Chewing Gum Manufacturing Equipment

Find innovative production technology for making chewing gum and connect directly with world-leading specialists

Chewing gum is usually a polymer that you mix with flavorings – which is something most consumers have no clue about. In a survey in Iceland, 85% of people said they didn't know the product contained plastic. While there are non-plastic options more recently available, the gum base is usually natural latex or a synthetic substitute. To decrease the impacts on the environment, some producers are shifting towards more environmental-friendly options.

Technology picks for chewing gum production

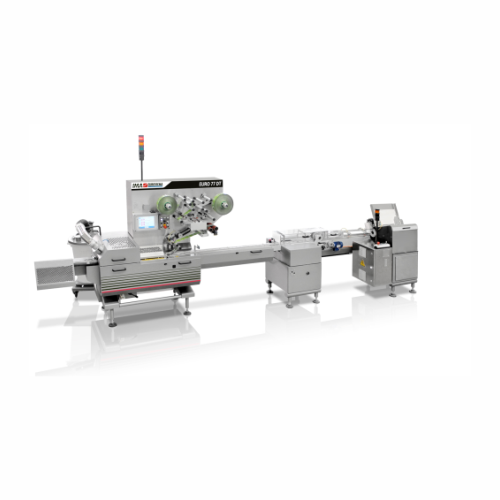

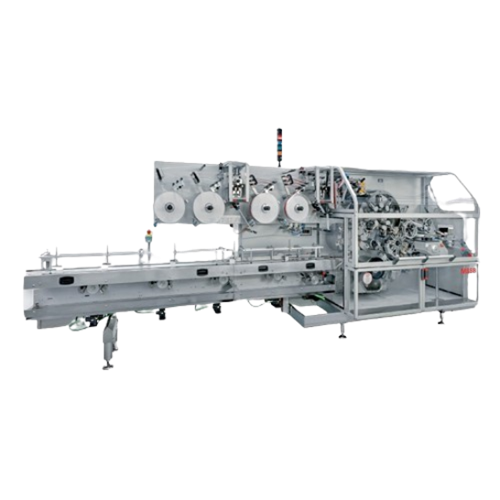

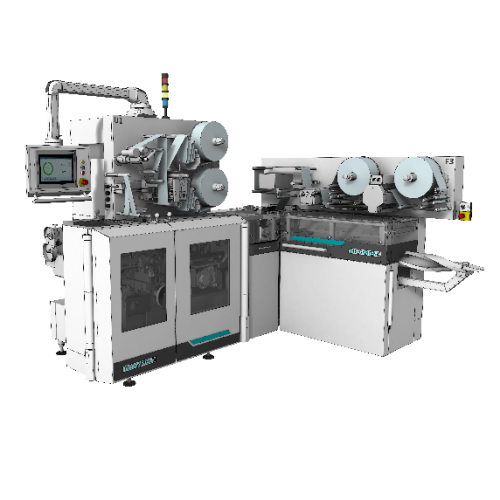

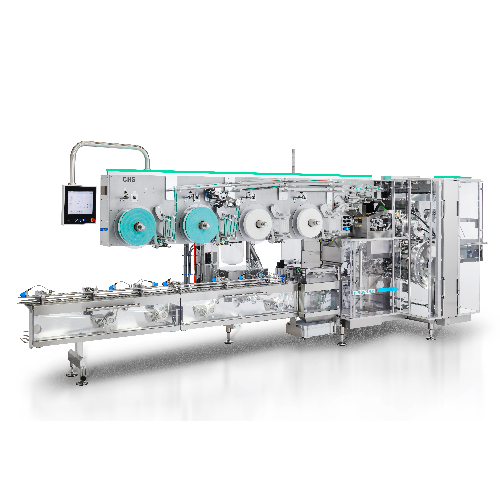

Fold wrapping solution for chewing gum tabs

Streamline your high-speed packaging line with a solution that expertly wraps ...

In vitro chewing gum release tester

Ensure precise analysis of active ingredient release from masticated dosage forms with ...

