Making Rapeseed Oil

Find innovative production technology for making rapeseed oil and connect directly with world-leading specialists

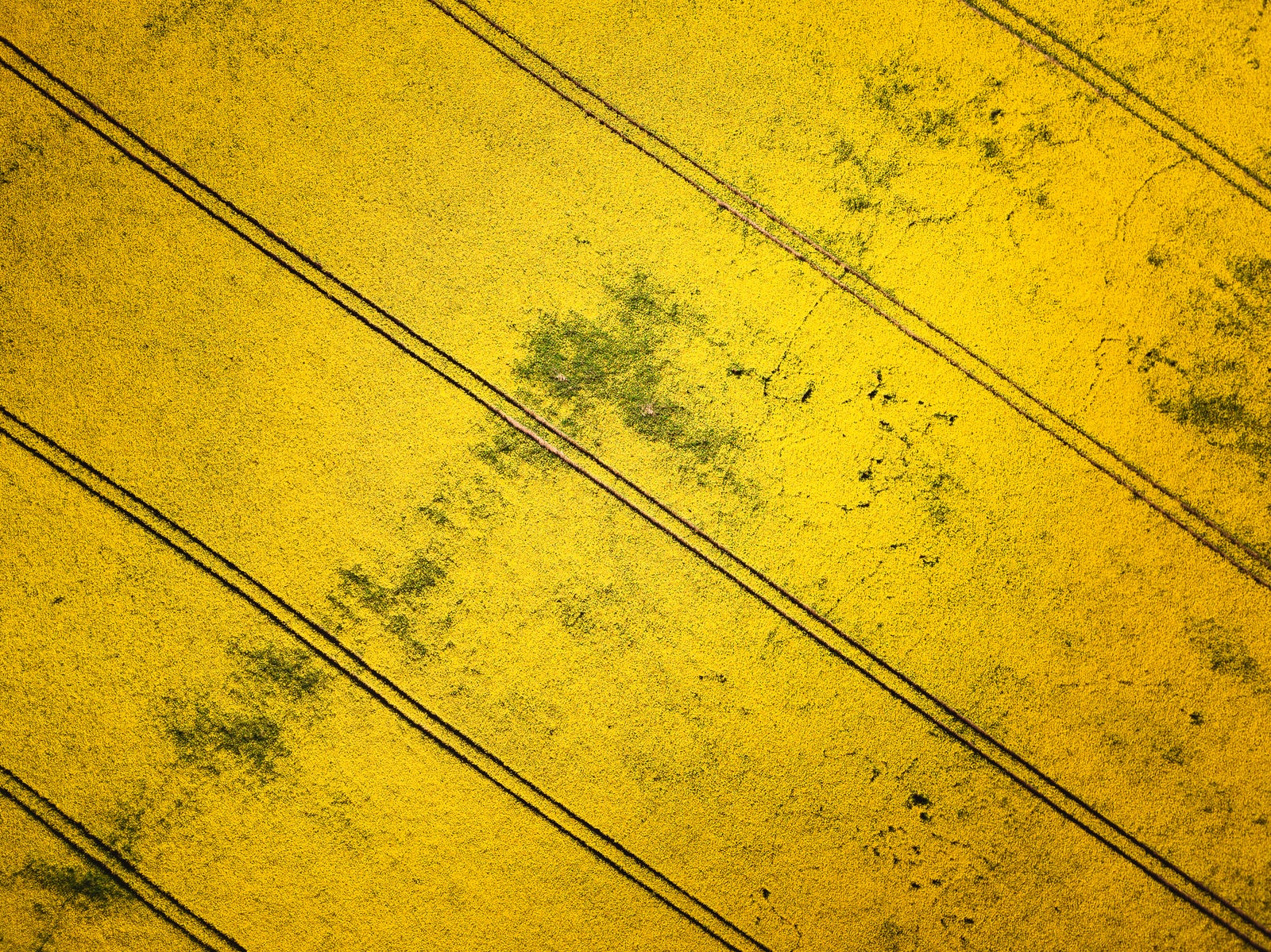

The rapeseed flower evolved high concentrations of substances that are anti-nutritive at best and toxic at worst. But new varieties developed in the 1970s lowered the content of glucosinolates and erucic acids. From then, the use of oilseed rape spread to several applications, from edible oil to biofuel to animal feed. Rapeseed oil processing technology has thus become foundational to industries spanning food production, energy, cosmetics, and pharmaceuticals.

