Making Marshmallows

Find innovative production technology for making marshmallows and connect directly with world-leading specialists

To make a good marshmallow, you need to get the air straight. With it, proper marshmallow manufacturing equipment and a few ingredients - categorized into sweeteners and emulsifying agents, like gelatin – help you achieve flavor. Popular around the world, the marshmallow market size reached $319.8 million in the US and Canada.

Stories about marshmallows

Select your marshmallows process

Tell us about your production challenge

The importance of air in marshmallow production

Air serves an important role in the quality and texture of the marshmallows, as they represent 40-60% of its content. The air creates bubbles that help form a standard product, giving it puffiness.

To produce marshmallow, you pump the air into the mixture. The more air pumped, the lighter the mixture will be. Be careful, though – when trapping too much air inside the marshmallow, it causes it to expand way more than the usual size, making it too light.

After forming the mixture, squeeze it through an extruder to produce the familiar pillow shape of regular marshmallows. Thereafter, send the marshmallow to a cooling drum where any excess starch may be removed, before packaging.

Creating good vegan marshmallows

Marshmallows are not vegan-friendly, as more conscious consumers tend to believe. The reason why is the use of gelatin, which is a binding agent in marshmallows. When combined with air, it gives it the fluffy foam texture we all like and also extends the product’s shelf life. But if you want to produce vegan marshmallows, then gelatin cannot be your choice, as it is a by-product from the animal industry. Try vegan substitutes instead. Some producers use carrageenan, a gel that originates from seaweed. Another option is the xanthan gum, a vegan gelatin which is fully plant-based.

Producers also need to mind the use of sugar when making vegan marshmallows. Sugar manufacturers often use bone char as a decolorizer in sugar processing. The bones are from cows, and they act as a filter to achieve the white sugar we know.

To create a truly vegan product, opt for other types of sugar, like the organic granulated one. Sugar that doesn’t go through filtration process is often vegan – which is true for demerara and muscovado types, for instance. You can also opt for beet sugar or for white sugar that has different filtration processes, such as with an ion-exchange system.

How to make sugar free marshmallows

Apart from vegan options, the market trends are also pointing out less or no-sugar products. This is true also for the confectionary industry, as people want to be healthier but still eat a snack from time to time. In North America, for instance, the sugar-free marshmallow market is expected to expand at over 8% CAGR through 2028.

You can still make fluffy and soft marshmallows without the use of regular sugar. You just need to substitute the sucrose using ingredients like maltitol and isomaltulose, a non-cariogenic sugar and unflavored gelatin powder. This is your main ingredient when creating the mixing that will go through the same process until it reaches consumers.

Processing steps involved in marshmallows making

Which marshmallows technology do you need?

Continuous mixer for batters and cremes

Achieve consistent texture and uniform cell structure in your cake batters and crèm...

Whipping agent solution station for egg solutions

Optimize your production of delicate egg-based foams with a versatile s...

Pressurized buffer tank for aerated products storage

Ensure consistent aeration and product quality with this pressurized...

High viscosity material mixer for bakery and chocolate

Efficiently mix and knead high-viscosity materials for premium cho...

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

Systems for processing confectionery rework

Optimize resource use and reduce waste by transforming confectionery rework in...

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Caramel cooking solution

Optimize your confectionery production with precise mixing, dissolving, and heat transfer technologi...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

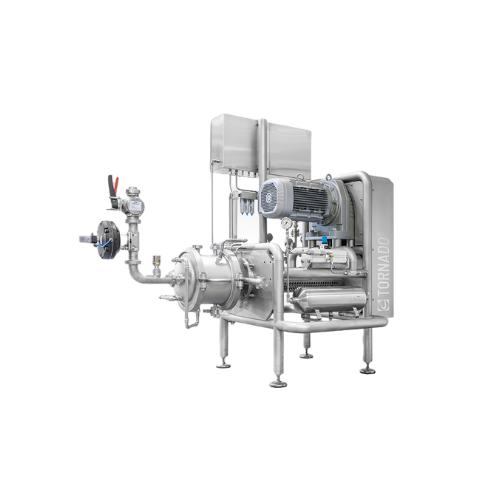

Continuous cooking system for jelly and marshmallow production

Elevate your confectionery production with a system desig...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Static cooler for jelly and foam manufacturing

Ensure the integrity of your confectionery with a cooling system designed f...

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

Aerator for candy masses

Enhance your candy production with precise and efficient aeration, transforming textures and creatin...

Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed ...

Aeration system for sugar masses

Optimize your production of aerated confectioneries with a two-step aeration system designe...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

Biscuit overwrapper for x-fold or hermetic sealing

Ensure each biscuit, cookie, and sweet treat is securely wrapped and s...

Colorful marshmallow extrusion for confectionery production

Elevate your confectionery offerings with a high-speed extru...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

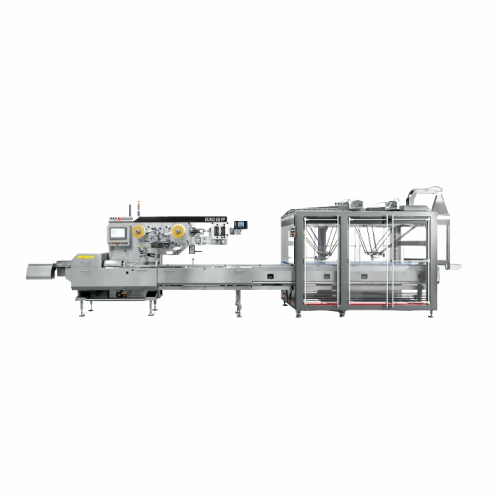

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Double twist wrapping machine for sweets

Optimize your confectionery packaging line with high-speed double twist wrapping, ...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Sandwich and biscuit depositing system

Achieve high-capacity sandwich and biscuit production while maintaining precision wi...

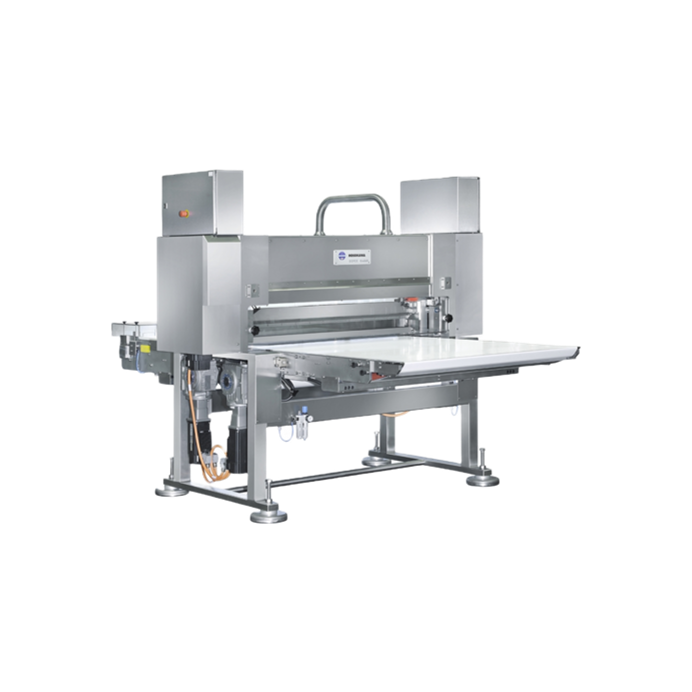

Industrial pressing system for convenience food

Optimize your production line with a versatile pressing system, designed t...

Clean-in-place (cip) system for sanitation processes

Ensure thorough sanitation in your production line with a streamline...

Industrial buffer tank for temperature and texture control

Achieve precise temperature control and optimal texture with ...

Industrial tray sealer for food packaging

Optimize your packaging operations with precise tray handling and versatile seal...

Belt dryers for gelatin processing

Efficiently transform liquid gelatin into high-quality solids with precise moisture cont...

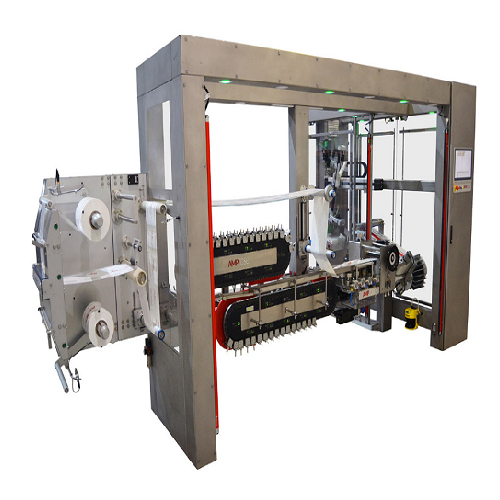

Mallow make up line equipment

Achieve diverse marshmallow designs with precision using advanced extrusion and coating techno...

