Leak test panels for industrial applications

Ensure the integrity of your critical components with precision leak testing that adapts seamlessly to your production line requirements, reducing operational downtime and enhancing quality control.

Performs Comprehensive Leak Testing for Engineered Parts

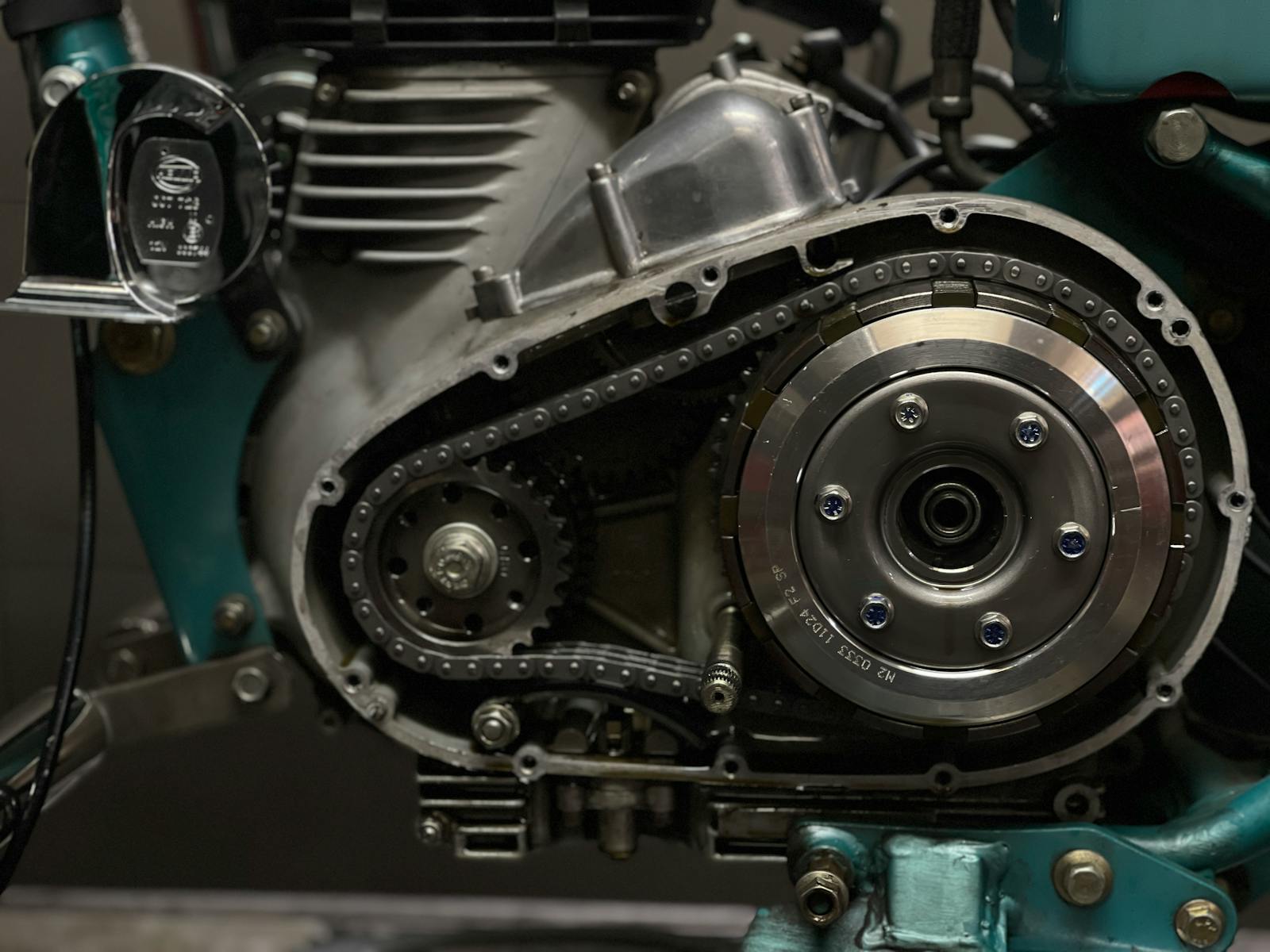

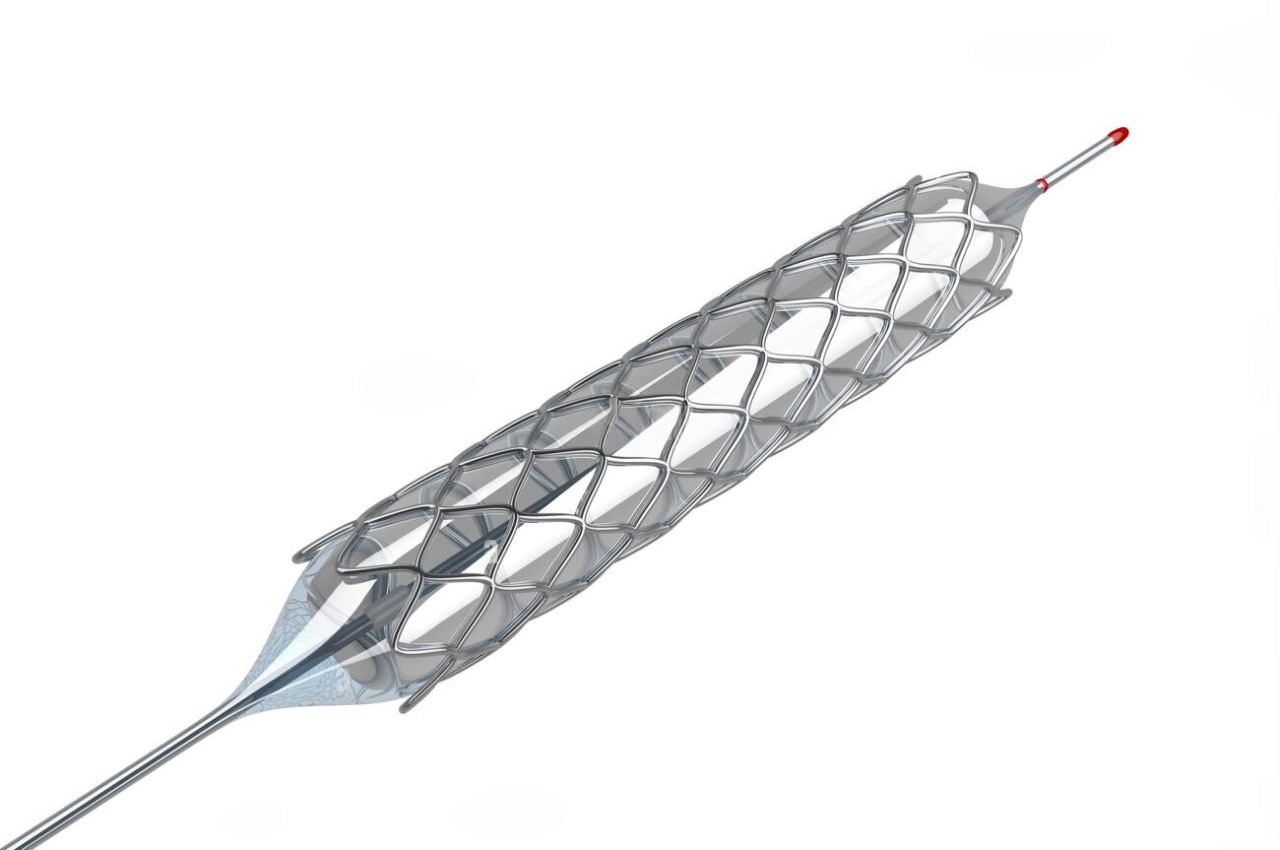

The Uni 500 from JW Froehlich Maschinenfabrik GmbH is a multifunctional leak test panel designed for versatile applications across industries such as automotive, medical technology, and manufacturing. This system stands out with its capability to handle multiple testing methods, including pressure decay, relative pressure, and mass flow, making it ideal for quality assurance in components like engines, transmissions, and injection molds. It seamlessly integrates into production lines, either as a standalone unit or part of a modular system, ensuring fluid and efficient operations. With advanced automation options, the Uni 500 facilitates precise and rapid testing, supported by an intuitive menu and data management system. Its robust design accommodates demanding environments, providing reliable performance while maintaining low energy consumption through optimized motor control. JW Froehlich offers various customization options and engineering support to tailor the Uni 500 to specific operational needs, ensuring compliance with industry standards and enhancing production line efficiency.

Benefits

- Optimizes leak detection across diverse components, ensuring product integrity and reliability.

- Integrates seamlessly into existing production lines, enhancing operational efficiency.

- Reduces testing time with its multifunctional capabilities, improving throughput.

- Minimizes energy usage through advanced motor control, lowering operational costs.

- Offers customizable configurations, accommodating specific testing requirements and industry standards.

- Applications

- Transmissions, Industrial tools, Engines, Medical devices, Fuel cells, Injection molds, E-mobility components, Turbochargers, Batteries, Automotive parts

- End products

- Automotive turbochargers, Cardiac stents, Electric drive units, Internal combustion engines, Lithium-ion battery modules, Injection molded plastic parts, Precision industrial tooling, Hydrogen fuel cell stacks, Surgical instruments, Electric vehicle transmissions, Car body panels

