Making Grated Cheese

Find innovative production technology for making grated cheese and connect directly with world-leading specialists

You usually make grated cheese from hard cheeses, like Cheddar, Parmesan, Edam, Red Leicester, etc. The process starts with processed cheese, in blocks or sliced, fed to the grating machine. After that, you mix it with ingredients that prevent molds from occurring and to reduce the grated cheese moisture. Then you dry the grated cheese and weigh it before it is ready for packing.

Stories about grated cheese

Select your grated cheese process

Tell us about your production challenge

Getting your cheese grating equipment started

The process for making hard cheese is similar to regular cheese except for the aging process. Extending the aging process makes the cheeses hard. In industrial grated cheese production, blocks of cheese or in large, sliced pieces go into the grating machine through a conveyor. These cheeses are usually the hard variety. After grating the cheese, you mix it with mold-inhibiting ingredients and anti-caking agents. They are important because they avoid molds and lumps from developing in freshly grated cheese. The next step it to convey the mix to a mechanical or tray drying equipment. From there, the grated cheese goes to an automated weighing machine that drops the correct weight of the product to the packing machine.

How do you prefer your cheese? Shredded and soft or grated and hard

Shredded cheese is usually a term used for grated soft cheeses since their appearance are long thin strips. Hard cheeses, when grated, look uneven or in powder-like form. The process of shredding soft cheese is similar to hard cheese. Soft cheeses, like hard ones, also require anti-caking agents and mold-inhibiting ingredients mixed after the grating process. The process of grating hard and soft cheese is similar, so you can use the same equipment for grating, drying and weighing.

Weighing your grated cheese and making it ready for packaging

The two most widely used packaging for grated cheese are plastic pouches/bags and hard plastic containers with lids. The packaging depends on the manufacturer’s choice, volume and weight of the product, and appearance. The advantage of hard plastic containers with lids is the barrier protection when handling the products. This minimizes the chance of squeezing the product. For the plastic bags/pouches, the advantage is the flexibility in handling. On the other hand, these packages are more prone to producing clumps on the grated cheese when squeezed. For large quantities of grated cheese, the preferred choice of packaging is the hard plastic container, as this minimizes the chance of producing clumps during handling.

Getting the best cheese: quality control in packaging

For any product that comes out of the factory, good quality control practice guarantees consistent quality with every single item in the production line. Even in packaging lines, defects can be found from sealing, packaging material, and volume or weight of the content. For example, dairy products, such as grated cheese packed in plastic bags or pouches, need to be sealed properly as exposure or contamination can cause the product to deteriorate rapidly. In addition, the development of molds from outside bacteria can be detrimental to the consumers’ health. Therefore, as part of a quality check, you can use inspection machines to detect such defects in the packaging line.

Processing steps involved in grated cheese making

Which grated cheese technology do you need?

Steam cooking system for dairy production

Ensure precise temperature regulation and efficient moisture control in cheese a...

Mechanized systems for hard cheese molding rooms

Optimize your cheese production with advanced systems designed to streaml...

Bottom valve for cheese vats

Enhance your cheese production efficiency with a flush-mounted bottom valve, designed for optim...

Professional grater for parmesan and hard cheeses

Enhance your processing line with a robust grater designed to efficient...

Commercial vegetable peeler for potatoes and carrots

Efficiently integrate peeling and polishing vegetables into your pro...

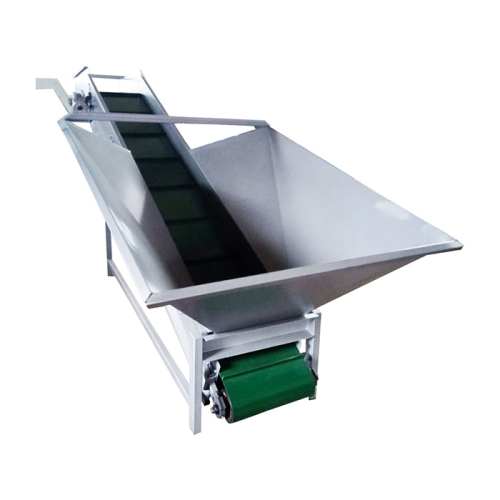

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-p...

Hydraulic box tipper for pallets

Streamline your material handling with precision and safety by integrating this hydraulic t...

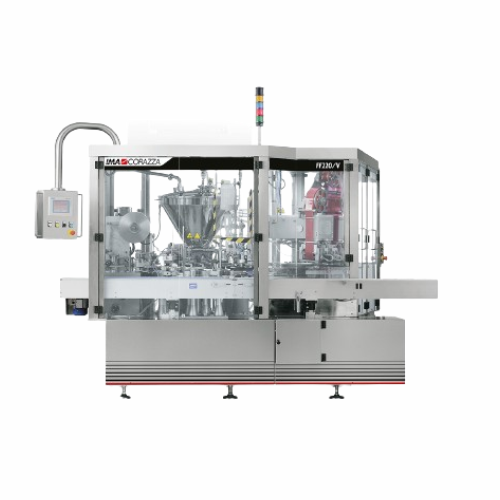

Dosing and tray handling lines for ready meals

Ensure precise dosing and seamless tray handling for a variety of ready mea...

