Making Chocolate Milk

Find innovative production technology for making chocolate milk and connect directly with world-leading specialists

Chocolate milk is a beverage containing milk flavored with chocolate powder or chocolate syrup. Cocoa powder, sweetener, sugar, and carrageenan are mixed with the milk and then pasteurized. As cocoa powder has a higher density than milk, carrageenan is used as a thickening agent to prevent cocoa powder from settling to the bottom.

Technology picks for producing chocolate milk

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Systems for transporting cocoa powders and ingredients

Efficiently transport and dose your cocoa powders and semiliquid i...

Cocoa powder processing line

Cocoa beans are first fermented, dried, roasted, and separated from their skins to obtain a coc...

Energy efficient grinder for plant-based milk

Buying pre-processed materials, such as flour, and handling and dispersing t...

Tell us about your production challenge

Processing steps involved in chocolate milk making

Which chocolate milk technology do you need?

Chocolate melting trays for small-scale applications

Efficiently melt chocolate with precision and ease using compact, el...

Double heating cabinet for melting and preheating chocolate

Optimize space while ensuring precise temperature control fo...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Capsule filling system with in-line weight control

Experience precise capsule filling with high-speed accuracy, designed ...

High throughput capsule filling system

Achieve precise, high-speed capsule filling with versatility, ensuring product integ...

Capsule filling system for high volume production

Maximize your capsule production efficiency with a system designed to s...

Bench-top blending vessel for small batch preparation

For small-batch liquid products, achieve precise mixing, heating, a...

Uht system for milk products

Achieve optimal product safety and quality for dairy and plant-based beverages with precise UHT...

Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchan...

Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines ...

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

Cold aseptic filling system for beverages

Ensure microbiological safety and high product quality with a versatile cold ase...

Capsule filling and sealing system for coffee production

Achieve precise coffee capsule production with a machine that se...

Capsule cartoning for coffee and tea products

Optimize your capsule packaging process with a solution that enhances speed ...

Capsule cartoning system for coffee and tea

Streamline your capsule packaging with a high-speed cartoning solution that ef...

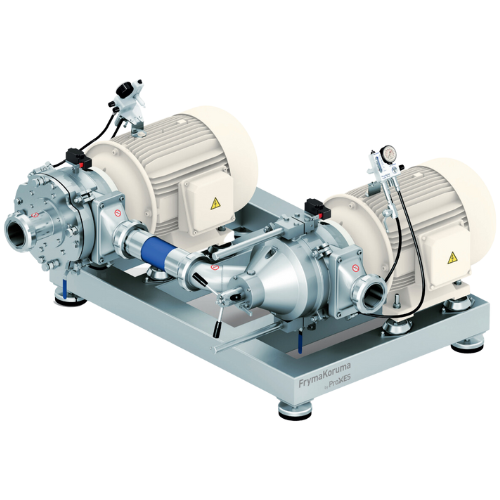

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Automated snap capper for various container types

Eliminate manual errors and repetitive strain with this high-speed snap...

Stabilizer dissolving systems for beverage production

Efficiently dissolve and disperse stabilizers in complex beverage f...

Continuous in-line blender for dairy applications

Achieve precise and homogeneous blending of sensitive dairy mixtures di...

High shear mixer for low viscosity products

Achieve precise mixing and dispersion for diverse liquid applications with a h...

Laboratory homogenizers for nanoparticles and emulsions

Tackle the challenge of achieving consistent nano-scale dispersio...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

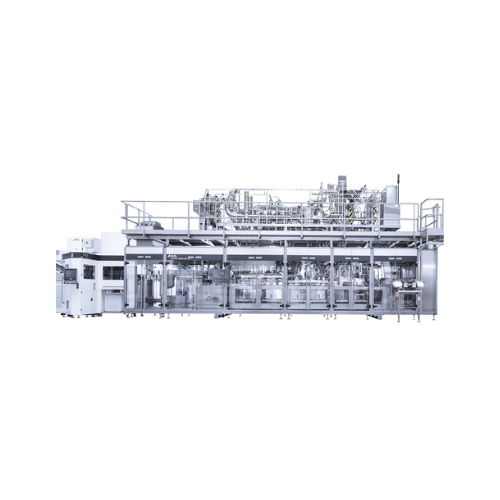

Beverage preparation system for large-scale production

Ideal for producers looking to scale up, this versatile system eff...

