Making Dry Powder Inhalers

Find innovative production technology for making dry inhaler powder and connect directly with world-leading specialists

The click and puff of inhalers is a universal signal for respiratory conditions. Inhalers quickly grew into preferred drug delivery systems for asthma and COPD. Dry inhaler powder formulation produces a more stable drug than liquid dosage forms. Moreover, inhaler ingredients are more resistant to bacterial growth.

Select your dry inhaler powder process

Tell us about your production challenge

Mill inhaler powder materials to achieve good particle size distribution

The recommended particle diameters for optimal aerosols preparation range from 1 to 5 µm. Smaller particles clump together while larger diameters lose their cohesive properties.

Reduce the diameters of coarse particles before mixing the ingredients for dry inhaler powder formulation. Jet milling applies high-impact forces combined with compressed gas to produce micro sizes.

Engineered blends improve the processing of dry inhaler powder formulations

Add carrier particles to the API mix to improve the processing properties of bulk powders. However, the particles of drugs and carriers must be chemically compatible. Their reciprocal adhesive forces need to be powerful enough to hold the mixture together during filling and storage. At the same time, they need to be quickly detachable during aerosol administration.

Coarse lactose monohydrate improves powder flowability during manufacturing and provides good carrier-particle separation. Lactose blends are formulated with drug contents of 5% (w/w) or less.

HPMC capsules are more stable for mono-dose inhaler systems

Mono-dose inhalers deliver a single serving of powder formulation by loading a capsule into the device before each use. Depending on the system, the capsule is activated by sheer force opening, needle-piercing, or cutting the capsule. But moisture content is a critical consideration for each technique.

Very dry conditions apply pressure on traditional gelatin-based capsules, causing them to crack before use. Hypromellose capsules (HPMC), on the other hand, is less hygroscopic and behaves well in both wet and arid environments.

Processing steps involved in dry inhaler powder making

Which dry inhaler powder technology do you need?