Cheese portioning dosing and wrapping solution

Effortlessly streamline cheese portioning with high-speed dosing and wrappi...

Cartoning solution for cheese portions

Optimize your cheese packaging with a flexible cartoning solution designed to accomm...

Separating packed cheese products from packaging

Efficiently separate individual cheese portions from packaging, reducing ...

Cheese packaging system for mixed cheese types

Optimize your cheese production line by seamlessly integrating a system des...

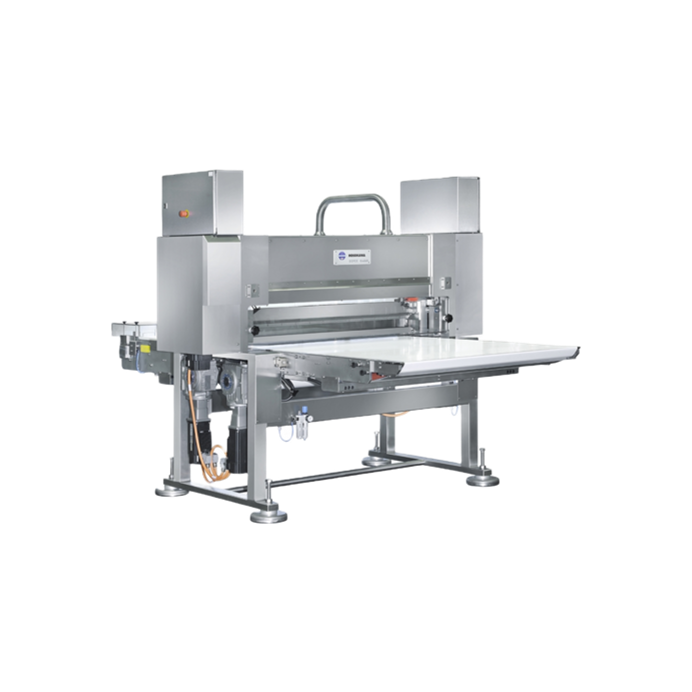

Processed cheese slice forming system

Effortlessly produce high-quality Slice-on-Slice cheese slices, cubes, shreds, and st...

Cheese grinder for fine cheese grinding

Achieve optimal protein emulsification and minimize waste with this high-capacity g...

Square and rectangular cheese cutter for bars and halves

Perfect for cheese processors needing precision, this machine ef...

Automatic cheese derinding system for rectangular cheeses

For cheese processors seeking effortless precision, this machi...

Cheese shredding solution for soft, semi-hard, and hard cheeses

Maximize cheese processing efficiency with precise shred...

Cheese portion thermoforming system for automation

Optimize your cheese production with precision portioning and efficien...

Cheese cutting machine for various cheese types

Optimize your cheese and meat processing line with high-speed, precise cut...

Disk cutter for round and block cheese

Achieve precise portioning for varied cheese formats with our versatile disk cutter,...

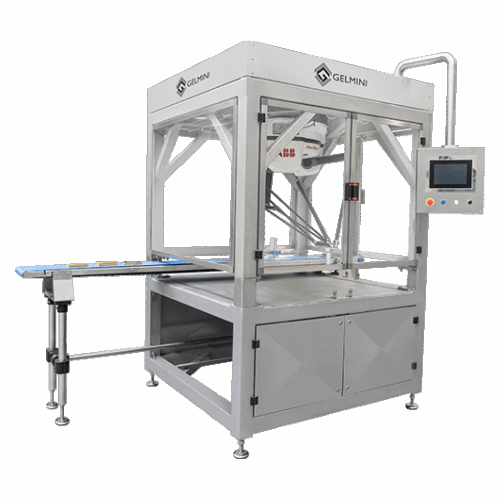

Wedge aligning robot for hard cheese

Streamline your cheese processing with precision and efficiency; this solution expertl...

High-capacity shredder for cheese processing

Achieve impeccable cut accuracy and consistent shred dimensions for high-volu...

Cheese shredder for high-volume applications

Streamline your cheese processing with a high-capacity shredder designed to d...

Full block cheese shredder

Maximize your production line’s efficiency with a versatile shredder that seamlessly proces...

Industrial cheese processing plants

Streamline your cheese production with custom-engineered systems designed to enhance ef...

Cheese processing plant

Transform your dairy processing with comprehensive, tailored systems designed to optimize production ...

Speciality cheese cutting system

Efficiently cut and portion a variety of cheese types, from mozzarella to cheddar, into pre...

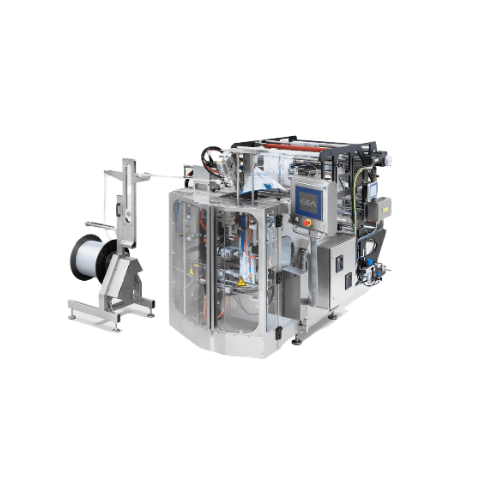

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

Vertical form-fill-seal packer for frozen vegetables

Efficiently streamline your packaging line with a versatile solution...

