Making Marmalade

Find innovative production technology for making marmalade and connect directly with world-leading specialists

Legend has it that the word ‘marmalade’ is a derivate of “Marie est Malade”. Supposedly, the acidic-sweet mixture was offered to Marie Antoinette when the Queen of France fell malade. Whatever the true origins of the name, marmalade processing equipment has quickly made the golden spread a pick-me-up for the masses.

Tell us about your production challenge

Control marmalade temperature with heating and cooling equipment

Heat combines your fruit pulp, sugars, pectin, and edible acids into marmalade, and it takes 15-30 minutes of boiling for gelation to form. Temperatures may reach up to 80°C in a vacuum cooker and up to 105°C in an open kettle.

But you then need to quickly cool down the mix to avoid caramelization of the sugar content. Moreover, prolonged cooking risks turning your gold-colored marmalade into a brown semiliquid.

Marmalade processing requires one part per five of fruit content

There is a fine line between marmalade and jam, but the former contains fruit peel in the mixture. Besides its high nutritional value, the citrus rind a rich source of pectin that gives the finished product its texture and spreadability.

Moreover, marmalades contain a minimum 20% fruit ingredient in the final product. A packaged jar must have at least 7.5g fruit content obtained specifically from the endocarp for every 100g of marmalade.

Sugars extend marmalade shelf life and enrich the finished product

Sugars are a key component of marmalade and, together with pectic substances, they help to build the natural gel-frame that holds the product’s consistency. Another major function of sugars is preservation. By locking in moisture, sugars keep bacteria from attacking the marmalade and extend the natural shelf life of the final product.

You may use a range of foodstuffs with sweetening properties, including honey and fructose syrup. Brown sugar is a secret ingredient used to give the finished marmalade an amber tint and a more candied flavor.

Processing steps involved in marmalade making

Which marmalade technology do you need?

Industrial cream doser for pastry applications

Efficiently dose and fill a variety of bakery and confectionery mixtures wi...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Emulsifying and blending system for liquid and semi-liquid food products

Efficiently emulsify and blend liquid and semi...

Food mixing and blending system

Enhance your production line with a versatile system designed for gentle processing needs, o...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Jam kettle for preserve and marmalade production

Ensure consistent flavor and texture in your jams and marmalades with pre...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

Blender for high viscosity products

When handling thick mixtures that challenge conventional systems, this specialized blen...

Powder blender for liquid mixing applications

Optimize your process with a compact blender designed to efficiently dissolv...

Industrial vacuum cooker for sauces

Enhance your sauce and jam production with an industrial vacuum cooker that offers cutt...

Industrial vacuum kettle for sauce production

Achieve optimal flavor retention and nutrient preservation with an industria...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Fruit processing system for jams and marmalades

Optimize your fruit-based product manufacturing with equipment designed fo...

Industrial cooker for food processing

Enhance your production line with versatile cooking solutions designed for precise te...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

Industrial low temperature freeze dryer for high sugar or acid content products

For processing challenging high sugar ...

Shelling mill for Iqf and frozen lumps

Precision-engineered for the seamless transition from frozen state to process-ready ...

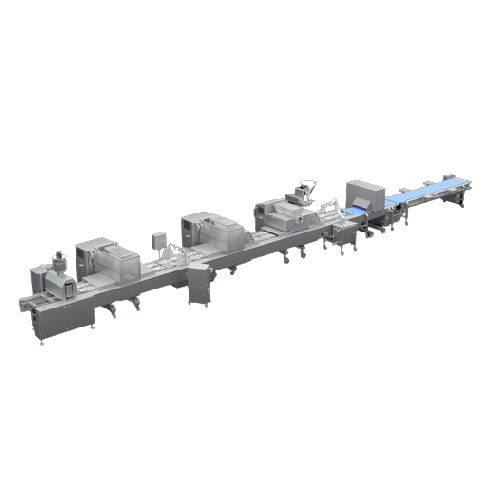

Multifunctional depositing line for bakery production

Optimize your bakery and food production with a modular depositing ...

High-volume spraying system for glazes and marmelades

Streamline your glazing process with a system designed to minimize ...

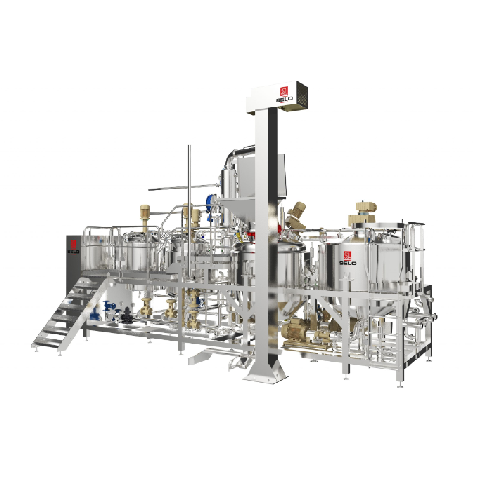

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Aseptic vacuum cooker-cooler for jams and marmalade

Ensure your fruit-based products retain vibrant color and taste while...

Vacuum cooker-cooler for jams and sauces

Optimize your food production with a vacuum cooker-cooler that enhances flavor whi...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

In-line filling and closing system for pre-formed containers

Looking to enhance production efficiency with a solution th...