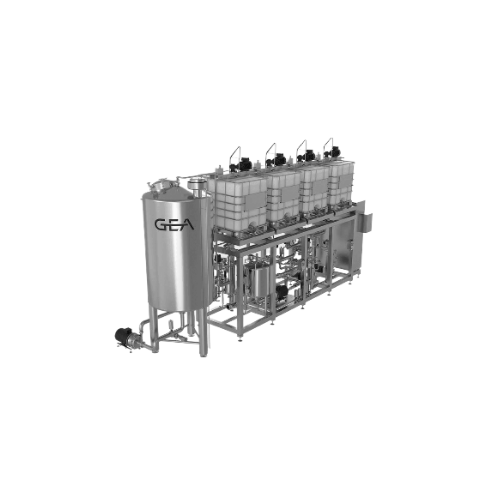

Syrup and beverage preparation system

Enhance your beverage production with a versatile solution that optimizes mixing, hyd...

Plate heat exchanger for food products

Achieve precise temperature control in your processing line with this plate heat exc...

In-line blender for dairy products

Streamline your dairy and beverage production with precision ingredient control and redu...

Uht processing unit for dairy products

Optimize your liquid food production with continuous, high-capacity UHT treatment th...

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high tem...

Mid-range capacity homogenizer for dairy and beverage

For operations demanding consistent product quality and high uptime...

Ingredient dissolver for small batches

Efficiently dissolve water-soluble powders and concentrates up to 200 cP with precis...

Preparation system for syrup and beverages

Streamline syrup and beverage preparation with a versatile system designed to r...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

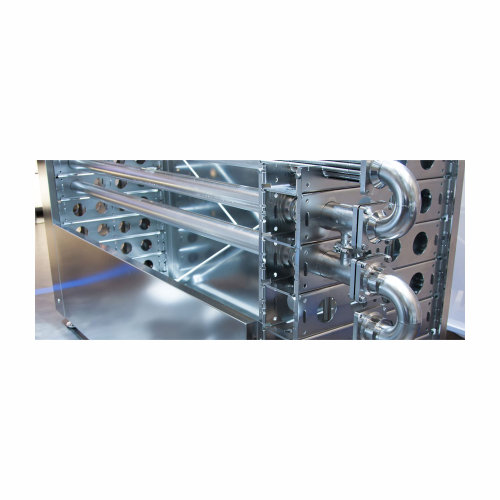

Tubular heat exchanger for food products

Achieve precise temperature control and energy efficiency with this innovative tub...

Aseptic tank for intermediate storage

Ensure safe and sterile storage for liquid and slurry products, minimizing product lo...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Batch mixing pre-mixers for dairy production

For dairy producers seeking uniform texture and consistency, these batch mixi...

High-shear mixer for emulsions, dispersions, and foams

Achieve precise emulsions and dispersions effortlessly with high-s...

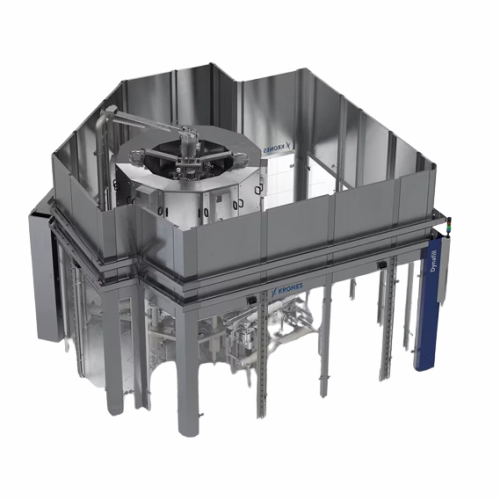

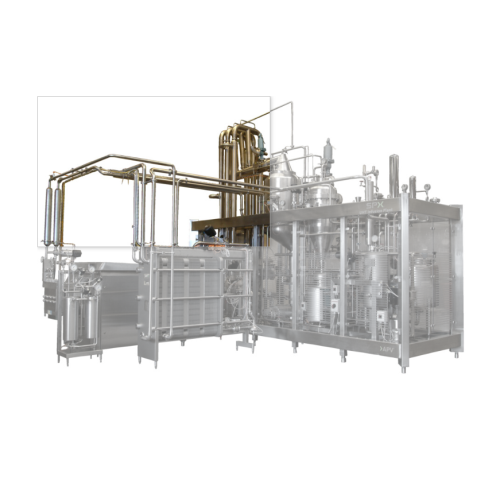

Combi ultra high temperature (uht) processing plant for dairy and beverages

Achieve precise heat treatment for diverse...

