Making Silicone

Find innovative production technology for making silicone and connect directly with world-leading specialists

Despite only one letter difference, silicon and silicone are two different things. While silicon is the 14th chemical element on the periodic table, silicone is a synthetic material that, among other chemical elements, contains silicon. Although commonly observed as plastic, technically silicone is rubber. Among others, silicone processing equipment mainly involves several high-temperature machines, mixers and molds.

Select your silicone process

Tell us about your production challenge

Silicone processing equipment and techniques

Silicone is a synthetic material composed of silicon, oxygen, carbon, and hydrogen. Being one of the main ingredients in silicone, the chemical element silicon is most commonly found in quartz, chemically known as silicon dioxide, from which it is reduced in a silicon furnace at temperatures as high as 1800°C. The leftovers of metallurgical-grade silicon are ground into fine powder. For silicone synthesis, it is crucial to add methanol to silicon to create chloromethane. Subsequently, a Müller-Rochow process starts by using a fluidized bed reactor heated at 300°C to trigger a reaction among particles forming a crude silane mixture.

The mixture is separated into various chlorosilane versions during a distillation process, and each version can further be processed depending on the desired end-product. Converted to polysiloxane chains via hydrolysis and polycondensation, difunctional chlorosilanes can be used as silicone fluids in cosmetics, textiles, and silicone rubber. As water-repellent yet breathable, trifunctional chlorosilanes are used in the construction industry. The three-dimensional silicone-resin networks are produced by undergoing hydrolysis and catalytic condensation. Finally, tertrafunctional chlorosilanes is used to manufacture pyrogenic silica, made by burning a crude silane mixture under a stream of hydrogen and air.

Silicone rubber production methods: extrusion

Silicone rubber is a highly versatile material that can be produced by a number of methods such as extrusion, injection molding, liquid injection molding, compression molding, calendering, and transfer molding.

Extrusion is a preferred method for producing silicone rubber due to its practical and cost-effective nature. The essential silicone processing equipment in this method is an extruder through which all raw materials, once shaped into strips or slabs, are pressurized, heated and molded using a designed heated die. After exiting the die, the silicone is processed in ovens that circulate hot air vertically and horizontally, steam vulcanization, salt bath cure, and infrared radiation cure. Extrusion transforms fine silica particles into a translucent paste which is practical for its flexibility and ability to be aesthetically altered for the desired product specifications. This method produces silicone for end products such as gaskets, tubing, and seals.

Silicone rubber production methods: liquid injection molding

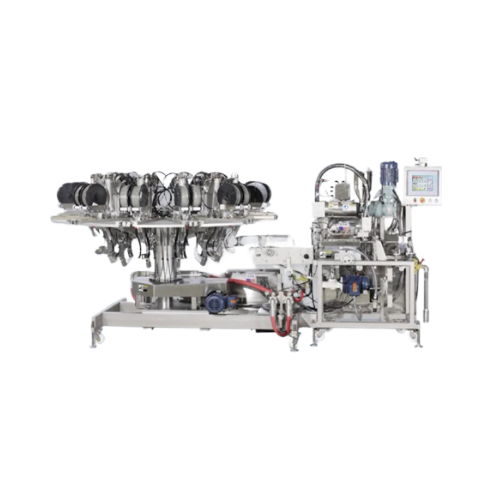

Liquid injection molding (LIM), also known as liquid silicone rubber (LSR), is used to produce high-volume durable parts and is suitable for creating complicated geometries.

The process starts in the pumping system where the base-forming silicone and the platinum catalyst parts of the liquid silicone rubber compounds are injected using supply drums, in addition to a separate container containing additives and pigments. The liquid silicone is pressurized into the machine’s pumping section with the injectors’ help. There, the metering pump will ensure that the liquid components mix and maintain a consistent ratio. Once it exits the metering pump, the mixture of base-forming silicone, catalyst, additives and pigments are combined by a static or dynamic mixer and forwarded into the nozzles. It travels from the cooled runner systems into the heated mold cavity, where the mixture is poured via the nozzles with automated shut-off valves to avoid leakage. Once the molding process is done and the product is cooled, the mold opens up.

Injection molding or liquid injection molding: where does the difference lie?

Among the production above methods, injection molding is the most common due to its ability to create products with a wide range of sizes, complexity, and application. The difference from liquid injection molding is the presence of mold halves and the raw material is forced into the hot cavity with a ram or screw-type plunger. The mold halves are clamped together, allowing for different shapes and sizes, from simple to complex and from small parts to large automobile body panels.

