Candy bars

Find innovative production technology for making candy bars and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Which candy bars technology do you need?

Vertical fill and seal bagging machine for bakery products

Streamline your bakery product packaging with this versatile ...

Horizontal cartoner for diverse industries

Streamline your packaging process with precise cartoning capabilities, effectiv...

Chocolate wrapping machine for confectionery production

Achieve precision and elegance in packaging with high-speed wrapp...

Entry-level flow wrapping machine for small and medium products

Optimize your packaging line with a high-speed flow wrap...

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrappin...

Horizontal flow wrapper for medium performance level

Offering high-speed, continuous flow wrapping, this versatile machin...

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Multi-lane ice cream wrapping system

Optimize your production line with a high-speed, multi-lane wrapping system designed t...

Schnitzel tenderizer with adjustable cutting pressure

For precise meat preparation, equip your production line with a sch...

Integrated production system for food processing

Optimize your food production line with this versatile system, designed t...

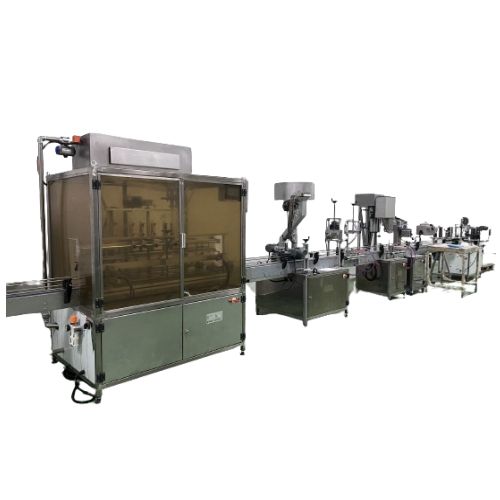

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Horizontal flow-pack solution for flexible wrapping material

Simplify your packaging process with a high-speed, three-si...

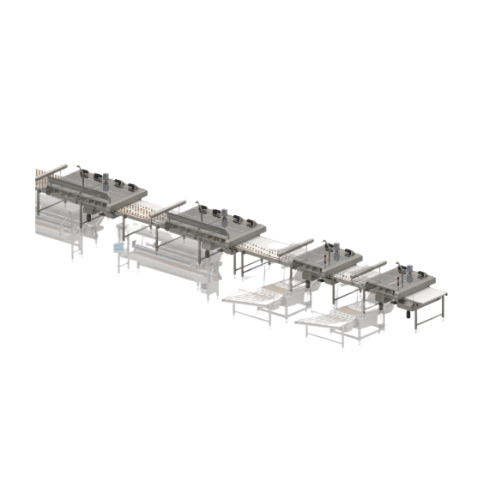

Linear mould system for ice cream production

Optimize your ice cream line with modular flexibility, allowing seamless adap...

Rotary mould machine for ice cream production

Streamline your ice cream production with a rotary mould machine designed fo...

Piston pump continuous ice cream freezer

Optimize your ice cream production with a continuous freezing solution that seamle...

Industrial ice cream continuous freezer

Ensure precise temperature control and product consistency in ice cream manufacturi...

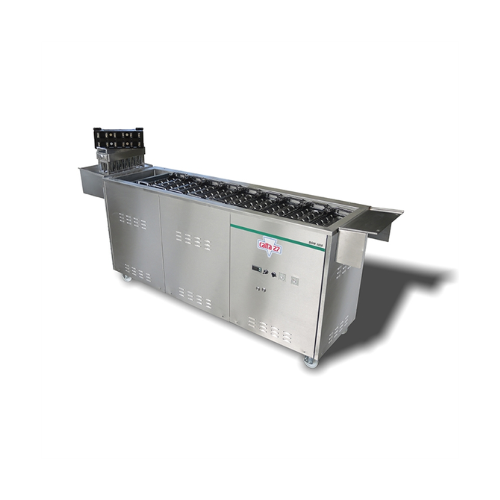

Hardening tank for water-ice lollies

Enhance your small-scale ice cream production with a versatile solution that allows yo...

Pilot plant for ice cream production

Optimize your ice cream production with a flexible pilot plant that seamlessly integra...