Continuous aerator for r&d and small scale production

Ideal for testing and scaling aeration processes, this compact mach...

Large-scale marshmallow production equipment

Capture the essence of classic campfire treats with precision-engineered equi...

Mini marshmallow production system

Streamline your confectionery line with versatile mini marshmallow equipment designed fo...

Twisted marshmallow cable production manifold

Achieve precision in twisted marshmallow production with a manifold designed...

Cleaning in place solution for food production systems

Optimize your cleaning process with an integrated clean-in-place s...

Dry ingredient blending solution for confectionery and bakery products

Achieve seamless integration of dry inclusions i...

Batch cooker for pectin jelly and caramel production

Achieve precise temperature control and uniform cooking with steam-h...

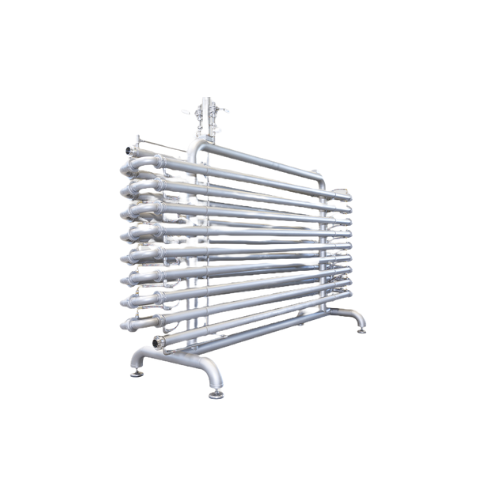

Thermosyphon cooker for marshmallow and confectionery production

Achieve precise and consistent cooking of confectionery...

Compact continuous aerator for bakery production

Optimize your bakery production with a compact aerator that delivers prec...

Continuous aeration system for bakery products

Optimize your bakery production with precise aeration and mixing, ensuring ...

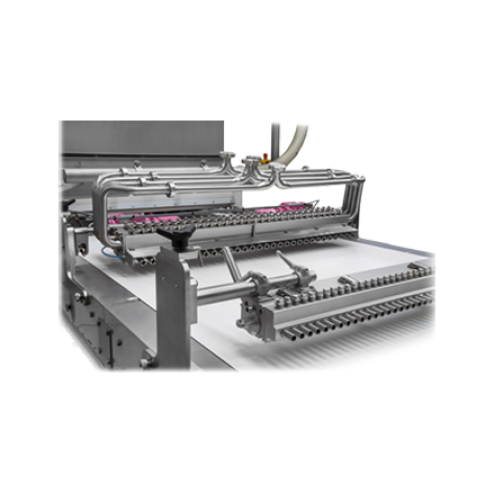

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

High precision dosing system for liquid media

Producing confectionery and bakery products implies mixing large amounts of ...

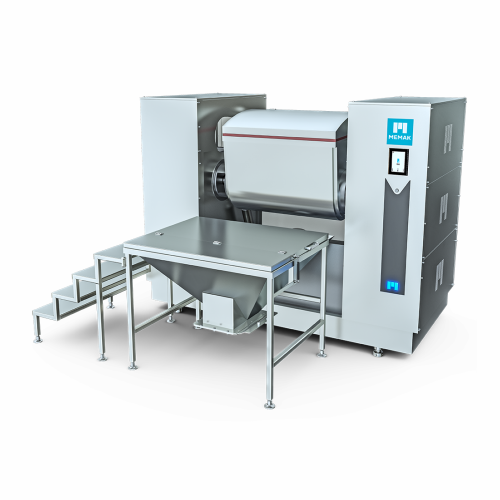

Large capacity confectionary mixer

The foaming process determines the quality of various confectionery products, from marsh...

Compact & pumpable food media mixer

The process of mixing ingredients for confectionery products like marshmallows and meri...

Guillotine cutter for confectionery

Confectionery products such as marshmallows, licorice candies, and fudges come out of e...

Mixer for aeration of confectionery and bakery products

Aerated products can be difficult to mix thoroughly without reduc...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Inline ultrasonic food cutting machine

Cutting sticky products in the food sector is not always an easy process. Small scal...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

High-speed flow pack wrapping machine for hard candy and jellies

For some high-quality candy which require individual wr...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Whipping machine for soft candy

Prepare your ingredients for any whipped or aerated product component. This is a pressurized...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...