Making Brittles

Find innovative production technology for making brittles and connect directly with world-leading specialists

Brittles are hard candies made of nuts such as peanuts and caramelized sugar. This candy has local variations around the world, such as panutsa mani in the Philippines, alegría in Mexico, and chikki in some parts of India. Are you interested in making one? Your peanut brittle making equipment should involve peanut preparation and processing, syrup preparation, ingredient mixing, slab formation and cutting, and packaging.

Tell us about your production challenge

Using peanut brittle making equipment to create your golden sweet

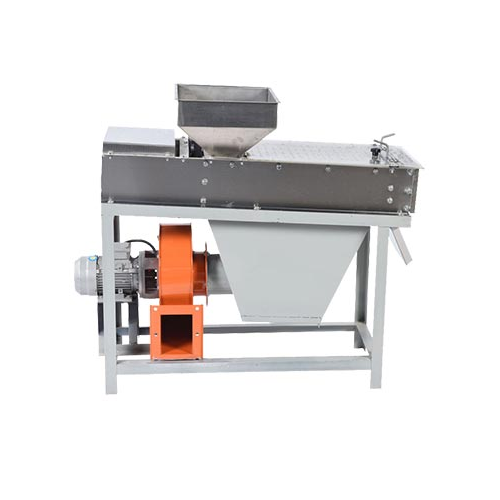

The peanut brittle processing line starts with the preparation of the peanut, which should be peeled and roasted. Peanuts can be baked at 350 °F for 10 – 15 minutes if shelled or 20 – 15 minutes if unshelled, or until the peanuts turn light golden brown. These are then peeled using a dry peanut peeling machine.

Using roller friction, the peels are removed in utmost 97% of the peanuts while maintaining peanut structure. Once peeled and roasted, you can mix your peanuts with cooked sugar syrup using a mixer. Now your peanut brittle is ready to be shaped and cut.

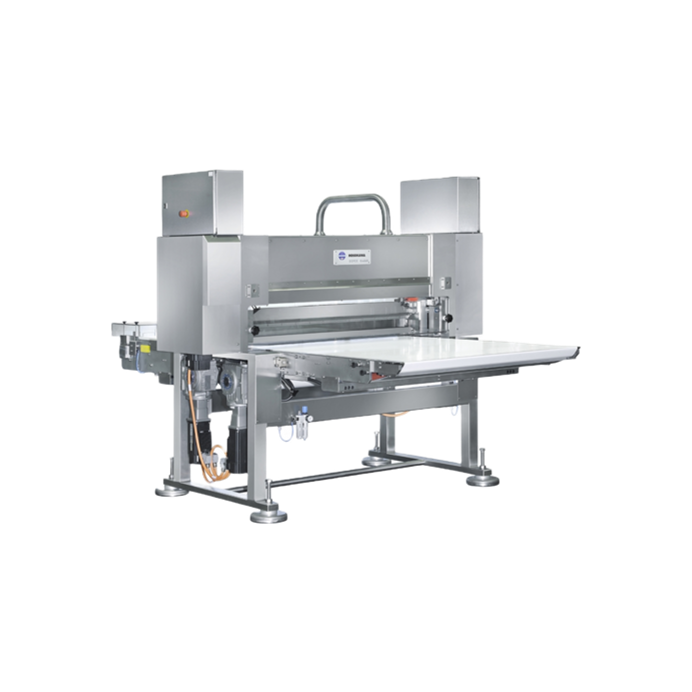

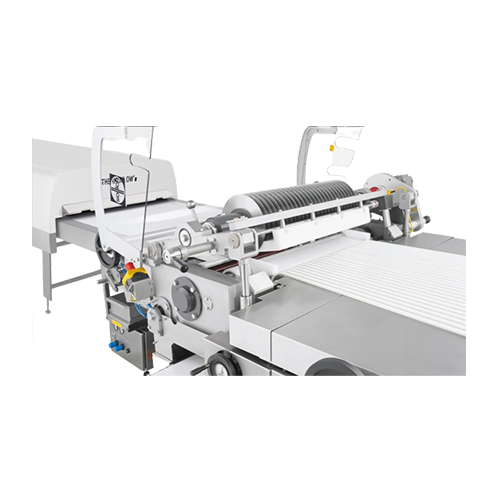

While warm, your brittle is spread out on a conveyor. The warm brittle and/or warm surfaces help keep your product pliable, easing the spreading process. Rollers in the spreading machine flatten your brittle as thin as possible. Afterward, the brittle is cooled, pressed again to ensure thinness, and cut into your desired shapes. The thickness and shape of your slices are controlled by the machine settings you can freely set.

Ensuring hard crack perfection for your sugar syrup

How you make your sugar syrup affects the final texture of your peanut brittle. Sugar syrup must reach the hard crack stage. You can use a calibrated candy thermometer during measurement for proper verification.

