Dairy alternatives

Find innovative production technology for making dairy alternatives and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in dairy alternatives making

Which dairy alternatives technology do you need?

Centrifugal separator for chemicals and minerals

Achieve precise separation of liquids and slurries with this high-speed c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

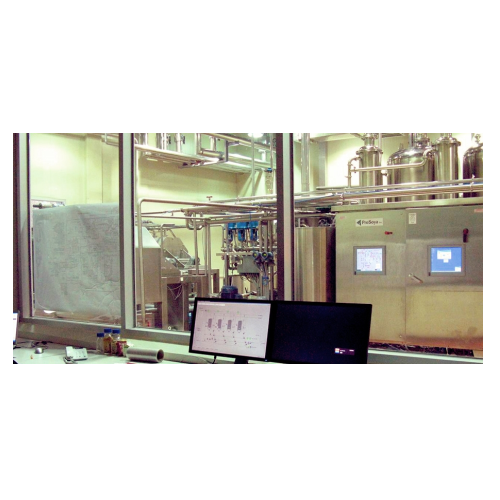

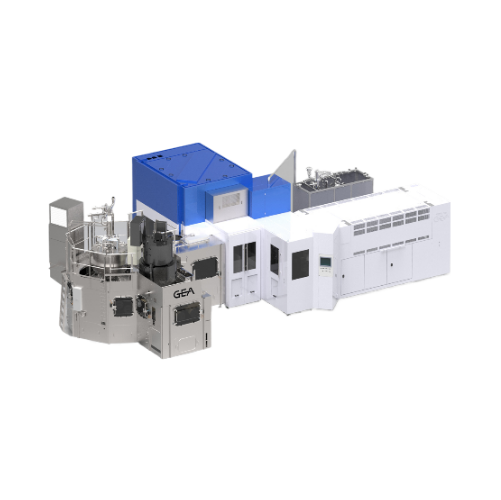

Oat milk processing plant

Transform whole oats into creamy, nutritious oat milk with precision, leveraging advanced continuo...

High-performance decanter centrifuge for dewatering

Achieve efficient and reliable dewatering by integrating a decanter c...

Soya milk production system

Efficiently transform soybeans into high-quality, non-beany soy milk with advanced processing te...

Soya protein isolate production line

Ensure the highest protein purity with this comprehensive production line designed to ...

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Empanada production line

Streamline your snack and pastry production with a compact solution that seamlessly integrates filli...

Sterilization pilot systems for small batch heat treatment

Optimize product safety and quality in small batch production...

Flat belt product transfer conveyor for food processing

Efficiently streamline your production line with a hygienically d...

Twin lane separator for automated tray sealing

Optimize your production line with this conveyor system designed to effortl...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Automatic tray sealer for high-speed food packaging

Optimize your production line with a high-capacity tray sealing solut...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Automatic tray sealing system for high-speed packaging

Experience seamless high-speed packaging with this versatile tray ...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

Bench mounted tray sealer with gas flush

Optimize your production line with a compact tray-sealing machine designed for pre...

Linear conveyor tray sealing

Experience unparalleled flexibility and efficiency in tray sealing with high-speed integration,...

High throughput tray conveyor system

Looking to streamline your tray sealing process? This modular conveyor system integrat...

High-speed tray sealer for food

Enhance your packaging line’s efficiency with a high-speed, in-line tray sealer design...

Industrial high speed tray sealer

Enhance your production line efficiency with precision sealing capabilities, accommodatin...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

In-line tray sealer for high-speed packaging

Optimize your packaging line with a high-speed solution that accommodates mul...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

High-capacity tray sealer for poultry, meat & seafood

Optimize your high-speed packaging line with this large-capacity tr...

Automatic tray sealer for high-speed packaging

Streamline your packaging line with an in-line tray sealer that adapts to t...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

Automatic inline tray sealer for food packaging

Streamline your packaging process with high-speed, reliable tray sealing t...

