Hummus Processing Equipment

Find innovative production technology for making hummus and connect directly with world-leading specialists

Hummus processing begins by blending chickpeas, tahini, lemon juice and olive oil to create the simple yet versatile dip loved by so many around the world. To prove their love for hummus, the Lebanese, in 2010, made the largest plate of hummus that weighed over 10 tonnes! To produce hummus industrially, you need a hummus production line that includes processing equipment such as cookers, industrial grinders, pasteurizers and packaging equipment.

Stories about hummus

Select your hummus process

Tell us about your production challenge

Processing the key ingredient: soaking and cooking chickpeas

Hummus’ name in Arabic also reveals the name of its main ingredient: chickpeas. Chickpeas are also know as Garbonzo beans. Vibrating trays separate the chickpeas from contaminants like twigs, dirt and other particles and then they are transferred to conveyor belts where they are washed with water. Then it’s time for them to soak into stainless steel vats filled with water. Sometimes, manufacturers add baking soda to the water to loosen the skins. Soaking takes anywhere between 8 to 14 hours.

The chickpeas grow and swell to be twice their original size and become softer. The skins can be removed either manually or with pressurized air. After all this, the chickpeas are cooked. In the hummus production line, manufacturers use cylindrical steam cookers and large pressure cookers to shorten the long cooking process. Cooking makes them even softer and prepares them for the grinding machines to be blended with other ingredients to create hummus.

Two methods of cooking chickpeas – boiling vs cooking

There are two methods of cooking chickpeas that manufacturers employ. The first method is draining the soaked chickpeas, removing their skins and transferring them onto trays and into an industrial steam cooker. The cooker is preheated at 124°C and the cooking time is around 30 minutes.

The second method involves the stainless steel vats that the chickpeas soak in – the vats for soaking are also repurposed as large cooking pots. The chickpeas are boiled in the vats for three hours during which some of the skins float to the top and are removed. This method is time-conserving as it does not include all the various steps between soaking and cooking. However, because some of the skins remain on the chickpeas, it can result in a lumpy consistency almost like peanut butter.

Innovations in the hummus production line

Hummus is made of chickpeas, tahini and spices. When the chickpeas are mixed with tahini, the tahini reacts with the water in the chickpeas and forms bacteria if it is not refrigerated immediately or preservatives are not added. Preservatives and stabilizers are therefore essential to extend hummus’s shelf life. However, being chemicals, preservatives and stabilizers alter the true taste of hummus and make it more grainy.

To combat the use of preservatives and offer hummus fans the freshest and tastiest hummus, Alon Kruvi and Rakesh Barmecha patented a make-your-own-hummus kit. The kit consists of three pouches filled with shelf-stable ingredients of hummus – chickpea puree, tahini and spices. Stored within a container in retort pouches, the three ingredients are kept separate to prevent spoiling and require no refrigeration until mixed together.

Low-sodium hummus made easy

Hummus is rich in fiber, healthy fats and vitamin B6 and is often part of low-fat diet plans. It is also a great source of plant-based protein and dietary minerals. On the other hand, hummus has a high sodium content. High sodium intake affects blood pressure and can cause heart problems.

To cut back on the amount of sodium in factory-made hummus, manufacturers choose to cook the chickpeas in water with no added salt and limit the amount of salt in the spice blend to a minimum. Some manufacturers also use unsalted sesame seeds for tahini to further minimize sodium content in their hummus. Low sodium diet improves health, so low sodium hummus is a highly recommended snack due to its many health benefits.

Processing steps involved in hummus making

Which hummus technology do you need?

