Making Nut Butter

Find innovative production technology for making nut butter and connect directly with world-leading specialists

Toast spread, oatmeal topping or salad dressing - nut butter can be used in various ways. Although in a culinary sense classified as such, peanuts, almonds, cashews and pecans, the popular choices for nut butter are, botanically speaking, not nuts. They are processed in a series of nut butter processing equipment to get the creamy, rich product ready for consumption.

Select your nut butter process

Tell us about your production challenge

From nut to butter – steps, ingredients and processing equipment

Nuts make up to 90% of nut butter, accompanied by salt, vegetable oil, dextrose and corn syrup to improve taste and texture. Nut butter production starts with harvest, which is helped by portable mechanical pickers. Harvested nuts undergo a process called shelling, passing through a series of rollers to crack them, followed by screens, blowers, magnets, and destoners to remove the shells.

Once they reach the factory, nuts are dry-roasted. Nuts are then quickly passed to the next piece of nut butter processing equipment – coolers, where they are cooled down to 30°C. Passing the cooled nuts through a gravity separator removes foreign materials before blanching them, in case the chosen nuts have skin. In contrast, the remains are removed by passing them further through the blancher in a continuous stream. Finally, the nuts are processed in a grinder, from where it goes to a stainless steel hopper, which is both a mixing and storage point.

Same but different - Nut Butter vs. Nut Paste

Although almost identical, the ingredients are the characteristic difference between nut butter and nut pastes. While, naturally, nuts are the predominant component of nut butter, other ingredients are added that help to develop taste, smoothness and consistency, such as sugar, emulsifiers and oils. On the other hand, nut pastes are purely nut products without any additions to modify their characteristics. Therefore, it is suitable as an ingredient in products such as ice creams, cookies or chocolates. However, it is essential to highlight that no actual regulations define the difference between a nut butter and a nut paste.

All the butters to go nuts for

Smooth or crunchy, sweetened or natural, added to savory or sweet meals, nut butter and nut pastes offer a wide range of products. The most popular choices are peanut, almond, cashew, walnut and pecan butter or pastes. Some of these products are rich in fiber, protein, and fatty acids as well as vitamins and minerals, which makes them an ideal addition to any meal.

Going nuts for peanut butter

Peanut butter was invented in 1890 by an American doctor as a protein substitute for patients unable to chew meat. It is made by grinding roasted peanuts with added ingredients to enhance its characteristics. One of the key steps in peanut butter processing is blanching – removing the skin. There are two different methods. A heat blanching process exposes peanuts to high temperatures which cause the skin to crack. The second method, water blanching, removes the skin by quickly soaking peanuts in a scalding water bath. The bleaching step is widely used, as blanched peanuts result in a smoother texture, but it is not necessary. Namely, the skin contains extra nutrients and a rich, nutty flavor.

Going nuts for almond, cashew and hazelnut butter

Although peanut butter is the most popular choice, other types of nut butter and pastes have been on the rise. Almond butter might be the second most popular choice as the consistency and production process are almost identical to peanut butter. Cashew butter also follows the production steps closely, but it skips the blanching step as it does not have skin. In contrast to the purely healthy options, hazelnut butter can be mixed with cocoa to make chocolate spreads. However, pure hazelnut butter is rich in Vitamins E and B.

The environmental impact of nut butter production

Although especially popular among the plant-based population, nut butter production yields some adverse environmental impacts. For instance, almonds, known as the least sustainable nut, require large amounts of water. It takes 819 gallons of water to grow one pound of shelled almonds. However, almond farmers have managed to cut down water use by 33% in the past two decades with the help of research-based farming improvements and water-saving technologies. Peanuts, on the other hand, are more sustainable nuts, as they grow in rainy areas requiring less water, similar to pistachio. Like others, the nut butter industry is moving towards more sustainable production methods by improving crop and yield, along with reducing waste.

Processing steps involved in nut butter making

Which nut butter technology do you need?