Mixing tank for soups, sauces, and dressings

Streamline your soup and sauce production with advanced mixing technology des...

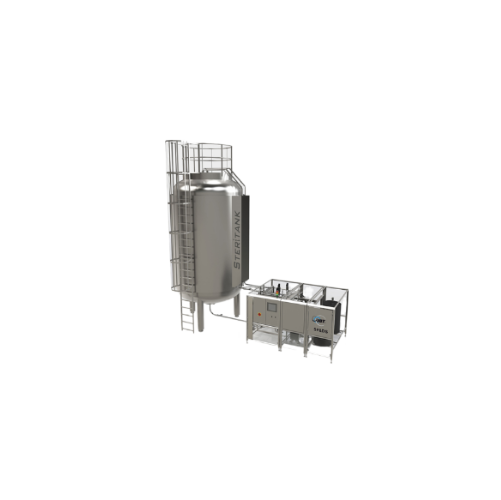

Aseptic storage tank for sterile liquid products

Ensure the sterile safety of your liquid products with a reliable storage...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Automatic tray sealing system

Optimize your packaging line with versatile tray sealing technology that accommodates various ...

Balance tank for pasteurization systems

Ensure consistent product quality with precise liquid holding and heating capabilit...

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

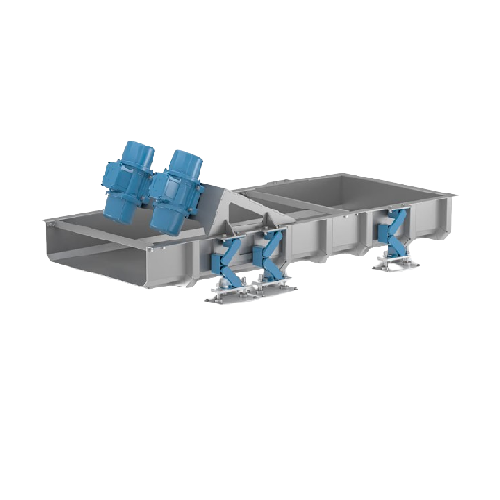

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Industrial block melt system for butter and chocolate

Efficiently transition solid blocks of butter, chocolate, or waxes ...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

In-line vacuum powder filler

Optimize your production line with precise, contamination-free filling for nutritional powders,...

Automated valve manifolds for clean-in-place solutions

Optimize your production efficiency with automated valve manifolds...

Barcode reading and verification system

Ensure every container has the correct product with a cutting-edge scanning system ...

Vacuum gassing seamer for infant formula packaging

Ensure low residual oxygen levels in your powdered products with a spe...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

Powder induction system for efficient liquid powder mixing

Achieve precise and dust-free powder incorporation into liqui...

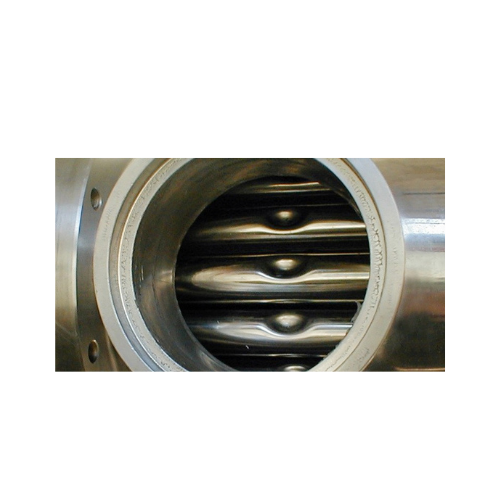

Tube-in-shell heat exchanger for low viscosity products

Enhance your beverage and food processing efficiency with a cutti...