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

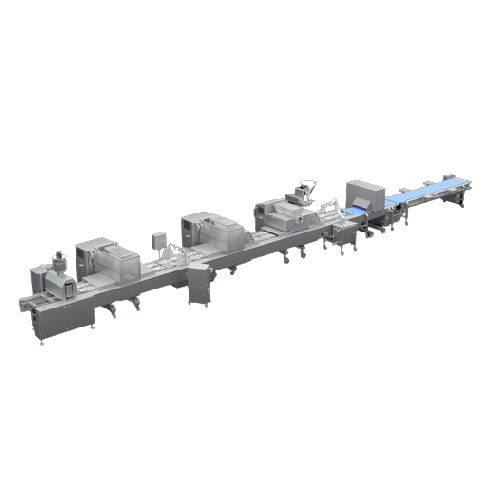

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

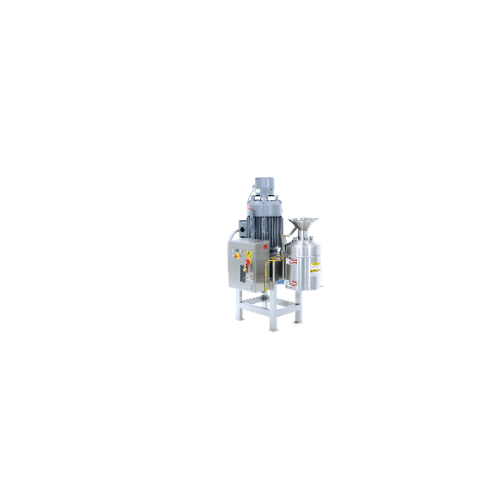

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Horizontal colloid mill for precise grinding

Achieve precise particle size reduction and reproducible results with our adv...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

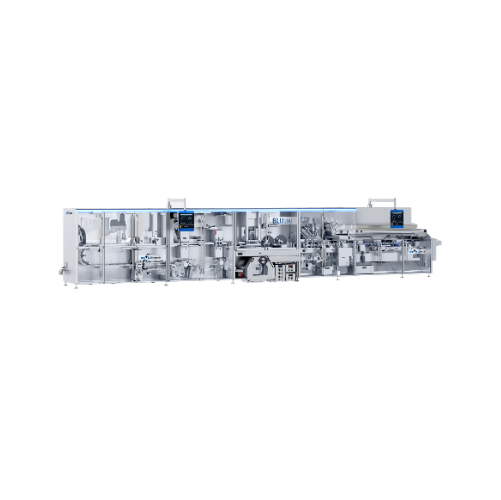

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Filling and sealing system for yoghurts and desserts

Efficiently fill and seal a variety of dairy and dessert products wh...

Tub filling and sealing for pasty products

Experience high-speed, precision tub filling and sealing designed for pasty pro...

Spindle mill for fine and super fine grinding of cocoa liquor

Achieve precision in grinding cocoa liquor and nut pastes ...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

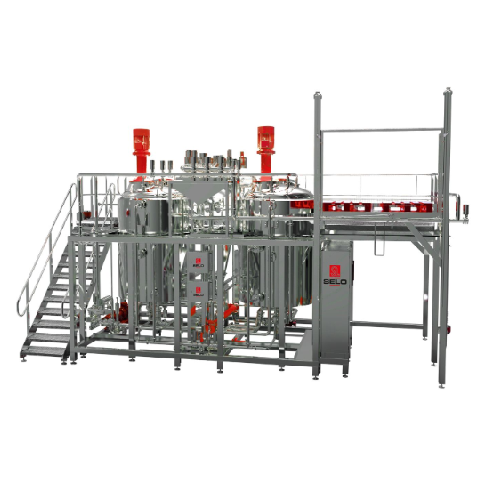

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

In-line mayonnaise emulsifying system

Streamline your sauce and dip production with a system designed for efficient emulsif...

Cleaning and sterilization system for food factories

Ensure optimal hygiene and safety in your production line with advan...

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Dense-phase powder conveying system

Optimize your powder processing with a system designed to handle abrasive and fragile m...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

Depositing line for cake production with paper cup denester

Optimize your cake production by seamlessly depositing marbl...

Multifunctional depositing line for bakery production

Optimize your bakery and food production with a modular depositing ...

Multifunctional dessert line for layered dessert production

Effortlessly create complex, multi-layer desserts or meal co...

Egg wash disc sprayer for bakery finishing

Achieve precise liquid application with minimal waste using this disc sprayer, ...

Full production greasing and depositing line for bakery products

Elevate your production process with a greasing and dep...

Ultra-clean vertical bag filler for viscous and particle-containing products

Streamline your viscous product packaging...