Solid and liquid silicone rubbers

Silicone rubber can be classified based on its viscosity – the difference between solid and liquid silicone rubber. Long chains of polymers with a high molecular weight result in a high consistency rubber, which is solid. Solid silicone is used for a variety of daily and industrial products. On the contrary, silicone rubber has a liquid texture when it contains polymers of lower molecular weight and shorter chains.

Due to it being safe as there were no added chemicals such as vulcanizing agents during molding, this type of silicone is used in the production of baby products as well as kitchen and medical supplies. Concerning the difference in production liquid silicone is injected into the mold through a vulcanization screw at a mold temperature of 170-200°C. Solid silicone, however, is cut into suitable size pieces and compression-molded.

Processing steps involved in silicone making

Which silicone technology do you need?

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Guarded hot plate for thermal conductivity testing

Ensure optimal insulation performance with precise thermal conductivit...

Smart miniature mass spectrometer for pharma freeze dryers

Optimize your freeze-drying process with a non-invasive tool ...

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

Immersion mill with sweep blade for high-viscosity products

Optimize your production line with this immersion mill desig...

Horizontal paste mixer for high-viscosity materials

Efficiently transform high-viscosity and challenging materials into u...

Coaxial mixer for high viscosity liquids

Achieve seamless blending of high-viscosity materials with a coaxial mixer designe...

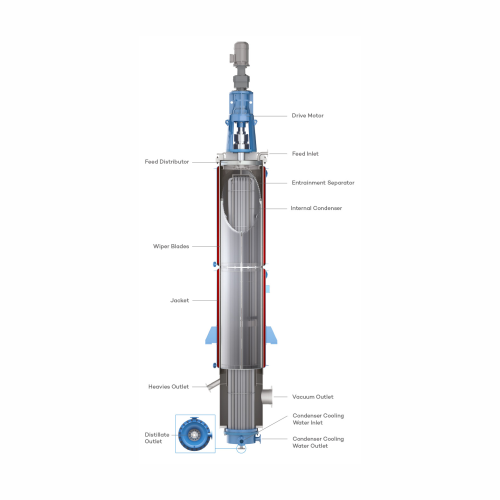

Wiped film evaporator for high boiling point materials

For challenging separations of high boiling, viscous, or heat-sens...

High-speed cutting mill for versatile material comminution

Efficiently transform diverse materials like plastics, textil...

Oil absorption testing instrument for carbon black and silica

Accurately measure oil absorption in powders to enhance fo...

Silicone spraying unit for laboratory and small-scale production

Ensure precise silicone application for cartridges, syr...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Stirred reactors with heating and cooling system

Optimize your production line with versatile stirred reactors, designed t...

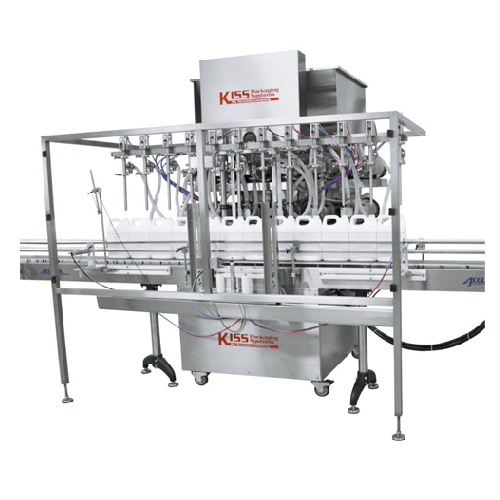

Auto-indexing filler for aqueous solutions and light oils

Streamline your bottling process with this six-head filler, pe...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Semi-automatic timed flow filler for aqueous solutions

Handle diverse liquid filling needs with precision, from thin oils...

Automated clipping system for flexible packaging

Achieve precise volume control and reduce material waste with this high-s...

