Salad dressing mixing Equipment

Find innovative salad dressing mixing equipment and connect directly with world-leading technology suppliers

The salad dressing mixing process involves water base, oil base, and acidic ingredients, which means emulsification is required for this process. You first need to pre-mix the water, starch, vinegar, and salt at around 90°C in the pre-emulsifier. Then, as the second step, you need to add the oil to the colloid mill or emulsifier. Here, vacuum or pressure homogenizer is often employed as they can produce higher-quality dressing compared to conventional cooker or mixer.

Which salad dressing mixing technology do you need?

Industrial premixing system for batch and inline processing

Streamline your production with advanced premixing systems d...

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

Standard batch mixer for salt and citric acid mixing

Achieve perfectly homogeneous blends of salts, sugars, and challengi...

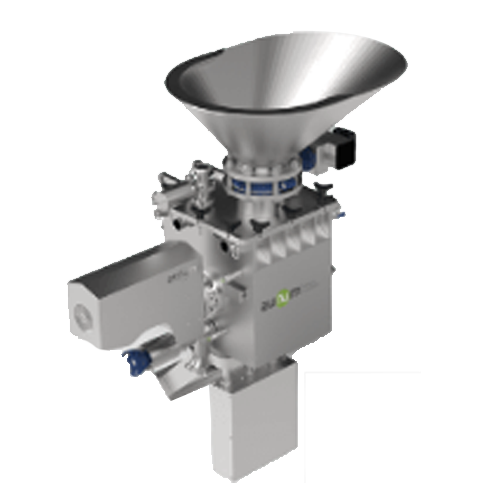

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Mixing tank for soups, sauces, and dressings

Streamline your soup and sauce production with advanced mixing technology des...

High-performance dispersing and mixing solutions

Enhance your mixing and dispersing processes with advanced fluid stream t...

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Colloid mills for shearing and mixing in food processing

Optimize your liquid formulations with precise colloid mills, en...

Industrial dissolver for liquid-solid mixing applications

Optimize your production line with an industrial dissolver tha...

Degassing and mixing unit for beverage production

Ensure precise beverage formulation and maintain high quality standards...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

Vacuum process system for food product mixing and emulsifying

Optimize your production of sauces, dressings, and condime...

Multistage mixer for emulsions and dispersions

Enhance your production with a versatile multistage mixer that ensures opti...

Industrial magnetic agitator for homogenizing pharmaceutical products

Achieve precise dispersion and homogenization in ...

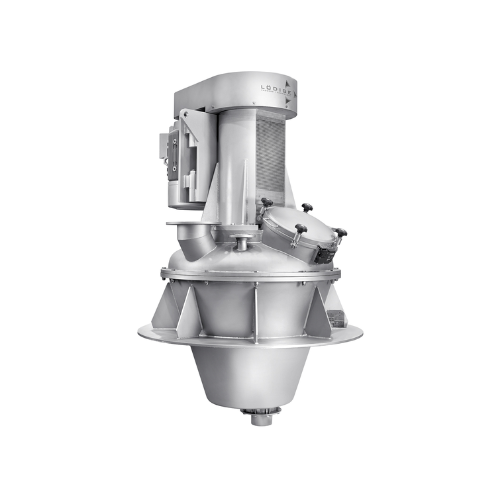

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

High-capacity manual mixer for industrial applications

Optimize your mixing process with a highly efficient, manually ope...

Storage tank for dairy products and juices

Designed for optimal preservation and hygiene, these storage tanks prevent sedi...

Melter for vacuum turboemulsifiers

Achieve optimal mixing, dispersion, and temperature control with precision-engineered me...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

Atmospheric powder induction system

Enhance your mixing efficiency with a system designed for rapid powder induction and th...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

Inline disperser for food production

Quickly achieve stable, agglomerate-free dispersions and emulsions with minimal manual...

Inline disperser for homogeneous emulsions and suspensions

Achieve precise control over particle size and distribution w...

Horizontal bead mill for industrial production

Ensure ultra-fine particle size reduction in high-demand processes with thi...

Multifunctional industrial mixer for processed cheese and sauces

Optimize your batch production with a versatile solutio...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Inline blender for liquid ingredients

Optimize your production line with seamless liquid blending, enhancing flavor consist...

