Chocolate Moulding Equipment

Find production technology for moulding chocolate, and connect directly with leading machine manufacturers worldwide.

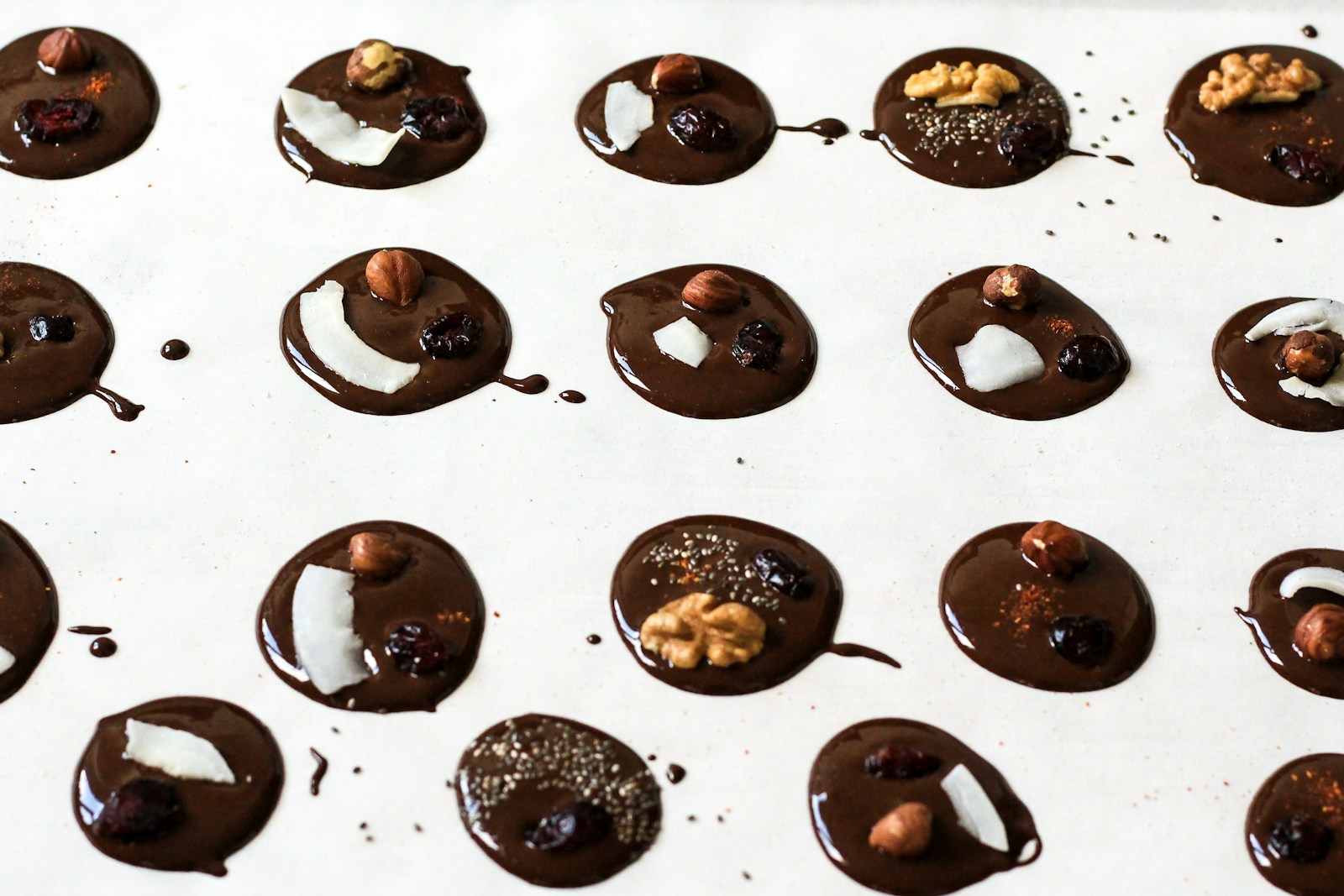

When molding chocolate, chocolate makers can go wild in choosing the shapes they like best. Just think of the Easter season with the millions of hollow figures around. Bonbons or chocolate bars are also perfect examples of chocolate molding. Chocolate moulding machines create your moulded chocolate by filling moulds of your choice with tempered chocolate and removing air bubbles through a vibrating motion. Remember that the molds must be clean and dry; otherwise, moisture can cause chocolate blooming.

