Making Instant Soups

Find innovative production technology for making instant soup and connect directly with world-leading specialists

Instant soup is quite popular due to its ease of use and quick preparation. Products like cup noodles and vegetable soup mixes are some of the examples commonly used by consumers. The instant soup processing equipment is used to dehydrate or dry components of the soup mixture to prolong shelf life and preserve the taste of the vegetables and other components.

Select your instant soup process

Tell us about your production challenge

What equipment do you need to make liquid and powder instant soup?

Instant soups are available in powder and liquid forms. To make powder forms, instant soup processing equipment includes dryers for spray drying or freeze-drying process, depending on the drying process chosen by the manufacturer. Vegetables or meat need to be dehydrated before grinding and blending them with other spices to create a powder mix.

Liquid soup forms require blending ingredients and heating them in a cooking vessel until a condensed product is obtained. Evaporators are used to reduce moisture and acquire a condensed product. The condensed product is cooled before pouring it into cans.

Drying vegetables and other ingredients using dehydration or freeze-drying process

Dehydrating food components can be done by air-drying, where hot and dry gas is applied to the food product, or through vacuum drying where heat is applied to the product under vacuum pressure conditions. Dehydrating methods can effectively dry the food, but it also loses much of its nutrients and taste after the process due to heat application. On the other hand, the freeze-drying process is expensive but allows the manufacturer to keep most of the food products’ taste and nutrients by drying the products at low temperatures.

After freezing the ingredients, producers apply heat while lowering the pressure to remove the excess moisture that looks like ice crystals. The ice crystals evaporate without going through a liquid phase, a step known as sublimation, which leaves us with dried instant soup components. Freeze drying also prolongs the products’ shelf life better than the dehydrating method since it is more effective in removing the water content of the products; this also means that the products are lighter in weight. Preparation time for freeze-dried products is also much shorter than the dehydrating method; it only takes a few minutes to rehydrate, while the dehydrating method requires about 20 minutes or more to fully rehydrate the products.

Enhancing the flavor of instant soup while making it last longer

Studies have been done to enhance the taste of the dried instant soup product and help prolong the shelf life. The patent EP19990917227 shows a novel process that has been developed by adding a sulphur-containing compound of about 0.0005 to 0.001% relative to the weight of the soup or sauce. This sulphur-containing compound is added at any stage during the production of the dried soup or sauce composition containing vegetables, mushrooms, and spices.

An example of such sulfur-containing compound is glutathione, which is used in the production of dried soy sauce to prevent a burnt taste from developing. The compound acts as a preservative while enhancing the flavor of the instant soup mix. It is also applicable for various instant soup components such as meat and vegetables.

Oodles of instant noodles

Instant noodle soups are composed of dried noodles with separate packs for seasonings and dried mixed vegetables. After mixing the ingredients to create a dough, the dough goes through a set of rollers to flatten it at the desired thickness before cutting it to form noodle strips. They are steamed at a high temperature before cutting them short to fit into shaped molds. Then, the remaining moisture is removed by frying them in oil. After frying, the noodles are cooled down before packing them together with the seasoning packs. As a dehydration method, blow-drying is also used as an alternative to frying where hot air is blown to the noodles at 80 degrees Celsius for 30 to 60 minutes.

The main ingredients for making instant noodles are salt, flour, starch, water and a type of alkaline mineral water called kansui. Kansui contributes to the gluten development and gelatinization of starch, both of which give the noodles the chewiness characteristic. Moreover, kansui provides the traditional yellow color to your noodles.

Processing steps involved in instant soup making

Which instant soup technology do you need?

