Making Probiotics

Find innovative production technology for making probiotics and connect directly with world-leading specialists

The billions of microbes living in our gut have a significant impact on gastrointestinal health, mood, and behavior. Every individual develops their microbiome community. Probiotic processing technology makes sure that harmful bacteria never outnumber good citizens.

Select your probiotics process

Tell us about your production challenge

Enrich the LAB cultivation medium with magnesium and manganese

Lactic acid bacteria (LAB) are used in many food products, but this strain requires a complex nutrient environment to develop.

Add manganese sulfate or magnesium sulfate to your cultivation medium to boost the metabolic activity of LAB. The minerals also act against external oxygen radicals and provide anaerobic growth for the bacteria.

Preserve cell viability with cryoprotectants when using probiotics processing technology

Freeze-drying your bacteria converts the probiotics into dried powder. However, freezing at very low temperatures and dehydration under vacuum stress the cells.

A cryoprotectant increases the viability of the cells, but different materials achieve different levels of protection. An emerging technique combines trehalose, sodium ascorbate, and skim milk to register a cell survival rate of around 75%.

Higher pH stability makes Bifidobacterium more resistant to post-acidification

Probiotic strains may produce acidity, affecting the stability of the product. Probiotics processing technology such as refrigerators reduce the pH value of bacterial cells in a phenomenon known as post-acidification.

The Lactobacillus delbrueckii ssp. Bulgaricus (STLB) species demonstrates a high relative drop in pH levels. On the other hand, Bifidobacterium has a lower capacity for developing acids, making strains like the Bifidobacterium lactis more resistant to post-acidification.

Ensure probiotic concentrations in end products meet claim requirements

Different regions around the world have separate regulatory labeling requirements for probiotic products. Proprietary blends are permitted, but individual dietary ingredients within a proprietary blend should be listed in descending order by their Colony Forming Units (CFU).

Any benefits declared about the strains should be backed up by scientific evidence that the amounts provided in the product are consistent with the information supporting the claim.

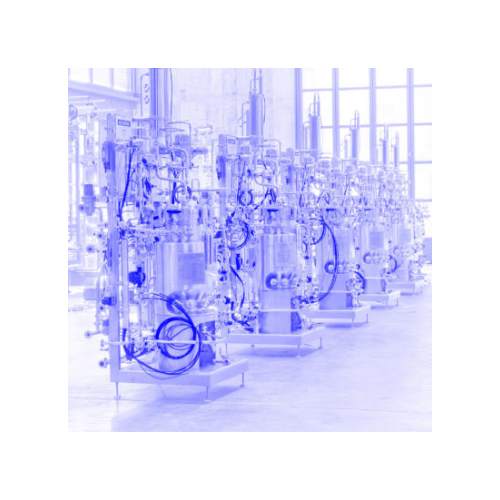

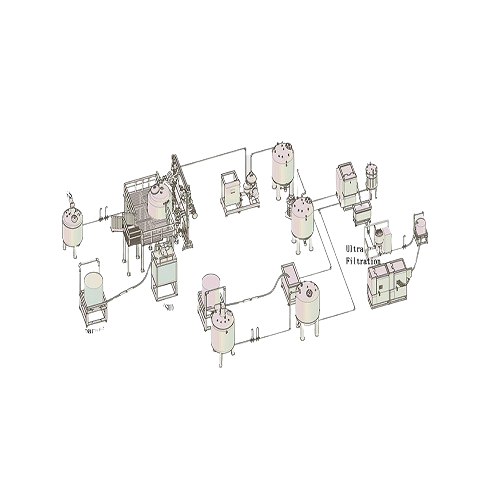

Processing steps involved in probiotics making

Which probiotics technology do you need?

Separators for pharma extraction

Optimize your pharmaceutical extraction process with innovative centrifugal separation tech...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

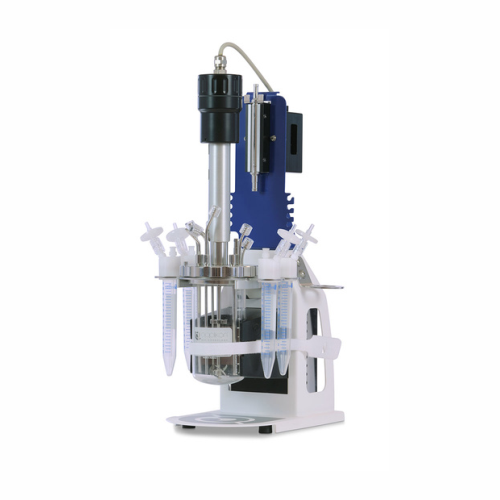

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Bioreactor mixer for gentle mixing applications

When handling sensitive biomaterials, ensuring optimal mixing while mainta...