Processing vessel for liquid, sauce, or cream products

Efficiently mix and integrate liquid, cream, or slurry products wi...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

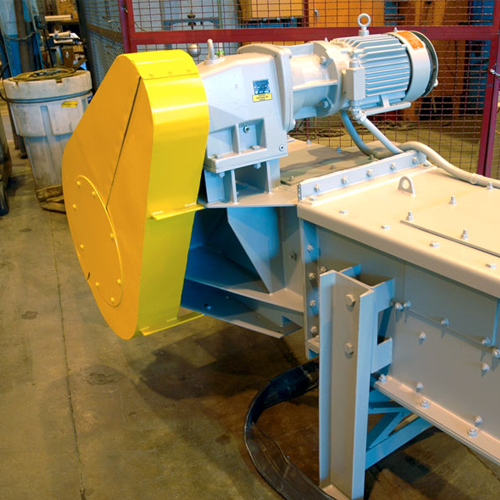

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Pv mixing vessels for industrial hire

Optimize your production mix with vessels that ensure precise blending, heating, and ...

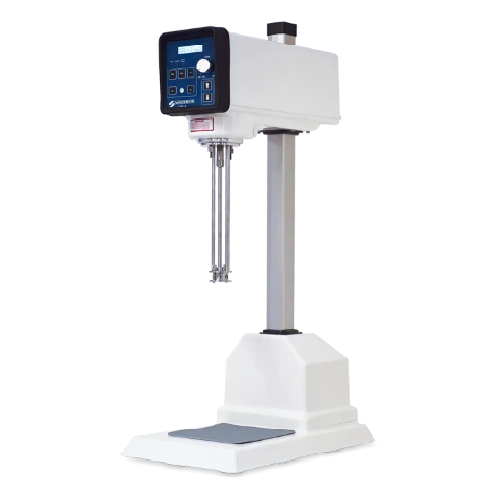

Laboratory disperser for high-viscosity products

Optimize your laboratory processes with precise mixing and dispersing of ...

Dispersing system for high-viscous products

Achieve precise mixing and dispersing of high-viscous products with advanced f...

Top-mounted disperser for high-viscosity products

Achieve rapid, uniform dispersion of ultra-high viscosity materials wit...

Vacuum dissolver for high-viscosity products

Elevate your production with precision mixing and deaeration, ideal for tackl...

Advanced dissolver for high-viscosity products

Handle ultra-high viscosity mixing challenges effortlessly with this advanc...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Industrial mixing dissolver for medium to large batches

Achieve precise mixing and dispersion of medium to large batch fo...

Explosion-proof dissolver for production applications

Ensure safety and efficiency in volatile environments with a robust...

Explosion-proof dissolver for chemical processing

Ensure safe and efficient dispersion in volatile environments with this...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Vacuum basket mill for high viscosity products

Achieve efficient fine grinding of high-viscosity products while minimizing...

Vacuum dissolver for large batch production

Optimize your mixing processes with a versatile vacuum dissolver designed for ...

Explosion-proof horizontal bead mill for paint production

Ensure ultra-fine particle size and consistent quality with an...