The hard crack stage establishes the stability of your peanut brittle. At the hard crack stage, the extremely high temperature fully completes sugar crystallization, imparting the hardest texture on your peanut brittle. Sugar concentration is at 99% or higher while moisture content is at 1% or less. The hard crack stage is reached when your sugar syrup is cooked at 300 to 310 °F. Failure to achieve this stage results in incomplete crystallization, leading to a rubbery product.

Raw or roasted? Which peanut should I use?

Are you thinking of choosing between raw or cooked peanuts for your peanut brittle? Don’t fret, as this is just rhetoric. You can use both; you just need to adjust where you will add each in the process.

Raw peanuts give better flavor to your syrup. These must be added at the start of the process to better incorporate a nuttier flavor profile into your syrup. On the other hand, roasted peanuts must be added near the end of the cooking process to prevent them from being burned or overcooked. These must be warm when added, freshly roasted with product temperatures of 250 °F, thereby preventing the undesirable crystallization of your syrup.

Chikki: One of the million varieties of peanut brittle

Additional ingredients can be added to your peanut brittle to make it unique. In India, their regional variant, chikki, introduces jaggery into the recipe, an unrefined Indian cane sugar. The jaggery is added to the sugar solution during the cooking process. Additional steps include chopping or sifting the jaggery before mixing with the sugar solution. Aside from the sugar, you will also need to dissolve the jaggery to ensure a smoother consistency.

Furthermore, in this case, the process of syrup cooking only targets the hard ball stage (250 – 265 °F, sugar concentration of 92%). To make the product healthier, you can consider adding other ingredients, such as chickpea, dried fruits, and sesame seeds.

Processing steps involved in brittles making

Which brittles technology do you need?

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

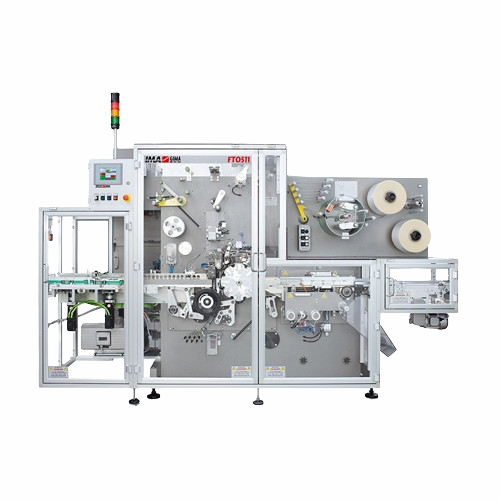

High-speed overwrapping for display boxes

Achieve seamless overwrapping of display boxes with ultra-high-speed capabilitie...

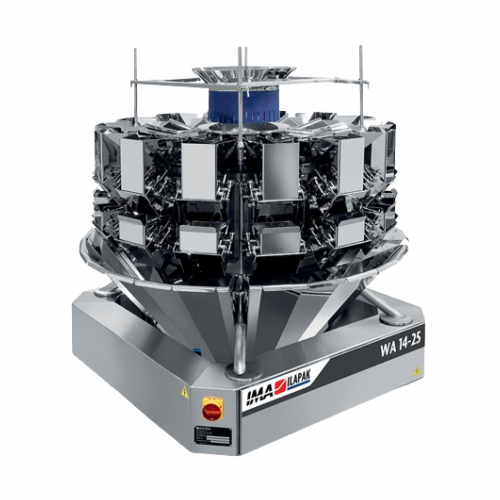

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

High-speed multi-head weigher for confectionery products

Achieve precise measurements and minimize waste in high-speed fo...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

Automatic lidding-up and filling-up for luxury boxes

Enhance your luxury packaging lines with reliable precision, as this...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Continuous caramel cooker for candy production

Achieve perfect caramel consistency with precise control as this solution c...

Crystallization process for chewy candy production

Optimize your confectionery production with precision crystallization,...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

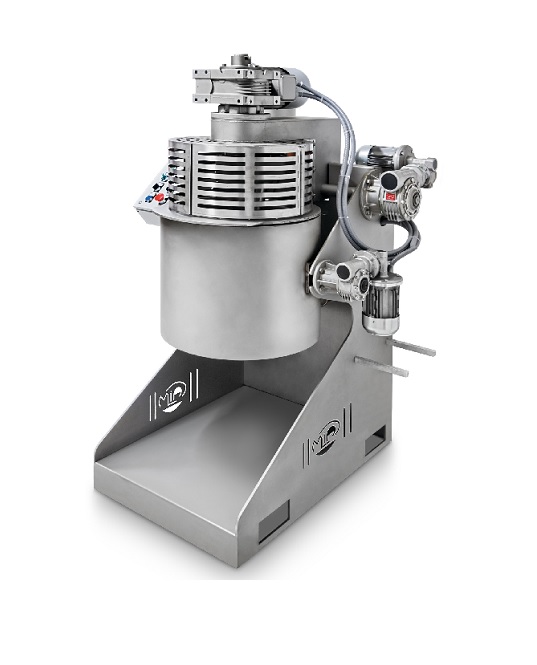

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

High shear mixer system for hydrocolloids

Streamline your confectionery production with a high-shear mixer designed for pr...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Industrial sugar melter

Efficiently melt and mix sugar with precision using a gas-fired batch cooker designed for optimal hea...

