Making Dragee Products

Find innovative production technology for making dragees and connect directly with world-leading specialists

Long was the time when you could only make dragée chocolate – or, to simplify it, to cover chocolate with a layer of chocolate or sugar and then polish it or not. Now, you can use a chocolate panning machine to offer different types of dragée items. Mind that the process of panning may slightly differ according to the product you are making.

Select your dragees process

Tell us about your production challenge

Carrying on the dragée production

To produce dragées, you can use a chocolate panning machine to apply an even layer of chocolate or sugar in all parts of the chosen product. It may be an almond, a slice of fruit or any type of nut. Chocolate panning machines have a rotating system to guarantee that all parts of the product receive the same amount of coverture. It also prevents ingredient concentration in the bottom of the pan. The pan rotates clockwise and anticlockwise and you can remove it for easy cleaning.

Chocolate thickness around the product depends on how many times you apply the coverture. The process needs to happen little by little, and you need to make sure the coat is already dry before putting more coverture. Blowing pipes usually help with this task. You can use the same chocolate panning machine for polishing, once you clean what was left of the coverture from the pan.

Should you pick up a panning or an enrobing machine?

Note that a chocolate panning machine covers all your products with the same amount of coverture. If you want to partially cover them, choose an enrober. It applies powder or liquid ingredients on the whole surface or only in part of it.

The process of making dragées differs for each type of product that you will cover, due to their shape and density. Products like cashew nuts, for instance, require multiple coatings to cover all their concavities. In this process, waste is an issue you may encounter when panning products. To help you with that, find equipment to which your chosen ingredients will not stick.

Shiny or opaque: putting the finishing touch to the dragée

A chocolate panning machine may require manual loading of products and coverture application. Some pieces of equipment automatically apply coverture using a spray pipe. Small batches help to do trial productions before going large scale. They are also an option for independent confiseries.

Your dragée products may have either a shiny or a dusted look. To make them glow, certain options are available. You can polish them with shellac, a common food-safe ingredient that extends the shelf life of the product, or with Arabic gum. You can also opt for other types of polishers, water-based and/or vegan, that have increased in the past years. For a dusted aspect, try pouring cocoa powder or sugar.

Processing steps involved in dragees making

Which dragees technology do you need?

Electronic tablet counter for tablets and capsules

Optimize your production line with precise counting solutions for a wi...

Thermoforming solution for clinical trials

Designed for precision and flexibility, this compact thermoforming machine stre...

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

Flow wrapper for preformed pieces

Optimize your high-speed packaging line with a reliable flow wrapper that seamlessly wrap...

Automatic sleeving for rolled and molded cones

Optimize your cone production line with precision sleeving and reliable det...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Double twist wrapping solution for candy packaging

Enhance your candy and gum production with high-speed wrapping that en...

Compact extruder and depositor for confectionery and bakery production

Streamline your confectionery and bakery product...

Chocolate depositor for small to medium production

Optimize your confectionery production with a versatile depositor that...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

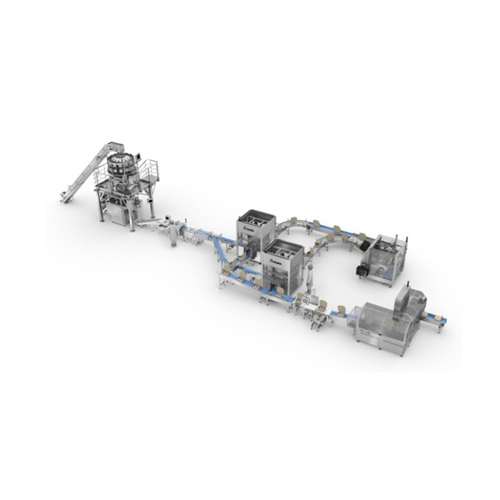

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Portable chocolate tempering degree checker

Ensure precise chocolate tempering to enhance product quality and consistency,...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Chocolate lentil, ball, and egg production system

Achieve consistent and precise shaping of chocolate lentils, balls, and...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

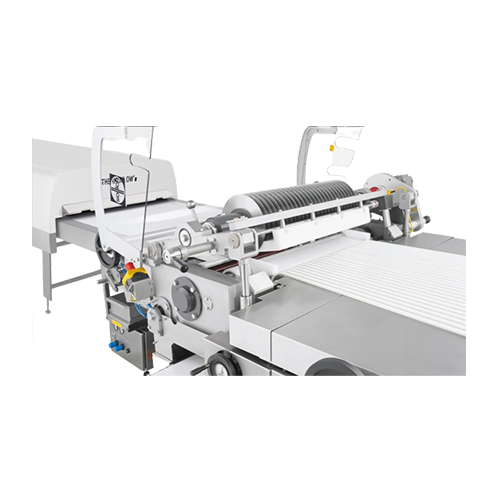

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Chocolate coating panning machine for confectionery

Enhance your confectionery product line with a precision coating solu...

Chocolate truffle extruder

Achieve precise and versatile production of chocolate truffles and snacks, with seamless integrat...

Big bag filling machine

Active pharmaceutical ingredients demand high handling standards to prevent cross-contamination. More...

