Peanut Butter Making Equipment

Find innovative production technology for making peanut butter and connect directly with world-leading specialists

To put into perspective, the average number of peanuts that you use to make a 12-ounce jar of peanut butter is 540 pieces. Peanut butter is widely used as a spread for most bread and biscuits. To make it, use raw peanuts and process them using peanut butter making machines.

Select your peanut butter process

Tell us about your production challenge

Peanut butter production and relevance of peanut butter processing machines

Most peanut butter is made from ground peanuts. They undergo several peanut butter processing equipment before turning into peanut butter. After shelling, cleaning and processing the peanuts, they undergo roasting in a hot air roaster at 240 °C (464 °F). This equipment helps them roast evenly at a high temperature. Next, they cool down to room temperature; this is to prevent them from losing too much oil. After blanching them using water or spin blanching, you ground them to a paste inside a grinder machine.

In this stage, you can gradually add additives such as sugar, salt, and hydrogenated vegetable oils. Cool the peanut butter from 60 °C to 38 °C (140 °F to 100.4 °F) Then, the final product is ready for packaging and can be inserted into jars. Compared to other spreads, peanut butter usually does not contain any artificial coloring and sweeteners. You can store it at room temperature, and will not spoil easily.

Stabilizers used in peanut butter products

Peanut butter makers use stabilizers or emulsifiers to create a stable and firm texture on peanut butter. The common stabilizers are hydrogenated oils (like canola and cottonseed oils), lecithin, and other mono- and diglycerides. These stabilizers ensure that the natural oils formed upon the peanut butter grinding process, coexist along with the paste, creating a consistent and spreadable peanut butter. In small scale peanut butter production—natural, it’s possible to make stabilizer-free peanut butter. This is due to health risks that stabilizers, which are trans-fat, impose. The only key factor is shelf-life; natural peanut butter is not meant to last longer than commercial peanut butter due to stability.

Standards for a great peanut butter

Overall, good peanut butter must have a natural, light-brown color. For stabilized peanut butter, it must have no noticeable oil separation and has a good amount of moisture from natural oils once they have gone through a mixer. Good peanut butter also spreads easily, with very little effort; it must show slight stiffness when mixed and has a firm consistency. For non-stabilized peanut butter, there should be no more than slight mixing required to disperse any natural oils. Whether you stabilize it or not, a quality peanut butter must have a good flavor and aroma.

FDA regulations and more standards for peanut butter

The FDA has regulations for high-quality peanut butter in the US. The fat content of peanut butter must not exceed 55% and no less than 90% peanut content. Stabilizing ingredients and seasonings must not also exceed 10% of the total weight. In addition, oil products that you add as stabilizers shall only be hydrogenated vegetable oils or partially hydrogenated vegetable oils. Also, regulations allow an average of one or more rodent hairs and 30 insect fragments per 100 grams of peanut butter. However, EU regulations are more proactive when it comes to prohibited additives, such as stabilizers. Some countries in Europe will strictly ban those products which contain the additive.

Processing steps involved in peanut butter making

Which peanut butter technology do you need?

Mortar grinder for reproducible sample preparation

Achieve precise and consistent material preparation with this mortar g...

Continuous mixer for cookie and snack dough

Achieve uniform and consistent mixing of cookie and snack dough with seamless ...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Chocolate melting and mixing kettle for small-scale production

Streamline your confectionery production with a compact k...

Laboratory homogenizer for viscous products

Achieve ultra-fine textures and improved consistency in pasty and semi-pasty p...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Tube filling solution for plastic and laminate tubes

Ensure precise tube filling and sealing with quick changeovers, enha...