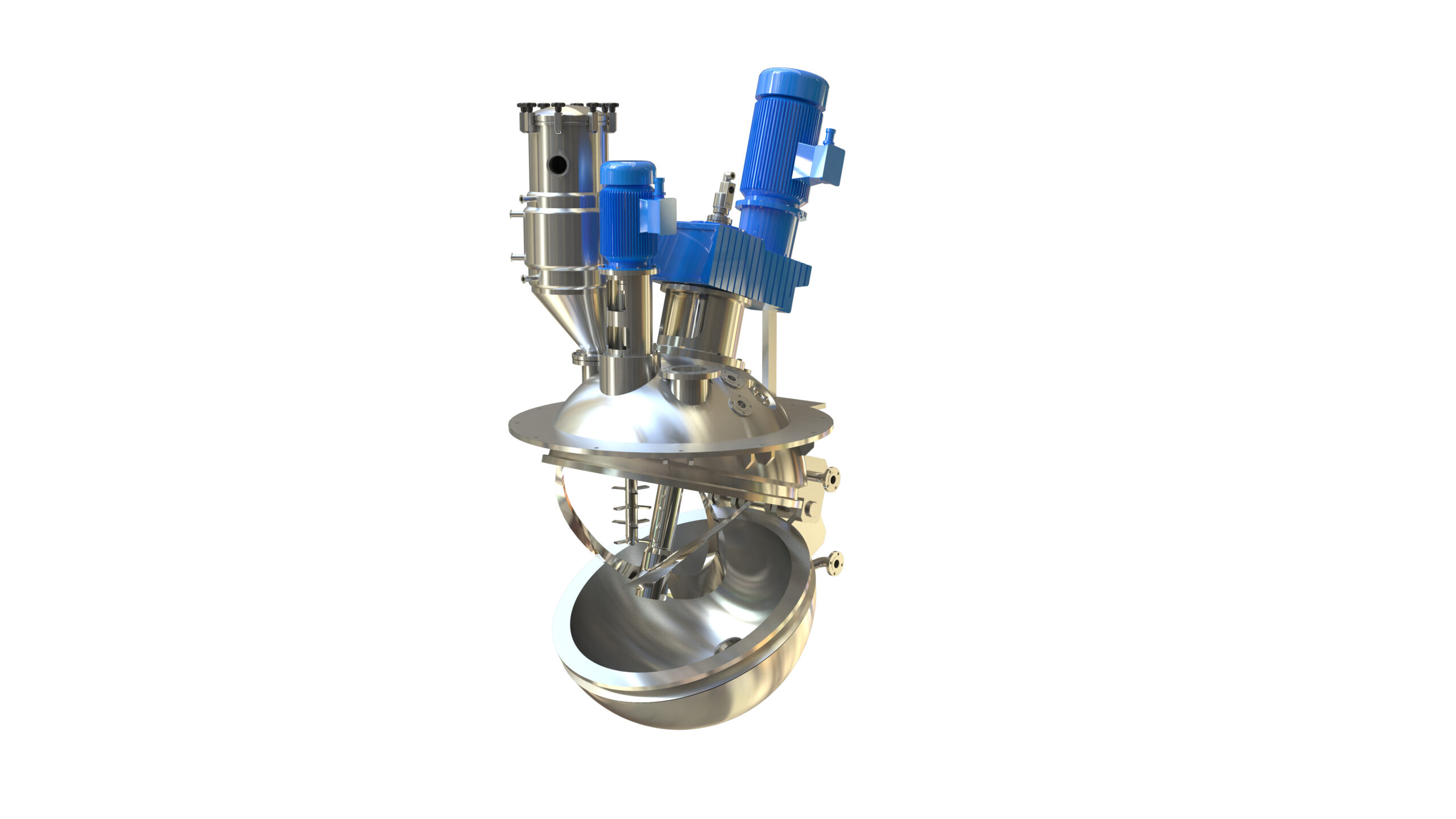

Super high shear mixer for nano to micron powders

Achieve high-precision mixing and surface treatment of nano to micron-s...

Lab mixer for powder formulations

Achieve precise particle mixing and coating with this stand-alone high-shear lab mixer, d...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Dpi blister strip weighing system

Ensure precision in your inhalation product lines with a system designed for real-time we...

Dpi inhaler production system

Enhance your inhaler production with precision assembly and integrated dosing, filling, and ca...

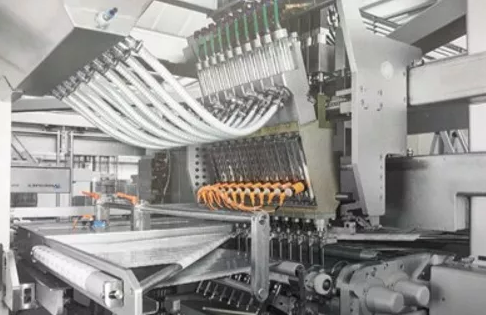

Commercial blister filling solution for dry powder

Efficiently fill and seal blister packs with precision, ensuring consi...

Micro-dosing system for inhalation blisters

Streamline your inhalation product production with precision micro-dosing, for...

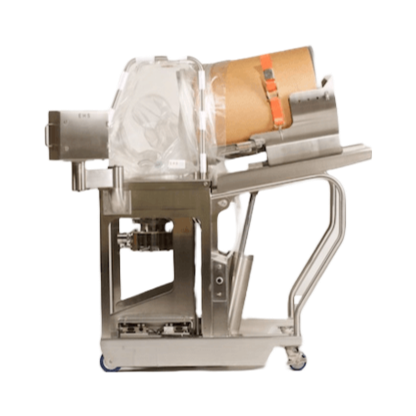

Disc filler for dry powder inhalers

Optimize your dry powder inhaler production with precision micro-dosing for diverse pow...

Custom automation for drug-device filling and assembly

Efficiently integrate precise filling and assembly for biopharmace...

Dry powder filling isolator for cgmp production

Achieve precise powder dosage and secure containment for hazardous materia...

3D powder mixer for active pharmaceutical ingredients

Proper mixing and homogenization are essential to achieve a reliabl...

Modular assembly line for healthcare products

Assembly setups need to be constantly rethought and reconfigured to adapt qu...

High containment big bag discharge docking system

The discharge of materials demands strict containment, particularly in ...

Accurate multiple dosing system for powders

Dosing multiple powders in a batch process is time inefficient, especially whe...

