Making Sunflower Seeds

Find innovative production technology for making sunflower seeds and connect directly with world-leading specialists

The classification of sunflower seeds changes according to the pattern of its shell or hull. If the shell is solid black, it is an oilseed sunflower. With these, you produce sunflower oil. If the shell is striped, it is a non-oil sunflower seed or confectionery sunflower seed. These usually become snack food products. Whether to make them as snacks or oil, processing sunflower seeds include steps like drying, screening and cleaning, grading, roasting and de-hulling, flavoring, grinding, pressing, refining, and packing.

Stories about sunflower seeds

Tell us about your production challenge

From bird feed to human snacks: uses of sunflower seeds

Sunflower seeds are one of many types of seeds used in food and feed production. In a typical production setup, you divide non-oil sunflower seeds into three categories according to size. Large seeds (in-shell) are roasted, salted, and packed for human consumption as snacks. Medium-sized seeds are de-hulled and packed for human consumption as well, mainly for the baking industry as an ingredient or garnish. The small seeds become feed for birds. A seed sizing machine will be of great help to size them according.

The first commercial use of sunflower seeds in North America was animal feed for poultries. Demand for sunflower oil is increasing due to its health benefits, and the seed also has nutrients and medicinal uses.

How to start processing sunflower seeds

The sunflower seeds process begins with drying the seeds using a dryer or sun-drying. After reaching a moisture content of under 10%, you move the seeds to wire screens to remove dirt. Then you transfer them to a large bin for further cleaning. Once this is over, grade the seeds according to their sizes: large seeds go to a large oven that will roast them; medium-size ones go to de-hulling machines to remove the shells before roasting in oil. You can apply flavoring and send them for weighing and packing.

Solid and liquid: sunflower seeds for oil production

Sunflower oil is the largest market segment for sunflower seeds. To extract it, you can use two different methods: cold press and hot press or refined sunflower oil. To start with, the seeds usually undergo cleaning, de-hulling, and grinding processes. For the cold press method, you press the seeds mechanically to extract the oil. Then it undergoes filtration to remove impurities. This method produces sunflower oil that is used for low heat cooking, and skin and hair care products.

In the hot press method, you slightly heat the seeds before mechanically pressing them. This method extracts more oil than the cold press one, but the taste changes along with its chemical properties due to heat application.

You can add a solvent, like hexane, to extract more oil out of the cake after pressing. Then you remove the solvent by boiling the oil using steam in a stripping column where it vaporizes. As it condenses, it is collected at the same time. Next step is to refine the oil by adding sodium hydroxide and then separating it using a centrifuge. The oil undergoes degumming and removal of wax by winterization process or cooling. Then put the oil in a bleacher pressure vessel and steam injection process to remove odors and give a clear or transparent color. Finally, measure the oil and pack it in containers. Refined sunflower oil is mainly used for high heat cooking as it is more stable in a wide temperature range.

Environmental impact of sunflower seeds

Growing sunflower plants for sunflower seed production is sustainable. The sunflower plants can be a source of food for birds and pollinators like bees, and can also help clean contaminated soil. The cake produced as a by-product in the oil extraction process can be used as livestock feeds, and the hulls can be used as animal beddings. Sunflower plants don’t need much fertilizer to grow and can even withstand drought.

Processing steps involved in sunflower seeds making

Which sunflower seeds technology do you need?

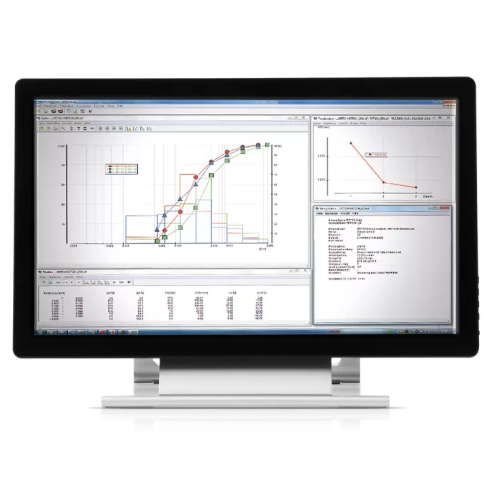

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

Electromagnetic sieve shaker for quality control

Achieve precise particle size distribution with this advanced electromagn...