Industrial shear pump for high-viscosity food applications

Optimize your high-viscosity food processing with a shear pum...

Linear filler for preformed containers

Streamline your packaging process with a compact solution that ensures precise filli...

Rotary filler for preformed containers

Ensure microbiological safety and extended shelf life for your liquid products with ...

Scraped-surface heat exchanger for industrial fruit processing

Optimize your production with this advanced scraped-surfa...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Customizable sanitary conveyor systems

Efficiently transport and handle diverse products with a sanitary conveyor system de...

Lobe pump for soft fillings

Efficiently dose and feed soft fillings for food products with precision, ensuring smooth integr...

Creamy filling dosing system

Effortlessly dose creamy fillings into your production line with precision, ensuring chunk size...

Mechanical homogenizer for fine cutting and emulsifying

Achieve precise particle size control and consistent texture in y...

Inline mechanical homogenizer for food processing

Achieve precise particle size and uniform texture in your emulsions and...

Versatile size reduction processor for food applications

Enhance your food production line with a processor that excels i...

Industrial depositor for automated recipe management

Effortlessly streamline your production with precise depositing cont...

Multipiston food filling machine

Experience precise and versatile portion control with high-speed, servo-driven piston depos...

High-speed piston depositor for food applications

Achieve precise portioning and rapid depositing of diverse food product...

Industrial depositors for flowable food products

Enhance your production line’s efficiency with precision depositing...

Single piston food depositor

Achieve precise portion control for diverse food products, from soups to chunky fillings, with ...

Tabletop food depositor for portion control

Streamline your food production with precise portion control, reducing waste a...

Compact food transfer pump

Effortlessly maintain your production flow with a compact transfer pump designed to handle a wide...

Commercial slow juicer for nutrient-rich juice

Achieve higher juice yields and nutrient retention by utilizing advanced tw...

Single-serving blender for home use

Create smooth, nutrient-rich beverages and culinary delights effortlessly, whether you&...

Single-serving blender for quick personal blends

Transform your favorite ingredients into nutritious smoothies, soups, and...

Semi-automatic filling and closing system for pre-formed containers

Streamline your packaging process with reliable sem...

High shear mixer for emulsions and dispersions

Achieve precise emulsification and dispersion with advanced high-speed mixi...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

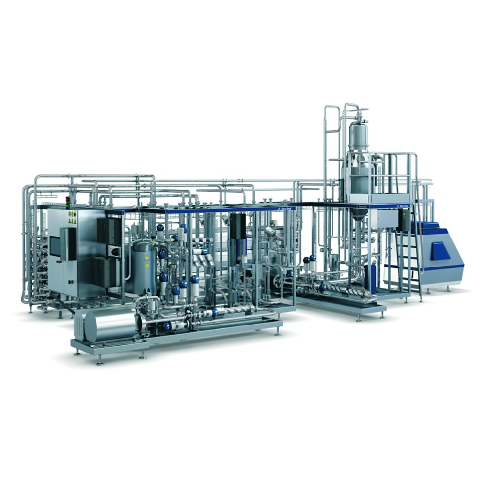

Efficient pasteurizer for prepared foods

Achieve precise heat treatment and reduce product waste with a modular pasteurizat...

Food processor for high and low viscosity products

Achieve consistent recipe results and streamline your operations with ...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

High shear mixer for emulsification and powder dissolving

Achieve seamless mixing and emulsification for high and low vi...

Contherm scraped-surface heat exchanger for viscous food products

Optimize your heating and cooling processes for stick...

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

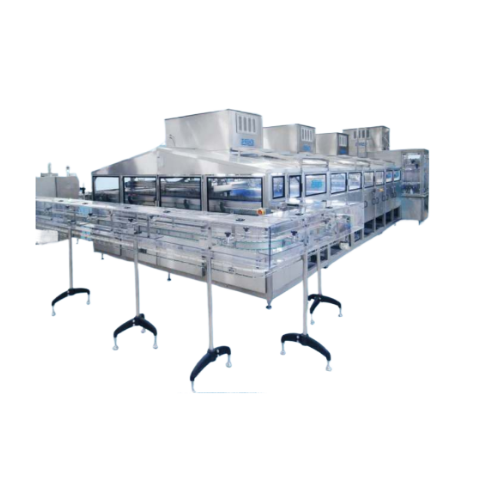

Automated cup filling solutions for liquid and viscous products

Ensure precise and hygienic filling of dairy, baby food,...