Sterilization in place fermentor for bioprocess applications

Optimize your fermentation processes with seamless integrat...

Small scale fermentor/bioreactor for multi-condition bioprocessing

Explore diverse fermentation conditions with precisi...

Small size multi-use glass autoclavable bioreactor

Optimize your laboratory space with this compact bioreactor that reduc...

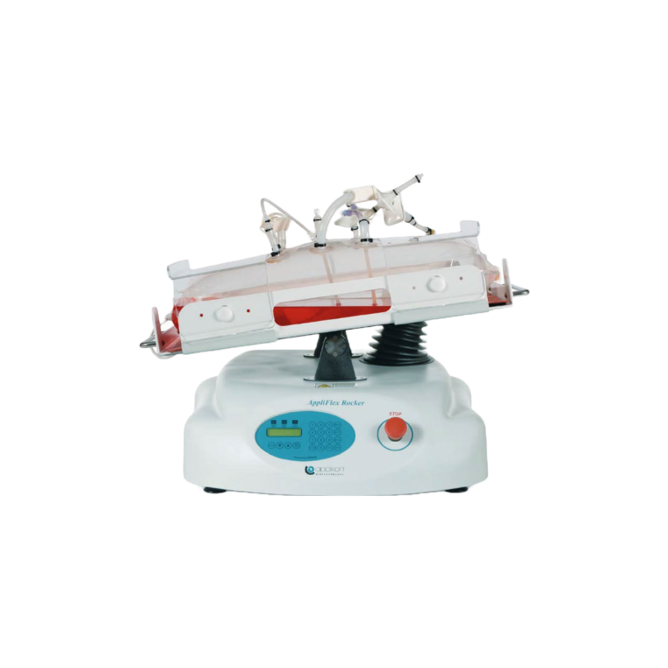

Single-use lab-scale bioreactor for upstream bioprocessing

Streamline your bioprocess development with a customizable, s...

Stainless steel bioreactor for small-scale bioprocess production

Optimize your bioprocess development with a modular sta...

Stainless steel bioreactor for cgmp production

Achieve reliable and scalable production of life-saving medicines with a cu...

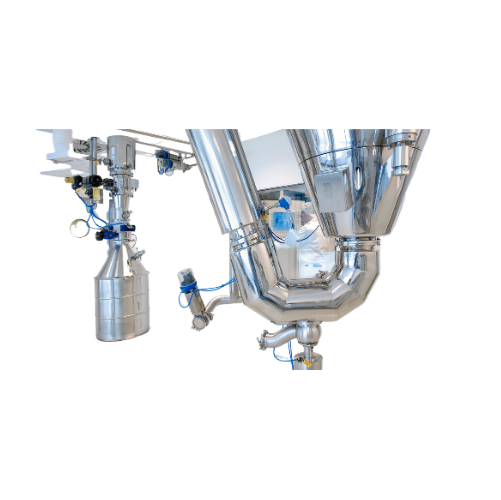

Vacuum transfer system for powders and granules

Effortlessly transfer and manage powders and granules with seamless integr...

Mini bioreactor for cell culture and microbial process development

Achieve precise control and reproducibility in small...

Parallel bioreactor system for cell culture and microbiology

Optimize bioprocess development with a scalable system desi...

Pharmaceutical water purification system

Ensure compliance with stringent pharmaceutical standards by integrating a reliabl...

Controlled rate freezer for biological and medical research

Ensure the integrity of biological samples while minimizing ...

Nitrogen determination system for laboratory analysis

Ensure precise nitrogen content analysis with cutting-edge steam di...

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products...

Autoclavable glass fermentor for biotech research

Optimize your fermentation processes with a versatile benchtop solution...

Modular bioreactor for low-volume production

Optimize your bioprocessing with a scalable solution designed for precise con...

Hybrid bioprocess system for cell culture and purification

Streamline your bioprocessing operations with a versatile sol...

Purified water storage tank for pharmaceutical use

Ensure the integrity of your pharmaceutical formulations with precisio...