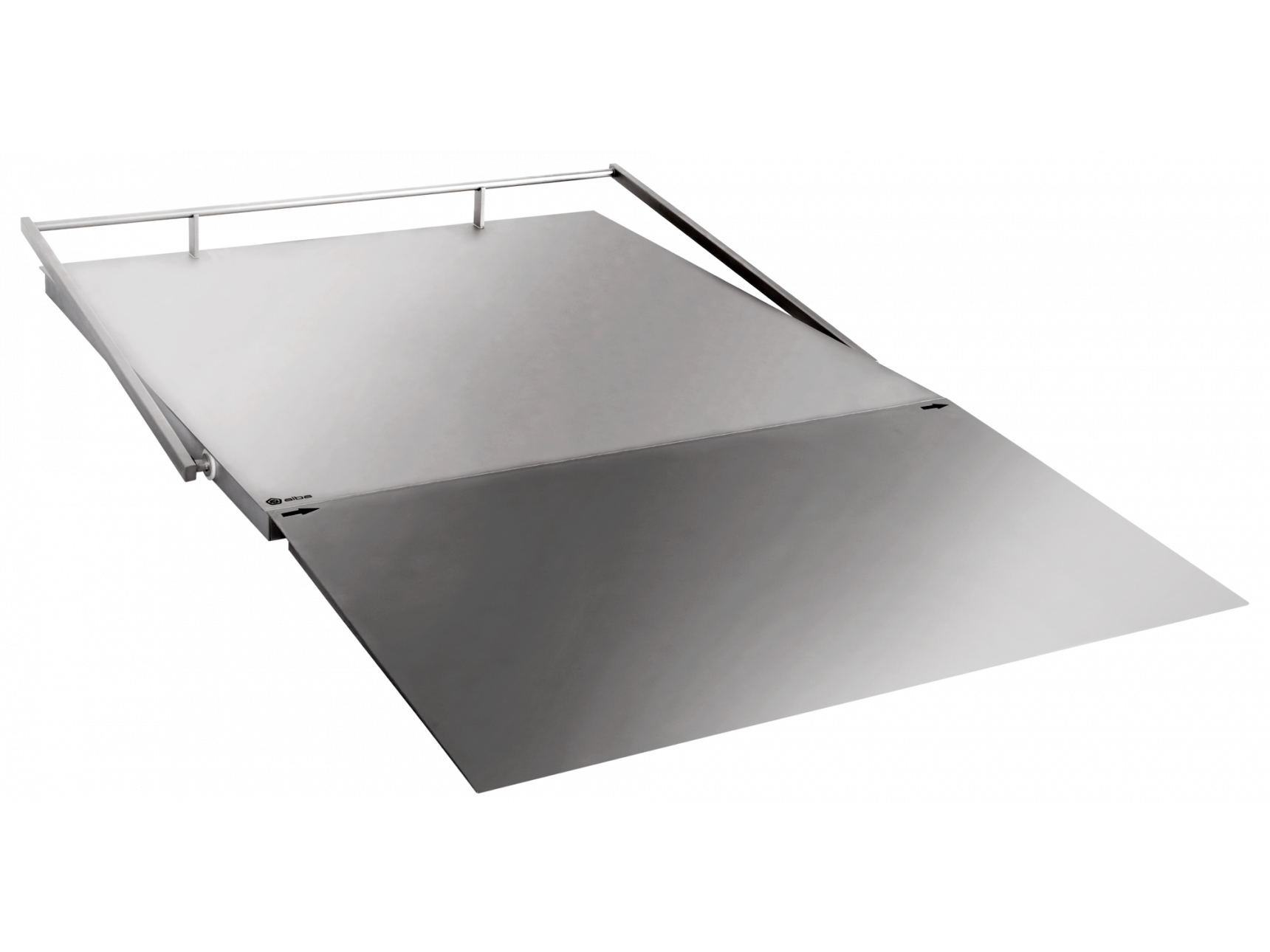

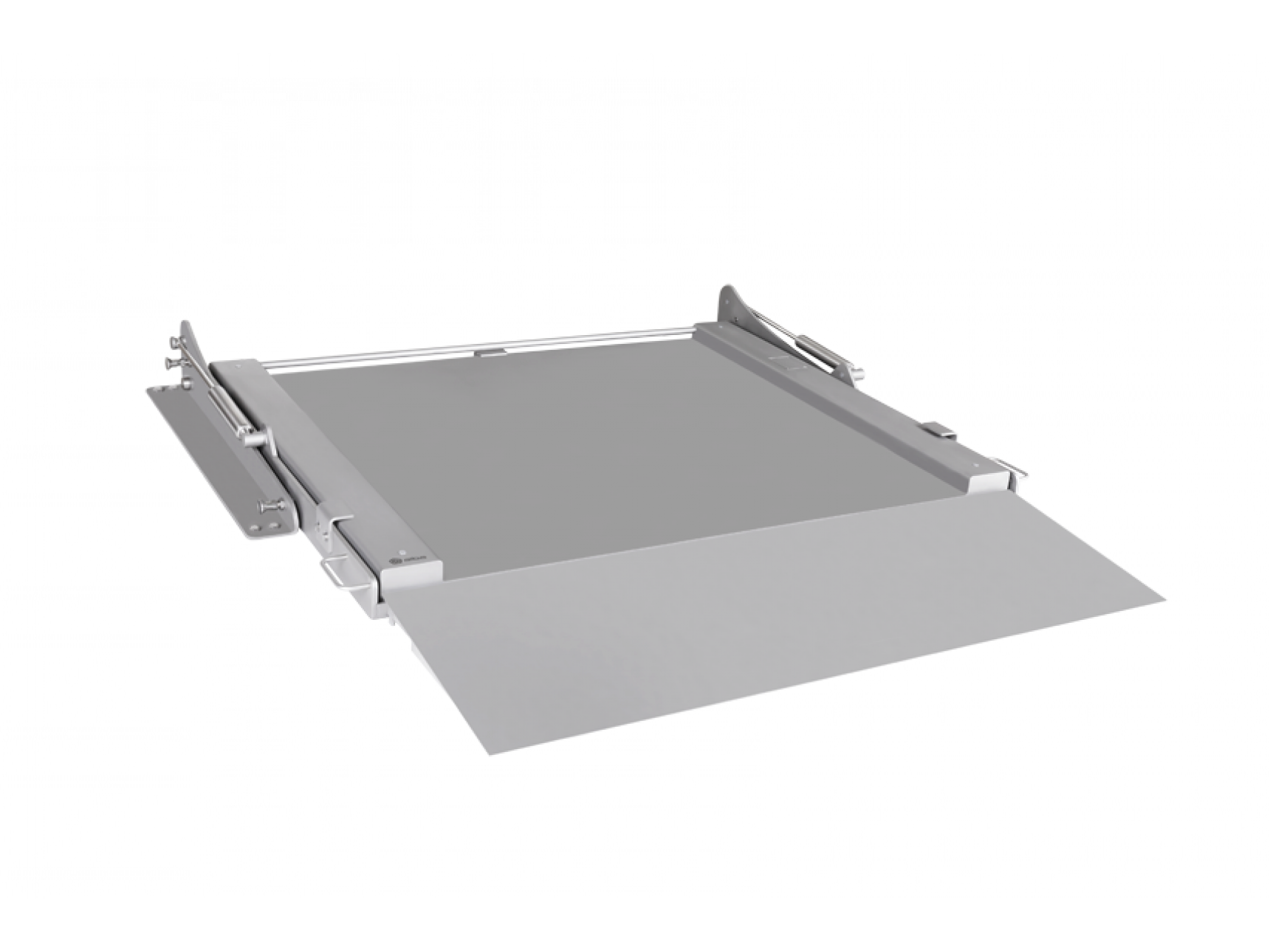

Hygienic floor scale

The food and pharmaceutical industries require maintaining high levels of sanitations as well as logisti...