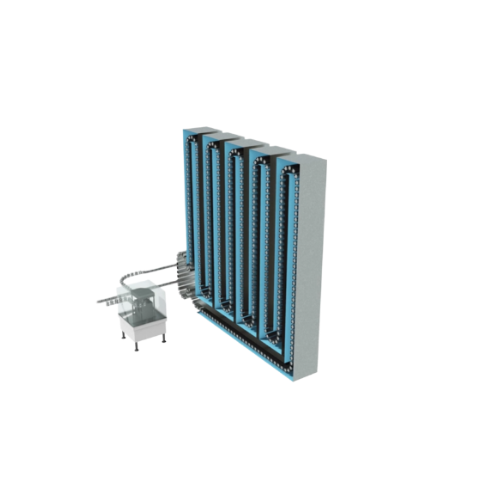

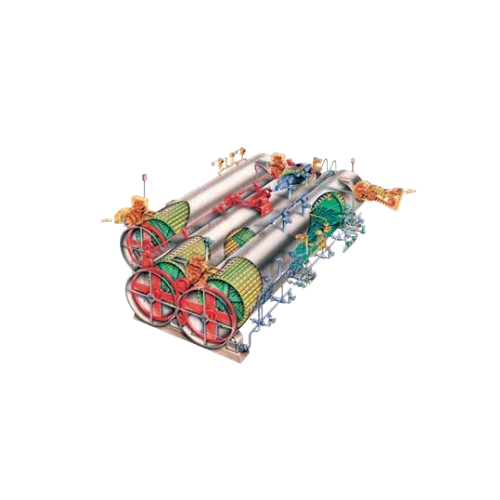

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous ...

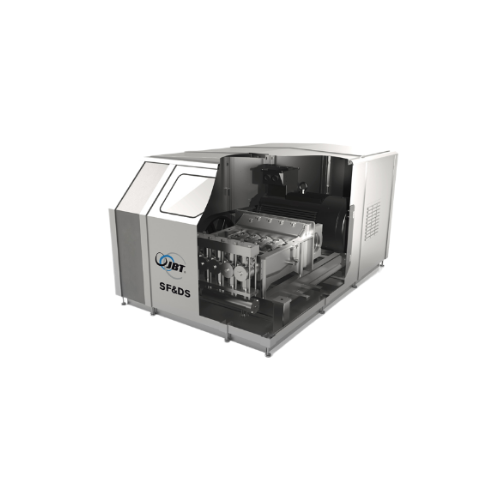

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

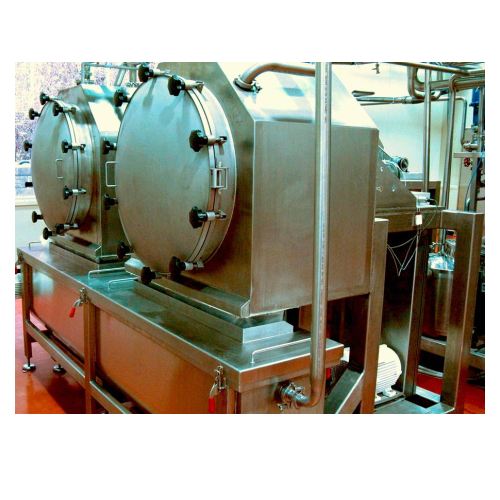

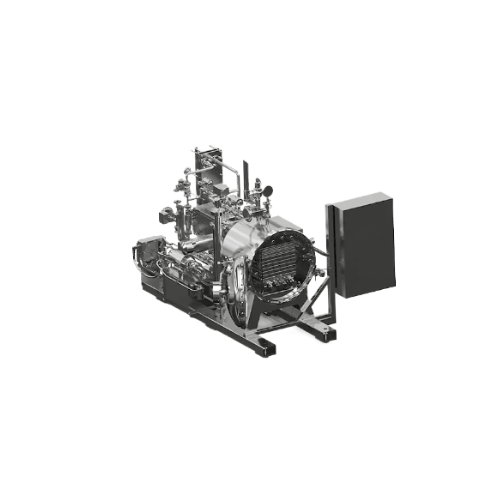

Pilot rotary retorts for laboratory sterilization

Optimize your prototype testing with precision thermal simulations to p...

