Making Lavender Oil

Find innovative production technology for making lavender oil and connect directly with world-leading specialists

Lavender oil is one of the most common essential oils in the market currently. Extracted from the herb Lavandula spp., this essential oil is used as a complementary medicine and as an additive. Studies have shown that lavender oil has sedative, carminative, anti-depressive, and anti-inflammatory properties. Like other essential oils, lavender oil extraction equipment must be capable of distillation, condensation, collection, and separation processes.

Select your lavender oil process

Tell us about your production challenge

Lavender oil extraction equipment and steps: the distilling process

To make lavender oil, you first must subject the collected flowers to steam distillation using a still. Once loaded with the ingredient, steam is injected into the still to vaporize the essential oils away from the plant material. You then transfer these to a condenser, wherein the vapor condenses into an oil and water mixture, which a separator collects. Your lavender oil will be the layer of liquid at the upper part of the mixture. You can collect and transfer it to bottles for final labelling and packaging.

You may also employ other methods for lavender oil extraction. These include solvent extraction, carbon dioxide extraction, and enfleurage, all of which use carriers and different lavender oil extraction machines to remove the oil from the plant material. However, it is still recommended that you use steam distillation since it will make your product appear more naturally made while promoting sustainability through the avoidance of chemical use.

Consumer uses and applications of lavender oil

It is believed that lavender oil has antiseptic and anti-inflammatory properties, suitable for healing minor burns and wounds. As an aromatherapeutic product, its aroma can be used to treat anxiety, insomnia, depression, and restlessness. As a food ingredient, lavender brewed into tea can be helpful in addressing digestive problems like nausea, stomach pains, and abdominal swelling. Consuming lavender tea can also relieve pain from headaches, sprains, toothaches, and sores.

As a topical solution, consumers must mix lavender oil with a carrier oil to better allow the absorption of the essential oil while reducing its potential to cause skin irritation. They can dilute 1 – 5% of your lavender oil to any carrier oil, such as vegetable oils, creams, or bath gels, prior to topical application. You may recommend dilution ratios and indicate these on your labels for your customer’s reference.

Lavender oil sustainability and environmental impact

With a low recovery rate, the production of essential oils is generally not sustainable. In addition, with the case of lavender oil distillation, environment and climate patterns influence the lavender flower itself. Studies show that lower environmental temperatures after precipitation decreases the concentration of essential oils in the flower while also decreasing its essential oil quality due to temperature biochemical regulation. Although lavender oil boasts a higher recovery rate compared to other essential oils, this is still a highly valued product which you should manufacture efficiently.

With these in mind, it is important to invest in your lavender oil distillation equipment. There must be no leaks, crevices, or possible spillages which can lead to wastage of a valuable product.

Lavender oil quality and regulations

Lavender oil is currently not regulated in either the United States or Europe. In the US, essential oils are generally unregulated and do not need approval from the FDA prior to market distribution. Europe also implements the same albeit with a difference, tagging the product as a potentially hazardous chemical. There have been reports from companies stating that ingestion of this product may be fatal especially if this is swallowed and enters the airways. With this, the EU requires complete labelling, including hazard statements, precautionary statements, or other supplemental information which would enable your customers to appropriately use the product safely as intended.

Make sure you use proper oil extraction machines and steam distillation equipment to maximize your lavender oil production so that the resulting product will have the highest quality and will be safe for consumer use. In addition, be sure to indicate the intended use and storage conditions in your label to better inform your customer about its intended use.

Processing steps involved in lavender oil making

Which lavender oil technology do you need?

Vacuum cold trap for lab applications

Ensure efficient separation and purification in biopharmaceutical applications with t...

Pressure control monitor for laboratory vacuum systems

Effortlessly maintain precise vacuum pressure in your lab operatio...

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

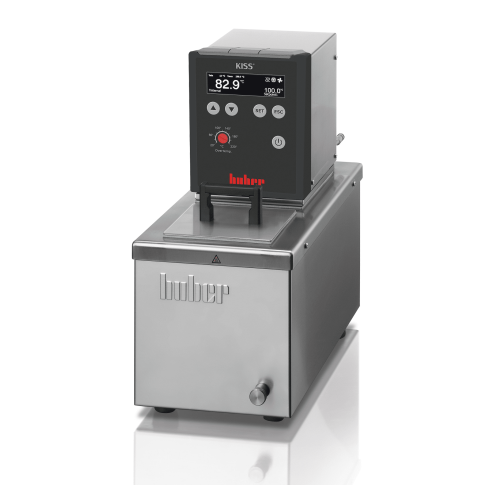

Laboratory heated circulator for precise temperature control

Achieve precise temperature control for your liquid formula...

Heated circulator for laboratory temperature control

Achieve precise temperature control for demanding applications like ...

Immersion chiller for laboratory applications

Achieve precise temperature control in extraction labs and research environm...