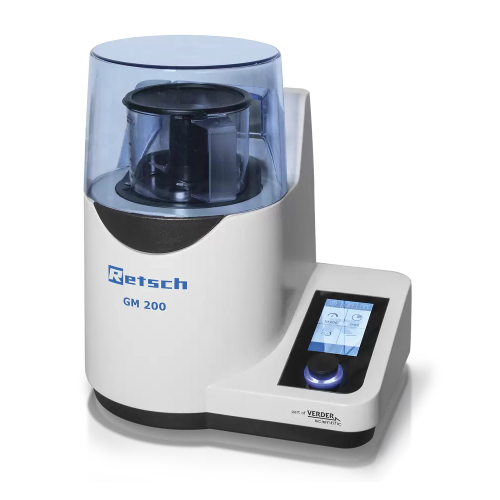

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Continuous ultra-high temperature processor for processed cheese

Ensure precise thermal treatment and enhanced flavor re...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

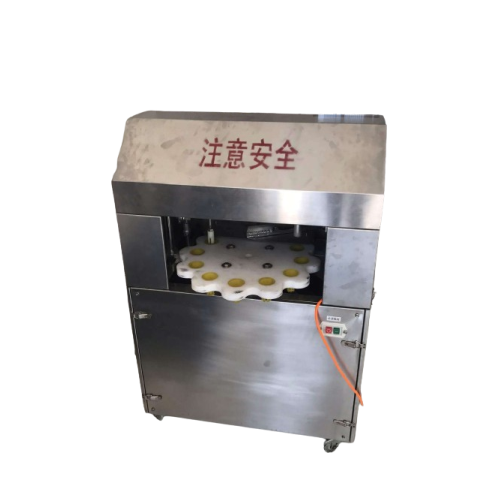

Sesame seed washing system

Eliminate the bitterness and impurities from sesame seeds efficiently, setting the stage for high...

Volumetric filler for liquid and viscous products

Achieve precise and adaptable filling for a wide variety of liquid and ...

Paste filling system for high viscosity products

Efficiently fill high viscosity products with precision and speed, reduci...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Batch conche for chocolate making

Achieve optimal texture and flavor development in your chocolate with precise control ove...

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control...