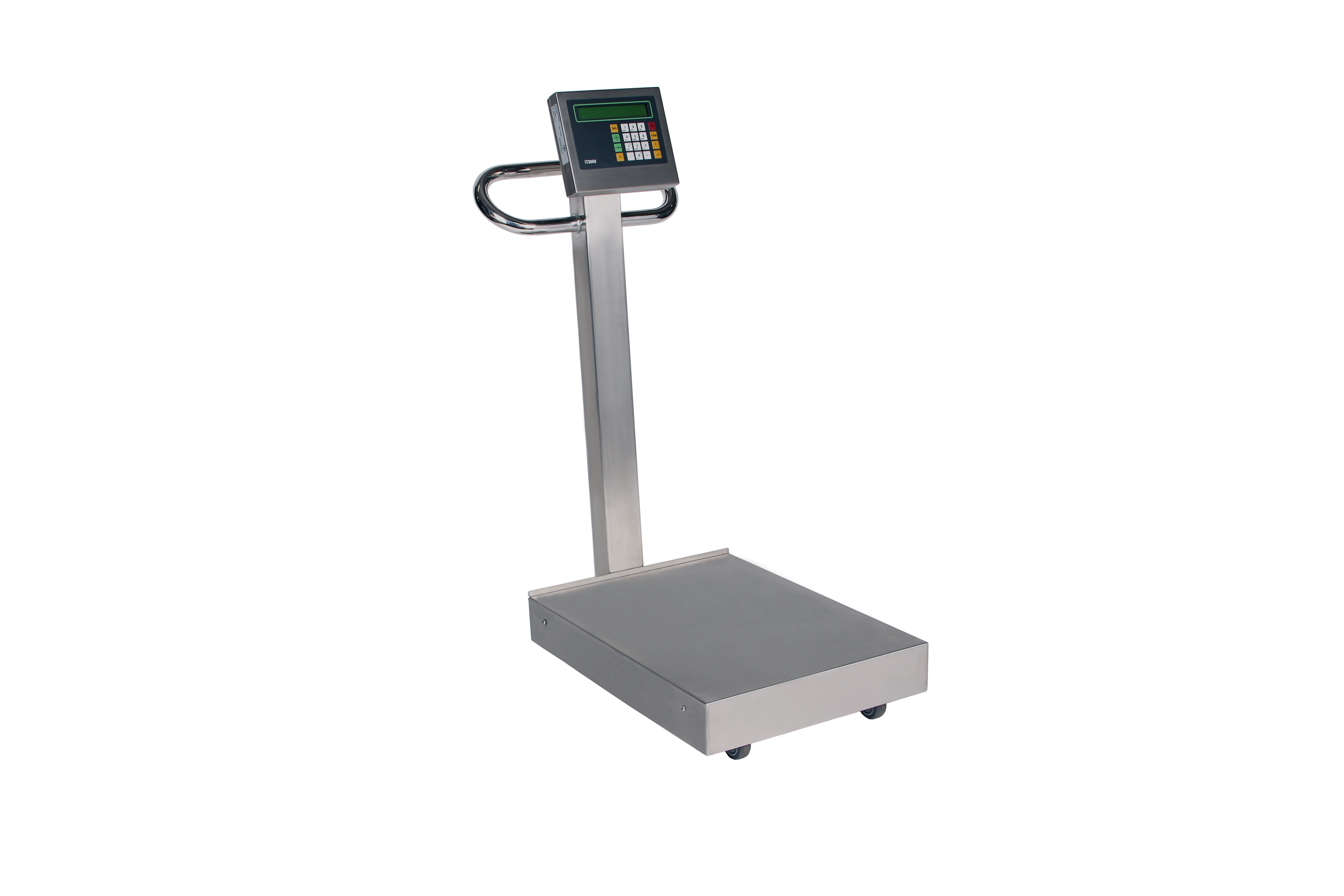

Hygienic mobile scale

Having a reliable and accurate weighing and measuring solution is absolutely essential, especially in t...

Fast gravimetric powder microdosing 50 - 200 g

Micro-dosing powders of high-value food or chemical products can be challen...

Gravimetric powder microdosing 2 - 100 g

Powders and granules are commonly dosed for the manufacturing of pharmaceuticals, ...

Gravimetric powder microdosing 0.400 - 2 g

If you need to process high value food, pharmaceuticals or chemicals, there is ...

Single-use powder handling bag

Containers for handling pharmaceutical and biopharmaceutical powders may be disposable, to av...

API powders storage bottle

Users who prefer rigid storage over single-use pharma charge bags, require lightweight solutions ...

Single-use containment valve

Safe transfer of liquids and hazardous powders into systems can be a challenge in pharma, bioph...

High containment closing system

Pharma and biopharma laboratories need fast effective solutions for tightly sealing bags for...

High containment sampler

Drawing a sample for evaluation from a running process is not a simple task, especially when dealing...

Metal detector for pharmaceutical powders

Powdered and granulated pharmaceuticals require careful screening against metal ...

R&D V-type powder blender

Many pharmaceutical processes rely on the complete blending and homogenizing of different powdered...

Pharmaceutical container lifter

Moving larger or heavier containers from height is out of the scope for standard handling eq...

Vacuum sack lifter

In the production of pharmaceuticals and other high-hygiene environments, manual handling of inputs or int...

Bin blender

Many pharmaceutical processes require the blending of powders or other granular ingredients, the mixing of settled...

Container lifter

Container handling in the pharmaceutical industry brings its own set of unique challenges. Traditional barrel...

Mobile drum lifter

The production of pharmaceuticals and other hygienic products often requires the handling of large and bul...

Powder transfer vessel

Intermediate bulk storage of pharmaceutical product requires specialist containers. For increased effi...

GMP Jib crane

Vacuum manual handling systems are the ideal way of quickly and safely moving small to medium sized loads in all...

Small feeder with flexible wall hopper

In many laboratory applications and production processes, smaller quantities of powd...

Metal detection system for aluminum packages

The magneto reflection system is ideal for detection of metals in aluminium f...

Checkweigher for sachets and sticks

The checkweighers for multiple lanes have a 1.5 times faster response speed and 2 times...

Fluid bed dryer for production scale

Fluidized bed drying (FBD) is a common process in the pharmaceutical industry for dryi...