High-shear mixer for emulsions, dispersions, and foams

Achieve precise emulsions and dispersions effortlessly with high-s...

Shear pumps for continuous on-line dispersion

Effortlessly achieve consistent shearing and mixing with versatile shear pum...

Side entry mixer for industrial tank applications

Ensure optimal mixing and blending of liquids and slurries with high ef...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

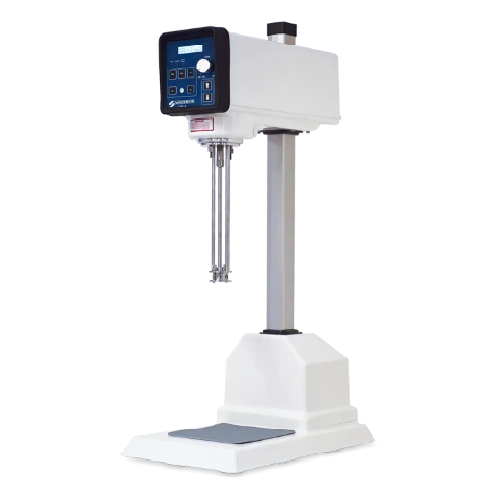

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Bench-top blending vessel for small batch preparation

For small-batch liquid products, achieve precise mixing, heating, a...

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

Emulsifying and blending system for liquid and semi-liquid food products

Efficiently emulsify and blend liquid and semi...

Stand dispersing unit for pilot plant applications

Achieve precise particle size reduction and efficient mixing with this...

High shear vertical mixer for dispersion and emulsification

Achieve seamless emulsification and homogenization in divers...

Steam jacketed kettle for cooking sauces and dressings

Enhance your sauce production with a steam jacketed kettle that en...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Turbo mixer for homogeneous solutions in food and pharmaceutical industries

Effortlessly achieve uniform suspensions a...

High-efficiency high-capacity reactor for industrial processing

Enhance production efficiency with a reactor system desi...

Aseptic magnetic mixer for hygienic production

Experience seamless mixing to the last drop with advanced levitating impell...

Emulsion processing system for homogenizing solids into liquids

Achieve precision in emulsifying and homogenizing proces...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

High shear emulsifier for hygienic applications

Achieve precise emulsification and consistent mixture quality with enhance...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

Brine preparation system for marination processes

Ensure consistent and high-quality brine and marinade mixtures with a s...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

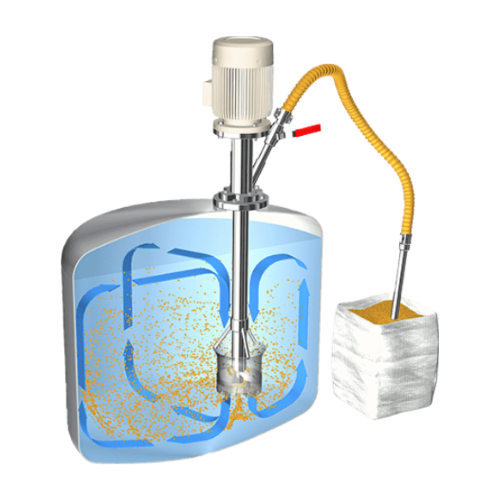

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Multifunctional cheese and sauce processor

Optimize your production of sauces, dressings, and confectionery fillings with ...

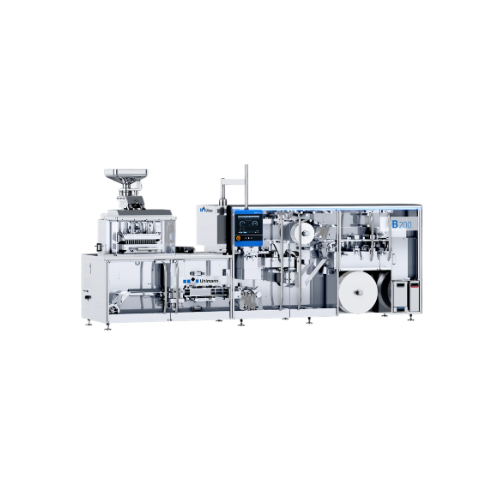

Manual dosing and capping for semi-dense products

Enhance your production line efficiency by seamlessly integrating manua...