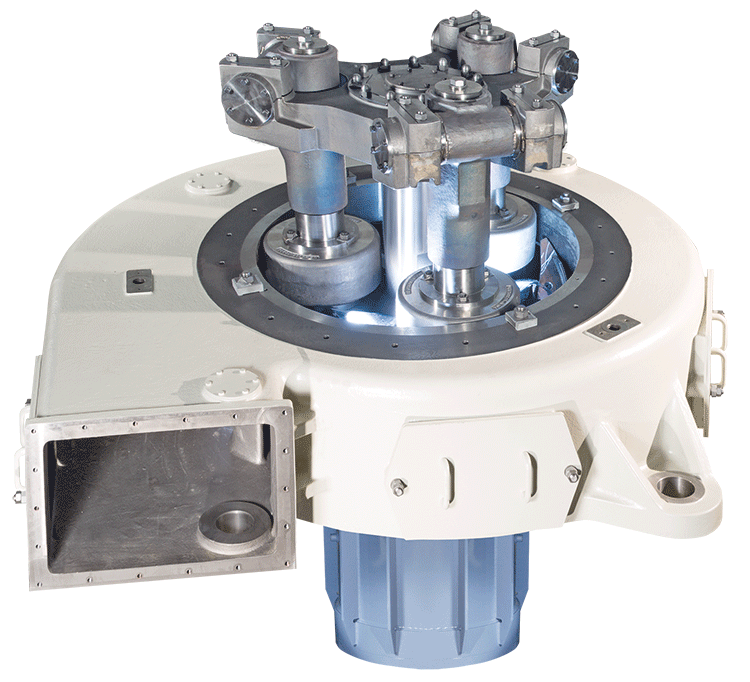

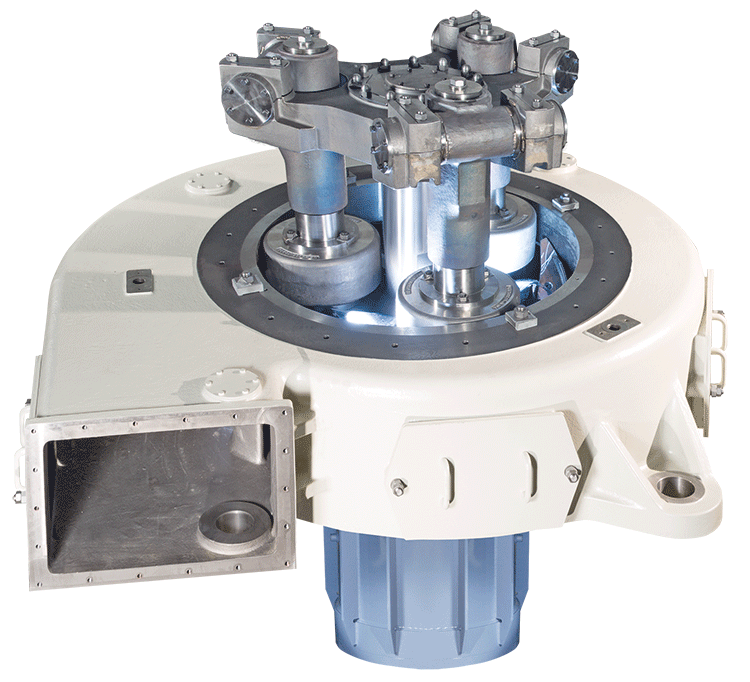

Horizontal bead mill for fine grinding in continuous process

Achieve ultrafine particle dispersion and consistent mixing...

Horizontal bead mill for ultrafine particle grinding

Achieve precision in ultrafine grinding with a system that allows fo...

Modular basket mill for industrial dispersion

Effortlessly enhance your production efficiency with this versatile solution...

High shear batch process homogenizer for production

Achieve efficient emulsifying, homogenizing, and dispersing with prec...

Explosion-proof production vacuum disperser for viscous products

Achieve precise and reliable dispersion of high-viscosi...

Industrial basket mill for medium viscosity products

Achieve precise particle size reduction and rapid pigment dispersion...

High-efficient industrial immersion mill

Achieve rapid, efficient dispersion and fine grinding in demanding production envi...

Explosion-proof dissolver with scraper for high viscosity substances

Ensure flawless dispersion with enhanced safety, d...

Vacuum basket mill for high-viscosity product milling

Achieve refined particle size and smooth texture in your high-visco...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Vacuum dispersion system for laboratory applications

Achieve precise mixing and homogenization under vacuum conditions, e...

Vacuum dispersion system for single-walled containers

Optimize your production line with an adaptable vacuum dispersion s...

Laboratory vacuum dissolver

Experience precision vacuum processing for your high-viscosity formulations, ensuring optimal di...

Dissolver for high-volume industrial dispersion

Achieve precise and efficient mixing with this dissolver, designed for sea...

Explosion-proof immersion mill for paints and varnishes

Optimize high-performance coatings production with an explosion-p...

Laboratory dissolver for multiple applications

Efficiently streamline your laboratory processes with this versatile dissol...

Lab and pilot plant dissolver for dispersion and fine grinding

Achieve efficient dispersion and fine grinding in laborat...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Vacuum dissolver for highly viscous products

Efficiently mix and disperse high-viscosity substances under vacuum to ensure...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Explosion-proof dissolver for hazardous area mixing

When operating in hazardous environments, maintaining consistent and ...

Lab stirrer for high-viscosity substances

Need precise, high-torque stirring for your complex formulations? This lab stirr...

Entry-level vacuum dispersion system for laboratory applications

Achieve precise dispersion and milling with this versat...

Laboratory and pilot plant horizontal bead mill

Achieve precision milling with minimal product waste, ensuring consistent ...

Nano bead mill for laboratory wet grinding

Achieve ultra-fine particle dispersion and consistent milling results with this...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Consistent material supply system for industrial applications

Ensure seamless production with a system designed for cont...

Precision dispenser for high-viscosity fluids

Achieve unparalleled precision in dosing and application with a dispenser de...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

Benchtop x-ray diffractometer for routine analysis

Achieve high-precision phase analysis and crystalline characterization...

Laboratory extruders for feasibility studies and r&d

Optimize your testing with laboratory extruders designed for precise...