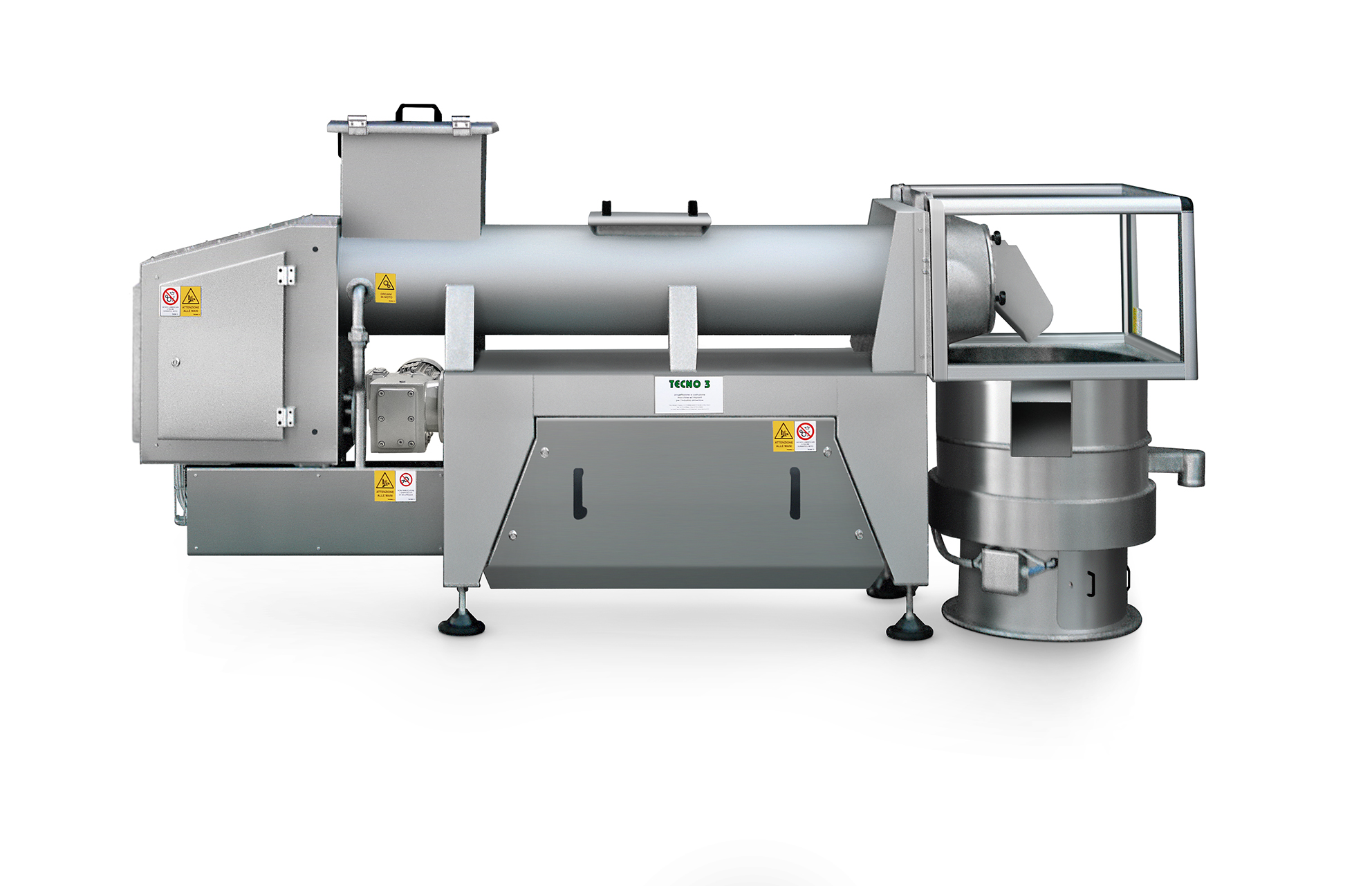

Double shaft batch mixer for chocolate production

Optimize your chocolate and confectionery production with precise mixin...

Pre-refiner for chocolate processing

Optimize pre-refining in chocolate and cocoa production with precise fineness control,...

Cocoa nib grinding system

Optimize your cocoa and nut processing with precision grinding to achieve a pumpable mass, ensurin...

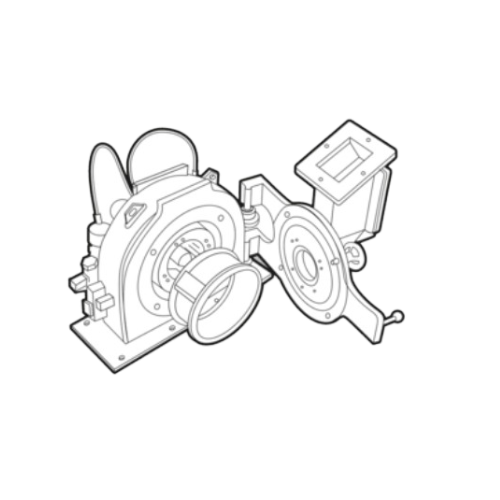

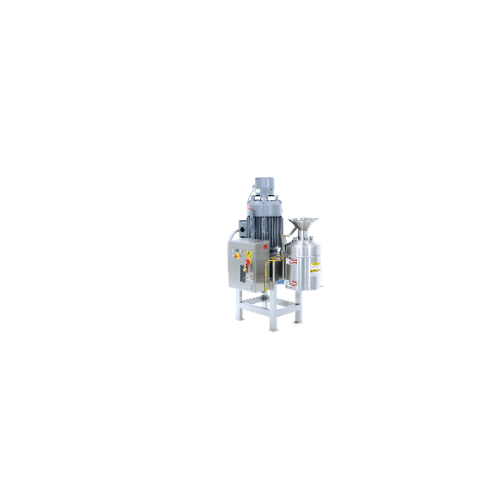

Nut and seed pre-grinder

When dealing with high-fat roasted nuts and seeds, achieving optimal particle size distribution can ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Industrial homogenizer for high pressure applications

Achieve consistent product texture and stability for your emulsions...

Packaging conveyor for efficient bag handling

Simplify your packaging line with a conveyor designed to efficiently transfe...

Single lane collator for packaging room

Streamline your packaging operations by efficiently collating, counting, and aligni...