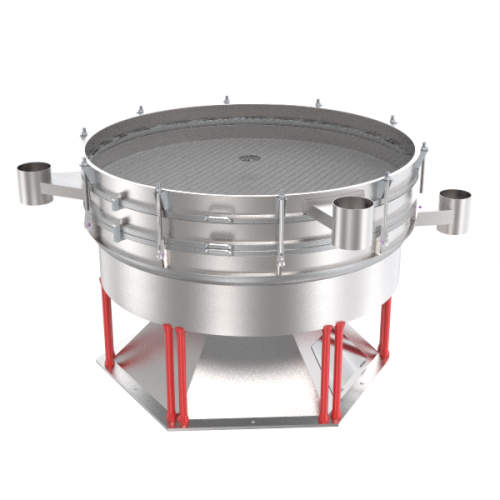

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

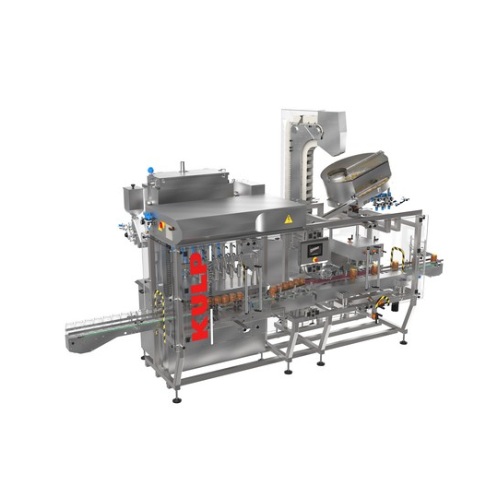

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

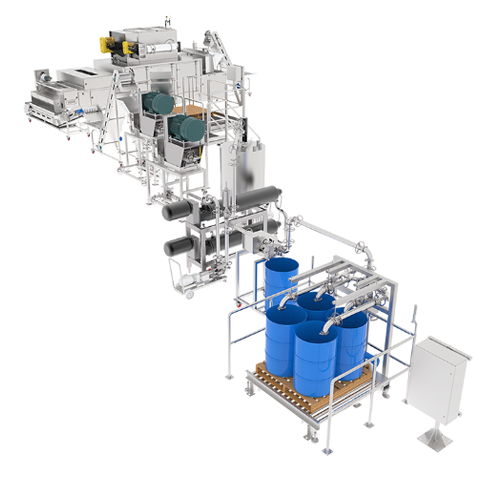

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Paste filling system for high viscosity products

Efficiently fill high viscosity products with precision and speed, reduci...

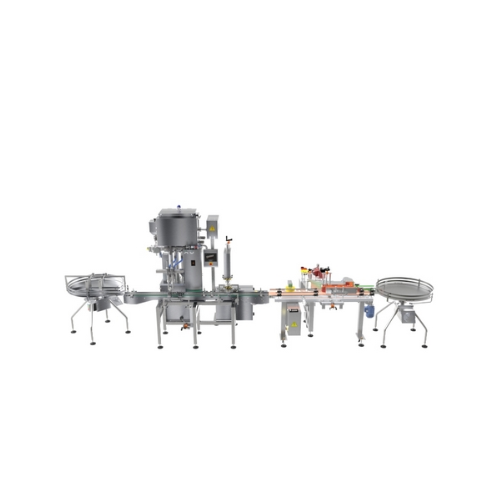

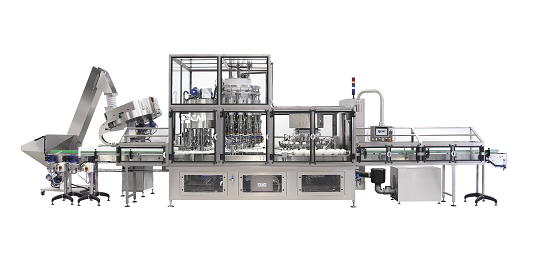

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Spindle mill for fine and super fine grinding of cocoa liquor

Achieve precision in grinding cocoa liquor and nut pastes ...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Chocolate processing unit for mixing and grinding

Achieve precise mixing and conching efficiency for premium chocolate an...

Pre-grinder for roasted nuts and seeds

Maximize efficiency in creating smooth nut and seed spreads with this pre-grinding s...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

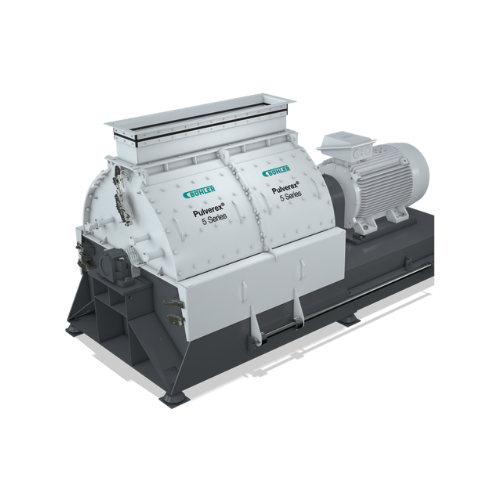

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

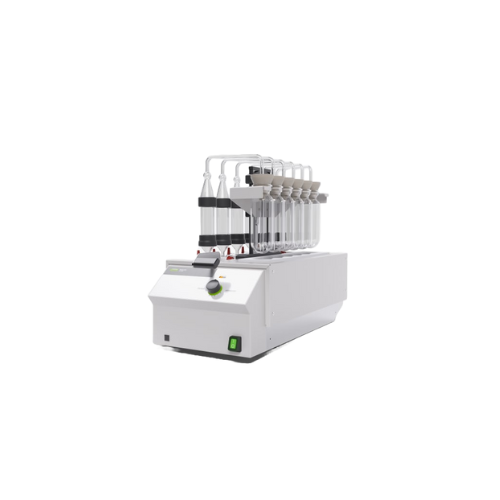

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Acid hydrolysis system for total fat determination

Streamline your laboratory workflow with a powerful hydrolysis system ...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Sanitary static blender for food and beverage

Optimize your mixing process with low shear, energy-efficient blending desig...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Semi-automatic piston injector for bakery products

Enhance your bakery production with precise delivery of a wide range o...