Stories about rapeseed oil

Select your rapeseed oil process

Tell us about your production challenge

Specialized rapeseed oil processing technology maximizes crop yield

Before the oil extraction process can take place, processors ensure that the seeds are of the desired quality. Breeders select the appropriate parent seeds to develop a foundation lot for growers.

Oilrape seeds undergo a process cycle to ensure that the sown material generates the highest yield. The main stages in the process are drying, threshing, sorting, and coating.

Apply mild drying to safeguard the germ

A new seed lot is brought in for processing directly after harvest, so it typically has a high moisture content. That wetness risks activating the embryo prematurely or developing microorganisms that spoil the lot.

But if the drying process is performed too aggressively, it could damage or kill the embryo. Drying is the longest step, but a gently-dried seed is well worth the wait.

Calibrate the threshing equipment to the rapeseed oil properties

Rapeseed has about 10 times more plant material than seed. Threshing cleans the seeds to a high degree, although not completely. Threshers may be considered part of the pre-cleaning phase.

Threshing equipment has a revolving arm that applies slight pressure to release the seeds. But care must be taken not to crush the seeds, so calibrate the speed accordingly.

Sort the seeds for viability

Not all seeds are equal. Some harvested seeds may not be viable or can vary drastically in size. Sorting equipment uses a range of techniques to separate them into groups.

Optical sorters scan the lot for mismatching colors, whereas air separators distribute seeds according to weight and density. A sieve system grades them for size and shape, but it also performs a cleaning process by letting debris and small particles fall through.

Ensure a uniform layer of treatment to protect oilrape seeds from pests and diseases

Sown seeds are susceptible to attacks from pathogens and insects. Treat your lots with a specialized blend to protect your yield.

There is a variety of coating techniques developed to apply the formula homogeneously. Rotary systems are better suited for film coatings and pour the mixture from a spinning disc onto the revolving seeds. On the other hand, a drum coater sprays the treatment directly on the seeds and is more regularly used for entrustments.

Extracting rapeseed oil in cold-pressed or hot-pressed method

The traditional method to extract oil from rapeseed is by cold-pressing. In fact, extracting oil from all types of seeds usually involves cold-pressing. This means that you clean and press the seeds without adding heat and chemicals like solvents. After filtering out the impurities, what remains is only the rapeseed oil. This method retains most of the rapeseeds’ nutrients.

The other method commonly occurs in commercial production and requires multiple processes resulting in a heavily processed rapeseed oil. To start with, heat and press the seeds and add a solvent called hexane to the remaining solids to extract more oil. Then wash the oil by adding caustic soda and spinning it at high speed using a centrifuge to separate the natural impurities. After that, cool the processed oil at low temperatures to thicken the wax and remove it from the oil. Then, finish the process with a bleaching process to lighten the color, and steam injection to remove unwanted odor. The result is processed rapeseed oil ready for packaging.

From rapeseed plant to cooking oil and other industrial oils

Between both rapeseed oil processing types of extraction, the cold-pressed method is healthier since it doesn’t undergo multiple processes such as high-temperature refining and the addition of chemicals. This method, however, can only extract around 70% of the oil from the seeds. Refined or hot-pressed rapeseed oil, in its turn, extracts up to 98% of it. But this process removes some of the nutrients that are naturally present in the seeds.

Rapeseed oil is one of the major vegetable oils available in the world. It comes from rapeseed plants, and these plants are extremely vulnerable to pests and diseases. And, while you need to treat them with fungicides and insecticides to protect it, this may also harm pollinating insects and other wildlife. Alternatives such as palm oil and olive oil require less pesticides for their plants. Palm oil has better yield and has the least amount of chemicals used in growing. But it also requires a huge land area that can cause destruction of natural habitats.