Soymilk processing plant

Enhance your plant-based production with our tailored soymilk processing plants, designed to efficie...

Bottom entry mixers for high viscosity products

Optimize your production line with mixers designed to handle both high and...

Ketchup manufacturing line

Streamline your sauce production with precision-engineered efficiency, allowing for seamless reci...

All-in-one system for making emulsions

To make smooth batches of mayonnaise or ketchup you need to use process equipment fo...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Batch processing system for emulsions and suspensions

Emulsions enhance foods with a creamy mouthfeel and richer flavors....

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Tank bottom mixer for high viscosity applications

Achieve seamless emulsification and homogenization of high-viscosity pr...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and juice processing

Ensure superior texture and stability in your liquid formulati...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

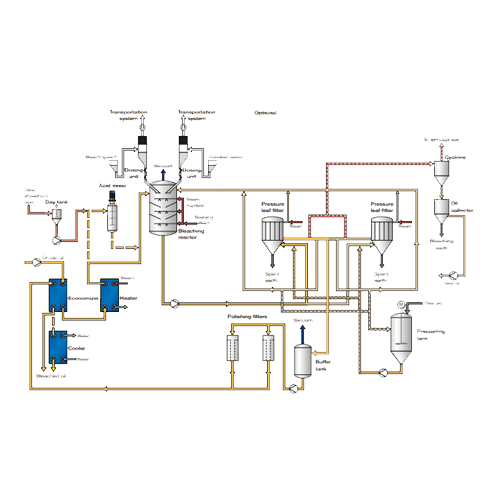

Bleaching systems for edible oil refining

Achieve clarity and stability in your edible oils with cutting-edge bleaching sy...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Hydro grind reactor for meat, vegetable, and vegan product processing

Achieve precision grinding and emulsification of ...

Inline wet mill for mayonnaise emulsions

Eliminate the challenges of achieving stable, uniform emulsions in your sauces and...

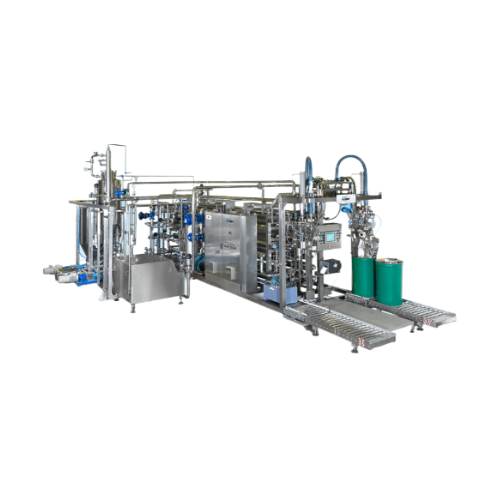

Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing syst...

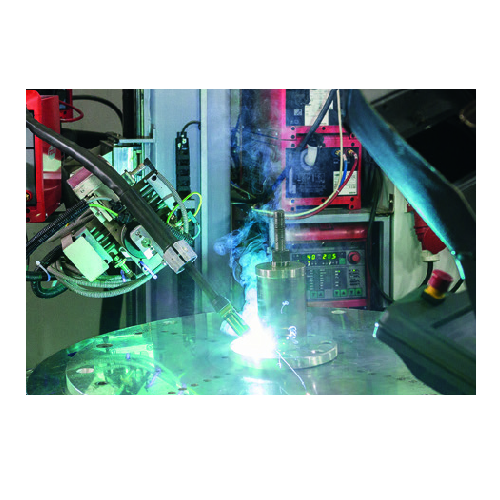

Traditionally welded silos for constrained installation sites

Ideal for facilities with limited space, these traditional...

Single-serving blender for home use

Create smooth, nutrient-rich beverages and culinary delights effortlessly, whether you&...

Scraped surface heat exchangers for high viscosity products

Ideal for continuous processing, these heat exchangers effic...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

Hygienic tanks for various processing needs

Achieve optimal processing and storage with customizable hygienic tanks, desig...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

Pet bottle production for small and medium outputs

Optimize your production line by manufacturing PET bottles in-house, r...

Homogenization and emulsifying system for fine foods

Texture and consistency are critical to foods with delicate composit...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Compact industrial sauce pan

Safe, reliable cookers that operate unobtrusively are required in any kitchen where space and t...