food industry

Ensure comprehensive quality control in your production li...

Vertical mixing solution for bakery and snacking industry

Streamline your dough processing with robust and reliable spir...

Conveyor belts for hot and cold product handling

Efficiently transport hot and cold goods with versatile conveyor solution...

Cheese moulder for cylindrical portions

Ensure precise portioning and molding of cheese into cylindrical forms, enhancing y...

Stainless steel centrifugal pump for liquid transfer

Optimize your food and dairy production with a reliable centrifugal ...

Mozzarella cheese moulding system

Optimize your cheese production with fully automated moulding and setting, ensuring consi...

Cooking and stretching solution for pasta filata cheese

Streamline your cheese production with precise cooking and stretc...

Cooker stretcher for pasta filata cheese

Enhance cheese quality and yield with this high-capacity cooker stretcher, designe...

Conveyor belt freezer for industrial quick freezing

Ensure optimal preservation of food texture and nutrition with this a...

Flexible continuous dough processing line for bakeries

For bakeries aiming to streamline operations, this highly adaptabl...

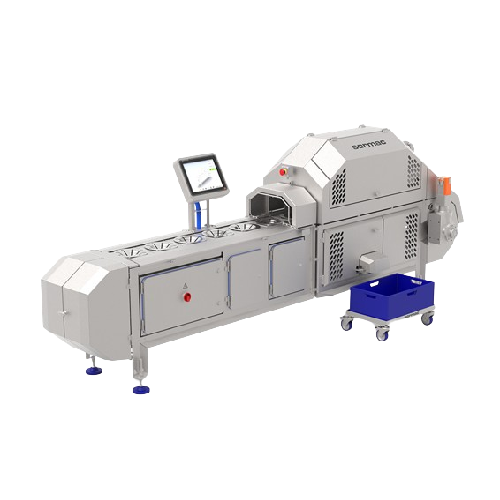

Iceberg lettuce decoring and cutting system

Optimize your salad production with precise decoring and cutting, ensuring max...

Dough mixer for high-volume bakery production

Effortlessly handle diverse dough varieties with precision using this mixer,...

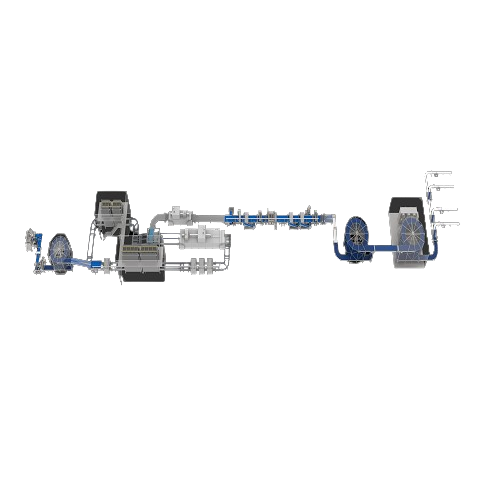

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

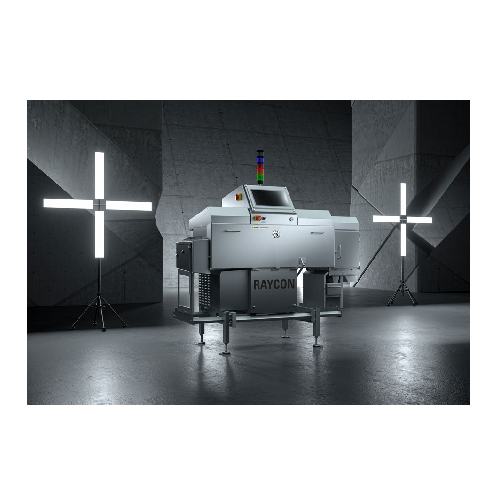

X-ray inspection system for unpackaged bulk products

Ensure product purity and safety in high-speed production lines with...

Industrial baking ovens for consistent and high-quality bread production

Achieve precise baking results with ovens engi...

Pre-dough preparation for bakery products

Streamline your bakery operations with pre-dough preparation, enhancing both dou...

Industrial freezing solutions for baked goods

For bakeries requiring precise temperature control, these systems ensure con...

Washdown Cartoner For Frozen Foods

When packing frozen foods into cartons, your packaging system should be cleaned by wash-...

Spiral cooler/chiller

Food manufacturers that produce ready meals such as pizza, burger patties, and bread require chillers a...

Spiral freezer

Frozen food manufacturers with products such as chicken parts, fish, and convenience foods require freezing pro...

Box erector and bag inserter

If you are looking to improve your throughput and eliminate labor associated with manual box er...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Horizontal dough mixer

The mixing of hard doughs or highly viscous product like chewing gum requires specialist equipment to ...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

Inline ultrasonic big scale food cutting machine

In the food industry, where accuracy in the cutting process is desired, u...

Inline ultrasonic food cutting machine

Cutting sticky products in the food sector is not always an easy process. Small scal...