Smart pack conveyor systems for packaging room

Efficiently manage the flow of snack and nut products from packaging to dis...

High capacity continuous puffer for popcorn

Optimize your snack production with advanced airflow and speed controls design...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Rotary oven for japanese peanuts

Achieve uniform coating and optimal roasting for Japanese-style peanuts with precise temper...

Seasoning system for snack products

Optimize your snack production with precise oil, salt, and seasoning distribution, ensu...

Automatic popcorn ball forming equipment

Streamline your snack production with high-speed, precise popcorn ball forming tec...

Continuous dry popcorn popper

For snack producers aiming to consistently deliver high-capacity popcorn output, this advanced...

Popcorn cooker/coater for caramel corn

Enhance your snack production efficiency with a versatile solution that combines coo...

Granulator for nut processing

Efficiently transform various nut varieties into uniform, sharp-edged granules while minimizin...

Conveyors for material handling in food processing

Streamline your snack production line with conveyors designed to effic...

Retractable spiral chute for bulk material handling

Enhance the integrity of your products by gently transferring bulk ma...

Spiral chute for gentle product handling in limited space

Optimize your snack and nut production by minimizing product d...

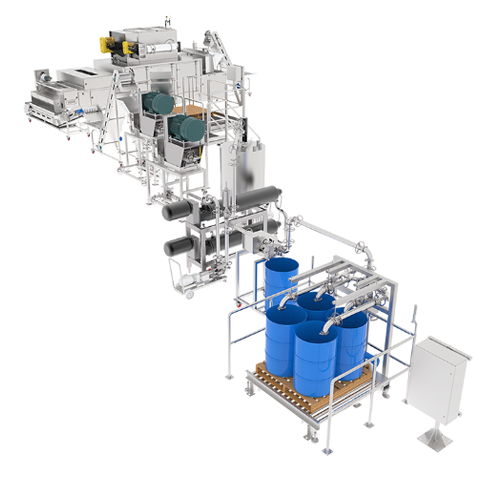

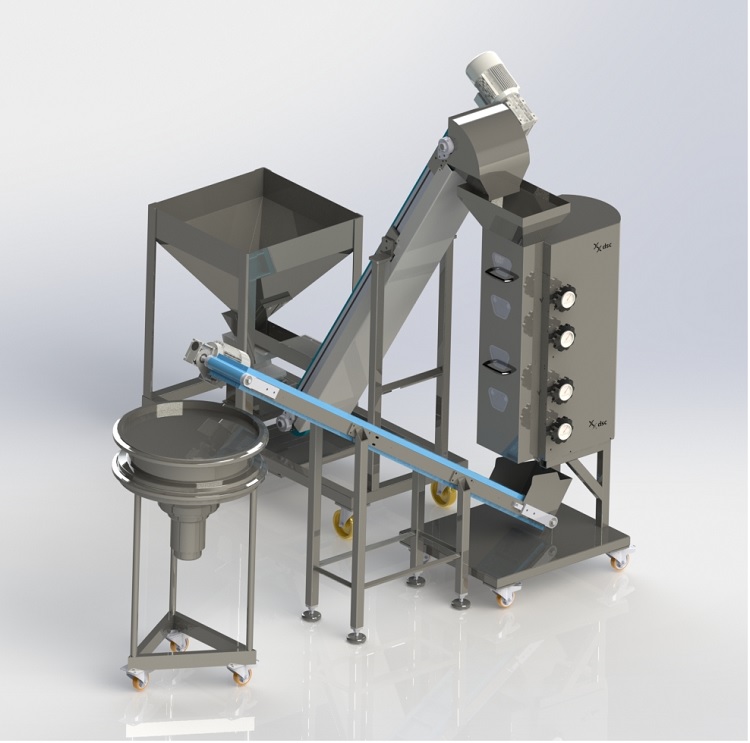

Integrated nut butter production line

Enhance your nut processing capabilities with a fully integrated production line that...

