Making Eye Drops

Find innovative production technology for making eyedrops and connect directly with world-leading specialists

Eyedrops processing is quite literally a sight for sore eyes. There is no shortage of eye care products, from eyewashes to anesthetics to antibiotics. But formulating eyedrops is a complex affair with multiple safety checkpoints. Technological advances bring a pair of fresh eyes to manufacturing, ensuring higher-quality products for specialized applications.

Select your eyedrops process

Tell us about your production challenge

Formulate eyedrops with a thickening agent to increase contact time

Vehicles for eyedrops are prepared from aqueous media, making them thin solutions. A runny product is less effective because it reduces contact time with the cornea. Formulate the solution with a viscolizer such as hyaluronic acid or polyvinyl alcohol to address this challenge.

These adjuvants increase the product’s viscosity so that it has a longer period in the eye and produces higher bioavailability.

Incubate the eyedrops solution in a microbial medium to test its sterility

Eyedrop solutions must pass the sterility test before they can be deposited into containers for shipping. The procedure involves inoculating the sample with a microbiological environment like a soy-bean casein digest medium.

The samples are deemed sterile if no growth is observed after 5 days of direct incubation. In the case of indirect incubation using a membrane filtration method, the testing period must run for 14 days.

Eyedrops processing using alternative preservatives

Multi-use eye drop products contain preservatives to prevent microbial growth. The most common agent used in manufacturing is benzalkonium chloride (BAK). But this substance raises health issues, especially in cases of dry eye disease.

A special polymer named PQ-1 (Polyquaternium-1) is used as an alternative preservative for both dry eye preparations and glaucoma medications. An anti-bacterial, PQ-1 keeps the product free from pathogens. But because of its larger molecular size, it does not penetrate human cells and drastically lowers the toxic risks compared to BAK.

Print the vital information directly on the packaging

The eyes are delicate organs, and packaging for ophthalmic drugs must adhere to stricter safety parameters than other dosage forms.

Bottle openings have to be sealed to protect the solution and ensure the validity of the use-by date. Besides the expiry information, the packaging must include the date of manufacture and storage recommendations.

Processing steps involved in eyedrops making

Which eyedrops technology do you need?