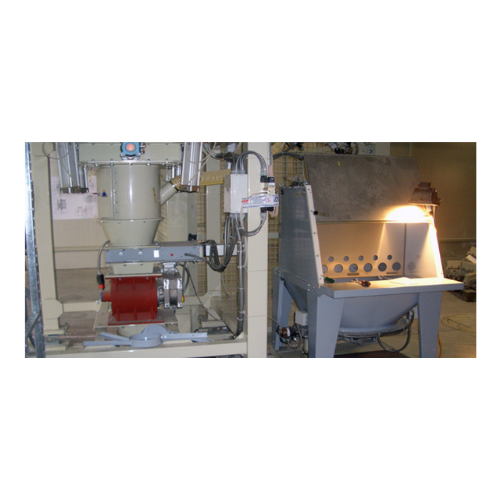

Inline powder analysis system

Ensure optimal powder quality with real-time measurement of moisture, density, and contaminant...

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

Lab-scale milling and processing platform

Effortlessly transition from lab-scale research to full production with a versat...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

Continuous granulation dryer for chemical and polysaccharide applications

Enhance your production with precise drying ...

Ultra high temperature treatment for small-scale production

Achieve extended shelf life and uniform product quality with...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Bin tumbler for efficient mixing

Achieve precise blending and homogenizing of powders and granules with dual-inclination des...

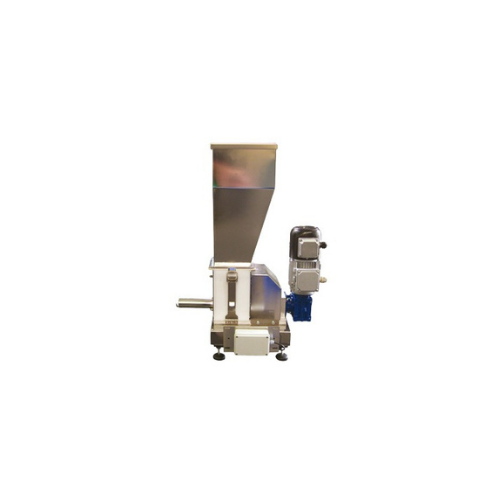

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

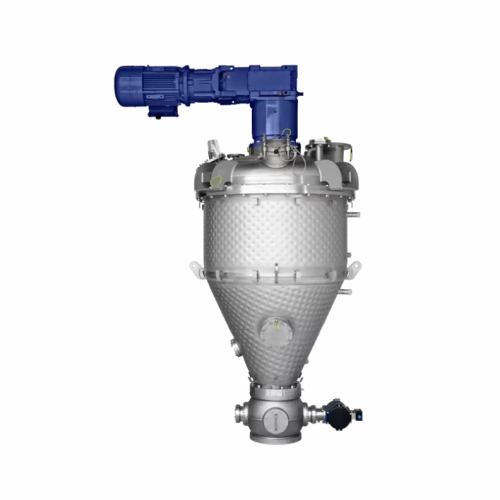

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Conical paddle vacuum dryer for powders and granules

Achieve efficient drying of sensitive materials with this versatile ...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Pre-breaker for initial material size reduction

Efficiently prepare your bulk materials for further processing by swiftly ...

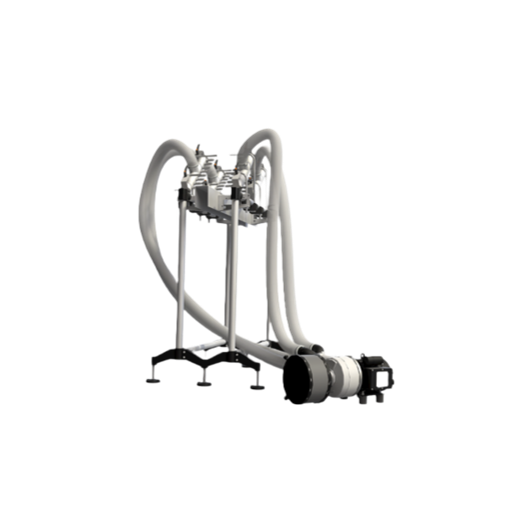

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

Additive mixing and dosing system for potato flakes

Achieve precise flavor and texture in potato flakes with this system,...

High-speed mixer for granulating and mixing powders

Achieve consistent granulation and mixing with precise temperature co...