Regulations in rapeseed oil processing

Some rapeseed plants come from genetically modified (GMO) seeds. In European countries, farmers cannot grow most GMO crops. However, countries like US, Canada, Japan, and China allow GMO crops. Another regulation to consider is the amount of erucic acid in the oil. It is a monounsaturated fatty acid which is deemed detrimental to health at high levels. Depending on the country, rapeseed oil is known as “canola oil” when used for cooking. To be safe for this activity, though, the erucic acid level should be around 2% or less. It is also possible to use rapeseed oil for automotive and chemical industry applications such as lubricants and biodiesel.

Processing steps involved in rapeseed oil making

Which rapeseed oil technology do you need?

Cold press for extracting vegetable oils

Efficiently extract high-quality oils from diverse seeds while preserving vital nu...

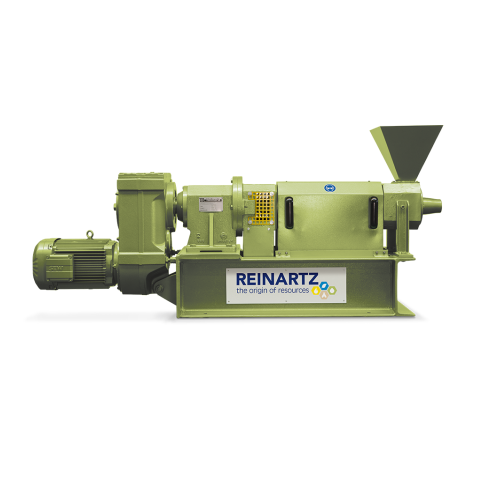

Screw press for mechanical oil extraction

Maximize protein extraction and oil yield with precision screw presses designed ...

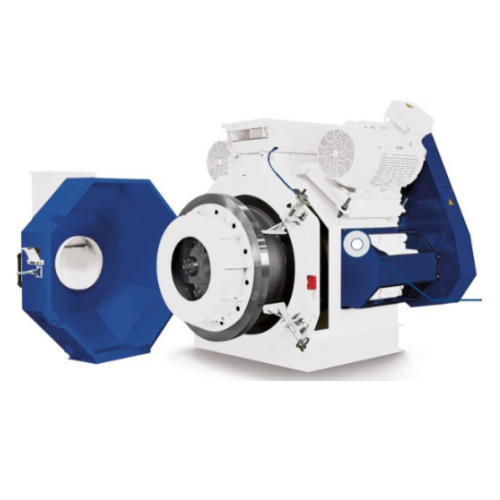

Pellet mill for animal feed production

Optimize your feed production with a robust pellet mill designed to enhance the dura...

Industrial hammer mill for granulate grinding

Optimize the grinding process in feed production with a high-efficiency solu...

Bucket elevators for bulk material handling

Efficiently transport and discharge granular and powdered materials with preci...

Continuous coater for pellet and extrudate liquid addition

Efficiently enhance your feed products by uniformly adding li...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Complete bottling lines for beverage industries

Optimize your bottling process with high-speed, precision-engineered lines...

3-phase liquid separation solution

Achieve precise separation of liquids and solids to enhance product quality and streamli...

Ultra hygienic filler for non-aseptic products

Optimize your production with high-speed filling and sealing of liquid prod...

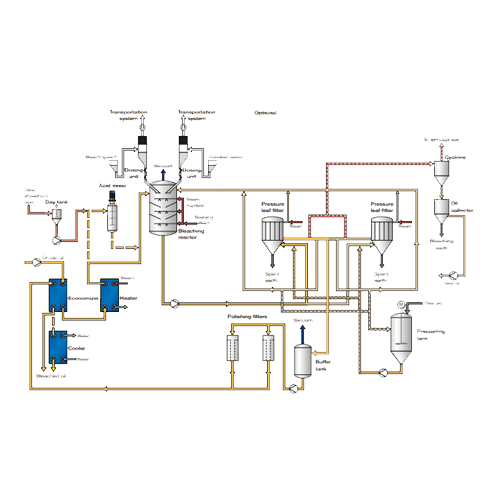

Oil and fat refining system

Ensure high-quality oil and fat production by efficiently removing contaminants such as phosphat...

Industrial oil degumming process

Achieve optimal oil purity and maximize yield with this advanced system designed to streaml...