Microbial cell clarification solution

Achieve high-yield, foam-free microbial cell clarification with minimal shear stress ...

Yeast centrifuge separator for pharmaceutical applications

Optimize microorganism recovery with high purity and efficien...

Industrial fermentation separator with nozzle bowl

Optimize your industrial fermentation process with advanced separation...

Continuous direct compression line for pharmaceuticals

Optimize tablet production with a seamless system combining contin...

Industrial high-pressure homogenizer

Achieve precise homogenization with superior flow rates and efficiency, ensuring optim...

Aseptic liquid dosing system

Ensure precise, sterile dosing of aseptic liquid products, enhancing product integrity and exte...

Pharmaceutical spray dryer

Unlock the potential of spray drying to enhance bioavailability, achieve controlled release, and ...

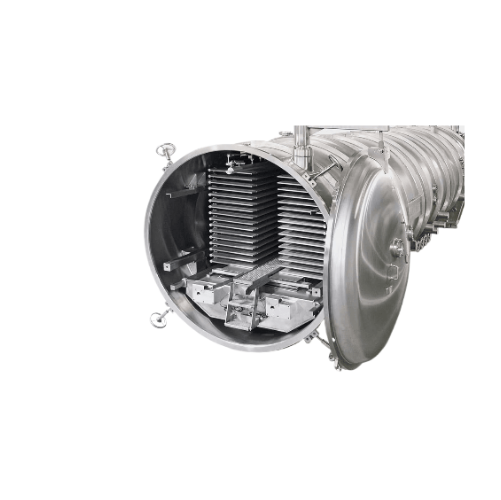

Batch freeze drying system for food and beverage preservation

Achieve precise and efficient preservation of your food an...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Horizontal shaft mixer for free-flowing materials

Achieve consistent mixing of diverse free-flowing materials with a reli...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Glass bioreactor for microbial fermentation and cell cultivation

Streamline your bioprocessing with this customizable gl...

Aseptic dosing system for heat-sensitive ingredients

Enhance product quality and reduce ingredient waste by precisely inj...

Aseptic dosing unit for sensitive ingredients

Ensure the stability of heat-sensitive ingredients with precise in-line dosi...

Microbiological safety cabinet for laboratory containment

Ensure seamless microbiological containment and operator prote...

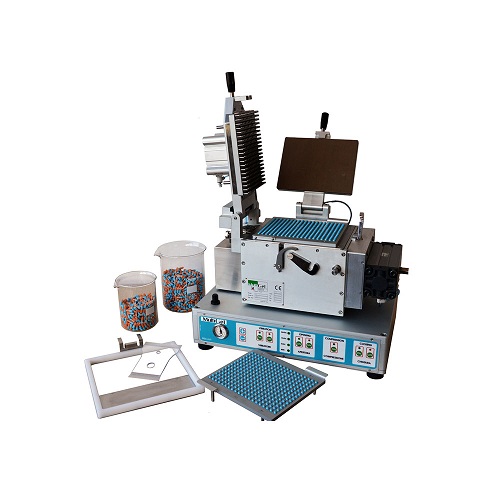

Capsule filling for nutrition and health products

Optimize your production line with advanced capsule filling capabilitie...

Batch powder mixer for circulatory dispersion

Optimize your batch production with a powder mixer designed for efficient di...

Lyophilization process optimization sensors

Achieve precise real-time monitoring of water vapor during freeze-drying, stre...

Dairy product filling solutions

Optimize your dairy production with advanced filling systems designed to enhance product saf...

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

Vision inspection system for tablets and capsules

Pharmaceuticals and healthcare product manufacturers dealing with oral ...

Pharmaceutical formulation and mixing tanks

Preparation lines for formulating pharmaceuticals include fixed and mobile tan...

Automatic laboratory capsule filler

Innovators in the highly regulated and highly dynamic pharmaceutical market place need ...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Automatic capsule filler for liquid solutions

Use of liquid filled hard capsules is increasingly popular with today’...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

Scale up capsule filler

For higher production volumes of pharmaceutical capsules, speed, accuracy and reliability of producti...

Benchtop weight sorter for tablets & capsules

For laboratory pharmaceutical R&D work or use in clinical trials, a...

Flexible contained powder discharge into drums

Powdered products are handled every day in the pharmaceutical and bioproces...