Food additives

Find innovative production technology for making food additives and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in food additives making

Which food additives technology do you need?

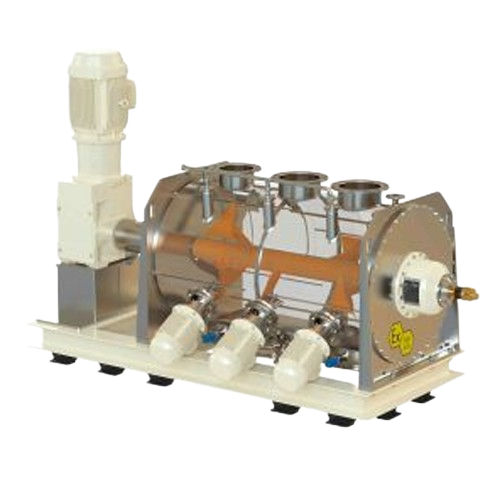

Horizontal batch centrifuge for chemical industry

Optimize your solid-liquid separation with a centrifuge designed for pr...

Cutting mill for soft and medium-hard materials

Efficiently reduce the size of diverse materials with precision cutting an...

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

25kg automatic dry powder packaging system

Optimize your packaging line efficiency with precise, high-speed handling for 2...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

Containment system for filter dryers

Ensure safe handling and containment of hazardous materials during sampling and discha...

Chemical filter dryer for fine chemical production

When processing chemical intermediates, precise filtration and drying ...

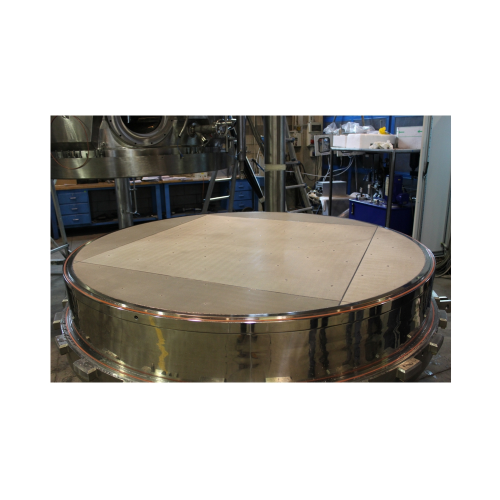

Multilayer filter plates for pharmaceutical and chemical applications

Achieve efficient filtration and separation in yo...

Horizontal vacuum paddle dryer for bulk production facilities

Achieve precise moisture control in powders with a versati...

Sterilizable filter dryer for pharmaceutical applications

Ensure full sterility and efficient moisture removal in critic...

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Conical screw vacuum dryer for hazardous and temperature-sensitive products

When you need precise moisture control for...

Horizontal pilot plant centrifuge for chemical processing

Enhance your R&D and pilot-scale processes with a centrif...

Horizontal pilot centrifuge for pharmaceutical applications

Achieve precise separation of solid and liquid phases with c...

Top discharge centrifuge for pharmaceutical production

Optimize your product yield and quality with precise filtration an...

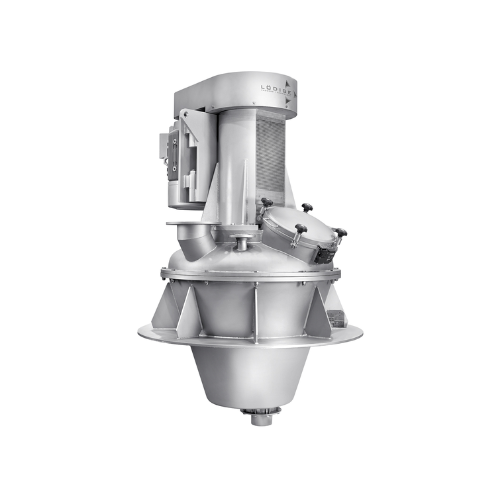

Classifying centrifuge for wet classification of fine particles

Ensure precise particle classification in continuous pro...

Pharmaceutical horizontal peeler centrifuge

Optimize product consistency and purity with precise separation and filtration...

Glass lined columns for chemical plants

Optimize your chemical processing with glass-lined columns, designed to ensure maxi...

Glass-lined mixing systems for pharmaceutical industry

Achieve consistent mixing and thorough agitation for complex formu...

Fluid bed granulation system for food and chemical industries

Achieve efficient granulation and drying of liquids with c...

Ultrapure water purification system for ion chromatography

Achieve consistent ultrapure water supply for analytical appl...

Carbon/hydrogen/sulfur analyzer for organic sample analysis

Ensure precise elemental analysis of carbon, hydrogen, and s...

Flash dryer for surface moisture removal in powders

Optimize moisture removal in heat-sensitive materials with rapid, uni...

Extensograph for assessing dough rheology

Optimize dough quality with precise rheological analysis, ensuring your baking p...