Fluid bed dryer for lab scale

Fluidised bed drying (FBD) is a common process in the pharmaceutical industry for drying compo...

Fluid bed dryer and mixer for lab scale

Designed for pharmaceutical R&D, a lab-scale fluid bed dryer and mixer/granulat...

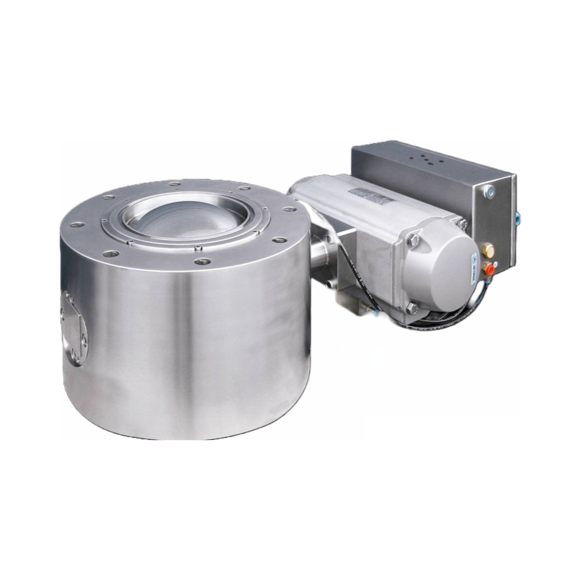

Magnetic agitator

Reliable mixing and agitation are essential to any quality production process that involves a fluid. This n...

Centrifugal disc filter

The pharmaceutical and bioprocess industries need filtration processes of particularly high quality t...

Spherical dryer

Drying vessels that are simple, reliable, and easy to maintain increases product quality and process efficienc...

Filter dryer

The pharmaceutical and bioprocess industries need filtration processes of particularly high quality to ensure the...

Transfer system for high-containment environments

A high-performance transfer port system that combines ultimate safety, ...

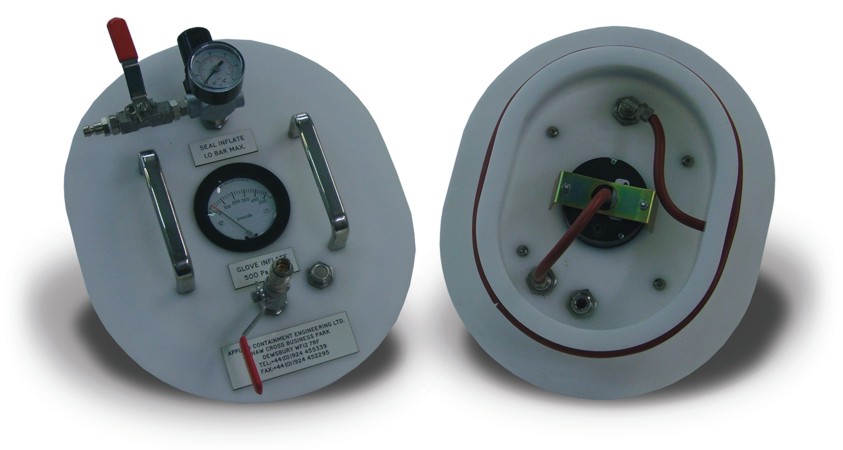

Half-suit tester

Designed to allow operators to perform sterility testing in an aseptic environment providing assurance of mat...

Glove tester

Testing device of the containment capability of gloves, which is as important as the other parts of the integrate...

