Making Cheese Spread

Find innovative production technology for making cheese spread and connect directly with world-leading specialists

Can you think of anything better than a slice of bread with some spreadable cheese for a snack? Production of cheese spread is similar to other types of processed cheese, but it contains more moisture to be soft and spreadable. Cheese spread starts with one or more types of cheese along with other ingredients and food additives such as stabilizers and emulsifiers. After mixing and vacuum cooking these ingredients, you can pour them into molds for cooling before packaging.

Technology picks for cheese spread

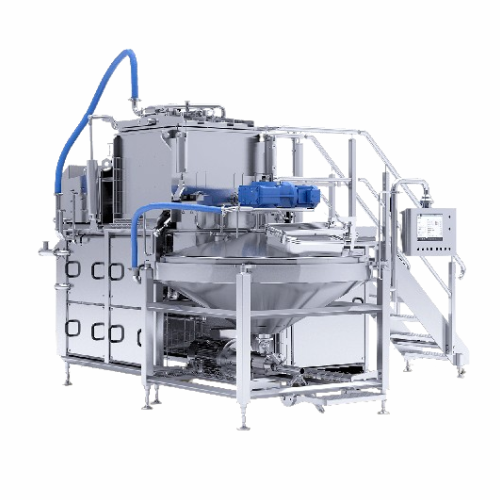

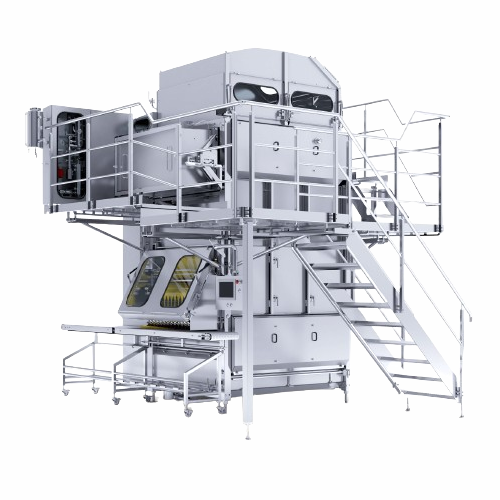

Batch processing system for processed cheese and various food products

Optimize your food production line with a multif...

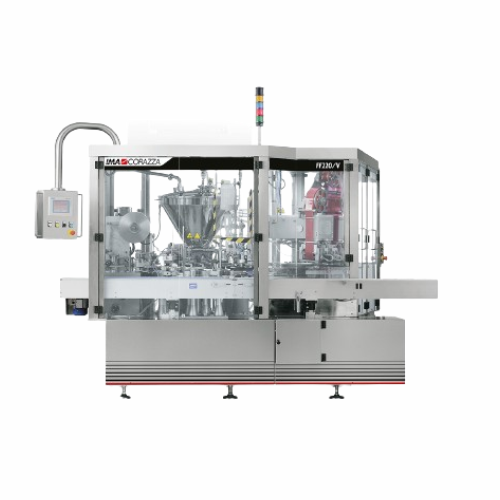

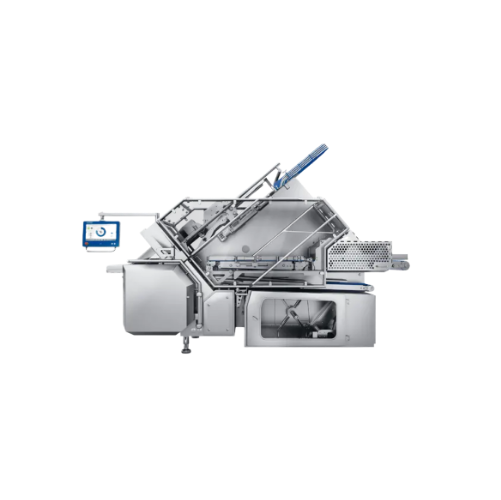

Foil wrapping machine for cream cheese

When producing cream cheese and selling them in foil wrapped bricks you need a relia...