Which chocolate moulding technology do you need?

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

Double spinning machine for hollow chocolate figures

Achieve perfect distribution of chocolate in molds with precision sp...

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

Hollow chocolate figure spinning solution

Achieve uniform chocolate coating in hollow figurines with precision spinning te...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

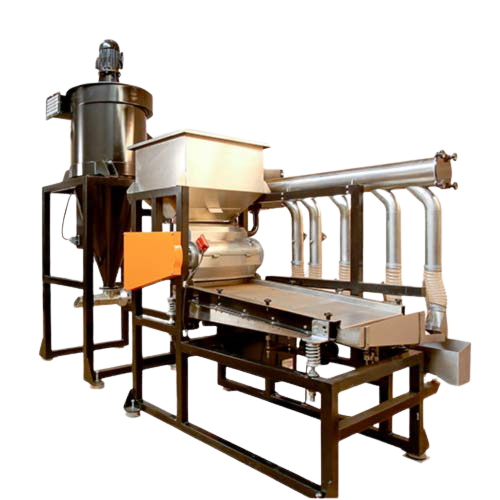

Precision chocolate production from cocoa nibs

Achieve ultra-fine chocolate textures by utilizing stone conching to bring ...

Buttercream filling applicator for chocolates

Enhance your confectionery process with precision dosing and moulding to cre...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

Dosing system for chocolate tablets

Enhance your confectionery production with a versatile solution for precise dosing and ...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

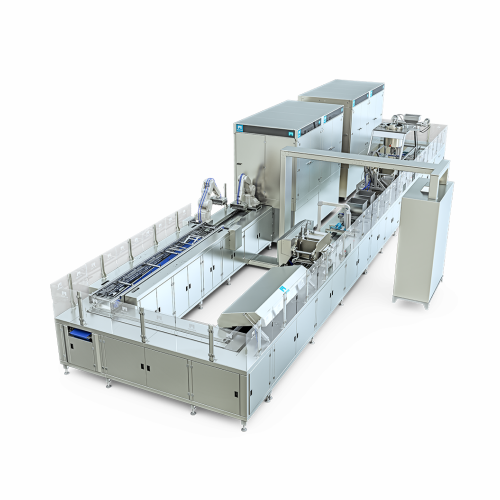

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Automatic chocolate shell moulding line

Enhance your production capabilities with a cutting-edge moulding line that deliver...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Chocolate moulding press for coco mass

Enhance your production line with precise chocolate moulding capabilities, shaping e...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

One-shot chocolate depositing system

Enhance your confectionery line with precise, high-speed depositing technology designe...

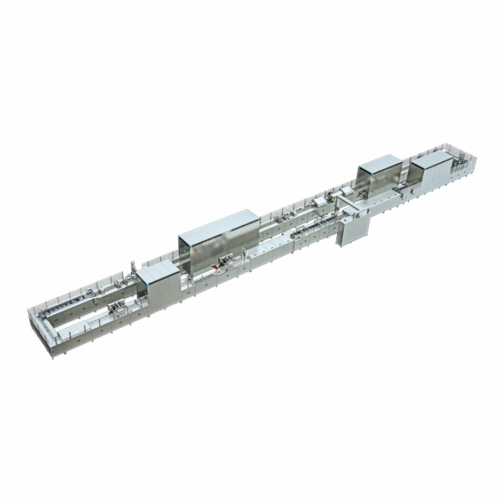

Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed p...

Loose mould line for chocolate production

Streamline your chocolate production with a high-throughput line that seamlessly...