High capacity continuous puffer for popcorn

Optimize your snack production with advanced airflow and speed controls design...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Rotary oven for japanese peanuts

Achieve uniform coating and optimal roasting for Japanese-style peanuts with precise temper...

Split peanut blancher for snack food processing

Efficiently transform roasted or dried peanuts into perfectly blanched pro...

Conveyors for material handling in food processing

Streamline your snack production line with conveyors designed to effic...

Spiral chute for gentle product handling in limited space

Optimize your snack and nut production by minimizing product d...

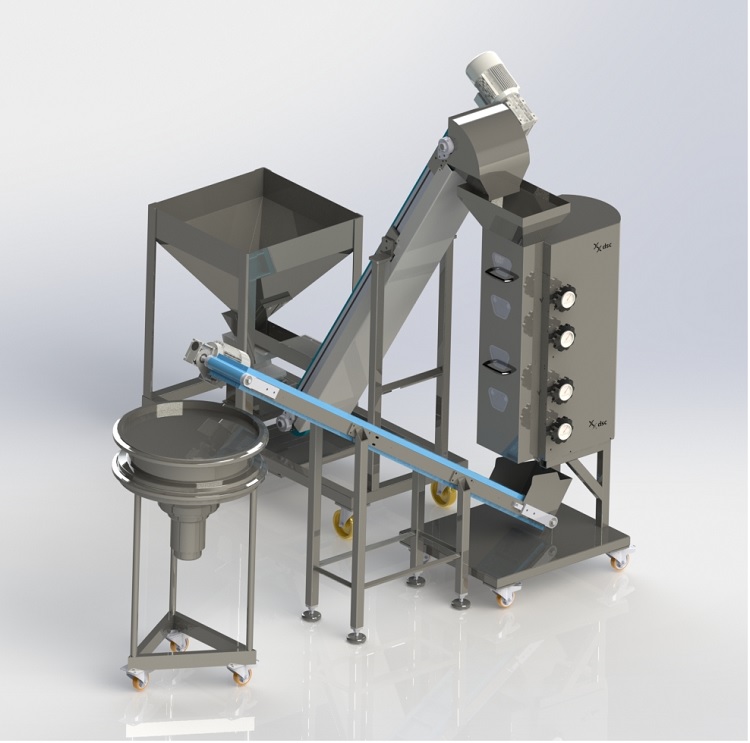

Integrated nut butter production line

Enhance your nut processing capabilities with a fully integrated production line that...

Nut butter mill for snack food processing

Efficiently transform various nuts into smooth, spreadable butters with precisio...

Rotary tampers for metal and glass containers

Optimize your food production line with high-speed rotary tampers, designed ...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

Battery production facilities with precision weighing

Achieve maximum product purity and precision in your production pro...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Inline mechanical homogenizer for food processing

Achieve precise particle size and uniform texture in your emulsions and...

Slicer for food processing applications

Efficiently achieve precise cuts and textures for a variety of food products, enhan...

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

Single piston depositors for bakery and food production

Optimize your depositing and filling processes with versatile equ...

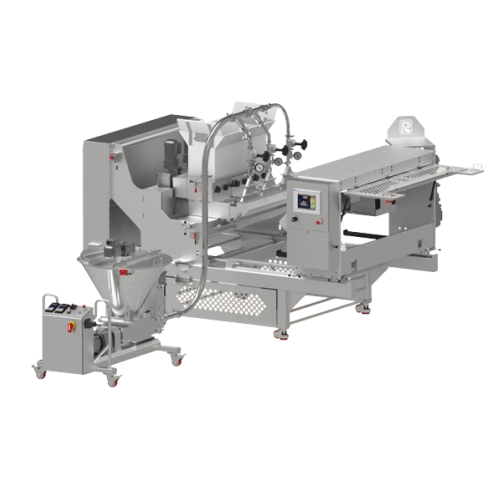

Automated sandwich production line

Optimize your sandwich production with high-speed automation that effortlessly handles d...

Vertical slow juicer for producing cold pressed juice

Achieve optimal juice quality and versatility with low-speed crushi...