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

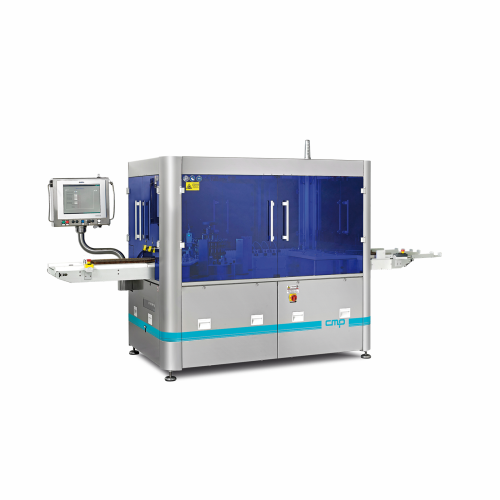

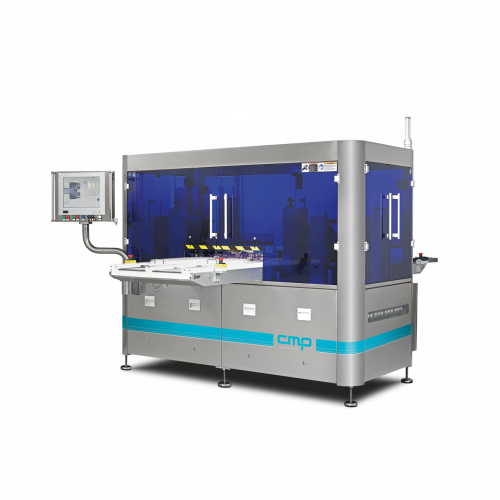

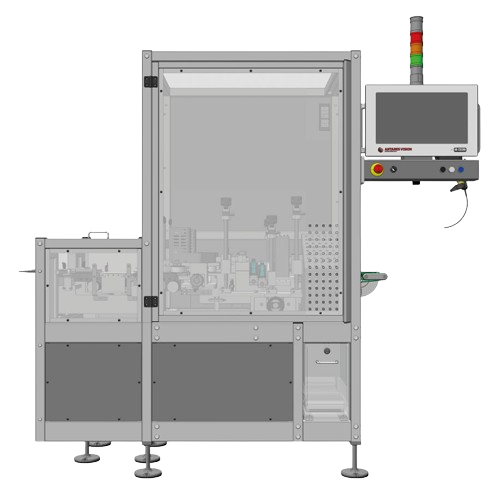

360 and leak Inspection system for glass containers

Ensure the integrity of every glass container with a comprehensive in...

Inspection for glass containers

Ensure the integrity and quality of your liquid formulations with high-speed inspection and ...

Filling and capping solution for bottles

Optimize your bottling efficiency with a robust solution designed to streamline fi...

Labelling system for blow fill seal (bfs) strips

Ensure precise labeling and traceability for your blow fill seal containe...

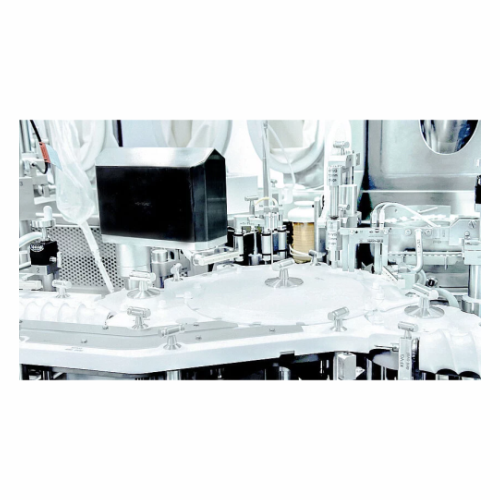

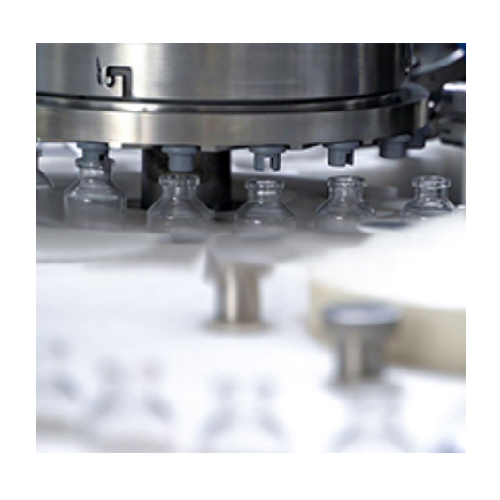

Rotary filling and closing system for pharmaceutical bottles

Optimize your large-batch liquid production with a high-spe...

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

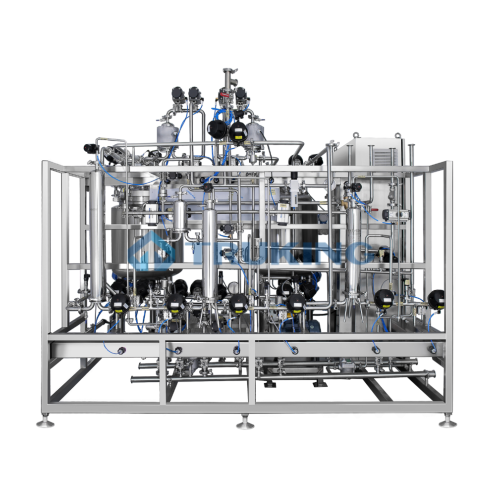

Purified water generation system for pharma applications

Ensure consistent purity in your therapeutics production with a ...

Purified water storage and distribution for pharmaceuticals

Ensure seamless water quality for critical pharmaceutical pr...

Wfi cooler

Ensure precise temperature control and contamination-free dispensing for high-value liquid formulations with this a...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

Liquid filling system for medical and pharmaceutical products

Enhance your production capabilities with high-speed liqui...