Stand-alone ultrasonic medium scale food cutting machine

Accurately cutting food products in their desired shape, is a pr...

Entry-level vertical cartoner for frozen food

When it comes to frozen food, selecting quality packaging is fundamental for...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Food crates washer

With the increasing demand of food production sectors for cutting costs, while increasing quality of produ...

Mobile high speed depositor of pizza sauce

As the demand for ready-made pizzas continues to grow, businesses face tremendo...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Moulding machine for pizza

A pizza molding machine must be able to size and shape doughs suitable for pizzas and pitas. It s...

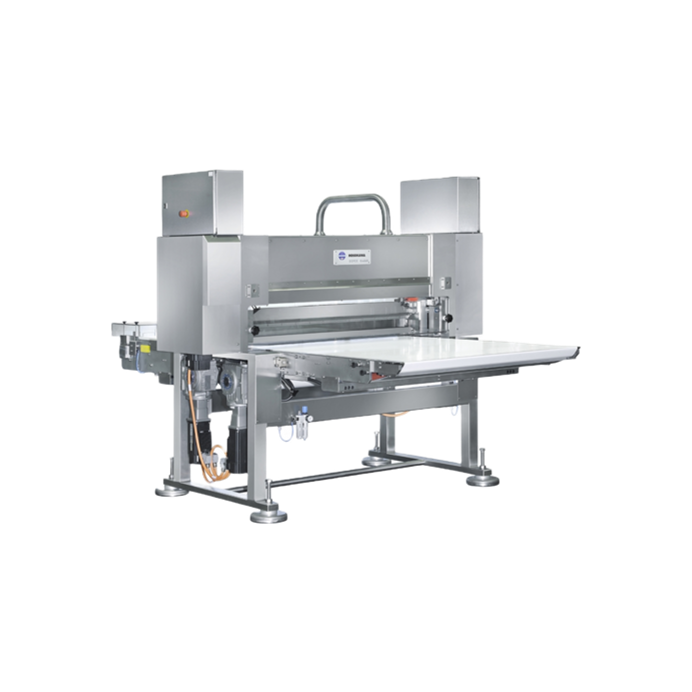

Semi-automatic dough sheeter

There is a wide range of commercial dough sheeters available, many of which are purpose-built f...

Stand-alone ultrasonic food cutting machine

For some foods such as cake, pizza, sandwiches or ice cream, the end product i...

Standalone metal detector for food

Adding advanced metal detection to existing lines can be difficult and expensive, often ...