Measuring mixer for small grain samples

Optimize the precision of your formulation processes with a solution designed for p...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

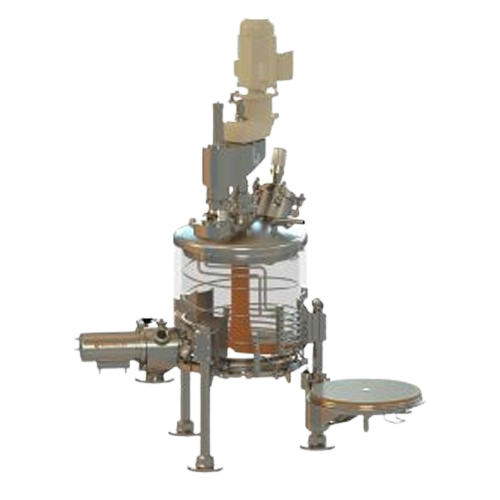

Agitated nutsche filter for solid-liquid separation

Ensure high-purity solid-liquid separation with minimized contaminati...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Homogenizer for high viscosity emulsion and dispersion

Achieve unparalleled dispersion and emulsification with a system d...

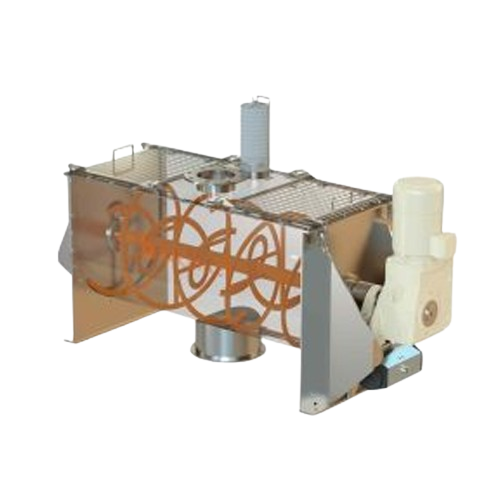

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Horizontal vacuum paddle dryer for thermosensitive products

For high-viscosity products like active pharmaceuticals or p...

Cip system for process tanks

Ensure high-level cleanliness and compliance in your production line with an efficient in-place...

Vertical conical screw vacuum dryer

Achieve precise moisture control with ultra-vacuum batch drying, ideal for thermo-sensi...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Bag feeding hopper for bulk solids

Optimize your material handling with a robust feeding hopper that seamlessly integrates ...

Nutsche filter-dryer for solid-liquid separation

Ensure precise moisture control and efficient solid-liquid separation for...

Roller compactor for pharmaceutical and chemical industries

Optimize your powder processing with precision compaction an...

Lifting device for vacuum boxes on Hvbfs

Eliminate manual handling risks and reduce maintenance downtime with a specialized...

Volumetric filler for bags and rigid containers

Optimize precision filling of powders and granules with a versatile soluti...

Hygroscopic material lump breaker

Ensure seamless processing by breaking down compacted or hygroscopic powders efficiently,...

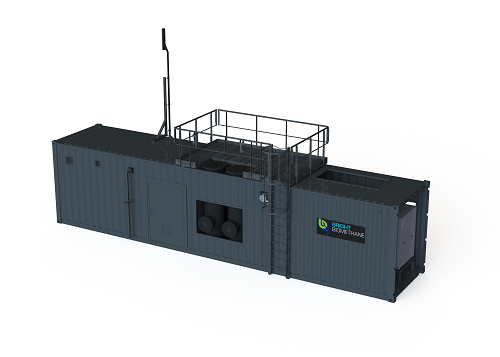

Industrial brine mix and chill system

Streamline your production with a versatile system that seamlessly blends and chills ...

Cyclone filter for pneumatic conveying systems

Efficiently separate and filter airborne dust in pneumatic conveying lines,...

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Liquid additive dosing system for industrial mixers

Achieve unparalleled precision in liquid ingredient integration with ...

Sampler for powdered and granular bulk materials

Ensure precise sampling of powdered and granular materials under varied o...

Rotary feeder for bulk material conveying

Enhance your material flow with precise metering and efficient conveying, ensuri...