Flexible horizontal cartoning solution for various products

Streamline your packaging process with this versatile carton...

Liquid dosing and assembly platform for pharmaceutical products

Optimize your production line with a seamless solution f...

Semi-automatic powder dosing system

Achieve precise micro-dosing for pharmaceutical powders with a flexible system ideal fo...

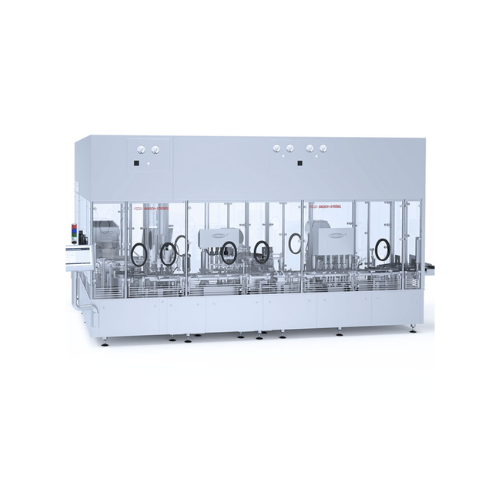

Aseptic filling solutions for Rtu vials, cartridges, and syringes

Optimize your aseptic filling processes with a system...

Nasal spray and eye drop filling solutions

Enhance the precision and flexibility of your liquid filling operations with ou...

Filling solution for consumer healthcare products

Navigate complex liquid product formulations with a versatile filling s...

Industrial manipulator for sterile and nonsterile filling

Maintain the integrity of high-value pharmaceuticals with a hi...

Sterile and nonsterile vial filling system for injectables

Achieve precision and safety in filling and stoppering with a...

Filling solution for non-injectable pharmaceutical products

Streamline your pharmaceutical production with a versatile s...

Sterility test isolator for injectables and sterile powders

Ensure sterility and compliance for injectables and biopharm...

Pharmaceutical turnkey project consultants

Streamline your biopharma production with turnkey solutions that cover everythi...

Pharma manufacturing process vessels

Ensure contamination-free production of sterile liquid formulations with process vesse...

Purified water generation system for pharmaceutical applications

Ensure consistent water purity for critical drug formul...

Touch screen dose calibrator for nuclear medicine

Achieve precise radiopharmaceutical dosing with seamless touchscreen op...

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

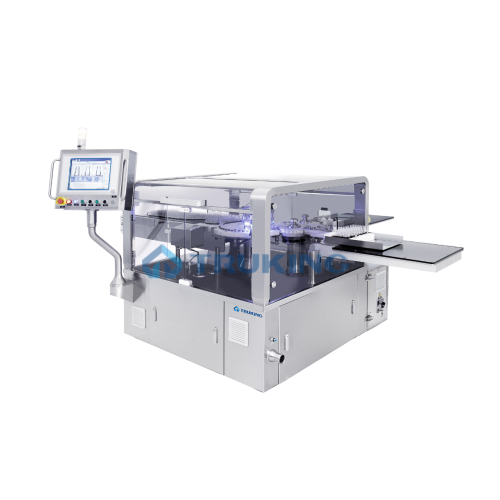

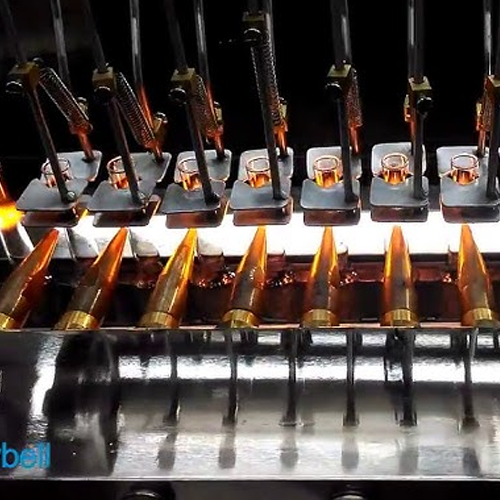

Ampoule filling and closing system

Optimize your production line with a high-speed system designed for seamless filling and...

