Making Surgical Instruments

Find innovative production technology for making surgical instruments and connect directly with world-leading specialists

Surgical instruments still involve a significant degree of manual craftsmanship to manufacture. But advances in surgical instruments technology today intertwine with expert handiwork to produce precise tools that make the difference between life and death.

Select your surgical instruments process

Tell us about your production challenge

Drive the furnace temperature up to 750°C to achieve austenitization in alloys

Surgical instruments are crafted from anti-corrosion materials, typically alloys composed of iron and carbon. The most common base material, Austenitic Steel Type 316, is also known as surgical stainless steel.

The austenite phase in alloys forms at temperatures exceeding 750°C but not reaching 1450°C. During austenitization, the carbon content drops as the heating rate rises, but it settles after the complete dissolution of cementite and ferrite in the material.

Use polishers to even out juts caused by surgical instruments technology

Forged tools are ground and sanded to shape precise, even contours. But surgical instruments technology causes burrs during the machining stage.

Scrub your forged scalpels and forceps in a barrel finisher to smoothen and buff them. Porcelain chips or other polishing compounds in the scrubbing equipment scour the instruments in a circular vibrating drum.

Control ductility in the final product with steady annealing

Achieving the correct annealing is critical to keeping surgical tools ductile. Treat the hardened products in a furnace to above the recrystallization point of the base materials but below their melting point. This varies between 60°C and 290°C depending on the composition.

This process evens out irregularities in the molecular structure of the metals and allows new grains to develop. Ductile metals are better able to handle concentrations of stress.

Repeat passivation techniques flush out iron reactivity

Frequent exposure to body fluids makes surgical instruments susceptible to corrosion. Any residue of free iron on the surface of the objects poses a risk.

Immerse the finished product in mild oxidants, such as concentrated nitric acid, to eliminate the chemical reactivity of iron. The passivation process dips the instruments in a series of pools until any trace of iron is neutralized.

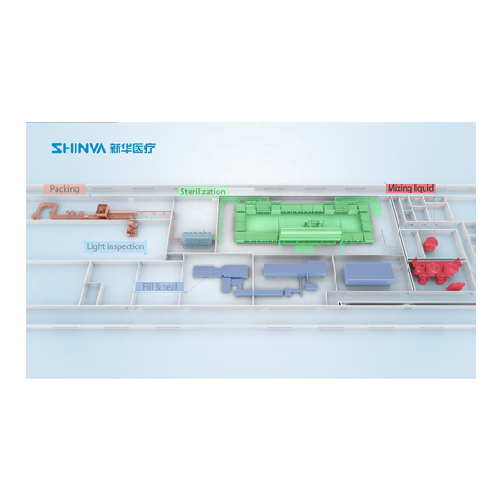

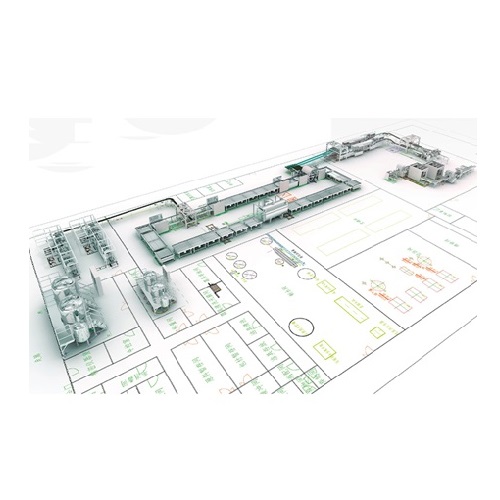

Processing steps involved in surgical instruments making

Which surgical instruments technology do you need?

Collaborative robot for fast and intuitive automation

Accelerate your production line with a versatile and intuitive cobo...

Robotic arm for small component handling

Streamline your production with a versatile robotic arm designed for small compone...

Leak test panels for industrial applications

Ensure the integrity of your critical components with precision leak testing ...