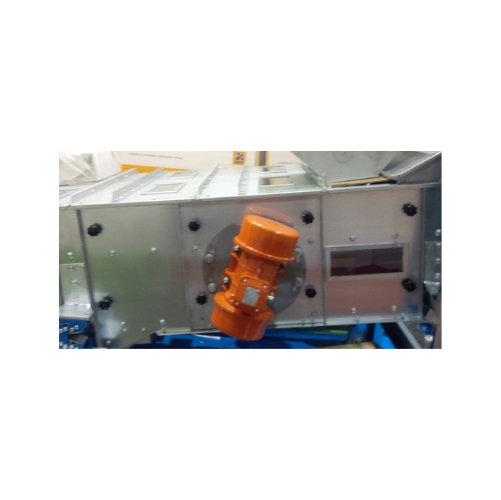

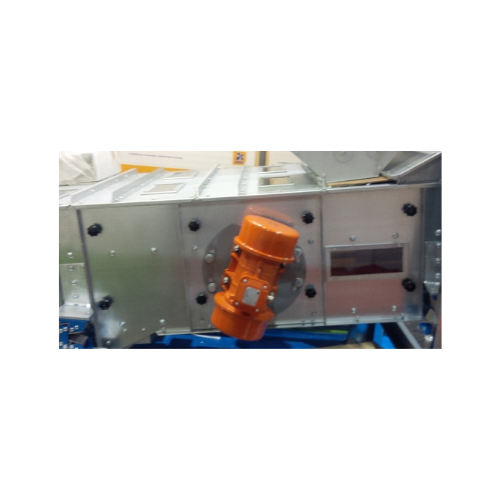

Electric motovibrators for flour milling sieving

Enhance precision in your milling operations with motovibrators that deli...

External electric motovibrators for efficient flour sieving

Optimize material flow in your milling operations with preci...

Industrial mixing dissolver for medium to large batches

Achieve precise mixing and dispersion of medium to large batch fo...

Explosion-proof production disperser for paint manufacturing

Ensure safe and efficient dispersion in volatile environmen...

Explosion-proof dissolver for chemical processing

Ensure safe and efficient dispersion in volatile environments with this...

Vacuum basket mill for high viscosity products

Achieve efficient fine grinding of high-viscosity products while minimizing...

Explosion-proof horizontal bead mill for paint production

Ensure ultra-fine particle size and consistent quality with an...

Horizontal bead mill for ultrafine particle grinding

Achieve precision in ultrafine grinding with a system that allows fo...

Modular basket mill for industrial dispersion

Effortlessly enhance your production efficiency with this versatile solution...

High shear batch process homogenizer for production

Achieve efficient emulsifying, homogenizing, and dispersing with prec...

Industrial basket mill for medium viscosity products

Achieve precise particle size reduction and rapid pigment dispersion...

High-performance production dissolver for large batches

Achieve precise and repeatable dispersion for complex formulation...

Dissolving system for high-viscosity products

Optimize the dispersion of high-viscosity liquids and pastes with this versa...

Explosion-proof dissolver with scraper for high viscosity substances

Ensure flawless dispersion with enhanced safety, d...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Laboratory vacuum dissolver

Experience precision vacuum processing for your high-viscosity formulations, ensuring optimal di...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Dissolver for high-volume industrial dispersion

Achieve precise and efficient mixing with this dissolver, designed for sea...

Explosion-proof immersion mill for paints and varnishes

Optimize high-performance coatings production with an explosion-p...

Laboratory dissolver for multiple applications

Efficiently streamline your laboratory processes with this versatile dissol...

Lab and pilot plant dissolver for dispersion and fine grinding

Achieve efficient dispersion and fine grinding in laborat...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Explosion-proof horizontal bead mill for fine grinding

Ensure precise, explosion-proof grinding in hazardous environments...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Efficient high-volume dissolver with scraper

For high-viscosity formulations, this advanced dissolver with integrated scra...

Lab stirrer for high-viscosity substances

Need precise, high-torque stirring for your complex formulations? This lab stirr...

Entry-level vacuum dispersion system for laboratory applications

Achieve precise dispersion and milling with this versat...

Laboratory bead mill for sample dispersion

Ensure precise particle size reduction with versatility and ease, enabling effi...

Nano bead mill for laboratory wet grinding

Achieve ultra-fine particle dispersion and consistent milling results with this...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Dissolver for mixing and processing in lab and pilot plant

Optimize your material dispersion and homogenization processe...

Wet spent grains pre-dewatering system

Optimize your brewery operations with a dewatering system that efficiently reduces m...

Turnkey stainless steel tanks

Optimize your liquid processing with versatile stainless steel tanks designed for efficient st...

Small-scale twin-screw feeder for powder handling

Perfect for precision in lab environments, this small-scale feeder effi...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Mango juice production line

Streamline your mango juice production with a complete solution that efficiently transforms fres...

Round motion separator for dry and wet screening

Optimize your production line with an efficient solution for precise scre...

Quickchange systems for vibratory separator screen changes

Streamline your production with a system that enables rapid s...

Wet granulation co mill for pharmaceutical formulations

Optimize your manufacturing process with precise particle size re...

Bigbag discharge station

Efficiently manage bulk material unloading with this solution, which facilitates seamless dischargin...

Loss-in-weight feeder for flowable particles

Ensure precise ingredient delivery with a feeder designed for high accuracy a...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

Industrial vacuum conveying system

Simplify bulk material movement and separation with a versatile vacuum conveying system,...