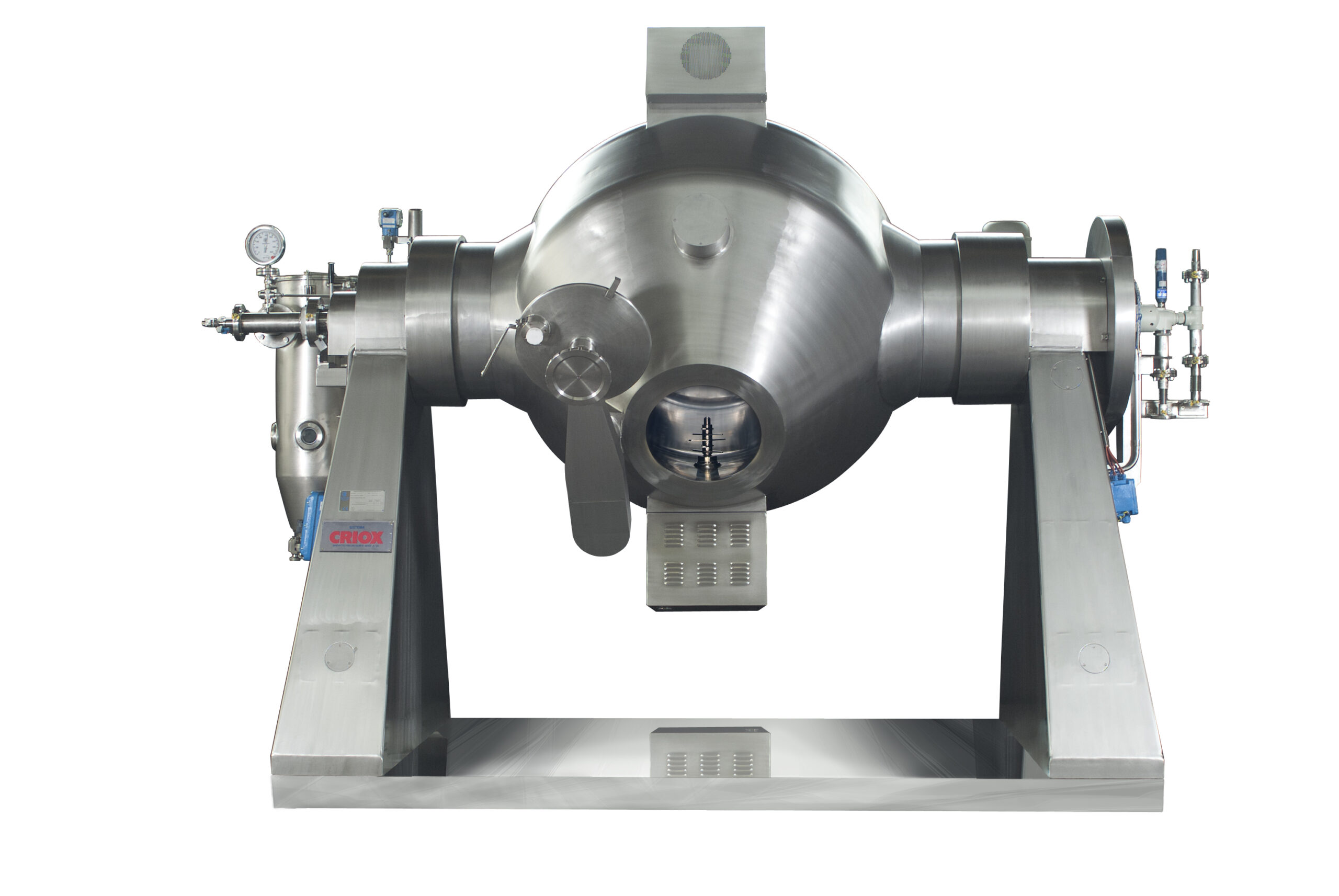

Rotary vacuum dryer

Powdered products tend to agglomerate during vacuum drying. This adds an additional step to the productio...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

Horizontal vacuum dryer with eccentric agitator

Conventional dryers are inefficient and can lead to significant mechanical...