Fluid bed processor for granulation and coating

Fluid bed processors offer efficient granulation and coating, streamlining...

Vertical pharma vacuum blender for bulk solids

Optimize your mixing of fine chemicals and pharmaceutical powders with high...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Fluid bed processor for large batch spray granulation

Optimize your production with precision granulation, drying, and co...

Vacuum and freeze drying plants for food and pharmaceuticals

Ensure high-quality, extended shelf-life products with inno...

Laboratory cone mill for even grinding

Achieve consistent particle size for laboratory powders with precision calibration a...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

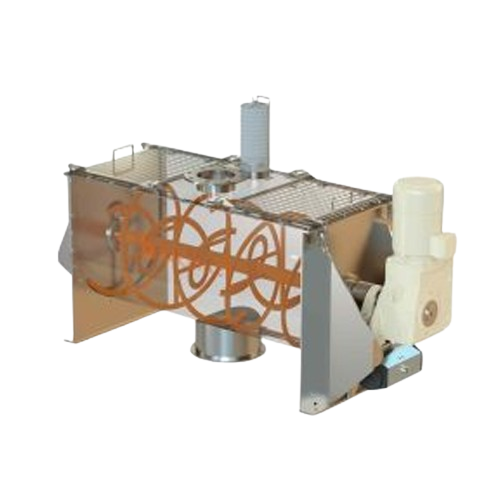

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Advanced powder dosing system for continuous production

Achieve precise powder integration into your liquid processes, en...

Cost-effective dosing container for minor ingredients automation

Optimize your production by streamlining ingredient han...

Particle size control equipment for pharmaceutical applications

Achieve precise particle size control for diverse materi...

Container mixer for dry and moist materials

Achieve exceptional mixing quality with variable filling levels, ensuring cons...

Fluidized bed spray granulators for liquid to solid conversion

Transform liquid suspensions into stable, dust-free granu...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Moist granulation system for pharmaceutical and chemical industries

Transform powdered materials into uniform granules ...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

Micro-ingredients doser for precise powder additives

Maintain precision and hygiene in your production line with a specia...

Direct discharge descender for product handling

Efficiently transport granulated materials without compromising their inte...

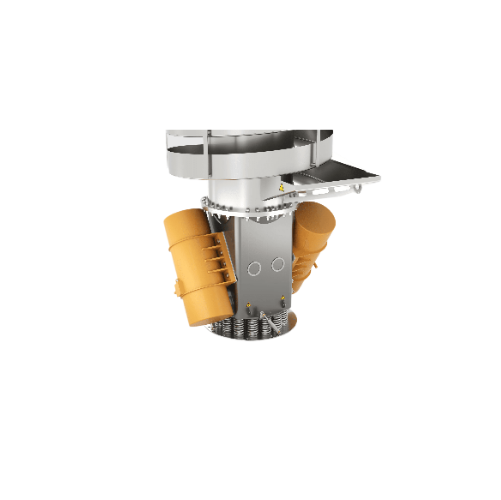

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Hygienic powder filling system for low throughput

Ideal for compact production facilities, this filling system efficientl...

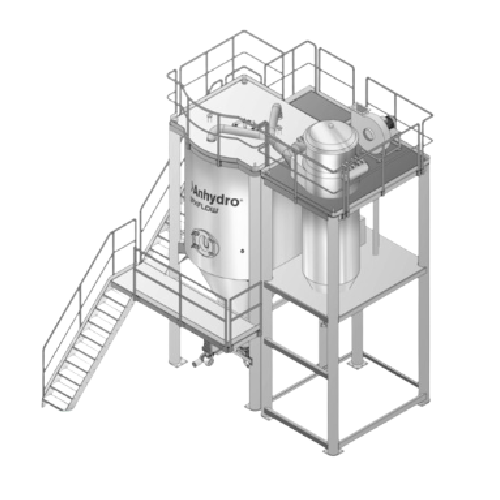

Spray dryer for agglomerated powders

Achieve uniform, coarse, and free-flowing agglomerated powders with precise drying and...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Spray dryer for whey and milk powders

Optimize your drying process for dense, agglomerated whey and milk powders with a spa...