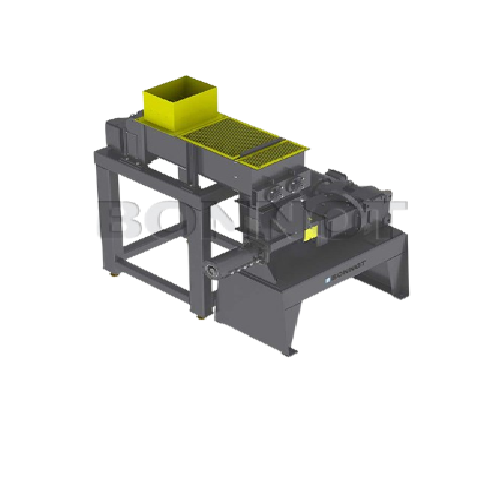

Terrier extruder for high volume material processing

Ideal for continuous high-volume processing, this extruder efficient...

Twin shaft feeder for optimized material feeding

Achieve precise material flow and optimize downstream processing with adv...

Vacuum extruder for high-viscosity materials

Optimize material processing with precision de-airing and temperature control...

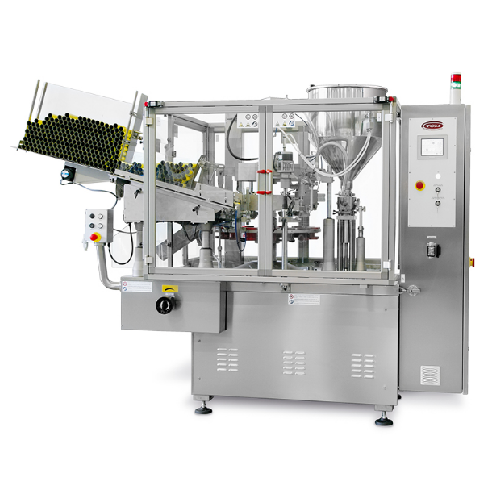

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robus...

Food processing scraped surface heat exchanger

Enhance your production line with precise temperature control and continuou...

Portable and fixed mount mixing system

Optimize your mixing operations with a versatile system that adapts seamlessly betwe...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

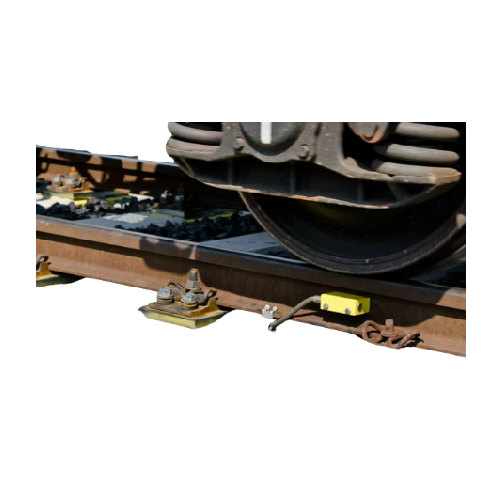

Pit scales for industrial weighing

Optimize material flow and ensure precise load determination with a robust pit scale sol...

Dynamic weighing for solids and liquids

Ensure precision in rail transport with innovative dynamic scales that provide lega...

Crane weighing system for precision measurement

Ensure precise and temperature-resistant weighing during high-demand opera...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Loss-in-weight feeder for bulk solids

Ensure precise and reliable dosing of bulk solids with a compact feeder that eliminat...

Apron weighfeeder for sticky bulk materials

Optimally handle challenging, sticky materials with precision and consistency ...

Industrial weighfeeder for hygienic applications

Achieve precise mass flow control with a hygienic design, ideal for appli...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

Optimal maintenance solution for industrial weighfeeders

Streamline your processing operations with a solution that minim...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

Bulk material handling with chain conveyor

Optimize your material transport with a solution designed for reliability in de...

Grinding and drying of CaCO3

Widely used in the construction industry as filling materials, calcium carbonate is usually mad...

Grinding and drying of bentonite

After crushing and drying mined bentonite, this clay mineral is usually processed through a...

Filter dryer

The pharmaceutical and bioprocess industries need filtration processes of particularly high quality to ensure the...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

Dehumidifier for difficult wet airflows

Sealed rooms can be challenging to dehumidify with ordinary dehumidifiers. The wet ...

Gypsum centrifuge

Especially designed for flue gas desulphurization, applications in coal fired power plants and waste incine...