Semi-automatic dosing table for ice cream cups and bulks

Ensure consistent and precise dosing for various ice cream produ...

Linear filling machines for ice cream production

Enhance your ice cream production with modular filling machines designed ...

Rotary filling solutions for ice cream cups and cones

Optimize your ice cream production with customizable rotary filling...

Lobe pump for industrial ice cream production with ammonia Nh3

Optimize your ice cream and dessert production with conti...

Lobe pump freezer for industrial ice cream production

Streamline your ice cream production with a semi-automatic lobe pum...

Batch mix preparation system for ice cream

Optimize your ice cream production with an efficient system designed for precis...

High-temperature short-time pasteurization system for dairy products

Optimize your dairy and ice cream production with ...

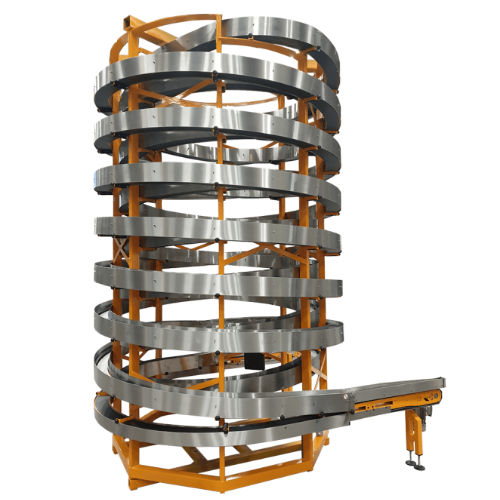

Wafer block spiral cooler

Enhance your confectionery production with a modular spiral cooler that ensures gentle handling an...

Transversal cutting for confectionery production

Achieve precise and customizable cuts in high-speed confectionery and bak...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

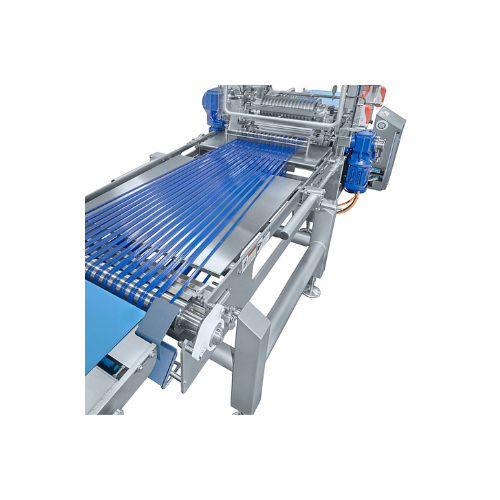

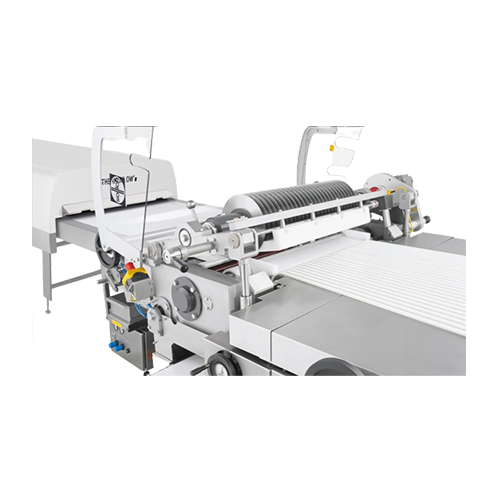

Dough sheeter for rotary-cut biscuits

Achieve consistently smooth dough bands essential for high-quality biscuits and confe...

Compact batter mixing system

For food producers aiming to ensure consistent batter quality, this modular system streamlines ...