Chocolate moulding line for filled and inclusions bars

Achieve seamless chocolate production with modular flexibility, al...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

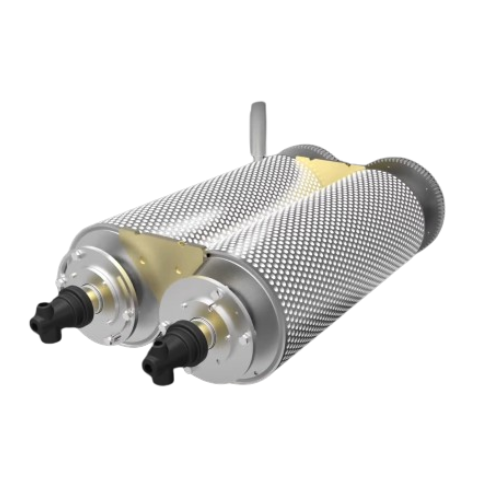

Laboratory roller for chocolate production

Easily switch between producing chocolate lentils, balls, and eggs with these f...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Chocolate depositor for small to medium production

Optimize your confectionery production with a versatile depositor that...

Depositor for solid and filled chocolates

Optimize your chocolate production with precision depositing for medium to large...

Wafer and biscuit feeder for chocolate moulding

Efficiently integrate wafers and biscuits into your chocolate production l...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Vertical tunnel for cooling and moulding chocolate

Efficiently manage chocolate temperature control and molding precision...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Simultaneous chocolate dosing solution

Achieve high-precision chocolate and ganache filling in a single step with this effi...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Simultaneous chocolate and ice cream dispenser

Unite the worlds of chocolate and ice cream with a machine capable of seaml...

Professional chocolate tempering system for artisan chocolatiers

Achieve precise chocolate tempering with quick changeov...

Professional chocolate tempering equipment for efficient production

Enhance your production capabilities with a versati...

Chocolate enrobing, moulding, and cooling tunnel

Optimize your chocolate production with this advanced tunnel, designed fo...

Wall chocolate fountain for continuous chocolate flow

Create a mesmerizing ambiance with a seamless chocolate waterfall, ...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Professional chocolate tempering solution for large workshops

Enhance your chocolate production efficiency with a machin...

Chocolate truffle extruder

Achieve precise and versatile production of chocolate truffles and snacks, with seamless integrat...

Chocolate enrobing and cooling tunnel 300/400 mm

Ensure seamless enrobing and precise cooling for chocolate products with ...

Chocolate bean to bar line 10kg

Developing new products, producing specialty chocolates, laboratory testing, and in-shop pro...

Chocolate bean to bar line 200kg

Installing a chocolate production line that works efficiently and smoothly can be a dauntin...

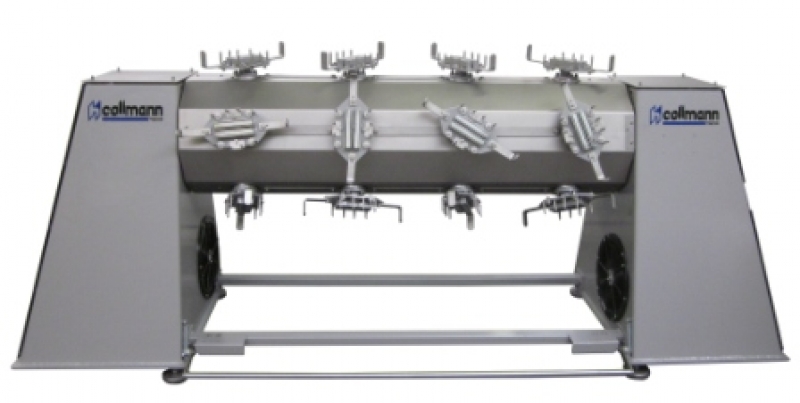

Compact 4-arm spinner for chocolate

For small productions or lab use in the manufacturing of chocolate hollow figures.

Big scale chocolate spinner

For larger production capacities of chocolate hollow figures.

De-moulder for flat bottom chocolates

De-moulding is often found to be a bottleneck in chocolate production and can be solv...

