Making Microtablets

Find innovative production technology for making microtablets and connect directly with world-leading specialists

Microtablets range between 1 and 4 millimeters, making the dosage form an excellent delivery system in polypharmacy. The size of the products makes them easier pills to swallow, but microtablets production brings a unique set of complexities.

Select your microtablets process

Tell us about your production challenge

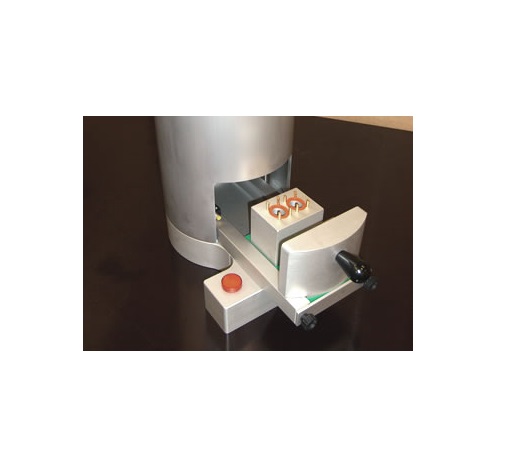

Align the punches in multi-tip tooling technology with precision

The millimetric dimensions of microtablets make compression force harder to control than for larger-sized tablets.

Adopting multi-tip tooling in your microtablets production process multiplies overall compression power by the number of tips in the equipment. While this technique distributes the weight in microtablets more evenly, misalignment between the upper and lower punch results in faulty compression.

Extend the coating process in microtablets production

The reduced diameter of microtablets gives them a larger surface area relative to regular-sized tablets. This physical property increases the speed of drug release once ingested and decreases the diffusion rate of the active pharmaceutical ingredients.

Microtablets designed for delayed release require an extended coating process. Spray coating using a fluidized bed system achieves uniform coats, but a high spray rate can develop cracks down the line if temperatures are too low for adherence.

Set your friability limit to 1% of body weight in minitablet production

The friability threshold of microtablets must not exceed a reduction of 1% in the total weight of the tablets.

Select a dusted sample with a total body weight of 6.5 g a place it into a rotating drum. After the rotating cycle is completed, dust the microtablets again and measure the weight. Check the products for chips or cracks.

Processing steps involved in microtablets making

Which microtablets technology do you need?

Dust-tight dispenser for metal detector test tablets

Ensure seamless integration of test tablets in high-containment envi...

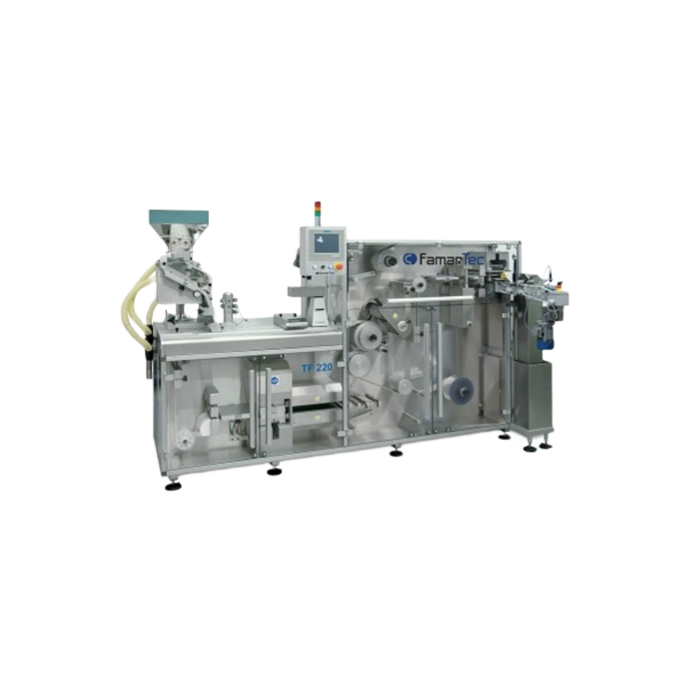

Blister packaging system for tablets and capsules

Designed for seamless 24/7 production, this blister packaging machine e...

Laboratory film coating system for development and clinical batches

Achieve precision in tablet coating with a versatil...

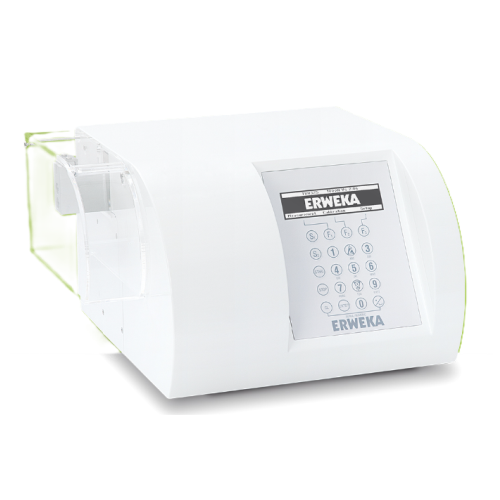

Tablet hardness tester

Ensure consistent tablet quality by precisely measuring hardness, thickness, diameter, and weight with...