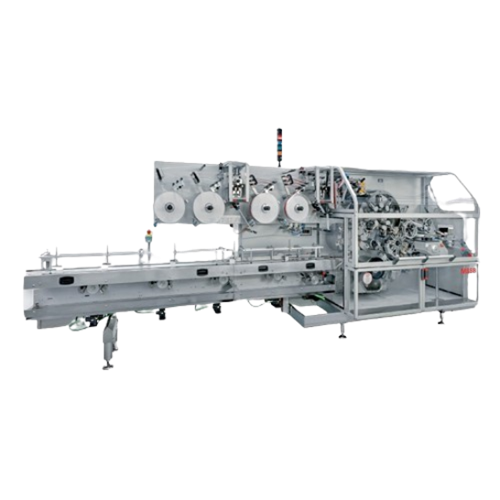

Small scale packaging machine for chocolate figures

Chocolate figures are a popular product type that relies on “eye appe...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

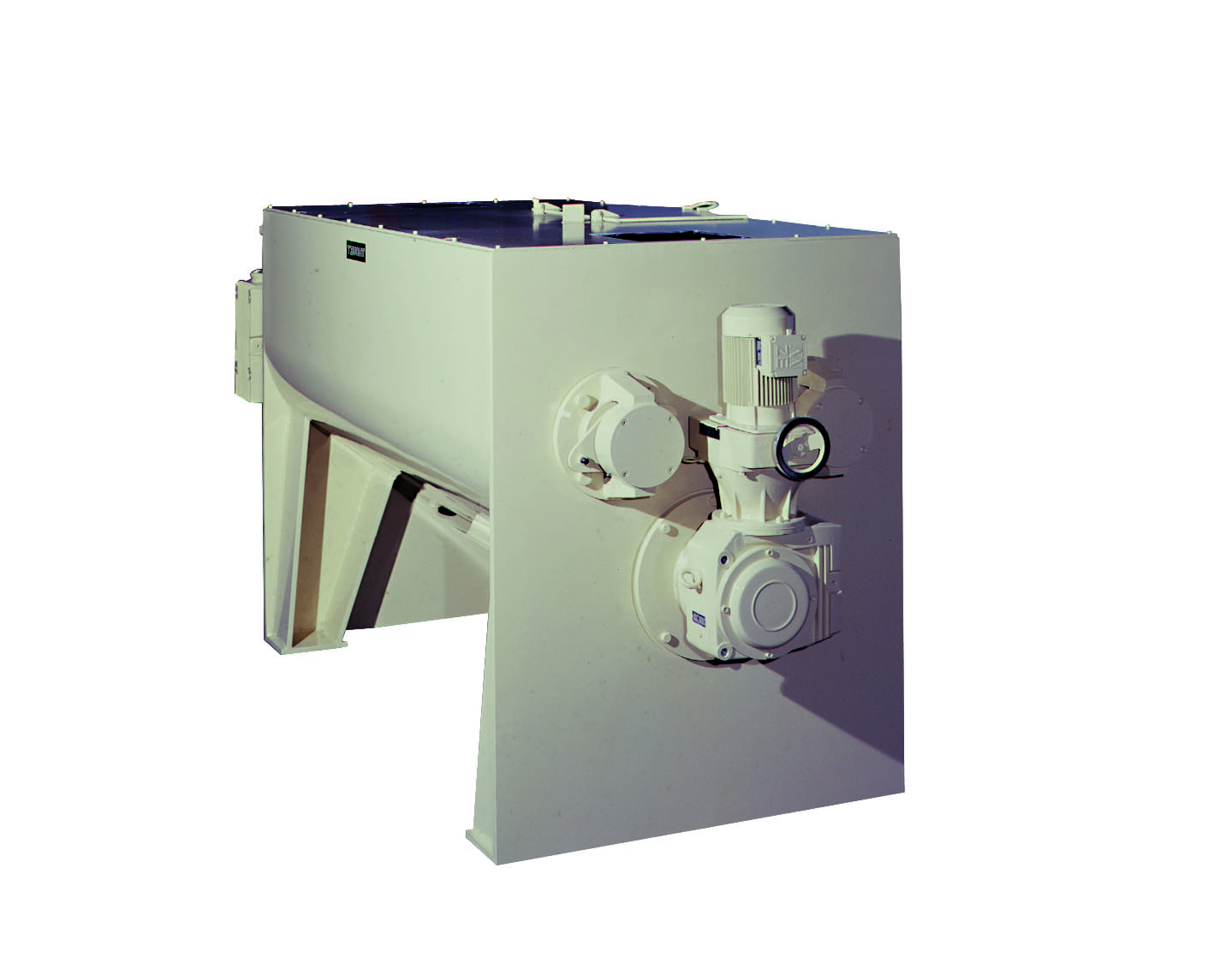

Mixer and kneader for sugar based recipes

For the production of chocolate paste based on refined or icing sugar, the decis...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Compact cylindrical roaster for beans, nibs and nuts

Roasting times and temperature can vary depending on the type of pro...

Longitudinal chocolate conche

High-quality chocolate requires specialized conching. Precise control of temperature and mixin...

Compact enrober

Cost-effective enrober for medium productions.

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...