Gentle can handling ejector for rotary cooker

Achieve seamless can transfer and sterilization with reduced damage during h...

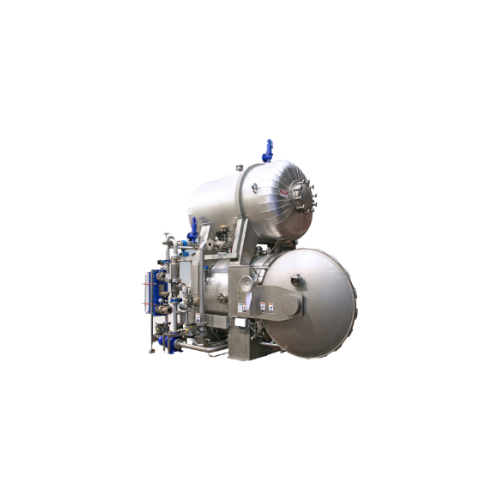

Rotary pressure sterilizer for canned food products

Streamline your canning operations with continuous high-speed sterili...

Heat exchanger for dairy and beverage applications

Optimize your liquid product thermal processing by directly regenerati...

Low energy suction system for food processing retorts

Optimize your sterilization process with innovative suction technol...

Coil heat exchanger for dairy and beverage processing

Quickly sterilize and retain product quality with this coil heat ex...

Uht sterilizer for dairy and high-viscosity products

Optimize your production of dairy alternatives and fruit-based drink...

Dual heating coil for dairy and beverage processing

Achieve precise temperature control for your liquid products with a s...

Deaerator for juices and dairy processing

Ensure the quality and shelf-life of liquid foods by effectively removing entrap...

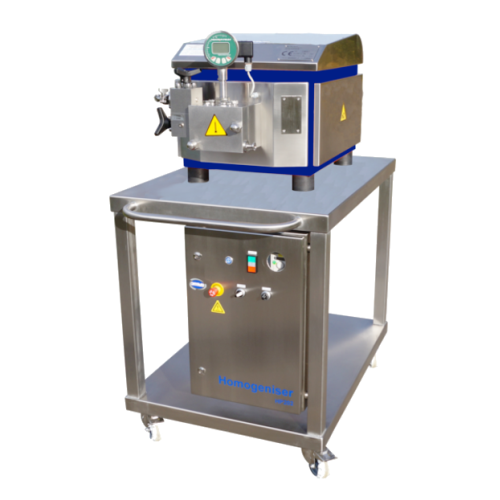

Industrial homogenizer for Uht sterilization systems

Achieve smoother product consistency with high-pressure homogenizati...

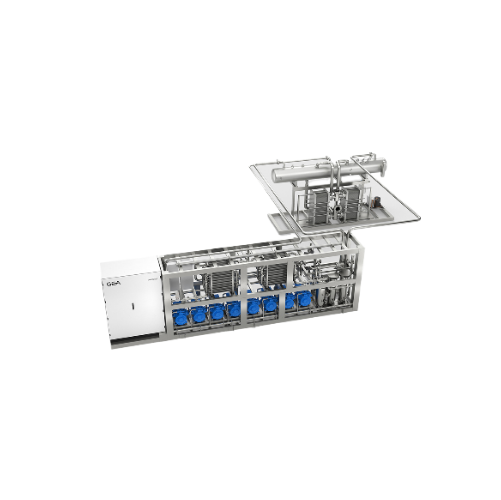

High temperature short time (HTST) dairy pasteurization system

Ensure precise pasteurization with advanced heat transfer...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Expandable high pressure processing system

Optimize your production line with an expandable high-pressure processing syste...

High pressure processing water filtration system

Ensure super clear water after high pressure processing to protect your s...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

High pressure processing for diverse food products

Maximize production versatility and ensure product safety with a high-...

Self-stacking belt for industrial freezers

Enhance your production line with advanced self-stacking belt technology, desig...

Industrial spiral freezer for high-volume food processing

Optimize your production line with a modular spiral freezer th...