Commercial slow juicer for nutrient-rich juice

Achieve higher juice yields and nutrient retention by utilizing advanced tw...

High-speed blender for commercial use

Designed for high-performance blending tasks, this solution integrates vacuum technol...

In-line filling and closing system for pre-formed containers

Looking to enhance production efficiency with a solution th...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

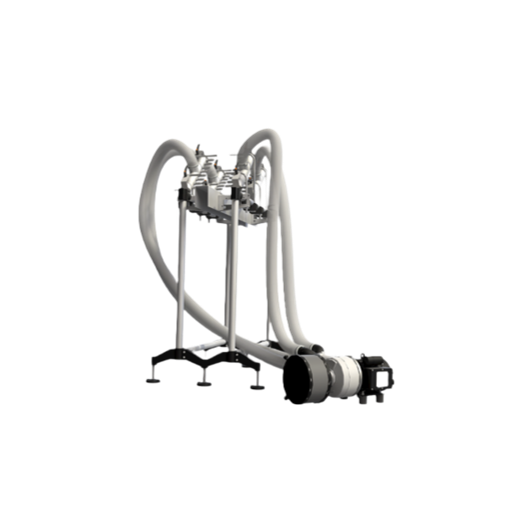

Powder feeder for consistent and accurate dosing

Ensure precise powder dosing with high hygiene standards to maintain prod...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Drum unloader for liquid ingredients

Unlock efficient unloading of viscous and liquid ingredients without the hassle of lif...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

Liquid sugar storage tank

Ensure seamless liquid sugar management in your production line with advanced storage solutions de...

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

Wet almond peeling machine for nut processing

Enhance your nut processing efficiency by achieving up to 98% peeling rate w...

Industrial peanut butter production line

Enhance your production line with this comprehensive peanut butter processing solu...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Almond sheller

Streamline your nut processing operations with a high-efficiency shelling machine designed for precision cracki...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Hydraulic oil press for efficient oil extraction

Streamline your oil production with a hydraulic oil press that ensures hi...

Automatic peanut peeling system

Achieve seamless peanut processing by eliminating red skins efficiently, enhancing the quali...

Food processing scraped surface heat exchanger

Enhance your production line with precise temperature control and continuou...

Refiner for spreadable cream and chocolate

Achieve optimal texture and consistency for your spreadable creams and chocolat...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Continuous extruder for protein bars and super foods

Optimize your snack production with a continuous extrusion solution ...

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

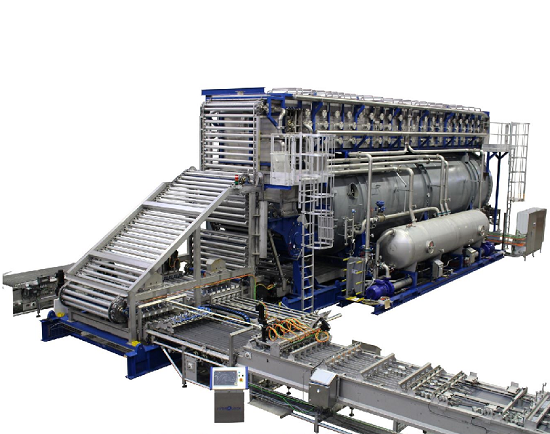

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Continuous sterilizer for tin cans and jars

A concern in the coffee industry is maintaining the freshness, taste, and qual...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Air knife drying system for containers

In food or beverage production where a product is filled into jars, there is often r...

Filling machine for viscous products

Chocolate paste and other viscous liquids require special handling to obtain the optim...

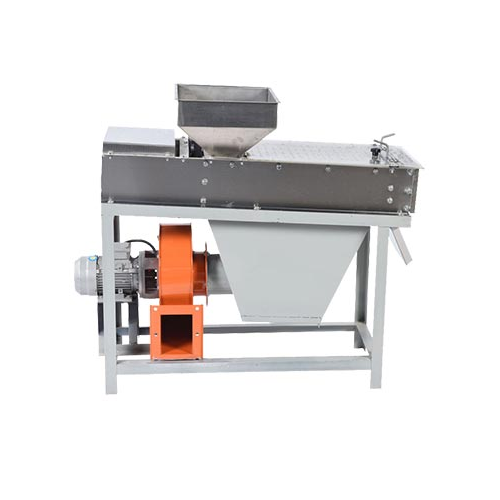

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Waterproof checkweigher

Features waterproof and dust proof cabinet and components. Its hygienic design is perfect for unpacke...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Versatile stone mill machine

In the food industry, when it comes to milling a wide range of products such as seeds and nuts ...