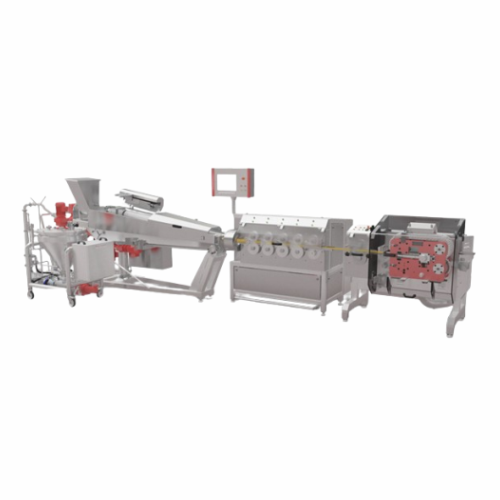

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

Forming, cutting, and wrapping products in multiple styles

Achieve versatile and efficient packaging for confections and...

Tell us about your production challenge

With plastic or not - choosing chewing gum equipment

The general ingredients for making chewing gum and bubble gum include a gum base that contains resin, wax, and elastomers. To give it a sweet flavor, you need to add sweeteners such as maltitol, glucose, corn syrup and even beetroot juice.

Artificial sweeteners like sucralose are also an option if you are looking for sugarless alternatives. They contain fewer or no calories – but, on the other hand, they can increase the risk of diabetes when overeaten. Softeners such as glycerin and vegetable oil ensure that the gum retains its moisture and flexibility.

To create a chewing gum production system, use a steam cooker, which sterilizes and melts the gum base. After that, a sigma mixer and an extruder helps to blend, smooth and form the gum shape. Cutting into smaller pallets and coating with candy are the last production steps before going through packaging and wrapping machines.

What is the chewing gum impact on the environment?

Chewing gums are only behind cigarettes in the list of most common street trash. While some governments and initiatives are able to clean part of it, other parts add up to the pile of plastic that ends up in the seas. The last remains. The polymers or synthetic plastics that compose chewing gums are not biodegradable.

More conscious customers already look for alternatives in order to decrease their consumption impact, as it can take hundreds of years before a piece of gum starts to decompose. In this sense, apart from the healthier gum options, plant-based, plastic-free chewing gum is also a thing.

Same methods, new ingredients: plastic versus non-plastic gums

While the manufacturing method for non-plastic gums is the same as for plastic ones, the source of ingredients differs. You produce biodegradable gums using tree sap, such as chicle. Other items you use to substitute the plastic and artificial ones are raw sugar, for instance, as well as real fruits, to give taste. This way you avoid regular and plastic production while providing an alternative whose base is chewable and chemical-free.

Processing steps involved in chewing gum making

Which chewing gum technology do you need?

Horizontal cartoner for diverse industries

Streamline your packaging process with precise cartoning capabilities, effectiv...

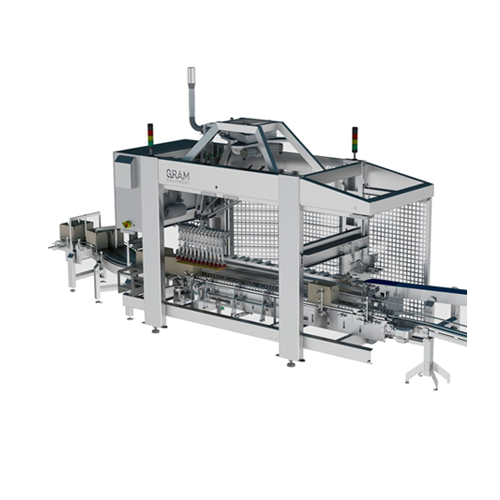

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Top-loading cartoner for bar and confectionery packaging

Optimize your high-speed packaging operations with a flexible ca...

Fold wrapping solution for chewing gum tabs

Streamline your high-speed packaging line with a solution that expertly wraps ...

Twin station fold wrapping machine for chocolate bars

Efficiently transform diverse chocolate and confectionery items int...

Fold wrapping solution for round pharma tablets

Ensure precise and gentle packaging of round tablets with our innovative f...

Flow wrapping system for hygienic food packaging

Enhance your packaging line with a modular flow wrapping solution that en...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Tablet press for confectionery products

Optimize your confectionery production with a high-speed tablet press capable of sh...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

Gum slabs flow wrapping solution

Streamline your confectionery production with precision-engineered portioning and wrapping,...

High-speed cut & wrap flow wrapping for confectionery

Experience efficient packaging with high-speed flow wrapping techno...

Flow wrapping for bulk confectionery products

Efficiently orient, feed, and wrap bulk confectionery items with seamless in...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Hard candy forming line for manufacturing

Experience seamless candy production with advanced forming technology, ensuring ...