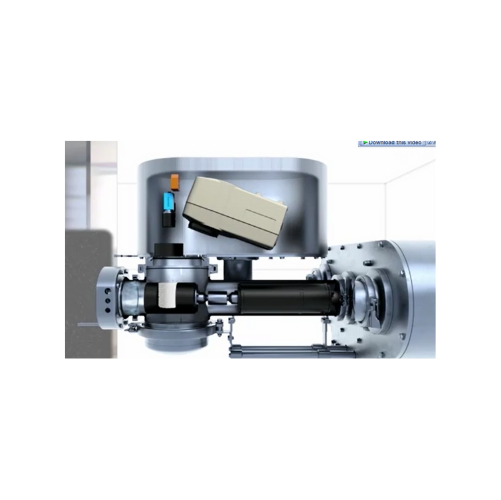

Co monitoring system for spray dryers

Ensure safety and prevent costly disruptions in your spray drying process by monitori...

Spice doser for powdered and free-flowing dry vegetables

Optimize spice and dried vegetable packaging with precise dosing...

Continuous pneumatic silo air filtering system

Ensure clean and efficient pneumatically conveyed materials by integrating ...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

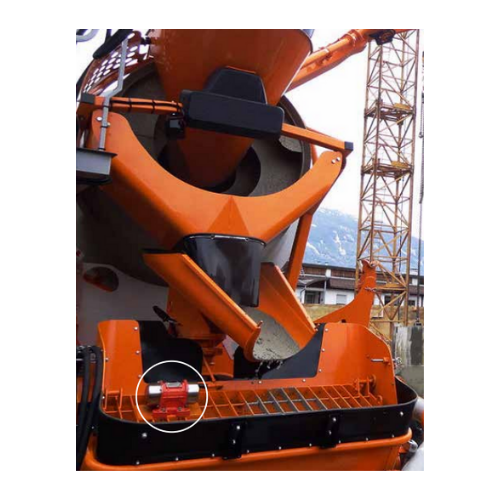

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Lump breaker for breaking agglomerates and lumps

Effortlessly break down challenging agglomerates and clumps to ensure smo...

Industrial buffer tank for temperature and texture control

Achieve precise temperature control and optimal texture with ...

Gravimetric single-screw feeder for free-flowing products

Optimize your dosing precision for powders and granulates with...

Vibratory storage hopper with inclined screw conveyor

Enhance your production line efficiency with a vibratory storage ho...

Volumetric auger filler for precise powder weighing

Optimize your production line with a high-speed volumetric auger fill...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Roller compaction for dry granulation in pharmaceuticals

Ensure consistent granule size and density in your product line ...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

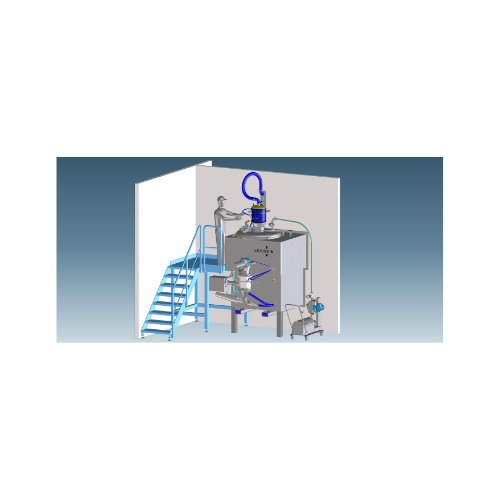

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Small scale spray dryer for r&d and production

For precise moisture removal in small batches, this flexible spray drying s...

Industrial fluid bed dryers for powder processing

Enhance moisture control and uniformity in powder products with dynamic...

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...