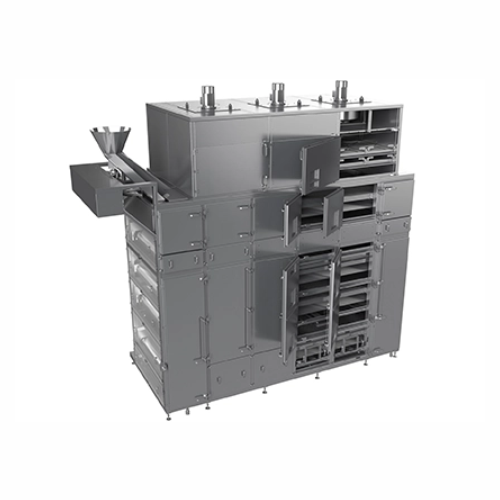

Industrial tunnel dryer

Optimize drying efficiency and maintain product quality with continuous tunnel drying, ideal for prec...

Pharmaceutical and laboratory product drying solution

Ensure precise moisture control for diverse products, from pharmace...

Continuous belt dryer for large-scale drying applications

Optimize your production with a continuous belt dryer, enginee...

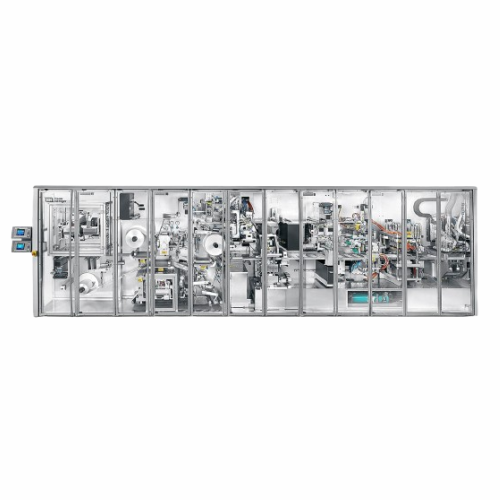

Web processing platform for pharmaceuticals and medical products

Optimize your medical and pharmaceutical production wit...

Modular quality assurance system for packaging lines

Streamline your packaging line with a versatile system that ensures ...

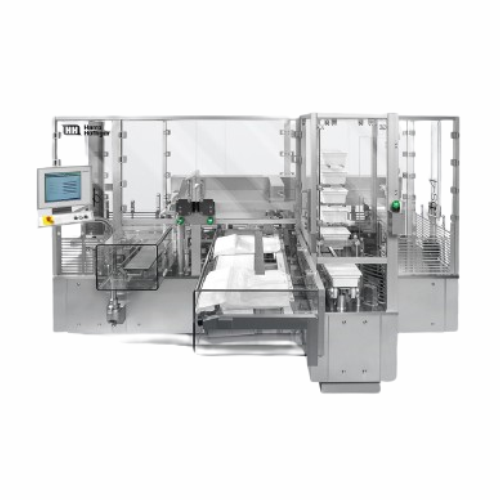

Double bagging solution for sealed tubs

Achieve sterile packaging for medical and pharmaceutical products with a compact, e...

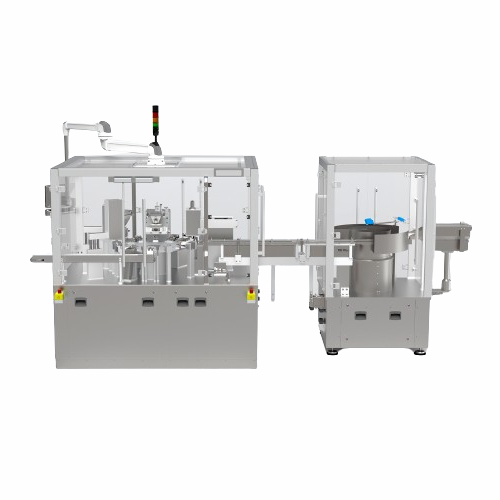

Rotary indexing table for dosing and assembly

Optimize production efficiency with a compact rotary indexing table that str...