- Steps before

- Component Assembly, Pre-Repair Testing, Initial Design Assessment

- Steps after

- Quality Assurance, System Integration, Post-Repair Testing, Data Export

- Input ingredients

- pressure sensors, external sensors, pressure regulators, valves, pneumatic measuring equipment, injection moulds, leaking components or assemblies

- Output ingredients

- leak rate, pressure curve, measurement results, statistical parameters, standard deviation values, mean leak rate, visualised measurements

- Market info

- JW Froehlich is known for manufacturing and supplying state-of-the-art testing and assembly systems for automotive and other industrial applications, renowned for precision, innovation, and expertise in tailor-made engineered solutions.

- Leak test methods

- Pressure decay/pressure rise, relative/differential pressure, mass flow

- Measurement channels

- Up to 8

- Interface Options

- RS 232, Profibus, Profinet, Ethernet, USB

- Data storage capacity

- Up to 100, 000 measurements

- Display Type

- 15” TFT touchscreen

- Pressure regulation

- Electronic proportional pressure regulator

- Automation

- Stand-alone or integrated system

- Special functions

- Volume-dependent leak tests, dynamic pressure, membrane tests

- Calibration tool

- LK 100/800 leak calibrators

- Power Source

- Battery-operated with USB recharge

- Result visualization

- ResultVisualizer software package

- Working mechanism

- Pressure decay/pressure rise, relative pressure/differential pressure, mass flow methods

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Stand-alone or as part of a system

- Changeover time

- Efficient multi-channel systems

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- LCD touchscreen / TFT touchscreen

- Discharge method

- Quick locking coupling

- Integration flexibility

- Stand-alone or system integration

- Multifunctional design

- Single or multi-channel systems

- Control panel type

- Touchscreen / LCD display

- Integration possibilities

- CAN bus / RS 232 / Profinet / Ethernet

- Modular design

- Stand-alone / System integration

- Measurement methods

- Pressure decay/rise / Mass flow / Relative/Differential pressure

- Special functions

- Auto mastering / Volume-dependent leak tests