Equipment For Making Mixed Nuts

Find innovative production technology for making mixed nuts and connect directly with world-leading specialists

Peanut, which (ironically) is a legume, is the make-or-break ingredient of your mixed nuts manufacturing process. “Deluxe” packs tend to avoid them, as their price is much more affordable than other nuts, therefore not being premium. For a regular mix, on the other hand, peanuts can be the major ingredient you’ll include.

Select your mixed nuts process

Tell us about your production challenge

From process to inspection - choosing equipment for the mixed nuts manufacturing

Pecans, walnuts, Brazils, almonds… once you select your set of nuts, you need to decide whether to roast or fry them. For example, when processing and making almonds, it is widely agreed that they are better roasted, whereas frying is the best method when processing cashews. Either way, mixed nuts manufacturing requires equipment that can adjust to the particularities of each ingredient. These include their shape, size and consistency, for instance, but also the oil absorption from each nut when frying them. As an example, roasted peanuts have a low oil absorption rate, and can be more challenging to fry.

Before manually or mechanically creating your set of nuts, you need to process and check them individually for defects. Again, each nut can be more susceptible to different damages sources, such as insects, birds, and rodents. General items you need to check to ensure the quality of the nut are discoloration, rancidity and molds. Mold can occur more in chestnuts and Brazil nuts, while hazelnuts may become bitter after the attack of plant pests.

Moisture, flavonoids: components to take care of

Nuts react differently to roasting and frying when it comes to certain components. Both methods deal well with reducing the moisture of the nuts, which helps increase their shelf life and avoids degradation.

A study regarding roasted peanuts found out that several production characteristics impact the look and flavor of the product. The longer the heat processing time, the darker the surface color – and the lesser moisture content present in the peanut.

Flavonoids are another thing to watch out for in mixed nuts manufacturing. They are natural products common to beans, vegetables, fruits and other types of food. They are responsible for giving vivid colors and have also anti-inflammatory, anti-oxidative and anti-carcinogenic properties.

Another study with almonds, pines, cashews and pistachios showed that neither roasting nor frying nuts affected their flavonoids content, compared to their raw state. The only exception was for pistachios, which saw an increase in it.

Minimum amount and clear information: regulations for mixed nuts manufacturing

In the United States, the Food and Drug Administration Department of Health and Human Services has specific requirements for the nut mix. It says, for instance, that there must be at least 4 variations of tree nuts ingredients. In case your product use peanuts, it’s possible to either choose only one variety or combine 2 or more of them.

The institution also established minimum and maximum percentages for the nuts. They tend to vary between 5 and 10 to 40% of each type. In case the percentage of one specific type lies between 50-60%, it’s mandatory to include such information in the package. “Contains up to 60% [name of the nut]” or “60% [name of the nut]” need to follow the name “mixed nuts” and be clearly visible to consumers.

Processing steps involved in mixed nuts making

Which mixed nuts technology do you need?

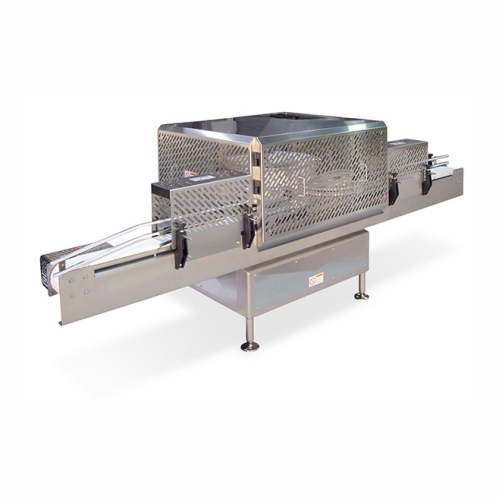

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

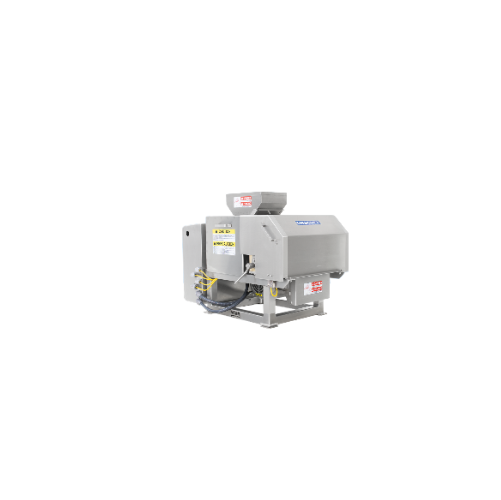

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Packaging solution for bulk vegetables and fruits

Ensure precise, high-speed packaging for diverse product sizes with a f...