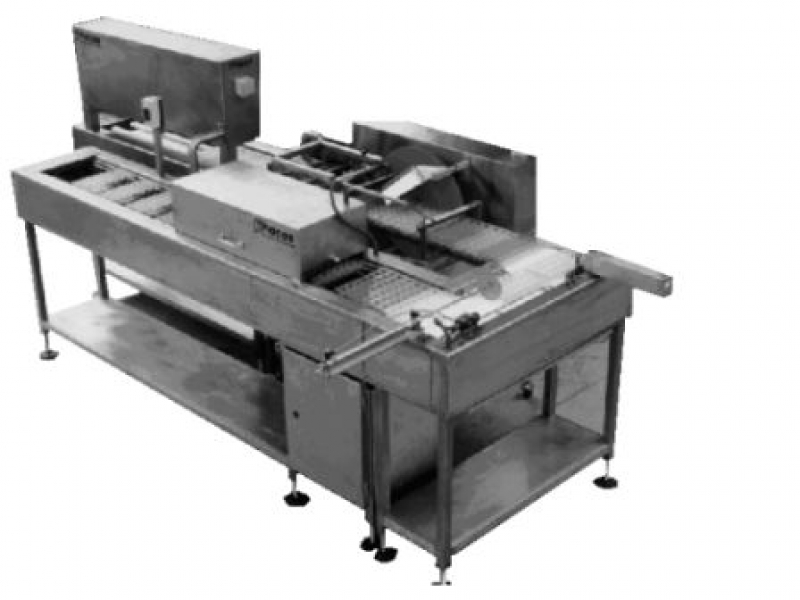

Semi-automatic moulding line for solid chocolates

Perfect for scaling up your production of tablets or filled chocolates.

Horizontal cooling tunnels for chocolate moulds

The perfect tunnel for semi-automatic production lines.

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Industrial long moulder for bakery production

Enhance your bakery’s efficiency with a high-speed long moulder ideal ...

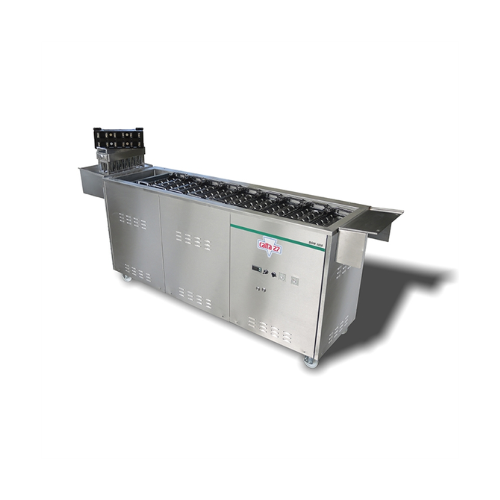

Hardening tank for water-ice lollies

Enhance your small-scale ice cream production with a versatile solution that allows yo...

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

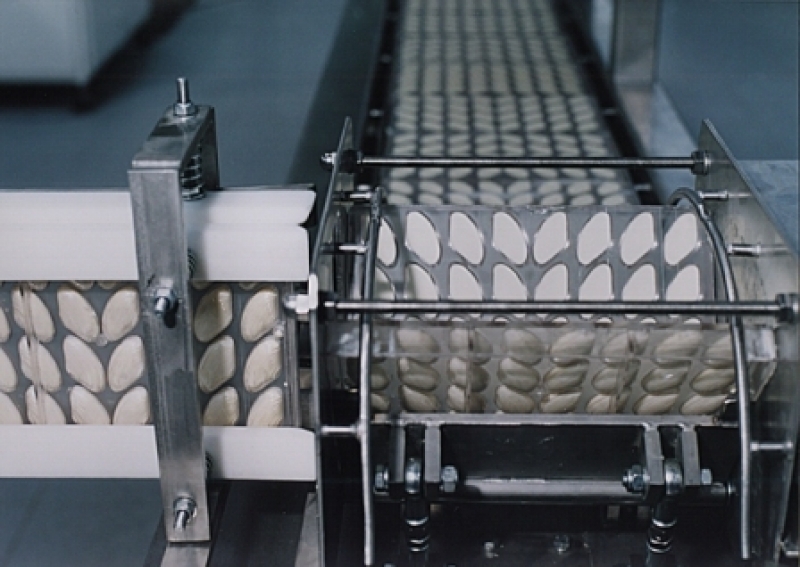

Automatic book-moulding system

Closes ‘book-moulds’ in order to produce eggs, balls, sea shells, and other 3-dim...

Hand moulding machine

Melting and tempering for convenient moulding of chocolates by hand.

Moulding line for pralines, tablets and cups

To automatize the process of moulding pralines, tablets, and cups in artisan ...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...