Full-membrane water for injection (wfi) generation system

Ensure consistent high-quality injections by integrating real-...

Sterile liquid preparation system for pharmaceutical use

Ensure the sterility and precision of your liquid formulations w...

Purified water storage tank for pharmaceutical use

Ensure the integrity of your pharmaceutical formulations with precisio...

In-line checkweighing and printing system for cartons

Ensure precision and efficiency in your packaging line with a compa...

Automated bottle and jar filling solution

Streamline your production and minimize waste with a versatile filling solution,...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Process analytical technology for lyophilization

Ensure product integrity by detecting trace contaminants and optimizing l...

Large bottle blow/fill/seal packaging system

Achieve precise liquid filling and sealing for large-scale production with hi...

Blow/fill/seal packaging system for sterile liquid products

Streamline your liquid product manufacturing with high-speed...

Blow/fill/seal packaging for large bottles

Need a high-speed solution for producing sterile liquid formulations in large v...

Insertion technology for sterile blow/fill/seal systems

Ensure sterility and precision in liquid pharmaceutical packaging...

Washing machine for pharmaceutical stoppers and caps

Streamline your aseptic processing with precise washing, sterilizati...

Vertical ultrasonic washing for pharmaceutical containers

Ensure immaculate cleanliness and sterilization of pharmaceuti...

Autoclave unloading isolator for sterile assembly

Ensure aseptic conditions and prevent microbial contamination during th...

Pharmaceutical preparation system

Achieve seamless integration in pharmaceutical processes with a preparation system that o...

Automatic inspection system for ampoules and vials

Ensure precision in pharmaceutical production with a comprehensive ins...

X-ray inspection for pharmaceutical vials

Ensure product purity by detecting contaminants in pharmaceutical vials with adv...

Automatic inspection system for sealing defects in ampoules

Ensure flawless ampoule sealing with a high-precision inspec...

Pharmaceutical drops and sprays filling system

Streamline your liquid formulation process with precision filling and seali...

Aseptic ophthalmic filling isolator

Ensure sterility and precision in ophthalmic solutions with a controlled aseptic enviro...

Ophthalmic filling solution for eye drops

Enhance your ophthalmic production line with a solution designed for precision f...

Micro-line vial filling solution for biopharmaceuticals

Ensure batch consistency and sterility in fill-finish operations ...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Motorized cap torque tester for bottle closures

Ensure precise seal integrity and compliance with bottle cap torque measur...

Triple combi filling and stoppering system for vials and ampoules

Optimize your liquid formulation process with a versa...

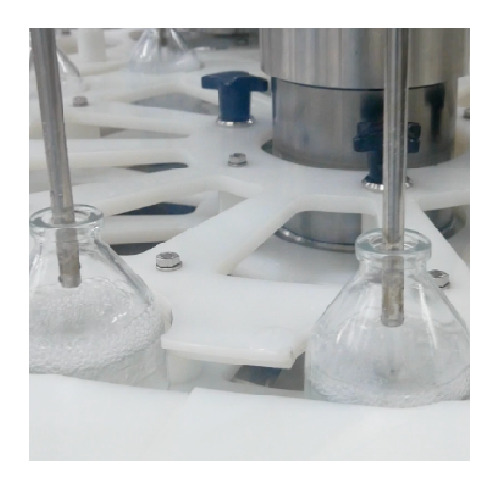

Automatic filling, nozzle placing, and capping line for ophthalmic solutions

Ensure precise dosing and secure sealing ...

Rotary vial filling and stoppering system

For high-speed production of sterile injectable vials, this continuous motion ro...

Continuous motion rotary vial filling and stoppering solution

Optimize your vial production with a high-speed, continuou...

Single-mold continuous bottle Bfs solution

Optimize aseptic production with this advanced solution, offering superior ster...

Plastic bottle Bfs leak detection solution for small volume injections

Ensure sealed integrity with precision leak dete...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Hygienic Cartoning Machine For Pharma and Health Products

When packing single or multiple vials, ampoules or devices int...