Cooling conveyor for baked goods

Efficiently adapt your baked and confectionery goods to ambient conditions, ensuring optima...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

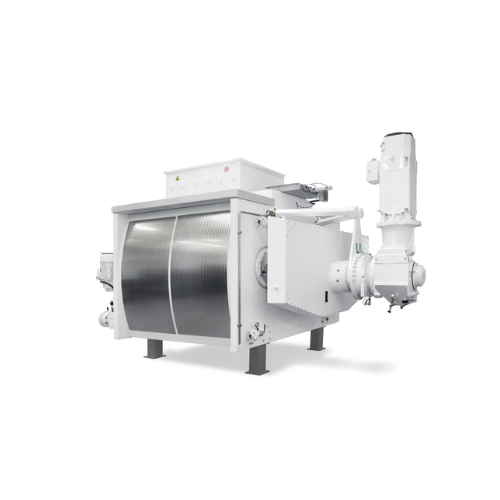

Double-overthrow conche for chocolate production

Achieve precise taste and texture in chocolate production with reduced en...

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Dough ripening conveyor for stick and fried noodles

Ensure optimal dough maturity and consistency with this conveyor, des...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Non-contact accumulator for packaging lines

Experience seamless integration and reduced product interference with this inn...

Compact accumulation conveyor for liquid containers

Optimize your space with an ultra-compact conveyor that ensures seaml...

Industrial cooker for soups and ready meals

Streamline your cooking operations with a versatile system capable of mixing, ...

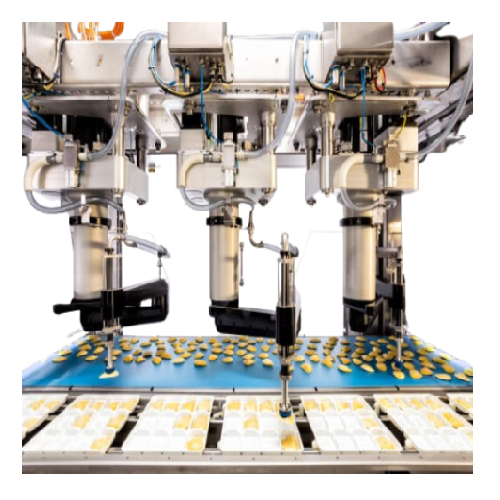

Biscuit slug loading system

Enhance your confectionery line with high-speed, precise slug loading that integrates seamlessly...

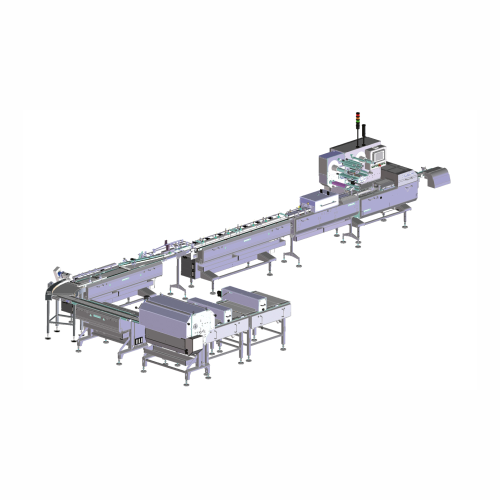

High-volume product distribution system

Efficiently manage high-volume snack and confectionery production flows with a syst...

Conveyor system for ambient product cooling

Ensure precise cooling of baked and confectionery products while maintaining l...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Industrial pressing system for convenience food

Optimize your production line with a versatile pressing system, designed t...

Shrink film sleeve wrapper for packaging

Achieve efficient packaging for diverse products with a versatile sleeve wrapper d...

Automatic tray sealer for preformed trays

Enhance packaging efficiency with a high-speed tray sealer designed for precisio...