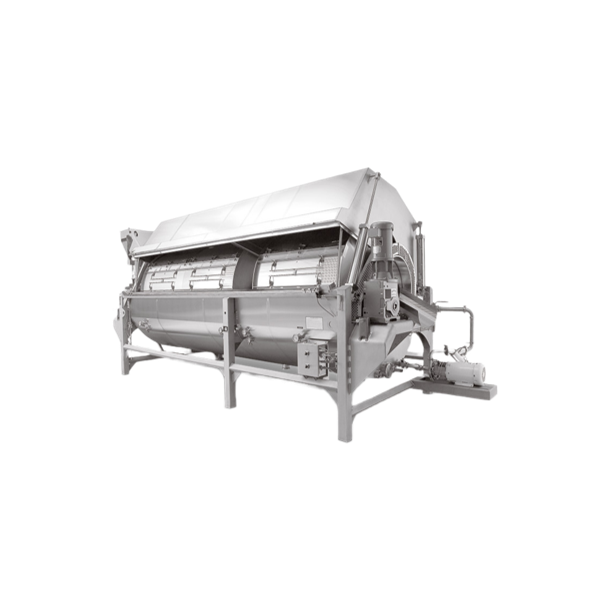

Multipurpose coagulation vats for cheese production

Streamline your cheese production process with multipurpose coagulati...

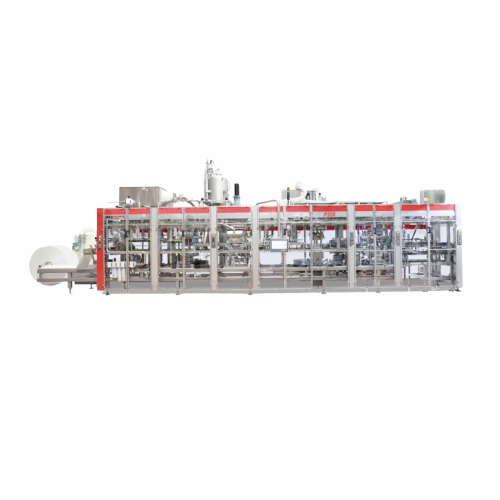

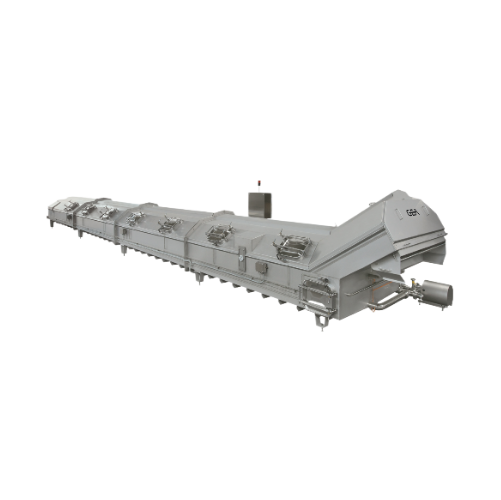

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Tell us about your production challenge

Cheese spread making process- cook it to make it spreadable

Starting from milk, it undergoes standardization, pasteurization, homogenization, culture inoculation, fermentation, and whey separation where you get liquid whey and solid curds. After draining off the liquid whey, you can now gather the solid curds and cut them into shape. These are placed in a container covered with cheesecloth and stored for the aging process.

Using a vacuum cooker you can mix the cheese with other ingredients (cream, milk fat, salt, various seasonings and water) and food additives. As for the moisture content, it should not exceed 60 percent. Likewise, the fat content should not be less than 20 percent. After heating and stirring the mixture, just pour it into various molds or containers for cooling.

Filling up smooth spreadable cheese

Packaging for spreadable cheese comes in pouches, glass jars, but the most common are hard plastic tubs. In a filling machine, suction cups place the containers in the rotary table that transports the plastic containers to the filling station. After the containers are filled, they are moved to a sealing station where moving arms place and seal aluminum foil over them. Plastic lids are used as covers.

Between cream cheese and cheese spread

While cheese spread is prepared from processed cheese, cream cheese goes through similar processes as producing regular cheese with a little difference at the end of the process. The difference starts after whey separation, where the solid curds are aged in a regular cheese production setup. But for cream cheese, the solid curds are mixed with salt and stabilizers, and then it undergoes further heat treatment and continuous mixing until you achieve the desired texture.

Processing steps involved in cheese spread making

Which cheese spread technology do you need?

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Steam cooking system for dairy production

Ensure precise temperature regulation and efficient moisture control in cheese a...

Refrigerated fermentation tank with cold water jacket

Enhance the precision of your cheese production with advanced therm...

Multipurpose coagulation vats for cheese production

Streamline your cheese production process with multipurpose coagulati...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Cheese vat for consistent curd size and low whey fats

Improve your cheese production with equipment designed for uniform ...

Cartoning system for triangular cheese portions

Streamline your cheese packaging process with precision-oriented cartoning...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

Cheese portioning dosing and wrapping solution

Effortlessly streamline cheese portioning with high-speed dosing and wrappi...

Flow wrapper for processed meat and cheese

Optimize wrapping efficiency and hygiene in your meat and cheese packaging line...

Processed cheese slice production system

Reduce recontamination risks in cheese production with a system designed for high-...