Mesh sieves for laboratory particle size analysis

Ensure precise particle size control for a wide range of materials with...

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

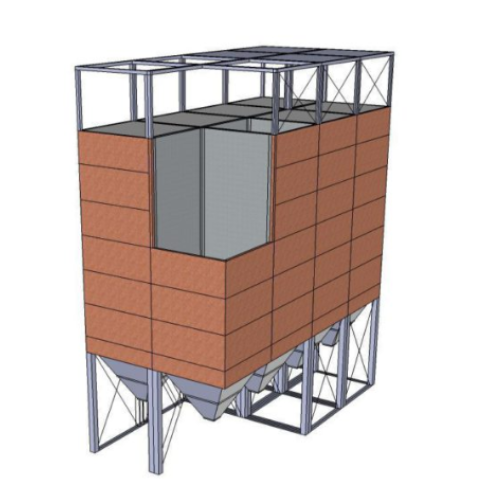

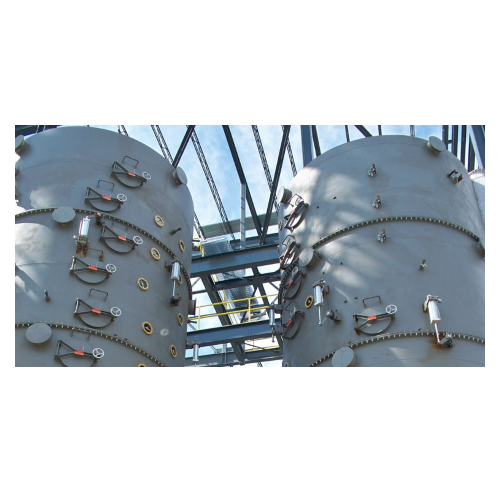

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

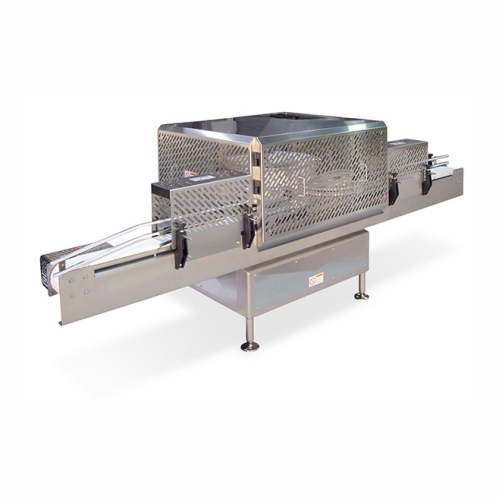

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

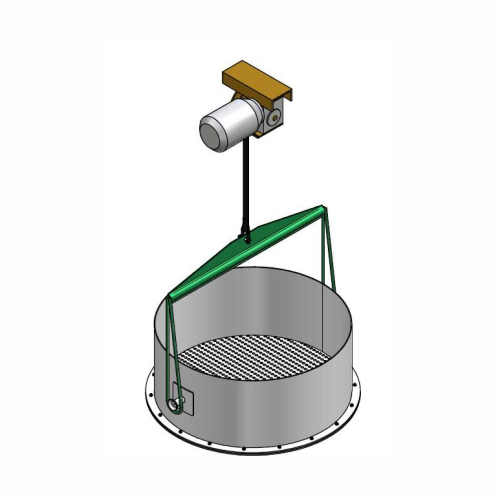

Sweep auger for flat bottom silos

Optimize your grain storage operations with a fully automatic sweep auger designed to eff...