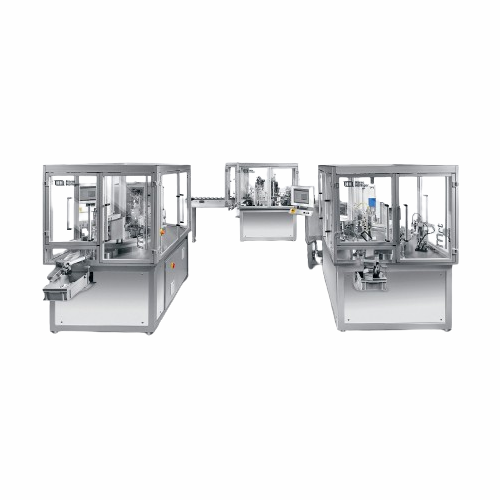

Round motion assembly platform for inhalers

Achieve high-efficiency assembly and inspection of inhalers and diagnostic dev...

Fully automated suture winding system

Simplify your surgical suture packaging with a system that ensures precision and spee...

Production of sterilized aluminum blister packs

Optimize your medical product packaging with our high-speed solution for p...

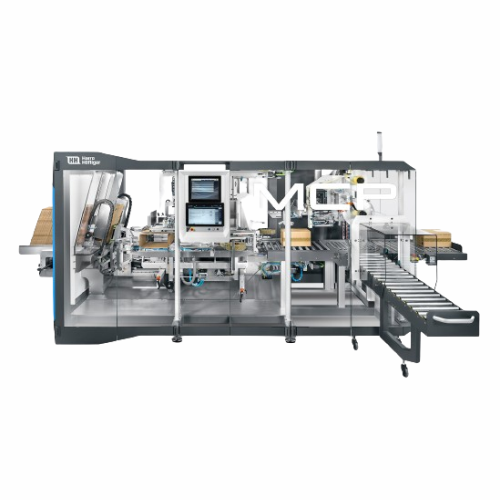

End-of-line casepacker for shipping boxes

Streamline your packaging line efficiency with this versatile casepacker, design...

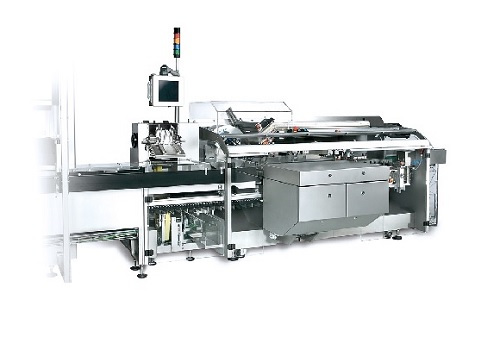

Flexible horizontal cartoning solution for various products

Streamline your packaging process with this versatile carton...

Powder dosing for lab and galenics

Ideal for precise dosing needs, this compact lab device streamlines powder filling proce...

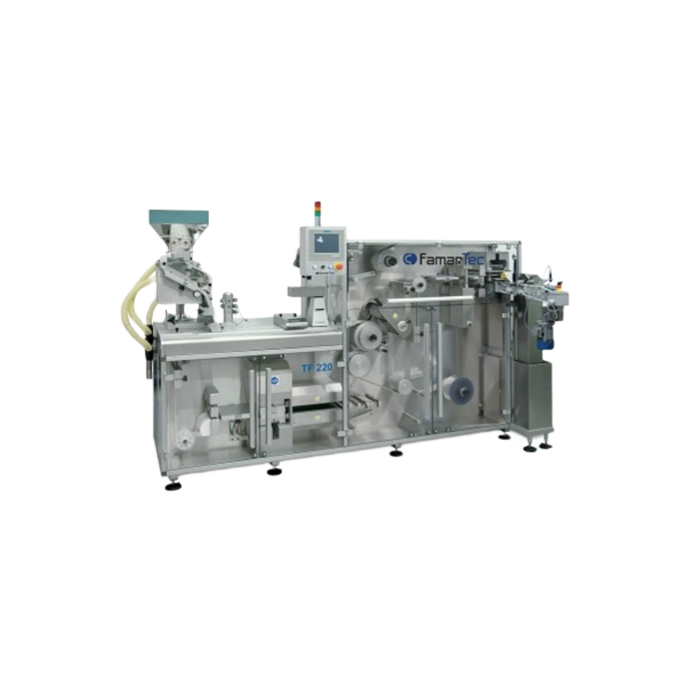

Commercial blister filling solution for dry powder

Efficiently fill and seal blister packs with precision, ensuring consi...

Versatile capsule filler for pharmaceuticals

Effortlessly switch between powder, pellet, and liquid dosing with this adapt...