Filling system for solids, pastes, and liquids

Eliminate contamination risks while achieving high-speed, precise filling o...

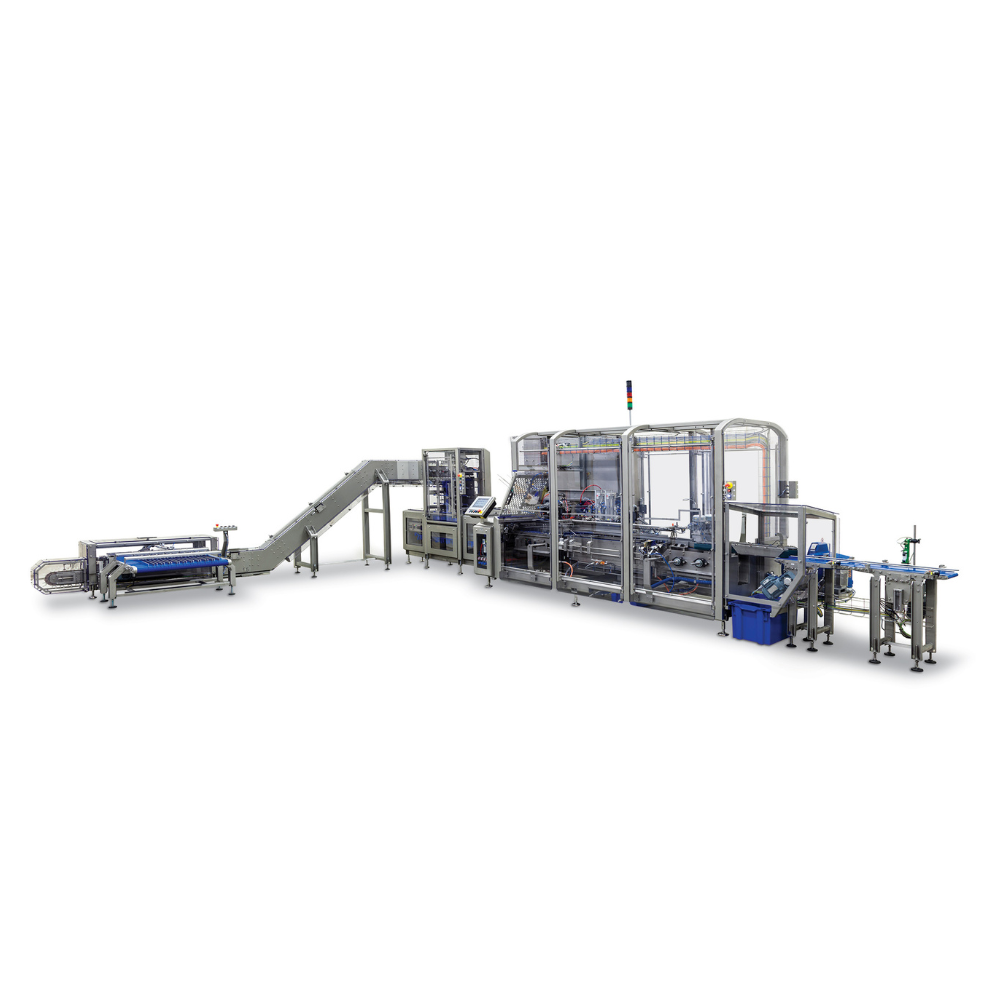

High-speed Cartoner For Single-Serve Products

Large-volume producers of single-serve packs, such as sugar sticks, instant ...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