Food processor for high and low viscosity products

Achieve consistent recipe results and streamline your operations with ...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

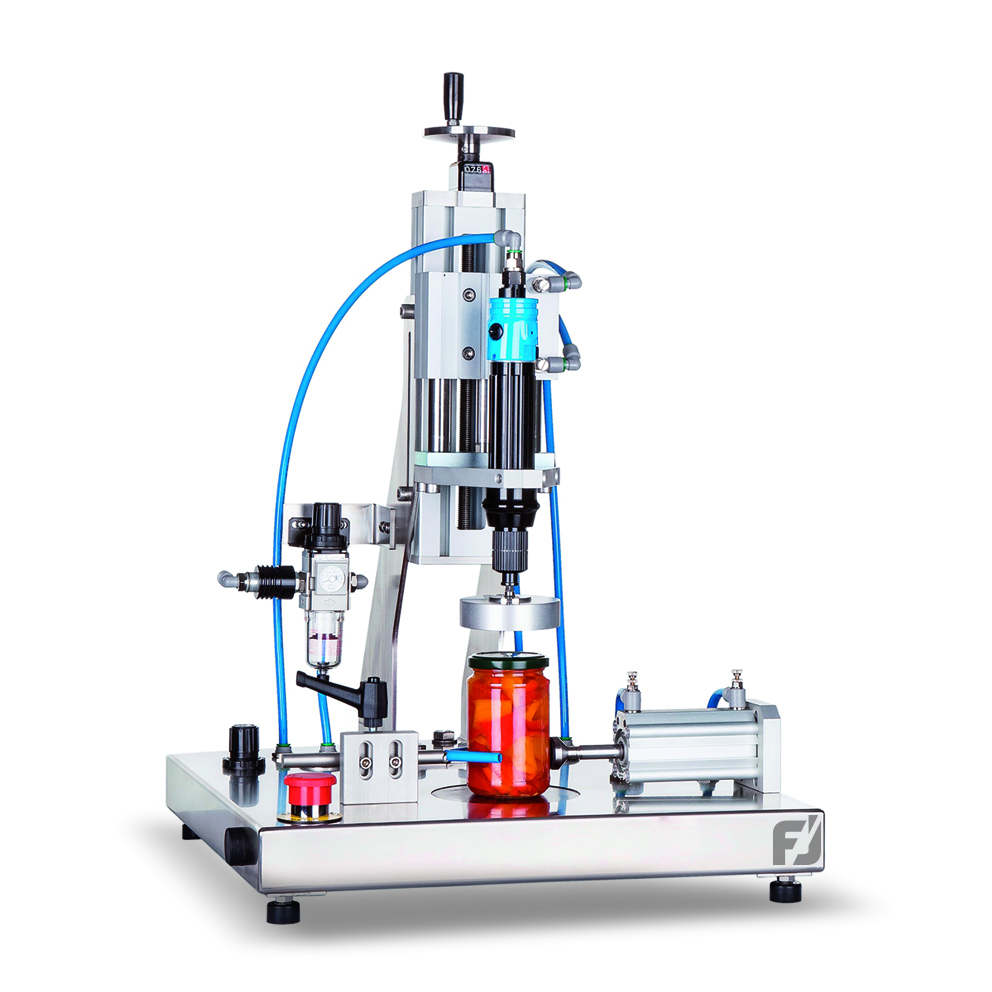

Manual monoblock for filling and capping jars

Optimize your jar filling and capping processes, even with high-temperature ...

Industrial dissolver for liquid-solid mixing applications

Optimize your production line with an industrial dissolver tha...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

Efficient jam and marmalade production line

Optimize your fruit and bakery product lines with equipment designed for high-...

Jam production line

Optimize your jam production with our sophisticated line that ensures high capacity, consistent quality, ...

Energy-saving cooling system for vegan products

High-viscosity products like hummus or chunky pasta sauces must be cooled ...

Capping Machine for Jars

In production lines that involve sterilization processes, jars that are not properly capped may expl...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

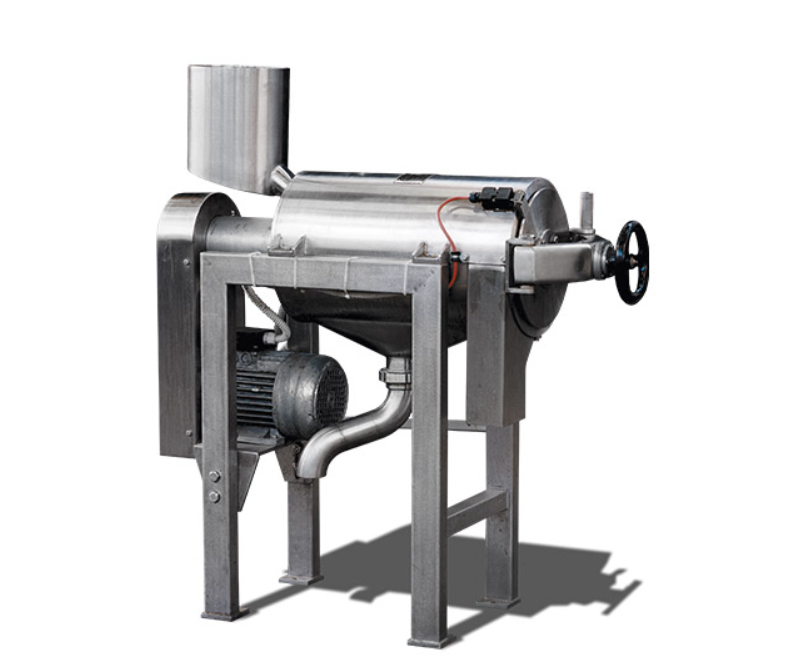

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...