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for con...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

In vitro chewing gum release tester

Ensure precise analysis of active ingredient release from masticated dosage forms with ...

Crystallization process for chewy candy production

Optimize your confectionery production with precision crystallization,...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

High-speed cut and wrap solution for confectionery products

Achieve seamless integration in your confectionery productio...

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

Flow wrapper for preformed pieces

Optimize your high-speed packaging line with a reliable flow wrapper that seamlessly wrap...

Flow wrapper for lollipops packaging

Achieve precise and high-speed lollipop packaging with continuous-motion flow wrapping...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

Dough ripening conveyor for stick and fried noodles

Ensure optimal dough maturity and consistency with this conveyor, des...

Versatile confectionery cut and wrap system

Enhance your confectionery production with a high-speed solution capable of ac...

Double twist wrapping solution for confectionery

Optimize packaging speed and precision with a machine designed to wrap di...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Dough feeder for flexible and gentle dough handling

Ensure precise, gentle handling and optimal integration with your pro...

Tray buffering system for downstream absorption

Handle production line disruptions effortlessly by temporarily absorbing t...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

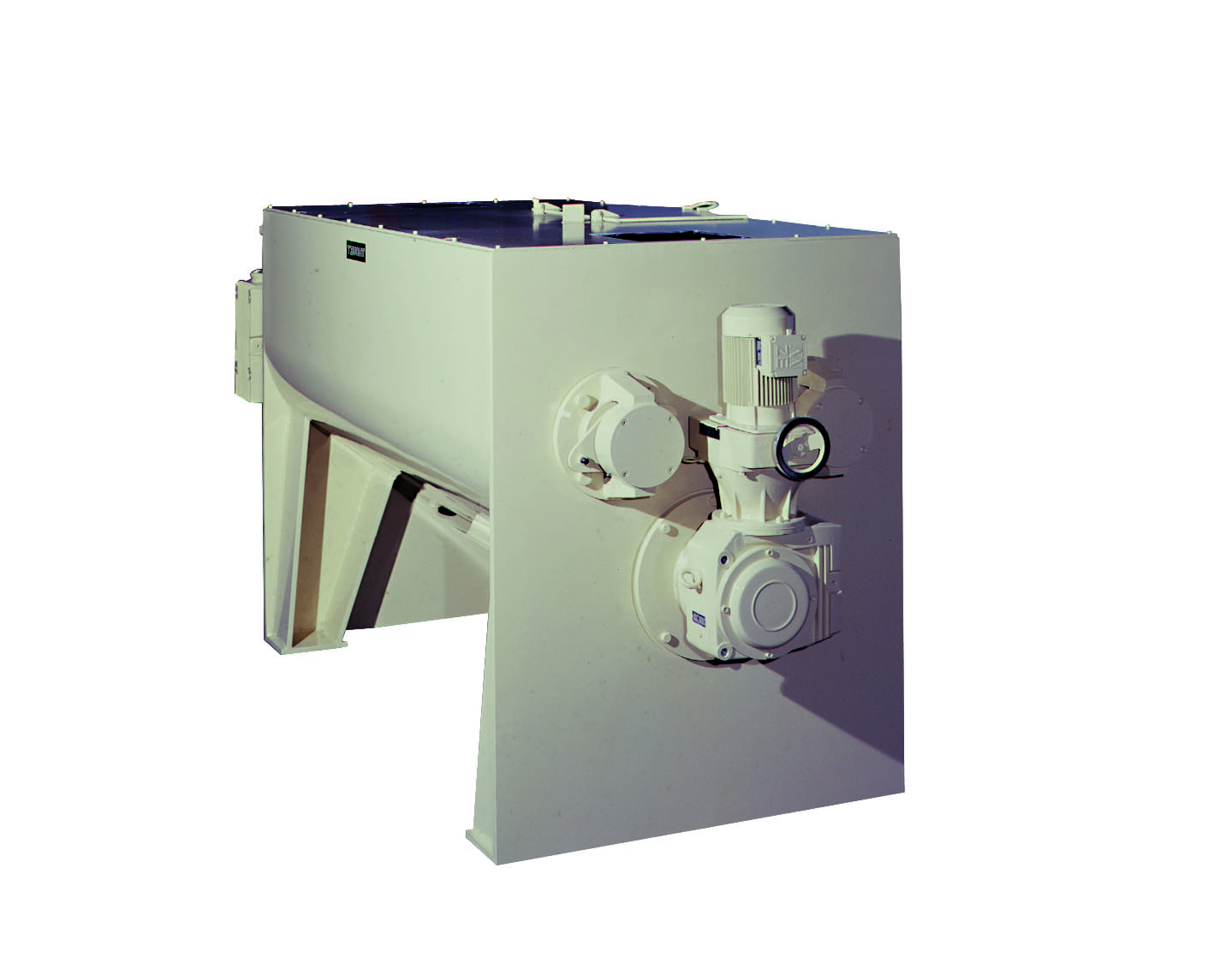

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

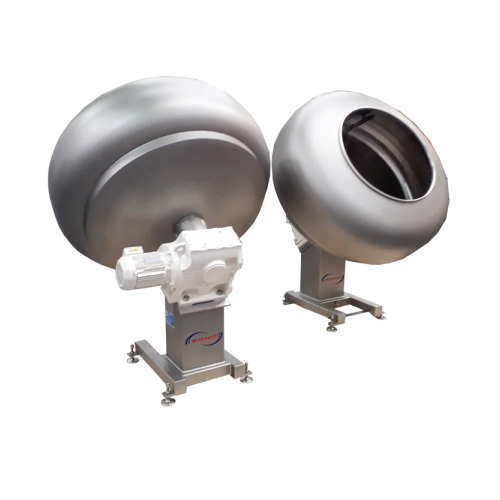

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Coating pans for precision culinary coatings

Achieve consistent, high-quality coatings on a diverse range of products, fro...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

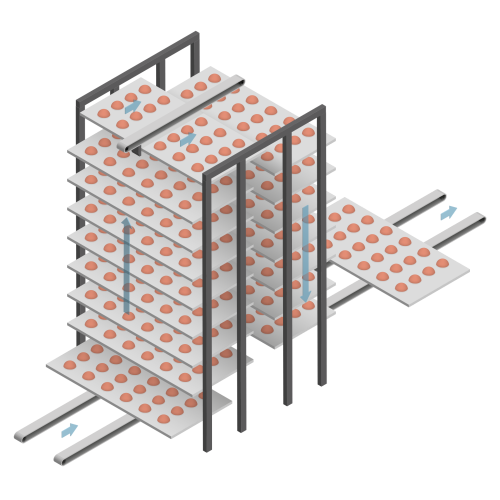

Plate and counter mould storage system for confectionery products

Streamline your confectionery production with an effi...

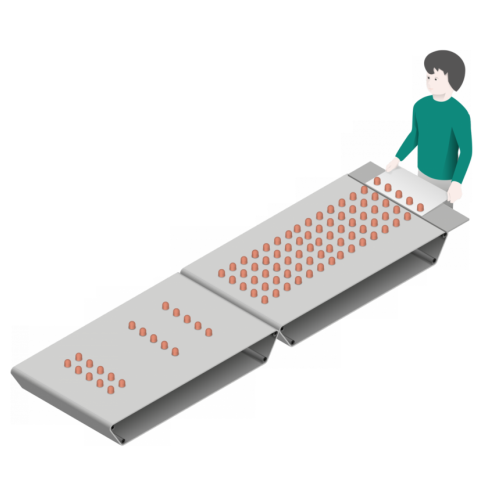

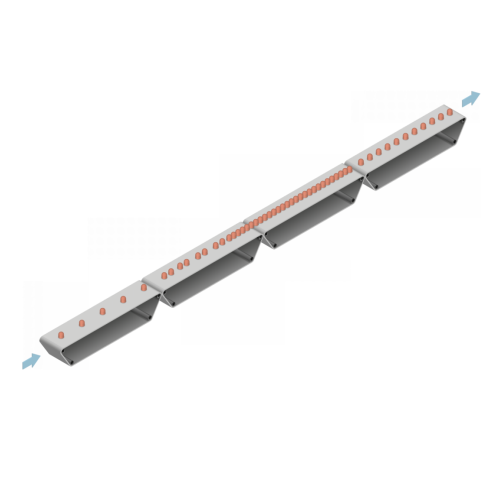

Row aligner for product packaging

Optimize your packaging line with precise alignment and high-speed product handling, ensu...