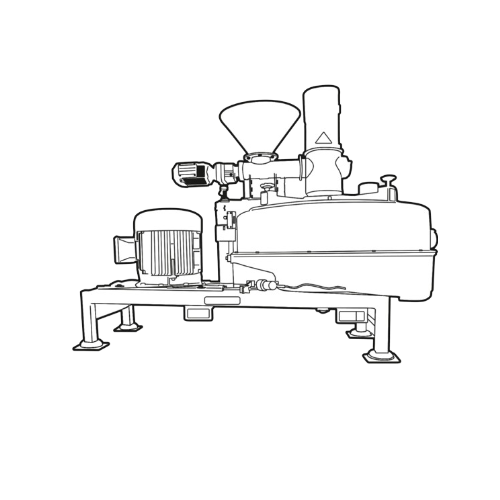

Nut butter mill for snack food processing

Efficiently transform various nuts into smooth, spreadable butters with precisio...

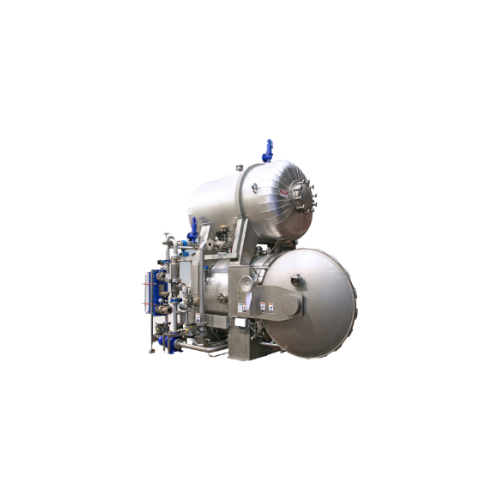

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

Heat exchanger for liquid and semi-liquid foods

Optimize your heating and cooling processes with superior heat transfer ef...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Forced circulation evaporator for tomato and fruit paste

Optimize your high-viscosity tomato and fruit paste production w...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Mechanical homogenizer for fine cutting and emulsifying

Achieve precise particle size control and consistent texture in y...

Slicer for food processing applications

Efficiently achieve precise cuts and textures for a variety of food products, enhan...

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

Versatile size reduction processor for food applications

Enhance your food production line with a processor that excels i...

Vertical slow juicer for producing cold pressed juice

Achieve optimal juice quality and versatility with low-speed crushi...

Cold press juicer for tough vegetables

Effortlessly handle tough produce with this twin gear, cold press juicer, designed f...

Jumbo twin gear slow masticating juicer for high-yield juice extraction

Achieve optimal nutrient retention and extended...

Commercial slow juicer for nutrient-rich juice

Achieve higher juice yields and nutrient retention by utilizing advanced tw...

High-speed blender for commercial use

Designed for high-performance blending tasks, this solution integrates vacuum technol...

Single-serving blender for quick personal blends

Transform your favorite ingredients into nutritious smoothies, soups, and...

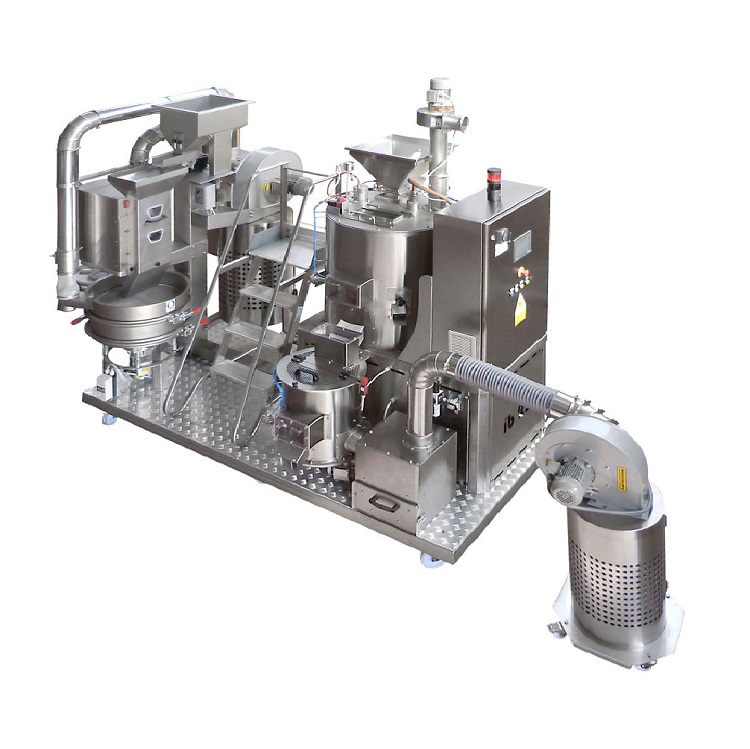

Industrial peanut butter production line

Enhance your production line with this comprehensive peanut butter processing solu...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Jujube pitting and nut removing solution

Streamline your fruit processing with this efficient solution designed to remove p...