Semi-auto case packer for flexible bag collation

Enhance your manual packing speed and flexibility with a semi-automatic s...

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Rotary oven for japanese peanuts

Achieve uniform coating and optimal roasting for Japanese-style peanuts with precise temper...

Split peanut blancher for snack food processing

Efficiently transform roasted or dried peanuts into perfectly blanched pro...

Popcorn cooker/coater for caramel corn

Enhance your snack production efficiency with a versatile solution that combines coo...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Integrated stirring cooking kettles for commercial kitchens

Streamline your culinary operations with innovative cooking ...

Industrial cereal popcorn making solution

Enhance your snack production with a versatile solution designed for creating a ...

Peanut brittle forming and cutting system

Efficiently transform sticky ingredients into uniform treats with our cutting-ed...

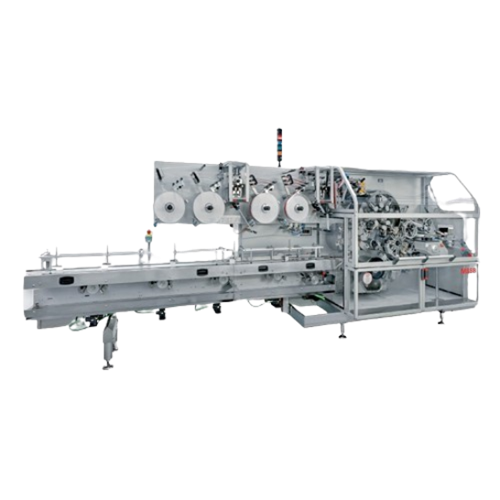

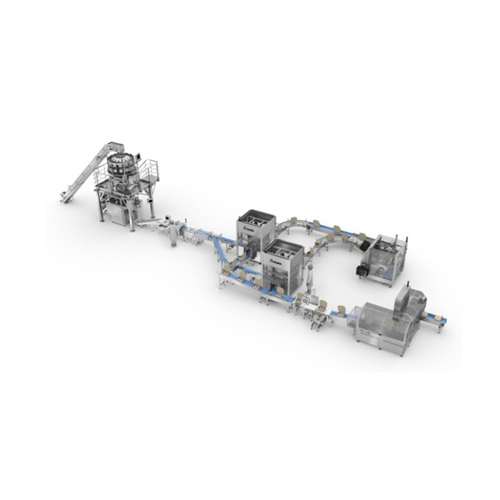

Automatic cereal bar production line

Efficiently transform diverse ingredients into consistent, high-quality cereal bars wi...

Dough mixer for pastry food processing

Achieve perfect dough consistency efficiently with this dough mixer, designed for se...

Automatic peanut peeling system

Achieve seamless peanut processing by eliminating red skins efficiently, enhancing the quali...

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Chocolate storage tanks for confectionery production

Optimize your confectionery production with state-of-the-art storage...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

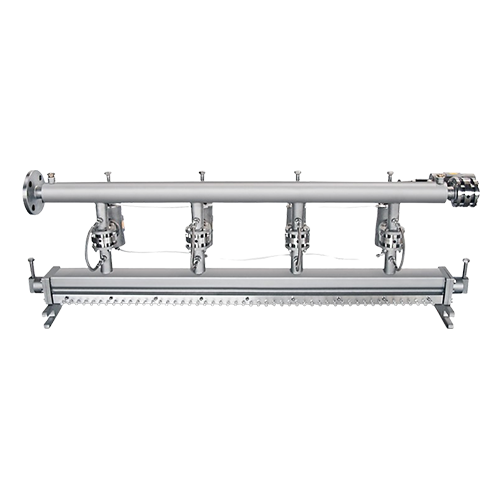

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Forming solution for candy and cereal bars

Achieve precision in bar production with a system that ensures minimal weight v...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Sugar and fondant coating solution

Achieve precise, multi-color or single coat applications with thin, uniform layers, seam...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Entry level cereal bar cutting table

The small-scale manual production of crunchy cereal bars, brittles, and similar produc...

Entry level cooker for cereal bar production

The creation of high-quality, flavourful crunch bars, brittles and similar pr...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...