Individually wrapped processed cheese slice production line

Efficiently produce consistent, individually-wrapped cheese ...

Separating packed cheese products from packaging

Efficiently separate individual cheese portions from packaging, reducing ...

Processed cheese slice forming system

Effortlessly produce high-quality Slice-on-Slice cheese slices, cubes, shreds, and st...

Pipeline metal detection for pumpable products

Ensure safety and quality by detecting and rejecting metal contaminants in ...

Square and rectangular cheese cutter for bars and halves

Perfect for cheese processors needing precision, this machine ef...

Wedge aligning robot for hard cheese

Streamline your cheese processing with precision and efficiency; this solution expertl...

Chocolate processing unit for mixing, grinding, and conching

Optimize chocolate production with precise mixing, grinding...

Laboratory conching solution for small batches of chocolate

Optimize your chocolate formulations with precise moisture a...

Industrial cheese processing plants

Streamline your cheese production with custom-engineered systems designed to enhance ef...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Cheese processing plant

Transform your dairy processing with comprehensive, tailored systems designed to optimize production ...

Automatic system for removing ripening bags

Optimize your cheese production with a high-speed system designed to efficient...

Speciality cheese cutting system

Efficiently cut and portion a variety of cheese types, from mozzarella to cheddar, into pre...

Milk clarifier for dairy industry

Enhance your dairy production with efficient milk and whey clarification, ensuring produc...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Industrial slicer for natural shaped food products

Achieve superior slicing precision and efficiency with high-speed tech...

Brining vats for pasta filata cheese

Enhance your cheese production with modular brining vats, designed for precise salt ad...

Hot water heaters for pasta filata cheese

Optimize your pasta filata cheese processing with precise heating control and ef...

Clarifying decanters for cheese curd production

Achieve precise separation and clarification of cheese curds, casein, and ...

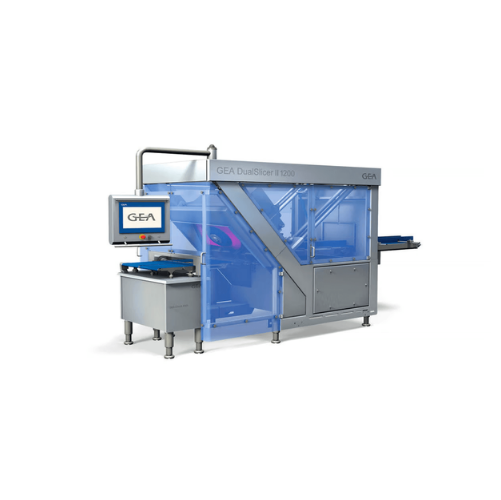

High-performance slicer for food processing

Achieve precise and consistent slices for your diverse range of food products ...

Steam cooker and stretcher for cheese processing

Optimize your cheese production with a versatile solution designed to eff...

Industrial food dicer for high-fat and cold-temperature products

Achieve precise and consistent cutting with a high-capa...

Spore and bacteria removal unit for dairy products

Ensure superior quality by precisely removing spores and bacteria from...

Fresh cheese former for hygienic production

Streamline your cheese production with a hygienic and no-mould solution that s...

Curd distribution system for cheddar production

Ensure consistent curd distribution for optimal cheese quality with our ad...

Curd making vat for cheese production

Achieve optimal curd consistency and maximize cheese yield with advanced dual agitato...

In-line blender for dairy products

Streamline your dairy and beverage production with precision ingredient control and redu...

Filler for yoghurt and white cheeses

For manufacturers seeking efficient, versatile filling for products like yoghurt and s...

Energy-saving cooling system for vegan products

High-viscosity products like hummus or chunky pasta sauces must be cooled ...

Foil wrapping machine for cream cheese

When producing cream cheese and selling them in foil wrapped bricks you need a relia...

Compact & pumpable food media mixer

The process of mixing ingredients for confectionery products like marshmallows and meri...

Tray sealer for food production

Companies in food industry know how essential packaging is in keeping food fresh and ensurin...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Flexible pasteurizer for packaged food

Autoclaves for sterilising and cooking food products are a mainstay of many producti...

Industrial tilting pan with cooling system

Raw materials need to be processed into finished, cooked products most quickly ...

Compact industrial sauce pan

Safe, reliable cookers that operate unobtrusively are required in any kitchen where space and t...

Industrial pressure cooker

Optimizing production processes and human resources to reduce energy consumption and save time an...

Industrial sauce pan

For the small and medium food industry, economical use of time, space and human resources is critical wh...

Complete cutting, mixing, emulsifying and heating system

From laboratory scale to large volume food or cosmetic productio...