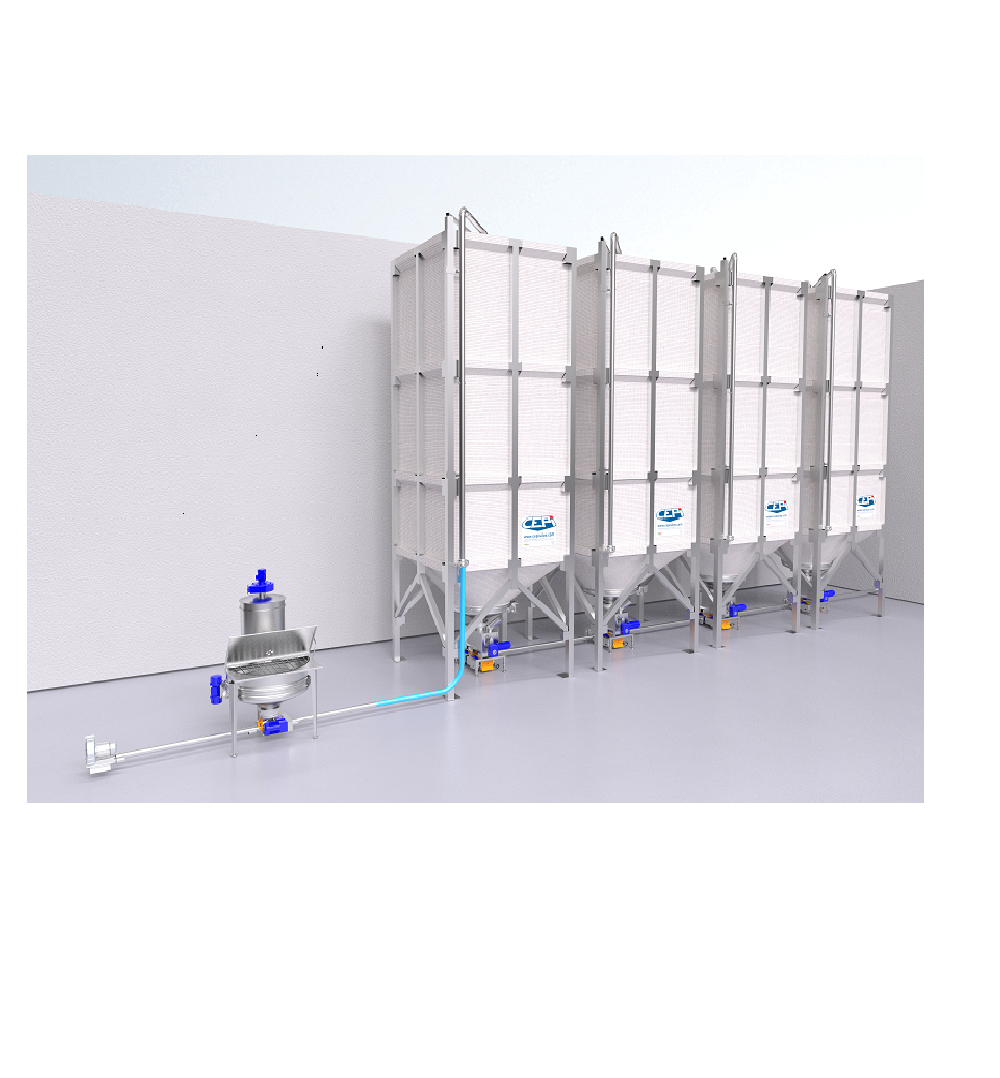

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

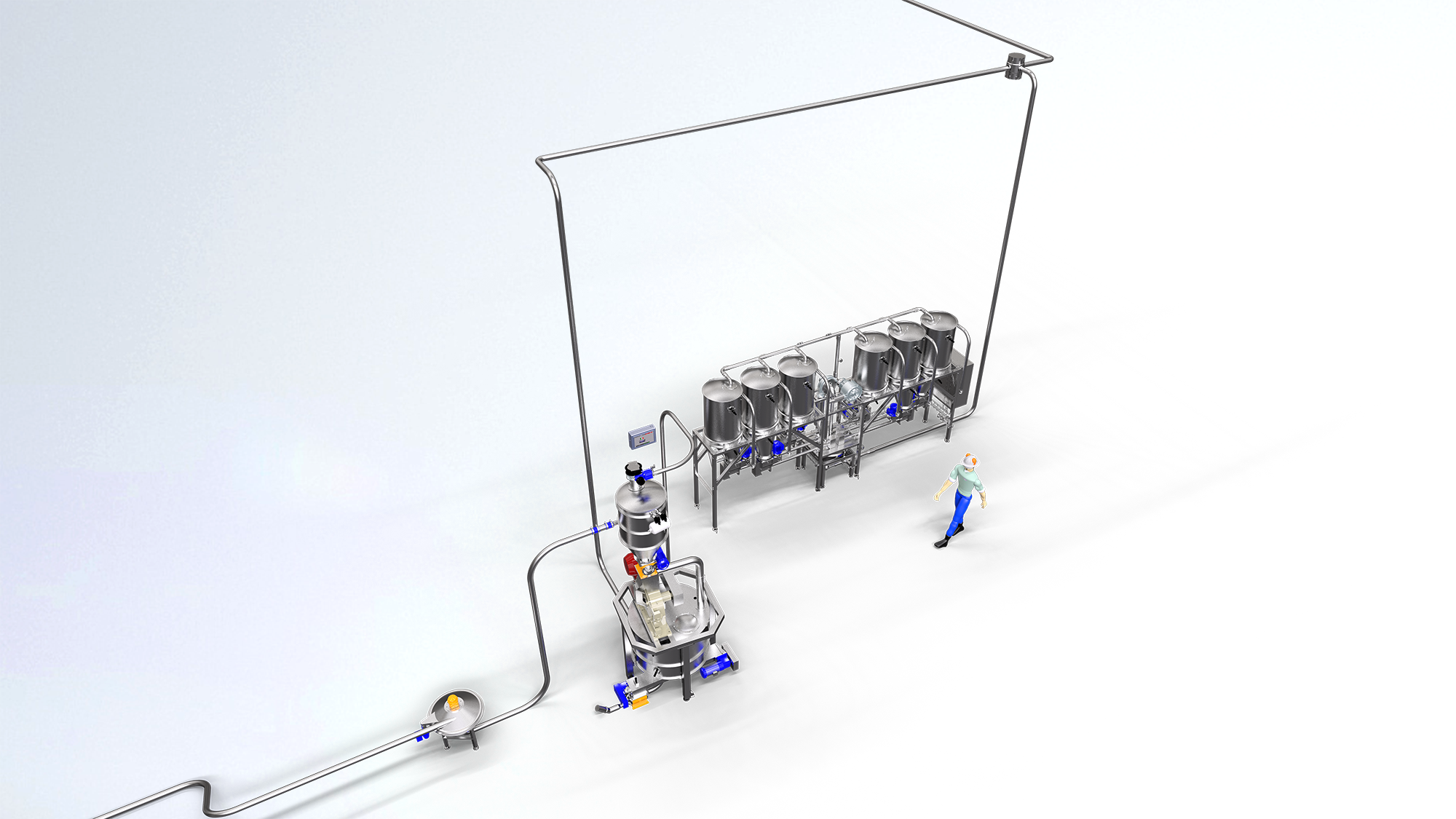

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...

Metal detection system

The inspection system automatically determines the best frequencies to maximize sensitivity for both f...