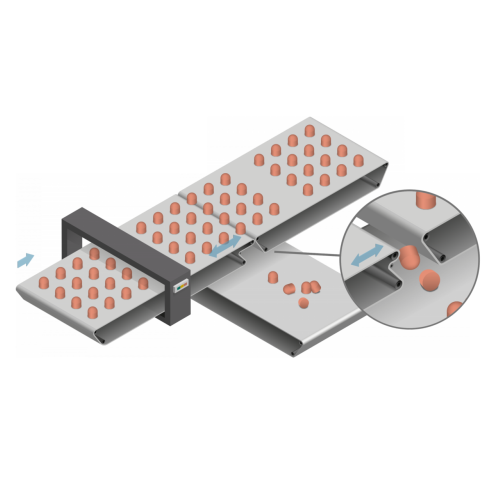

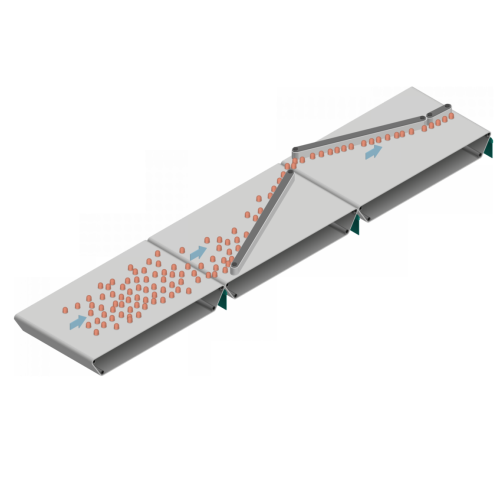

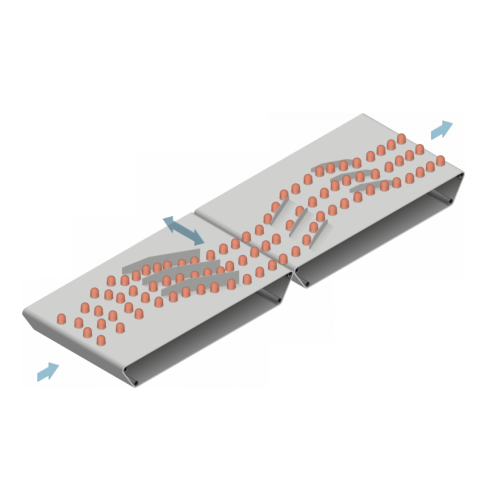

Separating and aligning conveyor for packaging systems

Efficiently manage the flow of diverse solid products like confect...

Vision-based robotic feeding system

Enhance your production line with precise robotic feeding, optimizing product placement...

High-speed forming, cutting, and wrapping for long soft caramels

Optimize your confectionery production with high-speed ...

High-speed double twist packaging for face cut confectionery

Achieve optimal presentation of multi-colored face cut conf...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High-speed forming, cutting, and wrapping for side and bottom folds

Streamline your confectionery production with a mac...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

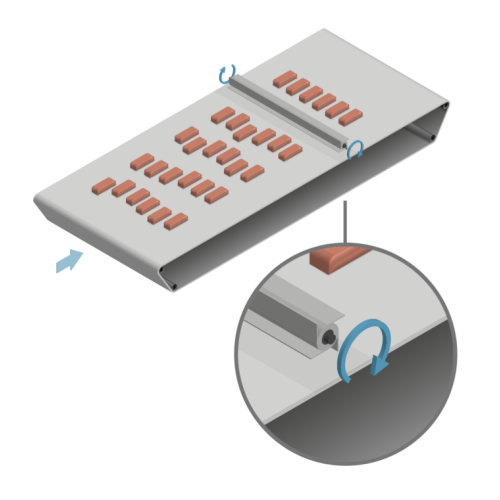

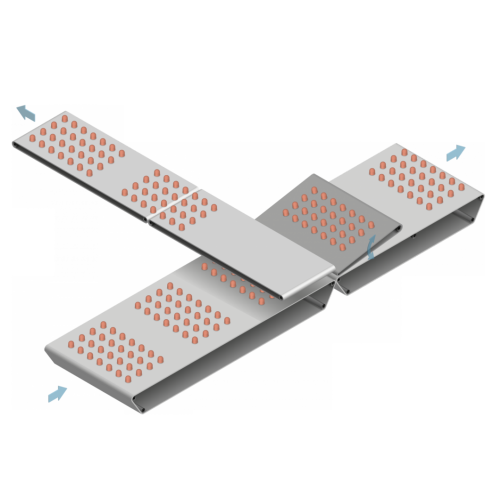

Cross transfer station for mould configuration products

Streamline the transfer of mould-configured products across your ...