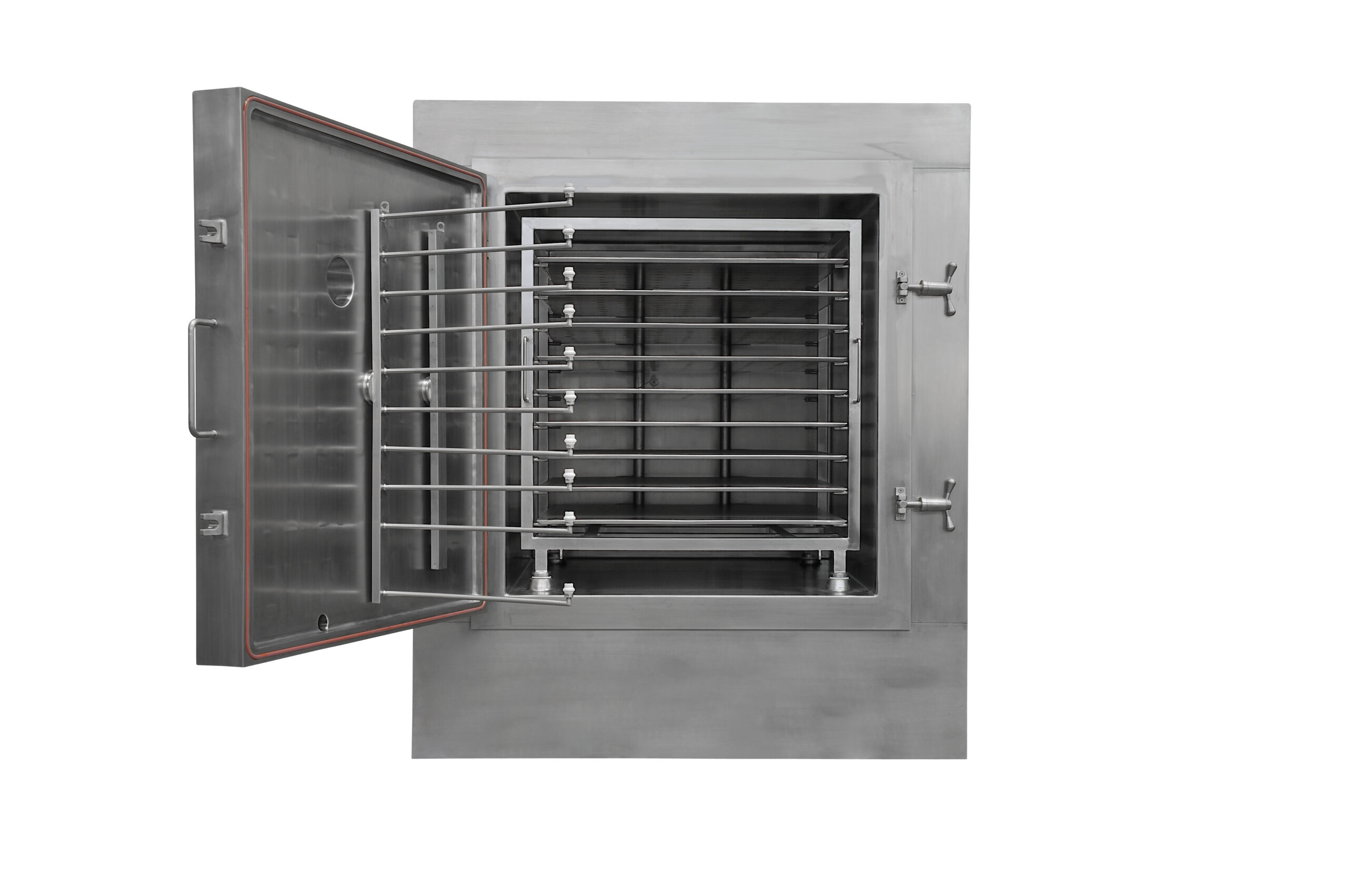

Vacuum tray dryer with clean-in-place system

Cabinet tray dryers can be difficult to clean, making their use difficult for...

Horizontal paddle vacuum dryer

Agitated vacuum dryers can be difficult to clean which makes them unsuitable for multi-produc...

Laboratory-scale vacuum tray drying oven

Vacuum drying is used to remove moisture from sensitive materials. Drying small ba...

Bellows for pharmaceutical powders

Thermal and mechanical changes can lead to stresses in industrial piping systems. These ...

High containment segment ball valve

Valves fitted in blenders and dryers can have dead spaces that prevent complete process...

Removable GMP compliant connections for tubing

Tubing frameworks can have rough welding joints, corners and sharp angles t...

Negative pressure isolator

Used for products biologically hazardous, that also require minimized cross contamination.

Vertical laminar flow cabinet

HEPA filtered vertical laminar airflow (down flow) creates an ISO 14644-1 (Class 5) work area ...

Biological safety cabinet class III

Specially designed for the handling of microbiological agents, when working with indige...

Hygienic floor scale with lifting device

The food and pharmaceutical industries require maintaining high levels of sanitati...

Flexible contained powder charging solution

Filling of transportation bags and discharging them into mix tanks or reactor ...

Flexible contained charging for split butterfly valves

Poly bottles with split butterfly valves are often used to transfe...

Dosing machine for nonfree-flowing powders

Fill poorly flowing powders, dry syrups and similar substances into various gla...

Restricted-access barrier systems

Create a physical barrier between the operator and the product. More flexible than an iso...

Flexible contained handling of powder transfer bags

Filling of transportation bags and discharging them into mix tanks or...

Crimping system

Flexible disposable containment systems in the form of specially designed plastic bags are an excellent choice...

Flexible contained drum transfer system

Transferring powders from drums to process equipment such as reactors or mills can ...

Flexible contained powder discharge into FIBC’s

Flexible intermediate bulk containers known as FIBC’s are commonly used in...

Flexible contained powder discharge into drums

Powdered products are handled every day in the pharmaceutical and bioproces...

Checkweigher for stand-up pouches

When working with several lines of stand-up pouches, you can benefit from controlling the...