Moisture analyzer for precise and reliable measurements

Ensure precise moisture control in high-value products like lyoph...

Mounting configurations for industrial agitators

Optimize your mixing processes with versatile agitators designed for effi...

Versatile magnetic mixer for pharmaceutical and biotechnology applications

Optimize your biopharmaceutical mixing proc...

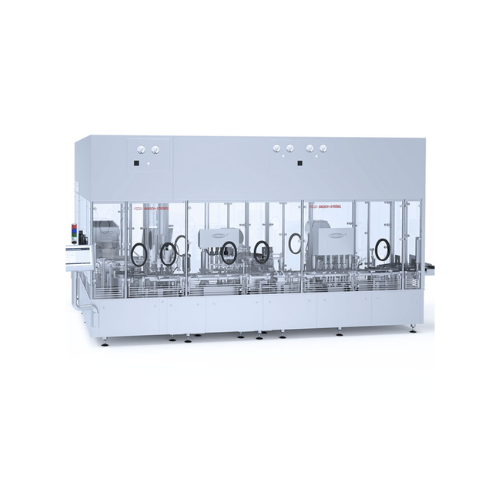

Bottle filler and capper

Achieve precise liquid filling and secure capping with high-speed, intermittent motion, ensuring con...

Volumetric filling system for cosmetic products

Streamline your production line with precise volumetric control, ensuring ...

Semi-automatic capper for twisting and screwing metal and plastic caps

Effortlessly achieve precise cap tightening with...

Industrial liquid filler for small to medium volume operations

Ensure accuracy and efficiency in liquid formulation with...

Horizontal flat pouching line for liquid soaps

Streamline your liquid product packaging with a dual-lane flat pouching lin...

High performance heat transfer system

Enhance your production efficiency with a system that shortens cycle times by increas...

Rotary evaporator for solvent evaporation

Achieve precise solvent recovery and concentration control with this rotary evap...

Supercritical Co2 fluid purification system

Optimize your extraction process with our supercritical CO2 fluid purification...

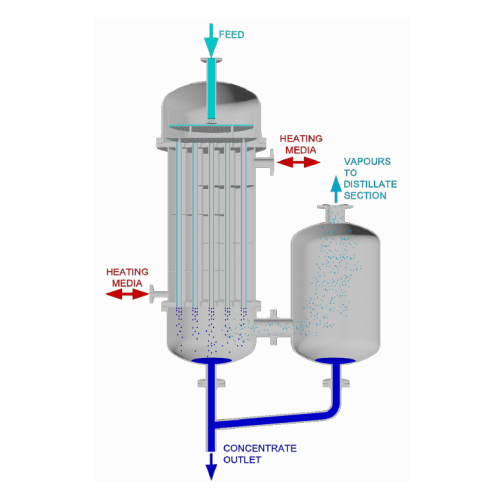

Falling film evaporator for thermal separation

Optimize energy efficiency in separation processes by utilizing gravity-dri...

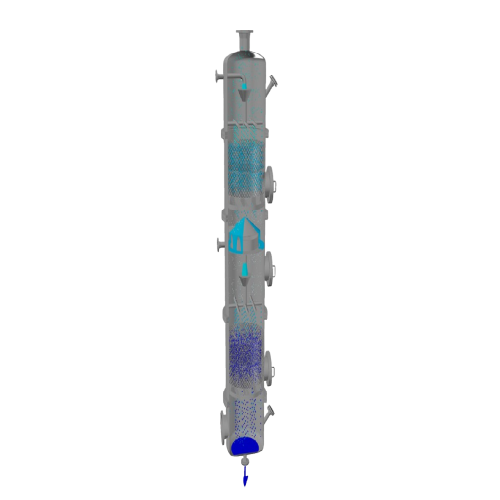

Rectification column for close boiling point separation

Achieve high-purity separation and distillation for compounds wit...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

High speed continuous motion liquid filling and capping system

Achieve high-speed, precision filling and capping for liq...

Continuous motion liquid filling and capping monobloc

Optimize high-speed liquid filling with seamless transitions from f...

Industrial recirculating chiller for laboratory applications

For consistent distillation results, maintain accurate temp...

Recirculating chiller for evaporation and extraction

Streamline your laboratory processes with a chiller that efficiently...

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

20l glass reactor for crystallization and isolation processes

Optimize your lab’s crystallization and isolation pr...

High-temperature forced convection oven for drying and sterilization

Achieve precise drying and sterilization for sensi...