Semi-automatic powder dosing system

Achieve precise micro-dosing for pharmaceutical powders with a flexible system ideal fo...

Sterility testing isolator for pharmaceutical labs

Ensure reliable sterility testing in a controlled sterile environment ...

Sterilizer loading solutions for biopharma and research laboratories

Streamline your sterilization process with ergonom...

Ethylene oxide sterilization for heat-sensitive medical products

Ensure sterility of heat and moisture-sensitive product...

Pharmaceutical sterilization with steam/air mixture

Achieve sterile, dry, and ready-to-use pharmaceutical products with p...

Steam sterilizer for biomedical lab research

Ensure the highest level of biosafety and scientific integrity with this stea...

Twin track pallet conveyors for assembly and testing

Enhance your production line’s efficiency with a system that s...

Saturated steam sterilizer for bio-pharma applications

Ensure sterility and compliance in your production line with versa...

Benchtop lab sterilizer for laboratory use

Ensure precise sterilization of various lab materials with a compact solution d...

Collaborative robot for handling and assembly applications

Optimize your automated production line with a versatile robo...

Compact machining center for high-precision manufacturing

Achieve unparalleled precision and speed in metal machining wi...

Modular cleanroom panel systems

Transform your cleanroom projects with modular panel systems that streamline installation an...

Pure steam generation system for sterilization purposes

Ensure sterile production with pure steam capable of eradicating ...

Cold trap for laboratory applications

Achieve efficient condensation and separation in laboratory processes with this versa...

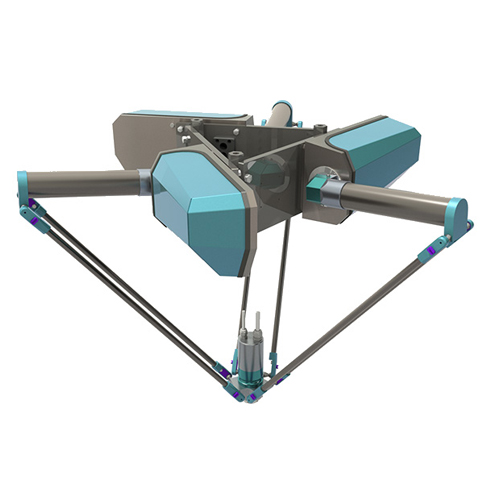

Delta robot for hygienic manufacturing processes

Enhance your processing line with precision and speed, ensuring hygienic ...

Stand-alone autoclaves with round chamber for laboratory and pharmaceutical use

Achieve seamless sterilization and pre...

Autoclaves for laboratory and production with square chamber

Optimize your laboratory space with compact autoclaves that...

Gmp contact part washers for pharmaceutical industry

Ensure product integrity and hygiene with specialized washing system...

Ethylene oxide sterilizers for medical devices

Ensure the complete sterilization of complex medical devices with advanced ...

Saturated steam sterilizer for pharmaceutical production

Ensure sterility for a diverse range of pharmaceutical products ...

Dry heat sterilization and depyrogenation oven for glassware

Achieve precise sterilization and depyrogenation of glasswa...

Biodecontamination system for small pharmaceutical enclosures

Achieve reliable sterilization in compact settings with th...

Saturated steam sterilizer for Ngo use

Meet the challenges of emergency medical sterilization with a versatile, manually op...

Hydrogen peroxide vapor biodecontamination unit for cleanrooms

Ensure a sterile environment by effectively biodecontamin...

Biodecontamination unit for clean rooms and laboratories

Achieve reliable, 6-log bioburden reduction with this automated ...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Ventilated autoclave for sterile product preparation

Ensure precise sterilization for injectable drugs and vaccine produc...

Reverse osmosis water treatment system for medical device cleaning

Ensure purity and compliance by seamlessly integrati...

Cutting and sealing solution for medical packaging

Optimize your sterile packaging process with precision cutting and sea...

Portable autoclave for sterilizing surgical instruments

Ensure precision and safety in sterilizing surgical instruments, ...

Automatic washer-disinfector for surgical and dental instruments

Ensure optimal hygiene and performance in medical instr...