Oil neutralizing technology for chemical refining

Achieve optimal purity and yield in oil processing with precise control...

Efficient desolventization and toasting solution for oilseeds

Optimize solvent removal and toasting in your oilseed proc...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

White flake desolventization for oilseed processing

Optimize your oilseed processing with a system designed to efficientl...

Flash desolventization system for oilseed processing

Achieve rapid desolventization with minimal heat exposure, preservin...

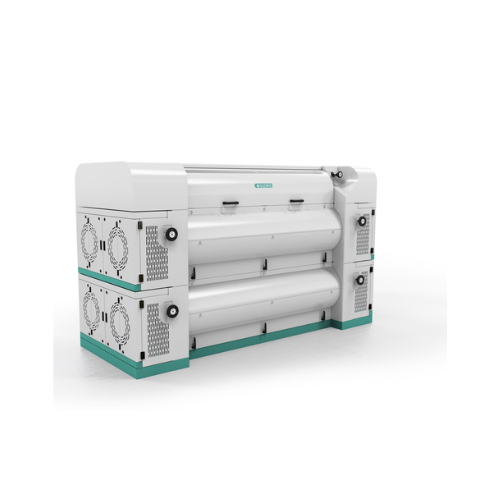

Industrial grain flaking solution

Enhance grain processing efficiency with precision-engineered flaking solutions, designed...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

High-throughput grain cleaner

Maximize efficiency in grain processing with a high-throughput cleaner designed to handle dive...

Seed conditioning system for soybeans and rapeseed

Streamline your oilseed processing by efficiently conditioning and deh...

Impact dehuller for sunflower, soybean, and cottonseed

Enhance oil extraction efficiency with a dehulling solution that g...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

High-performance cracking mill for oilseeds

Optimize your oilseed processing with a versatile mill designed to enhance eff...

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and m...

Vertical conveyor for bulk materials

Optimize your handling of bulk materials with a cost-effective solution that ensures h...

Decanter centrifuge for food industry separation

Achieve precise separation and ensure optimum product quality with our ad...

Vegetable oil separator for high-quality oil processing

Achieve optimal separation of oils and fats with advanced centrif...

Decanter centrifuge for vegetable oil clarification

Maximize oil recovery and purity with advanced decanter centrifuge te...

Bleaching systems for edible oil refining

Achieve clarity and stability in your edible oils with cutting-edge bleaching sy...

Centrifugal oil filter for removing oil impurities

Enhance oil purity and ensure efficient removal of impurities with thi...

Screw oil press for edible oil extraction

Optimize your oil extraction process with this screw oil press, designed to effi...

Hydraulic oil press for efficient oil extraction

Streamline your oil production with a hydraulic oil press that ensures hi...

Continuous mixer for accurate ingredient blending

Achieve precise mixing in continuous production with optimal control ov...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Seed conditioning system for edible oil processing

Optimize your oilseed processing with efficient moisture reduction and...

Degumming plant for edible oil refining

Achieve optimal purity and quality in edible oils through precise degumming process...