Laboratory homogenizer for pharmaceutical and biotech applications

Achieve precise homogenization for your laboratory n...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

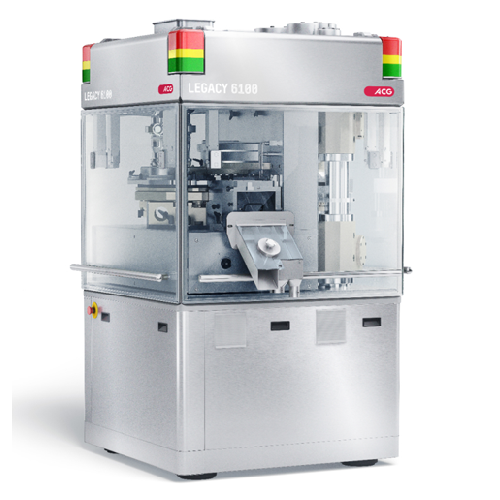

Single rotary tablet press

Streamline your tablet production with enhanced efficiency and precision, ensuring consistent tab...

Advanced fluid bed for pharmaceutical granulation

Achieve precise granulation and drying for pharmaceutical powders with ...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid-bed drying and granulation system

Optimize your production line with high-speed batch processing for efficiently dryi...

Liquid filling system for hard capsules

Easily fill two-piece hard capsules with liquids, pastes, and suspensions with prec...

High-speed capsule filler for large batch production

Achieve higher yields and reduce powder waste with a capsule filling...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

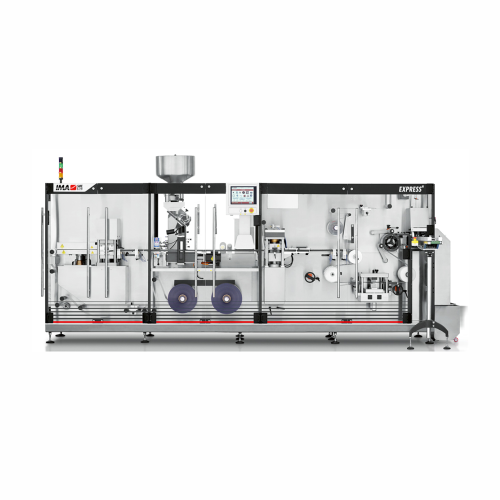

High-output blister packaging system

Maximize blister packaging efficiency with continuous-motion capabilities, ensuring su...

Intermittent motion cartoning machine for blister packs

Optimize your packaging line with a space-efficient cartoning mac...

Metal contamination detection for tablets and capsules

Ensure product integrity by detecting and separating metal particl...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Continuous wet granulator and dryer for R&D

Pharmaceutical laboratories need compact equipment to handle and produce small...

Dry granulator for pharmaceutical powders

In pharmaceutical industries, where large-volume production is the norm, compact...

Energy-efficient film coating machine for pharmaceutical tablets

Tablet coating involves applying a thin layer of coatin...

Fluidized bed system for the granulation and drying of pharmaceuticals

Pharmaceutical industries employ several process...

Pharmaceutical tablet coating machine

Tablet coating requires spraying, mixing, and drying procedures that must be carried ...

Semi-automatic forming and sealing blister machine

As a manufacturer of medical device, the packaging is a critical facto...

Clinical trial lab sealer for a laminar airflow bench

When running small production for clinical trials, stability studie...

Particle analysation monitor

Products like granules, tablets and capsules require inspection at numerous steps in the produc...

Laboratory Tablet Press

Pharmaceutical research and development projects may require small samples of high quality tablets fo...

Industrial blister packaging machine

High-volume, fully-automated blister packaging is the perfect choice for large scale p...

Small feeder with flexible wall hopper

In many laboratory applications and production processes, smaller quantities of powd...

Lab scale single layer tablet press

Automated pressing of tablets saves time and improves quality. In R&D or laboratory...

Granulation line of mixer and fluid bed dryer

A complete granulation line allows for the mixing and granulation of pharmac...

Single layer tablet press

High performance tablet presses for the modern production environment need to be fast, accurate an...

Rotary tablet press

For pharmaceutical tablet producers looking to reduce waste, costs and increase production volume, a hig...

Entry-level high-shear mixer for drug formulation

For pilot and lab-scale pharmaceutical formulations, a high-shear granu...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

Sorption dehumidifier with air-chilled condenser

It is not always possible to duct out the wet air from a dehumidifier ser...

Small portable dehumidifier

Water damaged areas require dehumidification to limit the damage and prepare the area for restor...

Sorption dehumidifier for large temperature differences

Small, humid areas can be difficult to dehumidify in humid ambien...

Sorption dehumidifier for deep drying

Humid ambient conditions such as those in tropical climates make dehumidification mor...

Dehumidifier for difficult wet airflows

Sealed rooms can be challenging to dehumidify with ordinary dehumidifiers. The wet ...

Sorption dehumidifier for overpressured rooms

Small humid spaces, used for processing or storage, often need a simple dehu...

Heat recycling sorption dehumidifier

Facilities that handle large amounts of water can become very humid. High humidity may...

Industrial desiccant dehumidifier

Dehumidification of medium sized manufacturing and processing facilities can be a dauntin...

Large scale desiccant dehumidifier

Moisture sensitive processing and storage facilities need low humidity environments to s...

Customizable dehumidifier

Dehumidification needs can vary significantly from one project to another. Dehumidifiers with a fi...

Checkweigher

A check weigher that is equipped with high speed/high accuracy force balance load cell. It meets stringent accura...

High-sensitivity metal detection system

Highly efficient metal detector with enhanced quality control and reporting capabil...