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

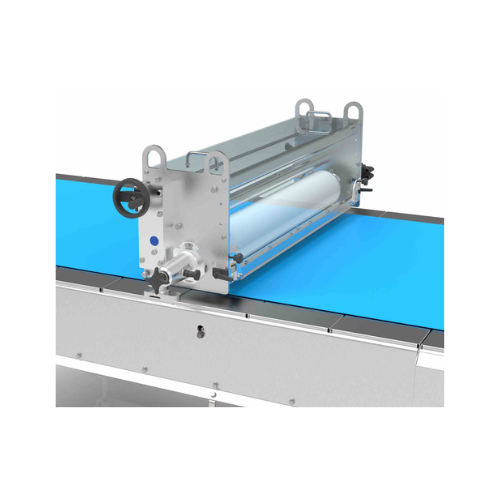

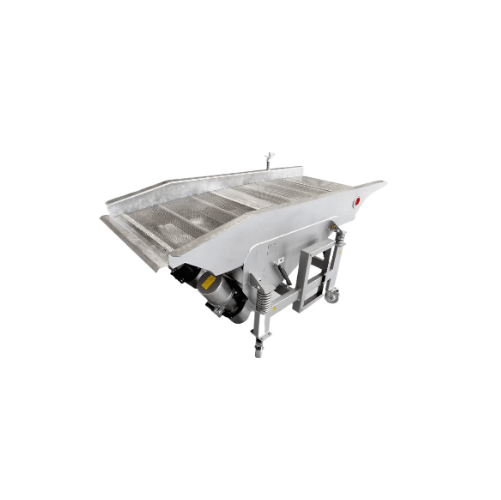

Vibrating calibration system for seed sorting

Achieve precise seed sorting and calibration with high-speed, continuous ope...

Mobile fluid bed dryer for small seed lots

Dry your small seed lots efficiently and flexibly with a mobile fluid bed dryer...

Material container emptying device

Efficiently unload and empty material containers with adaptable mounting options, ensuri...

Seed disinfection system for small seed lots

Streamline seed treatment with a powerful system capable of developing steam ...

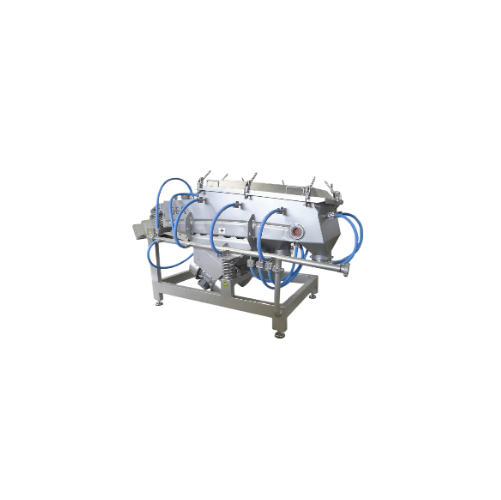

Seed disinfection and rinsing system

Optimize your seed processing by ensuring thorough disinfection and rinsing, maintaini...

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

High volume rotary dryer roaster for continuous drying

Achieve uniform drying and roasting with a continuous, high-capaci...

Nut roaster for consistent and high-capacity processing

Achieve uniform roasting and elevate your nut processing with pre...

High precision weigher for small package weights

Achieve precise micro-dosing with unmatched accuracy at high speeds, opti...

Oilseed cooker/conditioner for optimal seed preparation

Achieve consistent oil extraction and enhanced product quality wi...

Oil presses for oilseed extraction

Ensure efficient oil and protein extraction with specialized presses, enabling optimal s...

Seed counting and packaging system

Maximize your seed throughput with high precision counting and packaging technology, des...

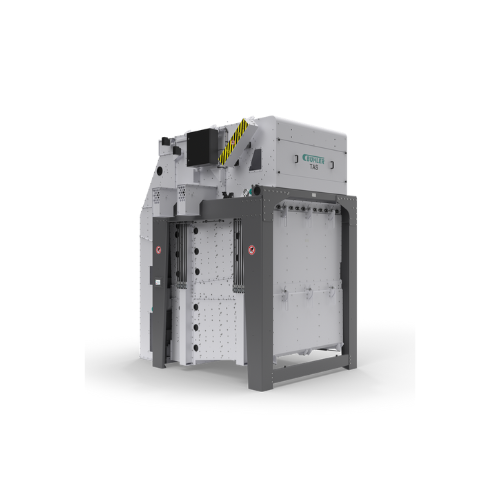

Indented separator for grain quality control

Achieve precise grain length separation with an adaptable indented separator,...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Sunflower seed dehulling system

Experience efficient dehulling for high-yield sunflower seed processing, enhancing kernel qu...