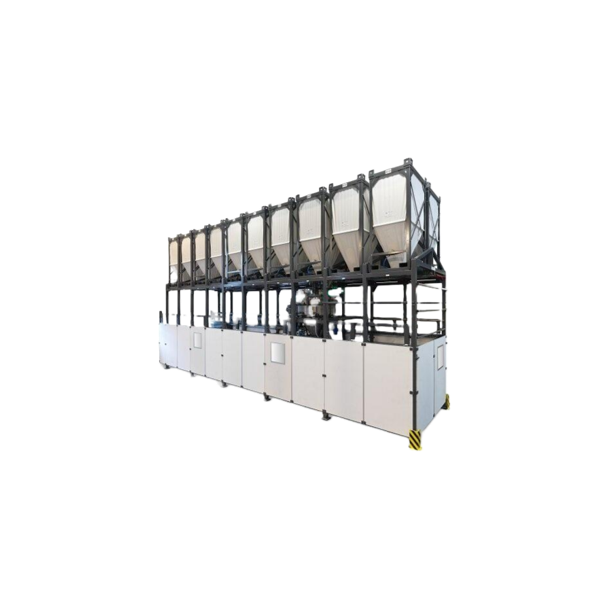

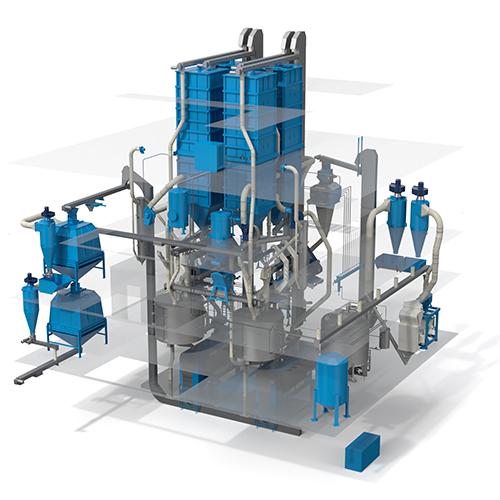

Automatic processing line for field crop seeds

The quality of field crops (ROW crops) is determined by their seeds. The br...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Refining plant for vegetable oil and animal fats

The main problems arising from refining process of vegetable oil and anim...

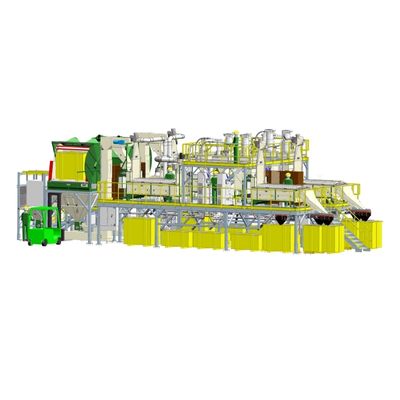

Oilseeds preparation plant

When producing customized flakes, pressed cakes, or other oilseed products, the oilseed preparati...

Sunflower oil extraction plant

Extracting sunflower oil using an organic solvent, usually hexane, has a big environmental im...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Organic soybean oil pressing plant

Soybean oilseeds are usually processed through extraction methods using hexane or other ...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

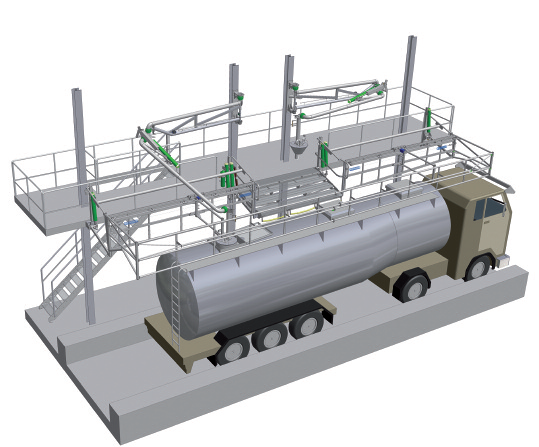

Top loading arm

Load or unload liquids from the top of the tanks safely and securely for trucks, railcars, small or big contai...

Folding stairs and safety cages

To ensure the safety of operator while working between a loading platform and road or rail t...

