Making Kombucha

Find innovative production technology for making kombucha and connect directly with world-leading specialists

Kombucha is a fermented drink made out of sweetened black or green tea. This slightly fizzy, sweet, and sour beverage has recently gained popularity for its health benefits. The main step in the kombucha making process is fermentation. Add the symbiotic culture of bacteria and yeast known as SCOBY at the base of the sweetened black or green tea to set off this reaction. The rest is up to your creativity. Enhance your kombucha with artificial or natural additives depending on the flavor you want to achieve.

Stories about kombucha

Select your kombucha process

Tell us about your production challenge

Ferment your kombucha at room temperature for up to 14 days

The brewing process of Kombucha starts with brewing a big batch of black and green tea in non-chlorinated boiling water. In a brew tank, this tea blend is sweetened with sugar, which will act as the feed of bacteria and yeast. Cool this sweetened tea blend and add SCOBY, a symbiotic culture of bacteria and yeast, for the fermentation process. Then transfer this concoction to sterilized jars with the previous batch of fermented kombucha. This process of including the previous batch is called “backslopping” fermentation process, and this method is often utilized when fermenting kombucha or yogurt. Cover the jars or the containers with a tightly woven yet breathable cloth and rubber bands. This tea blend then undergoes a fermentation process for 10-14 days in a room temperature setting.

After this period, remove SCOBY, strain this fermented kombucha, and contain them in bottles. Then kombucha undergoes the second fermentation process at a lower temperature (4℃) for a few more days. During this process, mix the fermented kombucha with sugar or fruit and vegetable concentrates depending on the flavor of the drinks.

Key to the Kombucha fermentation process - SCOBY

To brew a good kombucha, the drink has to go through two different types of fermentation processes. For the first and the primary fermentation process of brewing kombucha, a symbiotic culture of bacteria and yeast, so-called SCOBY, is considered an essential ingredient. Each of these circular jelly-looking houses of bacteria and yeast has different residents. This means, technically, the microbial elements of SCOBYs are different. Yet, they commonly have osmophilic yeast, which is accommodated in high sugar concentrations, and acetic acid bacteria (Acetobacteraceae) that oxidize sugar or alcohol and create acetic acid. Through this fermentation process, SCOBY allows the kombucha to have a fizzy and sour taste as it breaks the sugar into acids, CO2, and alcohol.

Your kombucha has to burp as well!

Just like little babies, you need to make sure your baby kombucha is burping once in a while. Due to the amount of carbon dioxide generated during the second fermentation process, the kombucha container will be full of gas. To prevent over-carbonation of your kombucha and just to check on your baby once in a while, you should open the jars probably every day during the fermentation process!

Processing steps involved in kombucha making

Which kombucha technology do you need?

Skid-mounted yeast propagation system for craft breweries

Enhance your brewing capabilities with a versatile propagation...

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Carbonation and can seaming solution for beverages

Optimize your beverage production with a seamless integration that sim...

Sterile carbonation system for beverages

Achieve precise carbonation for both common and specialty beverages with this vers...

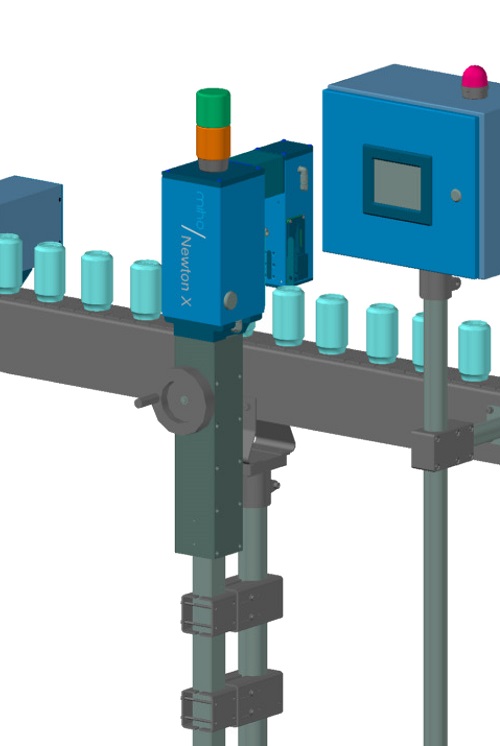

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Carbonation system for Co2 dosing in beer production

Achieve precise carbonation in every beverage batch with seamless CO...

Cross flow filtration for beer production

Optimize your beer filtration process and minimize product loss with advanced cr...

Mobile Cip carts for brewery cleaning

Streamline your cleaning process with mobile CIP carts that ensure constant temperatu...

Packaged beverage analyzer for alcohol and Co2

Ensure precise beverage analysis with a streamlined solution that integrate...

Packaged beverage analyzer for beer, wine, and cider

Ensure precision in beverage quality control with rapid, direct samp...

Co2 gas analyzer for beverage bottles

Ensure consistent carbonation levels with precise, non-destructive CO2 measurements i...

Automatic carbonated beverage mixing system

Optimize your beverage production by ensuring precise carbonation and mixing w...

Centrifuge separator for food and beverage clarification

Ensure high efficiency and minimal product loss in your producti...

