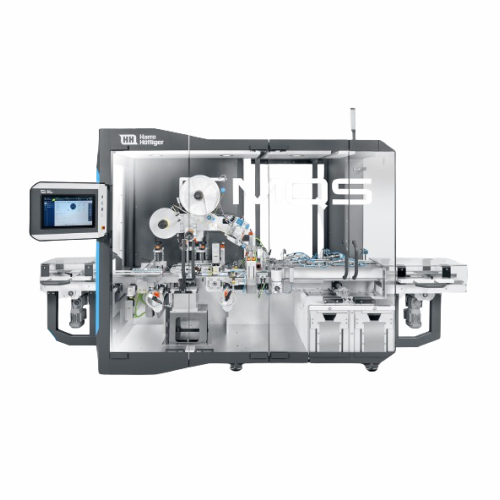

Modular quality assurance system for packaging lines

Streamline your packaging line with a versatile system that ensures precise serialization, reliable tamper-proofing, and comprehensive quality control for high-speed operations.

Integrates Weighing, Printing, and Labeling Systems

The Modular Quality System (MQS) from Harro Höfliger is designed to enhance your packaging line with precision weighing, printing, labeling, and serialization capabilities. This system addresses critical packaging challenges by ensuring every product is accurately weighed, coded, and secured with tamper-evident seals. Ideal for pharmaceutical and medical device applications, it supports a wide range of end-products, including blister packs, eye drop packaging, and unit-dose syringe packs. Operating at speeds of up to 300 products per minute, the MQS integrates seamlessly into existing lines with a consistent design and operating logic. Featuring a fully integrated weighing cell and adaptable camera systems, it guarantees compliance with stringent industry standards like GMP and FDA. The modular design allows for easy format changes and fast, tool-free maintenance, ensuring minimal downtime.

Benefits

- Enhances product security with reliable tamper-evident sealing.

- Reduces packaging errors via integrated camera control systems.

- Increases production efficiency by managing 300 products per minute.

- Streamlines compliance with precise serialization and labeling solutions.

- Facilitates quick format changes for versatile production needs.

- Applications

- Continence care, Medical devices, Inhalation products, Transdermal, Skin care, Ostomy, Surgical sutures, Oral delivery systems, Packaging materials, Diagnostic products, Wound, Eye care, Pharmaceuticals

- End products

- Skin cream tubes, Asthma inhaler cartridges, Eye drop packaging, Unit-dose oral syringe packs, Ostomy bags, Prepackaged surgical suture kits, Bandage packagings, Individually barcoded vials, Blister packs for pills, Transdermal patch packaging, Continence care pads

- Steps before

- Product assembly, Web processing, Dosing, filling, Production of portion packs

- Steps after

- Quality control, Tamper-evident closure, Packing, Labeling

- Input ingredients

- cartons, folding boxes

- Output ingredients

- coded cartons, labeled cartons, serialized cartons, weighed cartons, cartons with tamper-evident closure

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output

- 300 products/min

- Format range

- 5" and 7.5"

- Automation

- Integrated weighing cell

- Weighing accuracy

- 100% weight control

- Printing speed

- 300 cartons/min

- Serialization capability

- Yes

- Camera control

- Multiple cameras for monitoring and verification

- Tamper-evident closure

- Yes

- Working mechanism

- Modular Quality System

- Integrated steps

- Weighing, Printing, Labeling

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Changeover time

- Simple and Fast

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Space-saving installation area

- Design

- Consistent "look and feel" in design

- Format range

- 5" and 7.5"

- Integration type

- Modular platform

- Product handling

- Precise and reliable product transport

- Tool Requirement

- Format changeover is tool-free

- Weight control

- Fully integrated weighing cell

- Control panel type

- Consistent "look and feel" in design, operating logic and documentation

- Space-saving installation area

- Yes

- Flexible integration

- Standard coding and camera systems

- Format changeover

- Simple, fast, and without any tools

- Modular platform

- Integration of quality-relevant functions