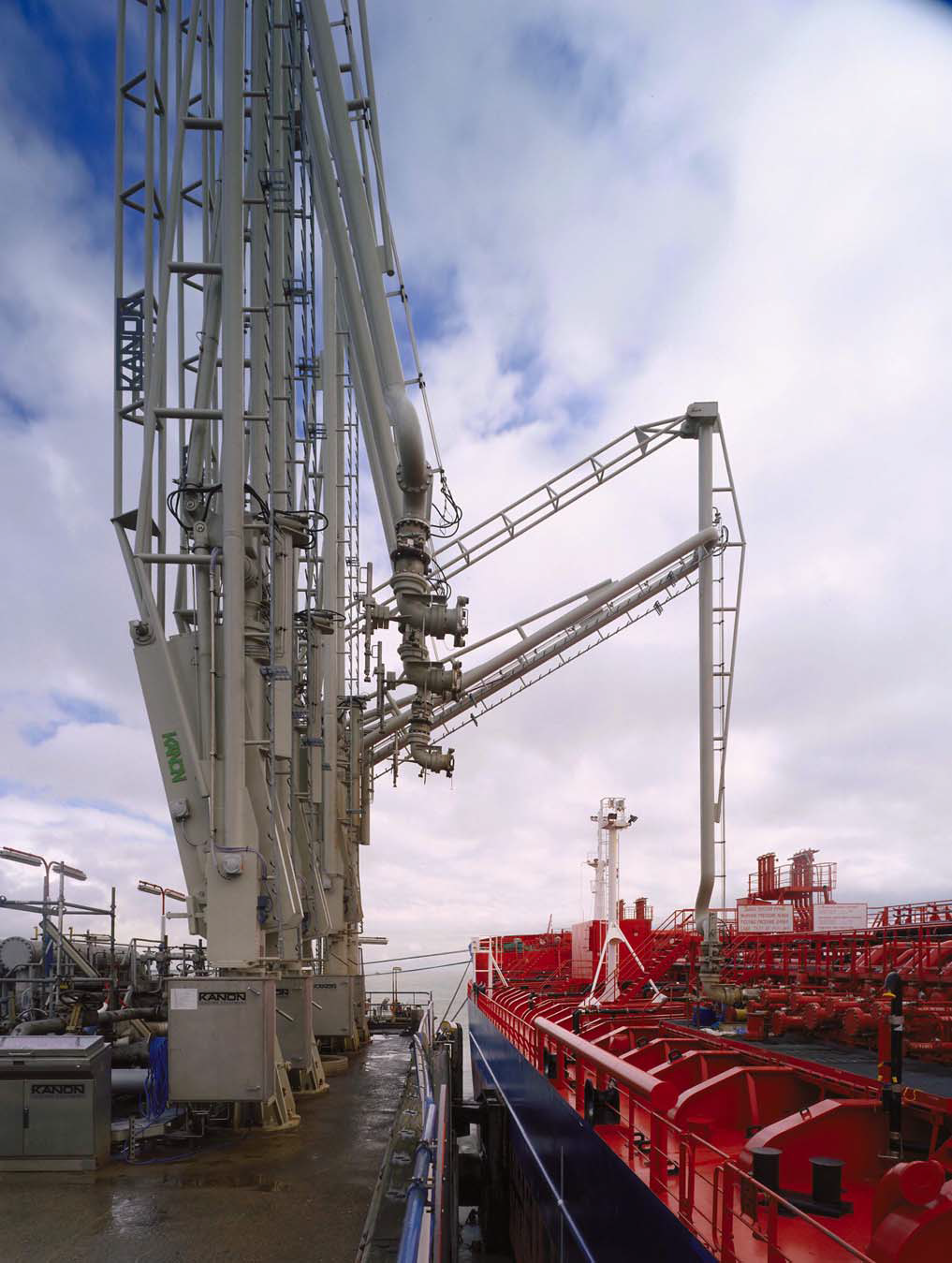

Marine loading arm

A hose or loading arm is needed when you load or unload fluids from a ship or transfer fluids between vess...

Bottom loading arm

Bottom loading/unloading arms are designed to be connected on the side or on the rear of the tanker and so...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

Vertical pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many in...

Horizontal pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many ...

Horizontal plate scavenger filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to ma...

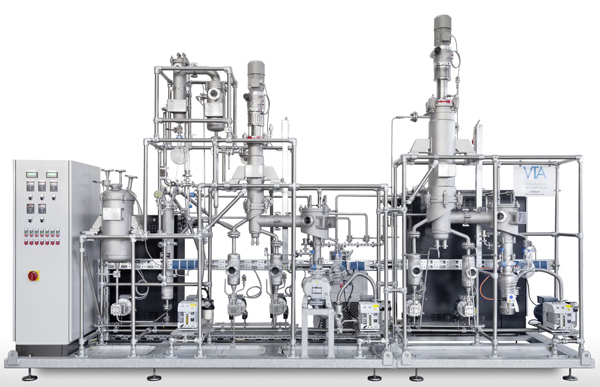

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Horizontal thin film evaporators

Horizontal thin film evaporators can increase the residence time of the product and achieve...

Filter pressure leaf

From chemical processing, to energy production, to edible oils production, product quality is often depe...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...