Ultra high temperature (uht) direct heating for infusion Esl plant

Achieve extended shelf life and superior flavor with...

Infusion Uht plant for dairy products

Achieve precise thermal treatment with minimal product alteration, enhancing quality ...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Aseptic tank for liquid food storage

Store and maintain the sterility of low and high acid liquid foods while ensuring prod...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Pasteurization Machine for Milk

Manual processing of dairy products can cause inconsistent quality between batches due to po...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

Sugar dissolving system for beverages

In the beverage industry, production of sweet drinks requires the addition of sugar s...

Mixing tanks for beverages

Juice production lines require multiple ingredients to be typically mixed with water. The incorpo...

Water treatment for beverage preparation

Water is one of the main ingredients in producing juices and other beverages. If i...

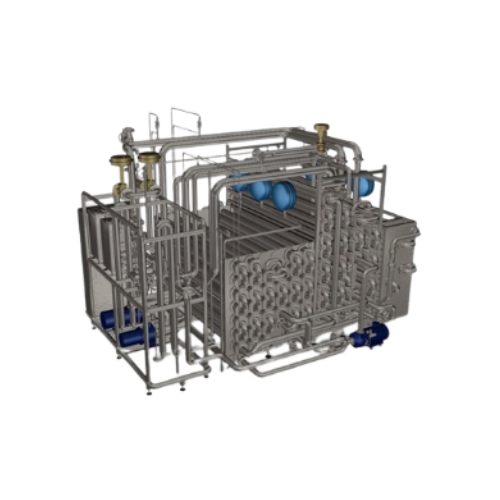

Continuous sterilizer for milk beverages

An important goal of heat processing in the manufacturing of milk beverages is to ...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

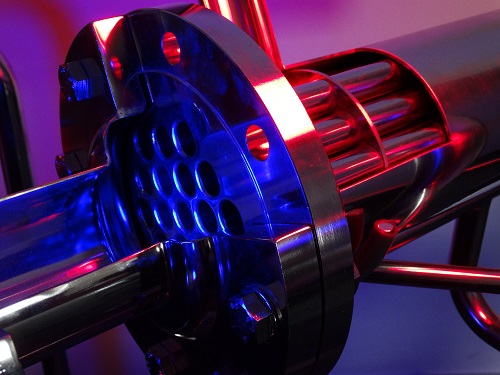

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products acro...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Laboratory size auto-steam shrink system

When managing sleeving projects, fast prototyping and testing can gain massive com...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

In-line tamper evident applicator head

Integrating tamper protection equipment into an existing production line means addit...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Advanced auto-steam shrink system

Design and development of shrink sleeves could be made much easier if small batches of sa...

Optical fill level controller

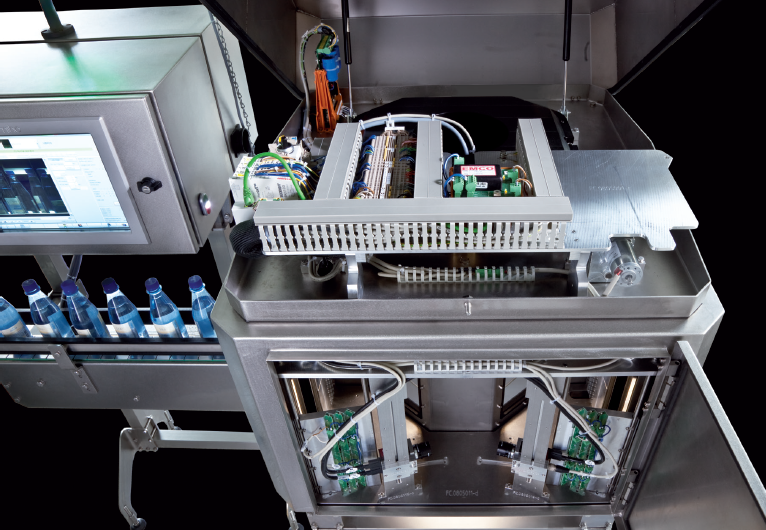

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...

Residual liquid inspection system

Inspection system that eliminates the risk of residual liquid, water or left over drink i...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...

Empty bottle height sorting system

An empty bottle sorting system that uses the light barrier technology. It detects bottle...

Hygienic pelleting press

The production of pelletized or granularized food products requires hygienic presses designed for hi...