Plastic bottle blowing-filling-sealing system

Optimize sterile liquid packaging with integrated blowing, filling, and seal...

Ultrasonic cleaner for surgical instruments

Ensure precise cleaning and disinfection of complex surgical instruments and d...

Soft bag form-fill-seal system for large volume injection

Streamline your production of intravenous and nutritional flui...

Laboratory series steam sterilizers

Ensure the sterility of your labware and culture media with reliable steam-based steril...

Multi-lane sachet packaging machine

Optimize your packaging line with this multi-lane sachet packaging machine, designed to...

Hot air plate type storage cabinet for endoscopes

Optimize the drying and storage of endoscopes with this advanced cabine...

Washer-disinfector for surgical instruments

Ensure thorough cleaning and disinfection of medical and surgical instruments ...

Manual door spray washer for surgical instruments

Optimize cleanliness and safety with a versatile manual door spray wash...

Storage cabinet for endoscopes

Ensure the safe, contamination-free storage and easy monitoring of endoscopes with a hanging ...

Medical drying cabinet for surgical instruments and glassware

Achieve optimal drying for precision instruments and glass...

Tabletop ultrasonic washer for surgical instruments

Achieve thorough cleaning and disinfection of surgical tools and prec...

Cassette autoclave for sterilization in medical settings

Ensure the reliable sterilization of medical and laboratory inst...

Dental equipment sterilizer

Ensure complete infection control and safety with advanced sterilization and cleaning capabiliti...

Disinfection transfer chamber for medical and laboratory use

Ensure surface sterilization of large quantities with preci...

Flexible endoscope washer-disinfector

Ensure precise cleaning and disinfection of complex medical instruments with a washer...

Automatic bottle washer for animal drinking bottles

When meticulous cleaning of animal drinking bottles and labware is es...

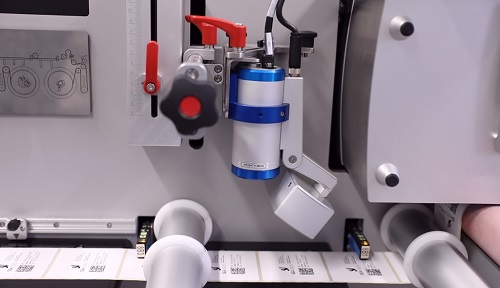

Serialized labels inspection and printing station

Labels are a key component in pharmaceutical packaging lines as they in...

Serialization tracking system

To accommodate different products of varied sizes, the pharmaceutical industry requires handli...

Semi-automatic forming and sealing blister machine

As a manufacturer of medical device, the packaging is a critical facto...

Automatic medical forming and sealing blister machine for packing capsules and tablets

Product safety is very importa...

Automatic forming and sealing blister machine for packing syringes

Controlling contamination is on every manufacturer&#...

Cold forming aluminum blister machine for capsules

Aluminum blisters are mainly used for packaging products that are sens...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Semiautomatic blister sealing machines for medical devices

Mostly used in the pharmaceutical and medical industries, bli...

Ethylene oxide sterilizer

When medical devices like syringes, catheters, dialysis cartridges, plastic dressings and sutures ...

Compact H2O2 disinfection system

Dry fogging provides safe, effective microbiological cleaning of critical areas in biotech,...

Entry-level blister packaging machine

Blister packaging is a popular packing method in the pharmaceutical industry thanks t...

Industrial blister packaging machine

High-volume, fully-automated blister packaging is the perfect choice for large scale p...

Continuous pack cartoner

High volume automatic cartoning is vital for large scale production of cosmetic or pharmaceutical pr...

Automatic blister packaging machine

Automated blister packaging is a popular choice for pharmaceutical production thanks to...

Horizontal cartoner for pharmaceutical applications

Automatic cartoning for cosmetic or pharmaceutical products is a requ...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

High capacity cartoner for pharmaceutical applications

Many pharmaceutical products are packed in protective and decorati...

Vertical cartoner for pharmaceutical applications

Many pharmaceutical and cosmetic products are sold in protective and de...

Horizontal intermittent motion cartoner

User-friendly cartooning solution with an intermittent motion for a wide range of p...