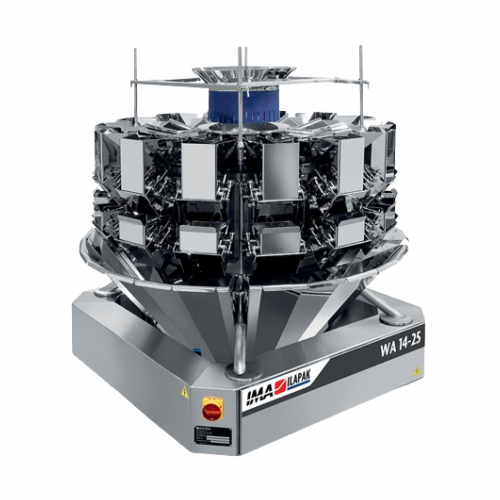

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

Continuous paper filter for frying oil

Ensure oil clarity and enhance product quality by continuously removing ultra-fine p...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Smart pack conveyor systems for packaging room

Efficiently manage the flow of snack and nut products from packaging to dis...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

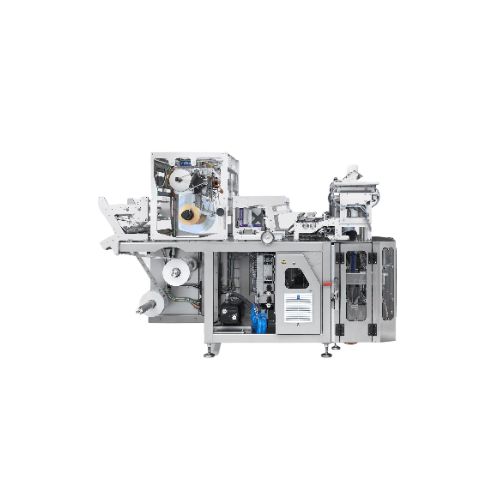

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Granulator for nut meats and cookies

Optimize your processing line with precision granulation, slitting, and scarifying of ...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

Electrostatic drum flavouring for uniform coating

Achieve precise and uniform flavor distribution on snack products with ...