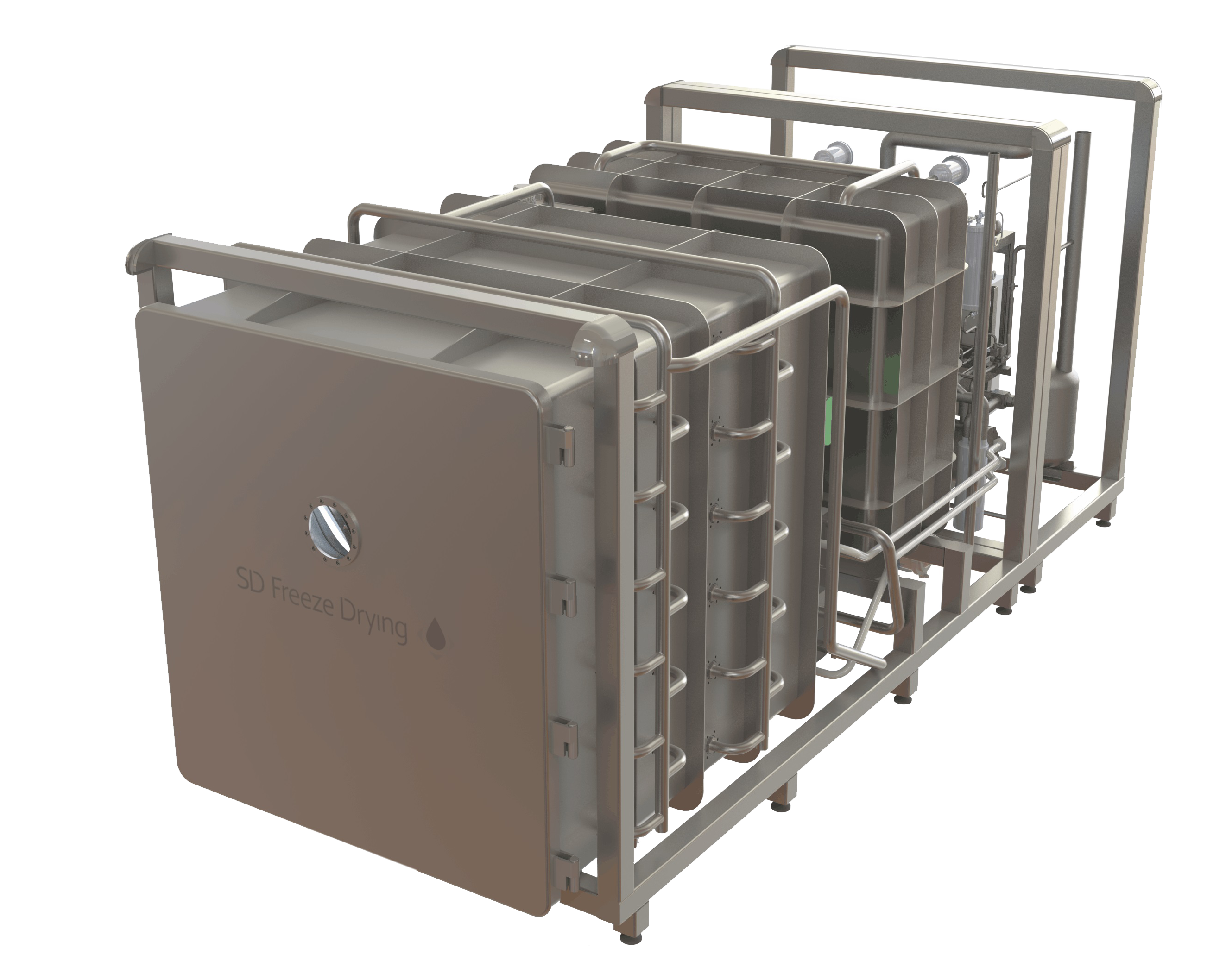

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Entry level HFFS Machine for flat sachets

Traditional horizontal form fill and seal sachet machines for lower volume lines...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Air knife dryer for pouches

Flexible pouch packaging is a popular choice for many consumer food products. Before final print...

Autoclave for canned food

Sealing and cooking products in cans, pouches or other containers is a very popular method of pres...

Pellet hardness tester

Control the quality of your pelletizing processes using a pellet hardness tester. Pellet hardness is o...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

Hygienic pelleting press

The production of pelletized or granularized food products requires hygienic presses designed for hi...