Automated sauce production lines

Streamline your sauce production with flexible lines designed for rapid recipe changeovers,...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

Homogenization and emulsifying system for fine foods

Texture and consistency are critical to foods with delicate composit...

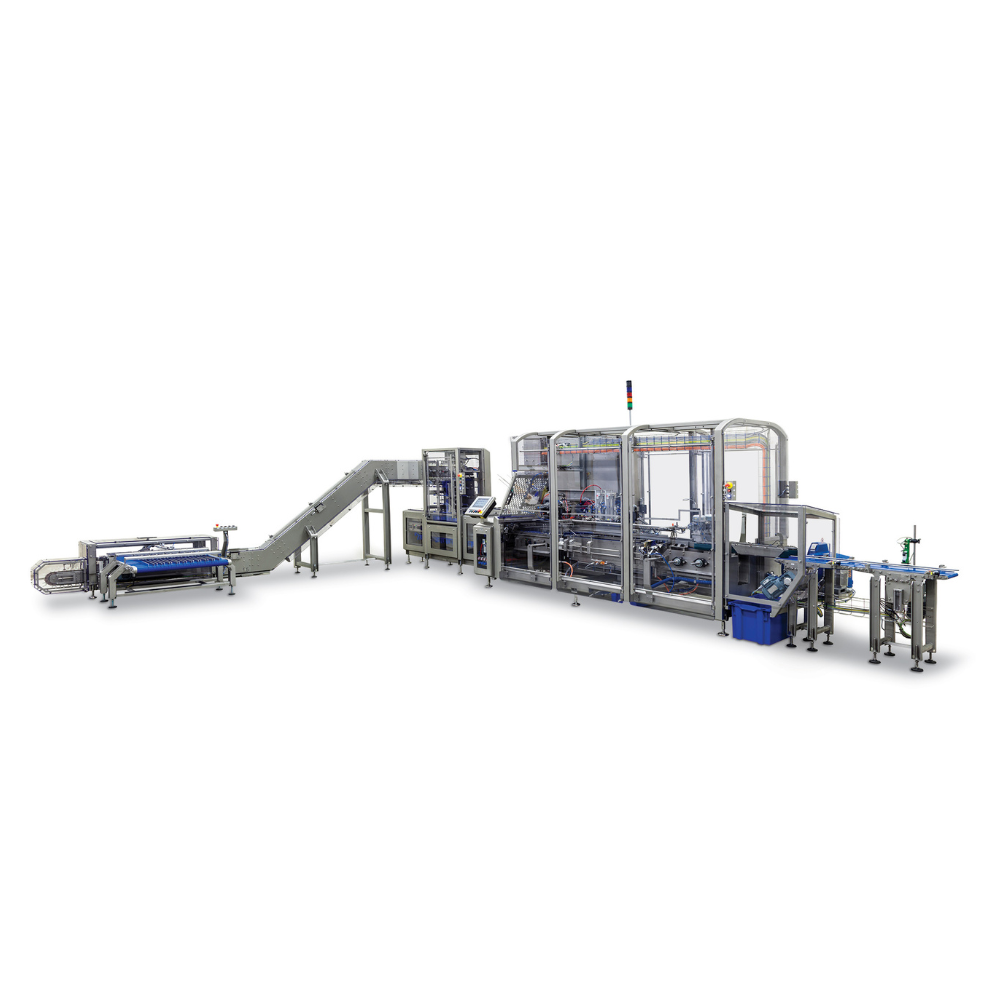

Tray erector

Corrugated trays come in many forms and sizes. Automate the process of erecting the trays to ensure consistent q...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Continuous kneader

Effective mixing of highly viscous products with extremely high solids content can be difficult and the re...

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...

Multifunctional cutting and dispersing machine

When processing alternative proteins or making products such as smoothies a...