Spiral freezer for high-volume food products

Achieve rapid, sanitary freezing with this spiral system, designed to handle ...

Industrial spiral freezer for high-volume processing

Optimize your high-volume food production with a robust spiral freez...

Structure supported spiral freezer for food products

Optimize your high-speed production with a versatile spiral freezer ...

Rotary level filler for low to high viscosity liquid products

Ensure precise fill levels and enhance production efficien...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

Aseptic filler for packaged dairy and beverages

Ensure product sterility and extend shelf life efficiently with high-speed...

High capacity volumetric filler for pumpable products

When you need high-speed, precise filling for diverse liquid and sl...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Extrusion blow molder for custom bottles

Enhance your production line by creating versatile and customized bottles with sea...

Industrial vibrating table for uniform product transport

Ensure consistent material flow and efficient transport with an ...

Brine preparation system for marination processes

Ensure consistent and high-quality brine and marinade mixtures with a s...

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

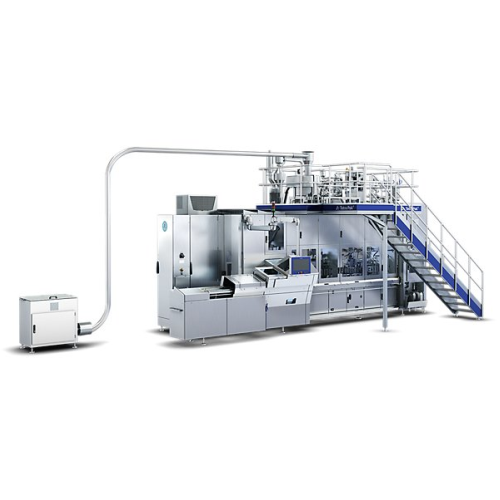

Aseptic filling system for sensitive beverages

Optimize your beverage production with an aseptic filling system that ensur...

Decontamination blow fill system for beverages

Optimize your beverage production with a technology that integrates preform...

Heat pump solution for spray dryers

Enhance your spray drying efficiency and sustainability with an innovative heat pump sy...

Horizontal stand-up pouching for beverages, dairy, and pet care

Optimize your liquid product packaging with rapid, high-...

Batch dissolver for crystalline sugar and dextrose

Streamline your ingredient preparation with high-capacity batch dissol...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Industrial grinder for plant-based beverages production

Achieve optimal particle size for seamless integration with your ...

Continuous carbonator for beverage production

Optimize your beverage production with seamless continuous carbonation, ensu...

In-line blender for beverage production

Enhance beverage production with a versatile solution that offers precise blending,...

Water treatment system for aseptic blending in Jnsd production

Ensure a reliable aseptic blending process for your bever...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

High capacity milk separator with polynode technology

Achieve unprecedented milk skimming efficiency and reduced environm...

Ingredient dissolver for small batches

Efficiently dissolve water-soluble powders and concentrates up to 200 cP with precis...

In-line blender for carbonated drinks

Optimize your beverage production with precise in-line blending and carbonation, redu...

Water treatment unit for aseptic blending in Jnsd production

Ensure aseptic quality and consistent flavor in beverages b...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Dual-line filler for tetra top packages

Maximize your production flexibility with a high-speed, dual-line filling solution ...

Filling machine for tetra rex® gable top cartons

Maximize efficiency and food safety in high-speed liquid filling with pre...

Aseptic filling solution for tetra classic packaging

Experience efficient aseptic packaging with high-speed operation, of...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Cardboard packer for secondary packaging

Streamline your packaging process with a high-speed, automated cardboard packer th...

Shrink wrapping system for flex portion packages

Optimize your packaging line with a high-speed shrink wrapping system des...

Straw applicator for tetra pak cartons

Ensure precise straw attachment and minimize production interruptions with a high-sp...

Straw applicator for tetra pak packages

Enhance your packaging efficiency with a high-speed solution that seamlessly attach...