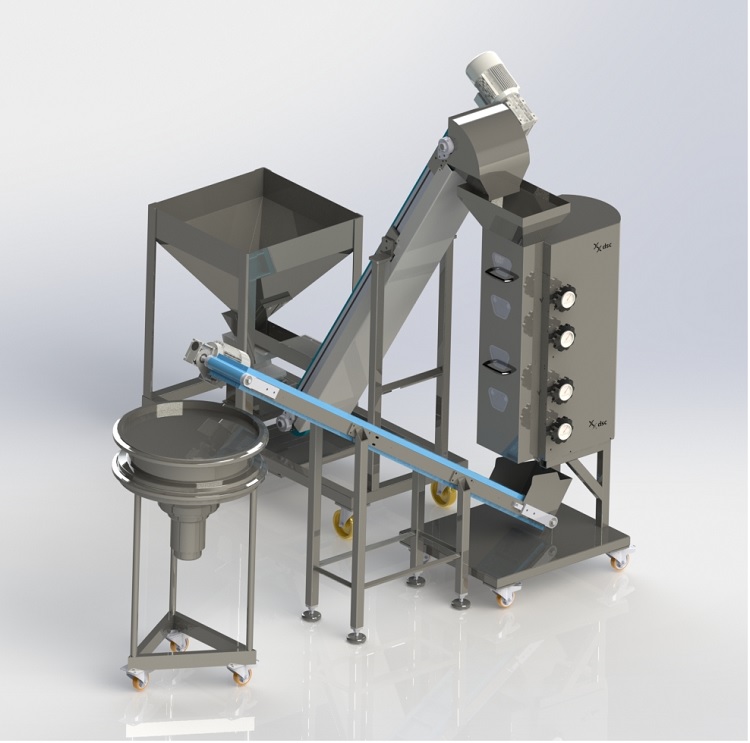

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

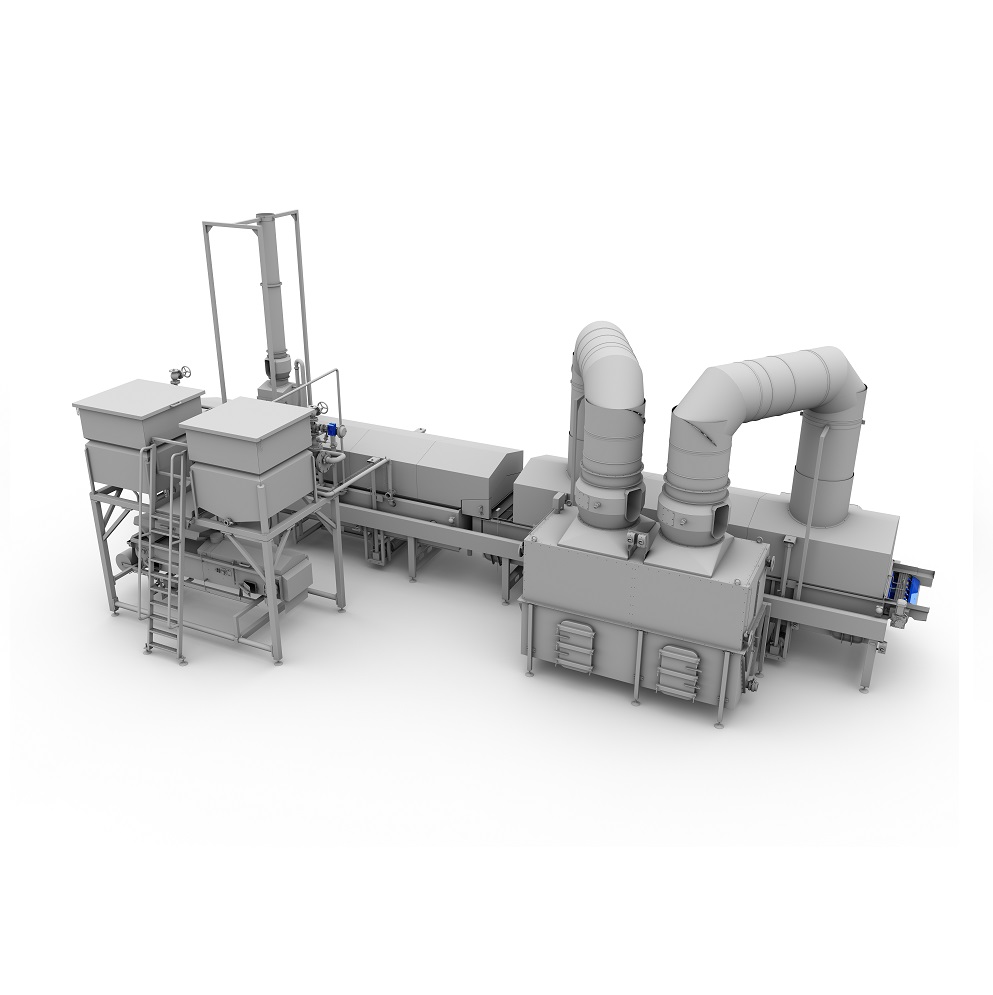

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

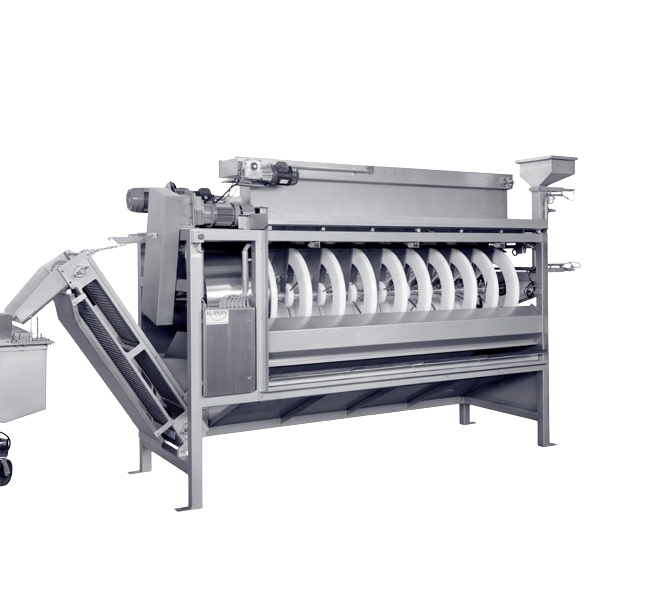

Continuous, automatic coating machine for peanuts

If you are in the peanut processing industry, bringing out delicious va...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

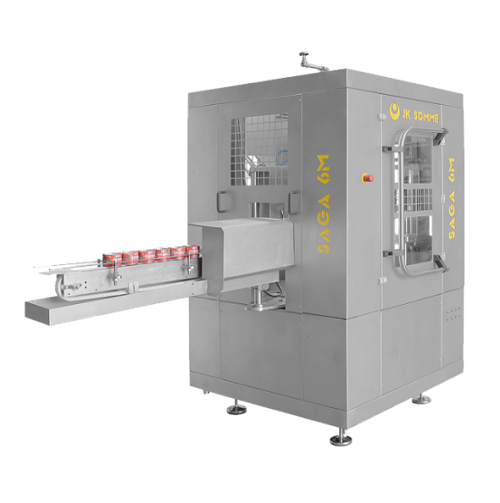

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Leak tester for vacuum packaging

Roasted coffee beans, as well as grounded coffee, rapidly diminish in flavor. The oxyge...

Industrial fine milling equipment for nuts

In a bakery environment fruit jams are often used for the decoration or filling...

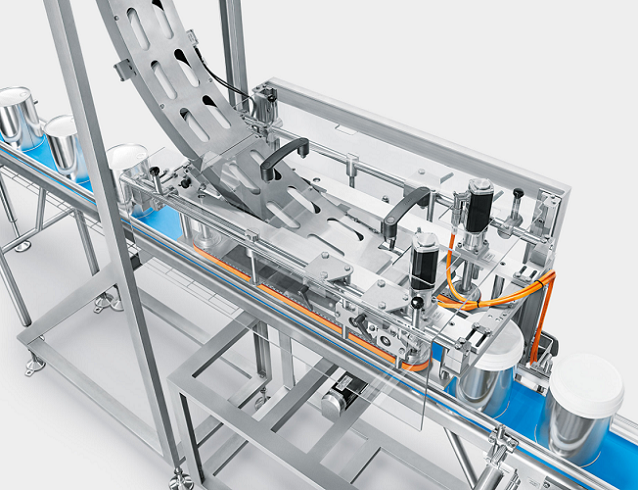

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.