Laboratory liquid viewer for colored glass bottles

In the pharmaceutical industry, an inspection to detect any particulat...

Laboratory liquid viewer for varying light conditions

In the pharmaceutical industry, you must inspect liquids in vials o...

Laboratory liquid viewer for transparent glass bottles

Impurities like hair, fibers, or glass, sourced from the environme...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Low speed Filler for large-volume parenterals

Large-volume parenteral bottles are usually manufactured with a resin that c...

Pharmaceutical formulation and mixing tanks

Preparation lines for formulating pharmaceuticals include fixed and mobile tan...

Pharmaceutical bottle filling machine

Filling machines for pharmaceutical bottles must achieve high production speeds while...

Ampoule filling machine

Filling ampoules or vials with parenteral fluids are an essential matter for which you need to consid...

Sampling probe for bioreactor samples

In biopharmaceutical and chemical industries, sampling is vital to develop, maintain,...

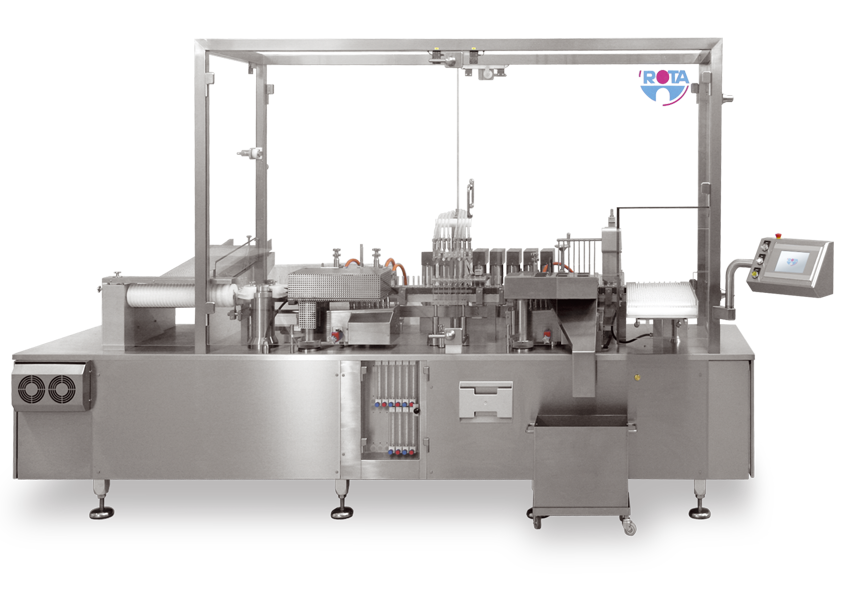

Start-up sterile filling line for ophthalmics

Commencing ophthalmic production requires sterile conditions and accurate me...

Sterile filling line for ophthalmics

Demanding very high standards, the ophthalmic market requires quality solutions for fi...

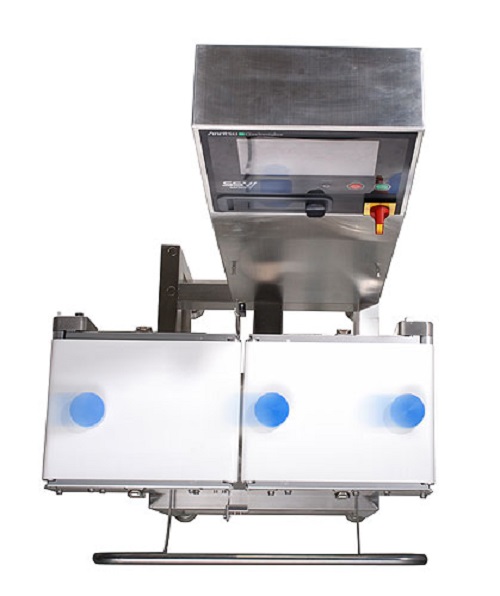

Small bottle checkweigher

Any small-diameter bottle, containing prescription medication or cosmetic applications, can be pro...

Versatile checkweigher

This Versatile checkweigher is equipped with a highly versatile strain gauge load cell. It is also sui...