Food processing scraped surface heat exchanger

Enhance your production line with precise temperature control and continuou...

Vertical scraped surface heat exchanger for food processing

For continuous production that demands consistent texture an...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Energy-saving cooling system for vegan products

High-viscosity products like hummus or chunky pasta sauces must be cooled ...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

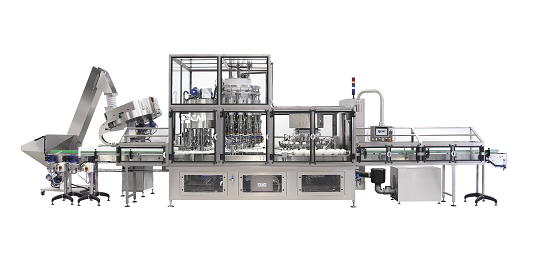

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

Bottle filling and capping monobloc

Spillage and overfilling are common problems in most production lines for bottled produ...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Industrial fine milling equipment for nuts

In a bakery environment fruit jams are often used for the decoration or filling...

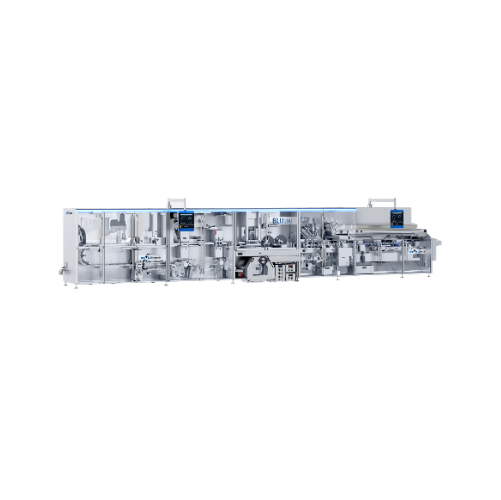

Standard FFS machine for spreads and sauces in mini portions

In the food industry, from a microbiological point of view,...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

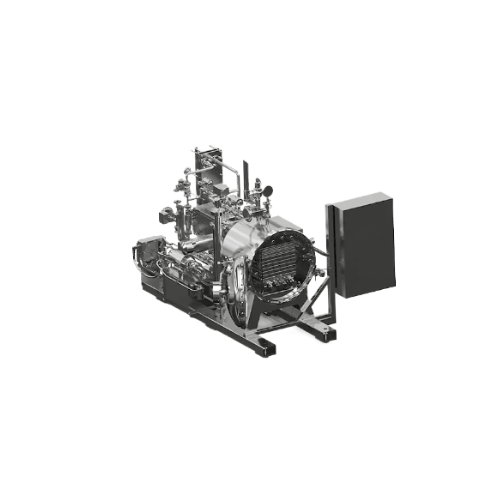

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Filling machine for viscous products

Chocolate paste and other viscous liquids require special handling to obtain the optim...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Compact cylindrical roaster for beans, nibs and nuts

Roasting times and temperature can vary depending on the type of pro...

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Multi-functional food processor for a high sugar percentage pastes production

For the development and production of hi...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Nut roaster

Nut roaster that guarantees a high-quality roasting of nuts and seeds with a batching capacity of 40 and 120 kg, d...

Basic mixer for granular foods

Straightforward blending solution for mixtures of beans, nuts, berries & powdered foods, ...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Infrared rotating drum steriliser

Sterilisation of foodstuffs is vital to maintain uncompromising standards of hygiene and ...

Versatile stone mill machine

In the food industry, when it comes to milling a wide range of products such as seeds and nuts ...