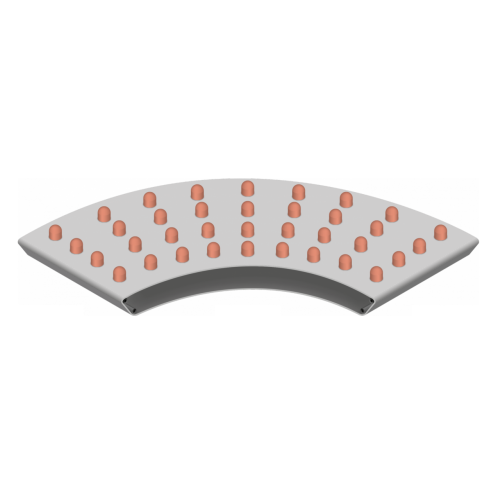

Curved conveyor for product transport

Streamline your product flow with a versatile curved conveyor, perfect for maintainin...

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration...

Flexible high-speed wrapper for confectionery products

Streamline your packaging process with a versatile machine designe...

Wrapping system for preformed products in double twist

Achieve precise packaging with our high-speed double twist wrappin...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High speed forming, cutting and wrapping machine for soft caramels

Enhance your confectionery line with a versatile sol...

Twin-lane high-speed forming, cutting, and wrapping system

Achieve unparalleled packaging efficiency with a high-speed t...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed forming, cutting, and wrapping for side fold packaging with comic strip

Maximize your output with high-spe...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

Forming, cutting, and wrapping system for soft caramels

Optimize your confectionery production line with a solution desig...

Forming, cutting, and wrapping products in multiple styles

Achieve versatile and efficient packaging for confections and...

Forming and wrapping system for soft caramels with comic strip

Elevate your confectionery packaging with a high-speed fo...

Modular high-speed wrapper for chocolate flow packs

Efficiently wrap a wide range of products, from chocolate bars to dis...

Modular high-speed forming, cutting, and wrapping for soft caramels

Streamline your confectionery production with a hig...

High speed wrapping solution for hard candies and toffees

Enhance your production with a high-speed solution designed fo...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Retrofit package for Ek1 packaging system

Upgrade older packaging systems to enhance efficiency and flexibility while acco...

Paper forming technology for sustainable packaging

Elevate your product’s sustainability with advanced paper formin...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

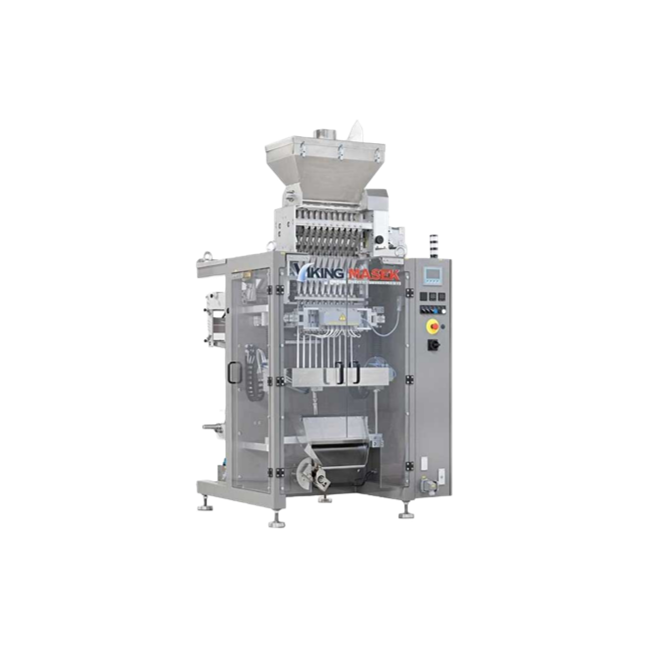

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Mixer and kneader for sugar based recipes

For the production of chocolate paste based on refined or icing sugar, the decis...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Cooker for gums and jellies

Prepare your ingredients for use in gummy and jelly products. This is a static cooking system de...

Batch cooker for hard candy

Prepare your ingredients for the production of hard candy. This is a line of universal candy coo...