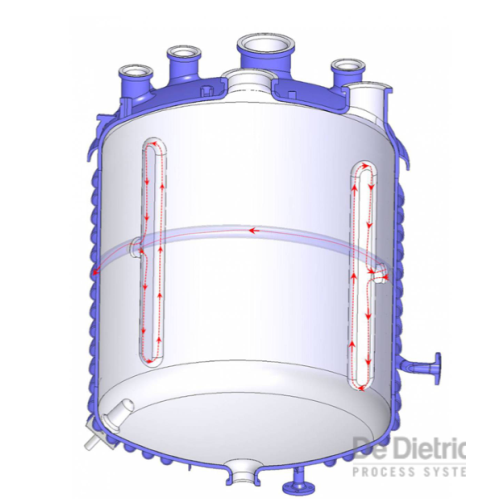

50l jacketed glass reactor with explosion-proof motor

Enhance your reaction processes with precise temperature and pressu...

50l jacketed glass reactor for synthetic reactions

Achieve precise control over chemical reactions and material synthesis...

50l stainless steel dual-jacketed reactor for chemical processes

Optimize your laboratory’s efficiency with a dual...

100l laboratory jacketed glass reactor

Optimize your batch processing with this 100L jacketed glass reactor, designed for p...

150l jacketed glass reactor for chemical synthesis

Achieve precise control over complex chemical processes with this sing...

Large capacity jacketed glass reactor

Achieve precise control over temperature and vacuum conditions with this versatile re...

2l single jacketed glass reactor system

Enhance your laboratory’s efficiency with a versatile reactor system, ideal f...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Accumulation turntable for bottling lines

Optimize your production line’s efficiency with a 42-inch diameter accumul...

Spray cooler for food and chemical industry applications

Achieve precise particle size control and encapsulation for melt...

Solid-wall bowl separators for pharma extraction

Optimize your extraction processes with precision solid-wall bowl separat...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Pharmaceutical drops and sprays filling system

Streamline your liquid formulation process with precision filling and seali...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Spray bed dryer for agglomerated powder production

Efficiently transform liquid feedstock into consistent, dust-free powd...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

Benchtop peristaltic dispenser

When you fill vials and ampoules, high standards of hygiene are required to avoid the risk of...

Benchtop piston filling equipment for vials in trays

Vials are difficult to fill individually through manual methods due ...

Semi-automatic vial crimper

In a small production line, crimping vials manually can cause fatigue to your operator due to mu...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Multi-head capper

For the stand-alone capping of bottles of up to 2.5litre capacity you need a robust and flexible machine wi...

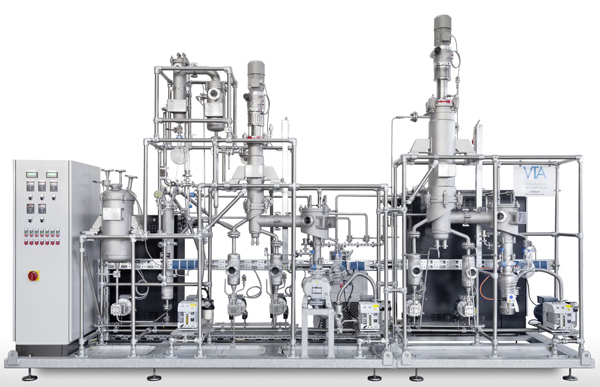

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

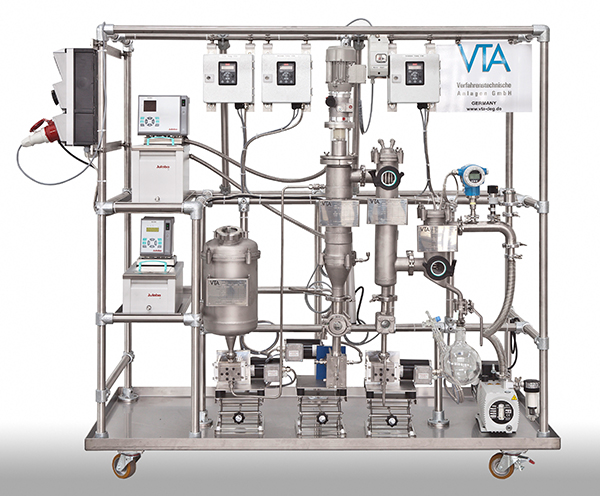

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

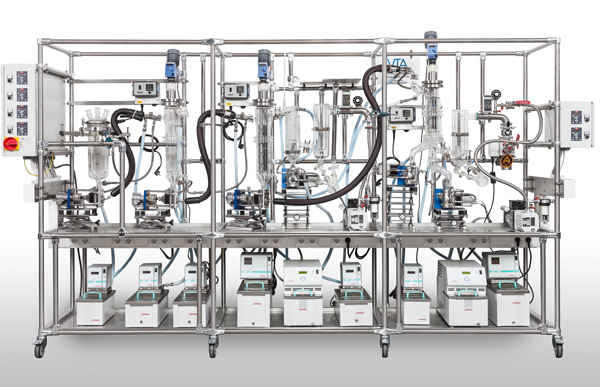

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...