Steam cooker and stretcher for cheese processing

Optimize your cheese production with a versatile solution designed to eff...

Industrial food dicer for high-fat and cold-temperature products

Achieve precise and consistent cutting with a high-capa...

Grinder and grater combination for professional kitchens

This versatile meat processing and cheese grating solution integ...

Professional cheese grater tool

Optimize your food preparation with a versatile tool that efficiently grates, slices, and gr...

Industrial hard cheese grater

Optimize your food preparation process with high-speed grating, perfect for transforming hard ...

Gdl and rennet dosing solution for white cheese production

Optimize white cheese production by dramatically reducing aci...

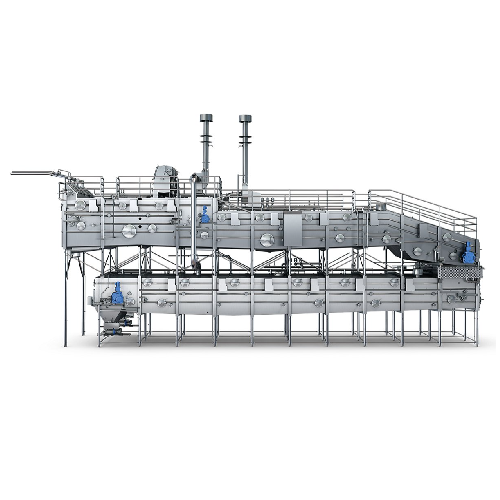

Draining matting solution for granular or matted curd cheese

Optimize your cheese production with a continuous, automate...

Fresh cheese former for hygienic production

Streamline your cheese production with a hygienic and no-mould solution that s...

Curd making vat for cheese production

Achieve optimal curd consistency and maximize cheese yield with advanced dual agitato...

Cryogenic freezing for small fragile foods

Quickly freeze delicate food items with precision using advanced cryogenic imme...

Shredder for fine particle size reduction

Optimize your production line with high-speed shredding technology designed for ...

Industrial washer for plastic crates

In the food production sector, hygiene regulations are getting stringent by the day. E...

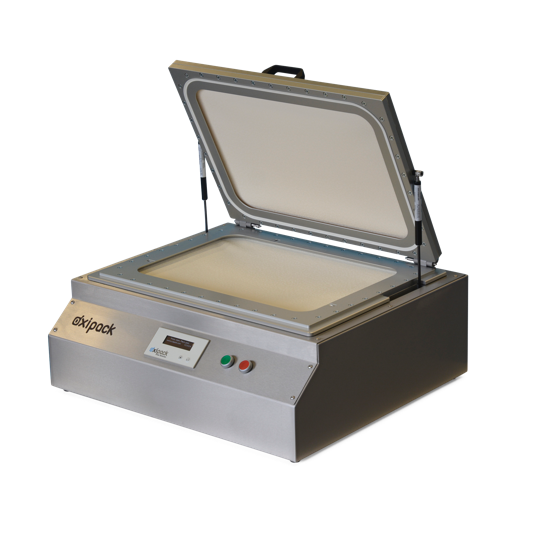

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Inline ultrasonic big scale food cutting machine

In the food industry, where accuracy in the cutting process is desired, u...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Food crates washer

With the increasing demand of food production sectors for cutting costs, while increasing quality of produ...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Conveyor belt metal detector for food products

Inspecting and rejecting finished food products for metal contamination is ...

Standalone metal detector for food

Adding advanced metal detection to existing lines can be difficult and expensive, often ...

Cheese grater

Breaking down large blocks into grated, shredded, powdered or planed cheese requires multiple graded discs that ...

Dairy Packaging Machine

The use of sachets and pouches for powdered or shredded dairy products is an increasingly popular for...

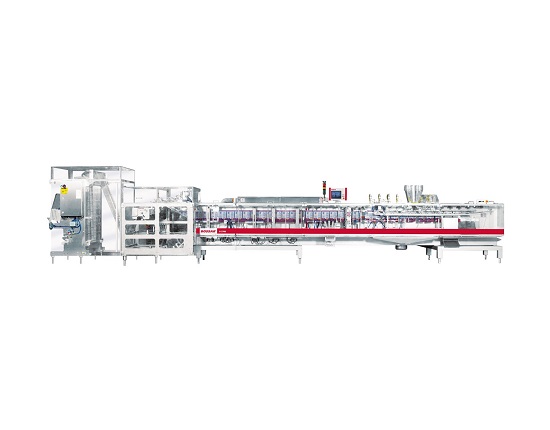

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Checkweigher for stand-up pouches

When working with several lines of stand-up pouches, you can benefit from controlling the...