Optical sorter for nuts or dried fruits

Ensure maximum food safety and quality by efficiently sorting and removing shells, ...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

Impact dehuller for sunflower, soybean, and cottonseed

Enhance oil extraction efficiency with a dehulling solution that g...

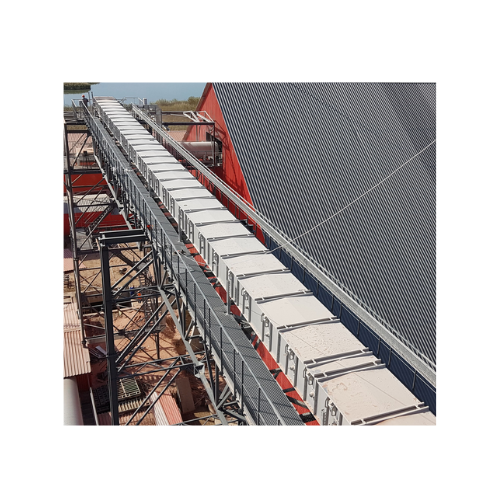

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Fully automatic bagging station for granular products

Streamline your packaging line with a high-speed solution designed ...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Enclosed belt conveyor for grain handling

Optimize your material transportation and ensure dust-free operations with this ...

High-performance cracking mill for oilseeds

Optimize your oilseed processing with a versatile mill designed to enhance eff...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Bagging control system for centralized operations

Streamline your bagging operations with a centralized control system, d...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Spiral chute for gentle product handling in limited space

Optimize your snack and nut production by minimizing product d...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Bucket elevator for grain and powder products

Efficiently transport bulk materials like grain and powder vertically with p...

Double story paddy sieve for rice cleaning

Efficiently cleanse and separate impurities from rice, lentils, and grains, ens...

High capacity grain sifter

Efficiently separate and clean a variety of grain types with minimal space requirements, ensuring...

Dry bin filling for delicate fruit

Achieve gentle, high-throughput filling of delicate fruits with minimized manual interve...

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Centrifugal oil filter for removing oil impurities

Enhance oil purity and ensure efficient removal of impurities with thi...

Screw oil press for edible oil extraction

Optimize your oil extraction process with this screw oil press, designed to effi...

Coffee, dried nuts, and cocoa beans roaster

Achieve precise and customizable roasting for a variety of beans and nuts with...

Industrial roaster for coffee, nuts, and cocoa beans

Optimize your roasting processes with a versatile solution designed ...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

High capacity grading sieve

An industrial vibratory separator machine is multi-purpose, able to carry out a variety of diffe...

Simple valve sack packer

Sometimes in the packing process, product leaks out of the top of a bag that has just been filled. A...

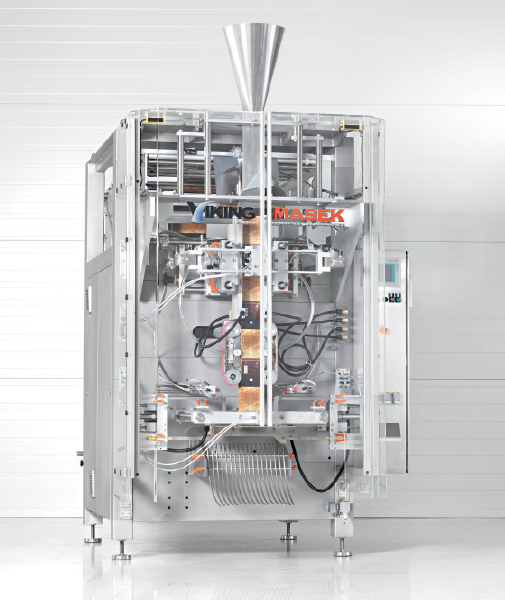

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...