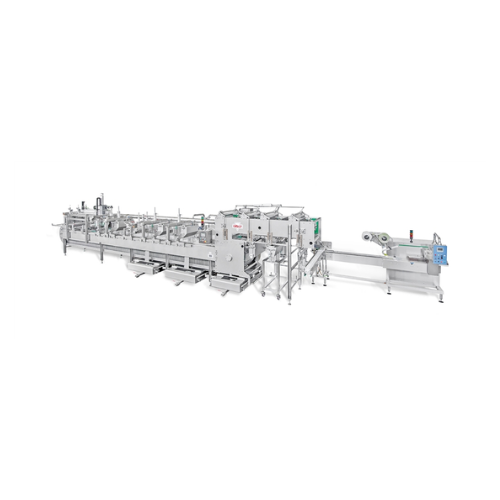

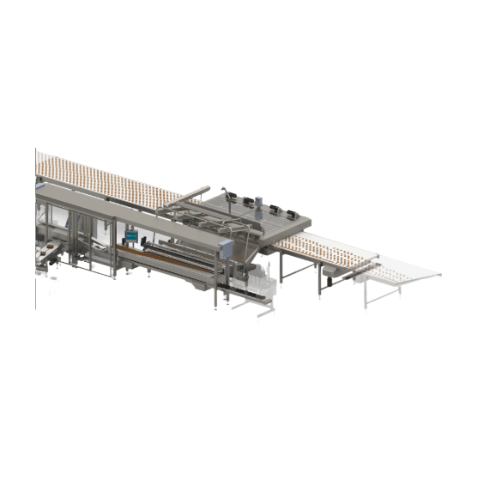

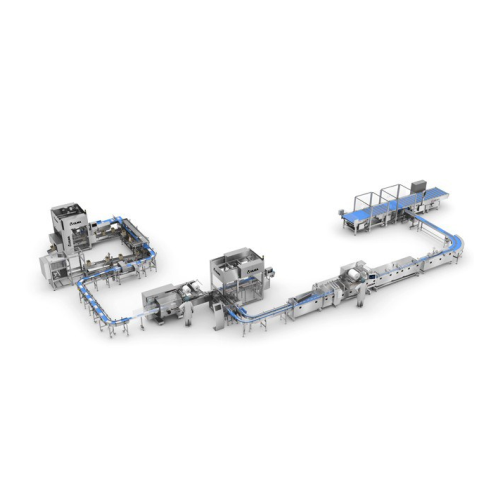

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Table top extruder for customizable extrusion processes

Discover versatile extrusion capabilities for developing complex ...

Ice cream transfer and dipping solution

For ice cream manufacturers looking to maximize production efficiency, this solutio...

Ice cream extrusion system

Optimize your ice cream production with a versatile system designed for efficient extrusion, shap...

Belt dryers for gelatin processing

Efficiently transform liquid gelatin into high-quality solids with precise moisture cont...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Chocolate storage tanks for confectionery production

Optimize your confectionery production with state-of-the-art storage...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

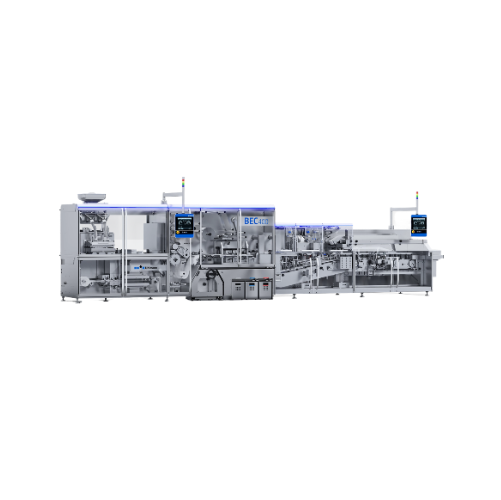

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

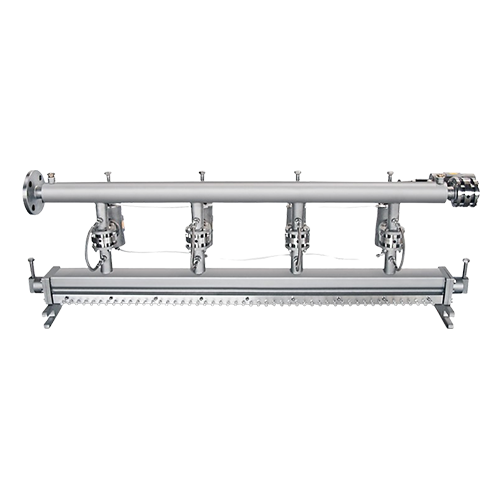

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Forming solution for candy and cereal bars

Achieve precision in bar production with a system that ensures minimal weight v...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Forming system for cereal bars and nut mixes

Effortlessly transform diverse ingredients like cereals and nuts into precise...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Pick & place vision system for packaging quality control

Ensure flawless product packaging with a vision system that enha...