Continuous sugar dissolving system for beverages

Optimize your beverage production with an efficient sugar dissolving solu...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

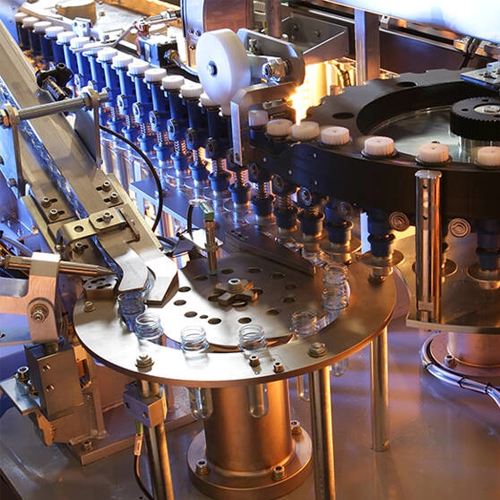

Esl beverage filling system

Ensure extended shelf life and maintain beverage quality with sterile filling and decontaminatio...

Aseptic filling system for sensitive beverages

Optimize your beverage production with an aseptic filling system that ensur...

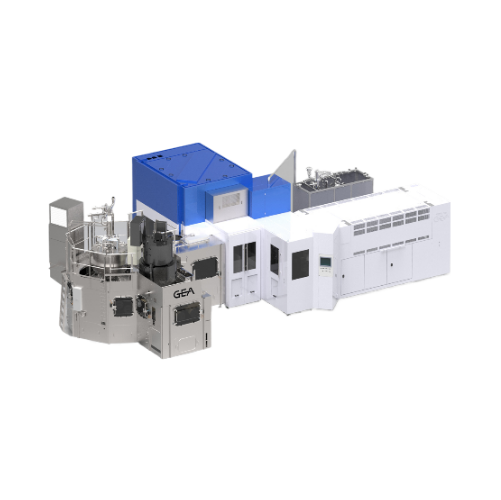

Decontamination blow fill system for beverages

Optimize your beverage production with a technology that integrates preform...

Cip system for breweries

Optimize your brewing efficiency by integrating a comprehensive cleaning and sterilization system th...

Bright beer tanks for breweries

Enhance your beverage production with precise carbonation and conditioning, ensuring excepti...

Cold block process technology for breweries

Optimize your fermentation and storage with integrated cold block process tech...

Fermentation and storage solutions for breweries

Enhance your brewing process with robust fermentation and storage tanks d...

Large-volume stainless steel brewery tanks

Optimize your fermentation and storage operations with precision-crafted tanks,...

Yeast management for brewing high-quality beer

Ensure consistent beer quality and optimize your brewing process with advan...

Innovative brewing process for optimized wort quality

Revolutionize your brewing operations by optimizing subprocesses fo...

Carbonated beverage can filler - 4 spout open fill

Optimize canning carbonated beverages while minimizing CO2 loss with t...

Level bottle filler for wine and spirits

Achieve consistent fill levels with precision sensor technology, ideal for ensurin...

Volumetric bottle filler for distilled spirits

Ensure precise volume control and compliance with regulatory standards in y...

Counter pressure filler for carbonated beverages

Ensure optimal carbonation and minimal oxygen exposure during bottling, e...

Counter pressure can filler for carbonated beverages

Achieve precise carbonation levels and minimal oxygen exposure in ca...

Counter pressure bottle filler for carbonated beverages

Maintain carbonation levels while filling bottles efficiently, en...

Counter pressure bottle filling system for carbonated beverages

Enhance your bottling efficiency with a versatile counte...

Carbonated beverage can filler for beer and kombucha

Looking to enhance your beverage production efficiency? This can fil...

High performance industrial pasteurizers

Enhance your liquid processing with fully autonomous pasteurizers that ensure opti...

In-line blender for beverage production

Enhance beverage production with a versatile solution that offers precise blending,...

Storage tank for food liquid storage

Ensure seamless liquid product handling with precision-engineered storage tanks design...

In-line blender for carbonated drinks

Optimize your beverage production with precise in-line blending and carbonation, redu...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Customizable pilot-industrial fermenters bioreactors

Designed for precision fermentation, these fermenters and bioreactor...

Continuous pasteurization unit for beverages

Optimize beverage shelf life and safety with this versatile pasteurization un...

Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system en...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Beer pasteurizer

Contamination and cross-infection by microorganisms is a major risk in the production of foods and beverages....

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Pasteurizer machine for sensitive beverages

When you want to expand your beverage production line, following a new global ...

Mixing tanks for beverages

Juice production lines require multiple ingredients to be typically mixed with water. The incorpo...

Water treatment for beverage preparation

Water is one of the main ingredients in producing juices and other beverages. If i...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

Inline syrup room

The beverage industry requires high-quality syrup. Soft drinks, fruit juices, still drinks, ice tea, flat o...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

Residual liquid inspection system

Inspection system that eliminates the risk of residual liquid, water or left over drink i...

Empty bottle height sorting system

An empty bottle sorting system that uses the light barrier technology. It detects bottle...