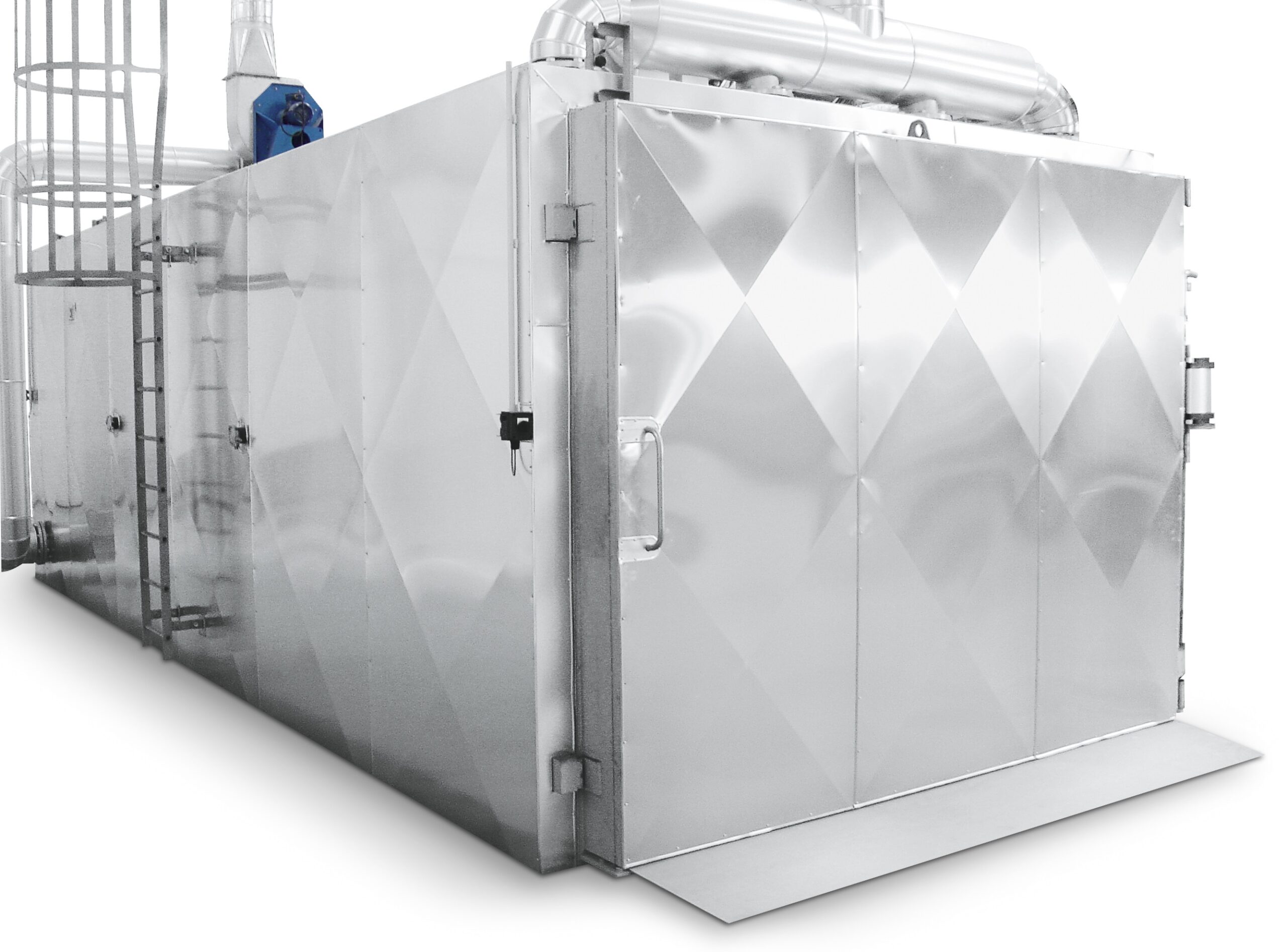

Ethylene oxide sterilization chamber

Designed for the terminal sterilization of temperature sensitive medical-health produc...

Steam and air mixture sterilization autoclave

Specially designed for sterilizing large batches of parenteral solutions.

GMP autoclave

When sterilizing and dealing non-thermolabile products, you will want to get a hold of those resistant to the te...