Lyophilization process optimization sensors

Achieve precise real-time monitoring of water vapor during freeze-drying, streamlining lyophilization cycles to enhance product quality and maintain sterility without process interruptions.

Monitors and Analyzes Lyophilization Processes

The LyoFlux 200 TDLAS Sensors, from Physical Sciences Inc., revolutionize lyophilization by providing non-invasive, real-time monitoring of water vapor mass flow. These sensors enhance the freeze-drying process for biologics and pharmaceuticals, such as vaccines and protein therapeutics, by enabling continuous measurement of product temperature and resistance. Utilizing Tunable Diode Laser Absorption Spectroscopy, the LyoFlux 200 allows for seamless scale-up from laboratory to production environments, maintaining aseptic conditions. Ideal for pharmaceutical manufacturers and biologics developers, it helps determine heat transfer coefficients without manual intervention. Designed to integrate smoothly into your processes, the LyoFlux 200 supports compliance with industry standards, ensuring high product quality through Quality by Design principles.

Benefits

- Enhances product quality by providing precise, real-time monitoring of lyophilization parameters.

- Reduces manual intervention and labor costs by streamlining data analysis through automated measurement.

- Maintains product sterility in aseptic production environments with non-invasive sensor technology.

- Simplifies scale-up from development to full-scale production, ensuring consistent batch quality.

- Supports regulatory compliance through accurate, continuous assessment of critical process parameters.

- Applications

- Biologics, Freeze-drying applications, Drug development, Life sciences, Pharmaceutical manufacturing, Pharmaceuticals

- End products

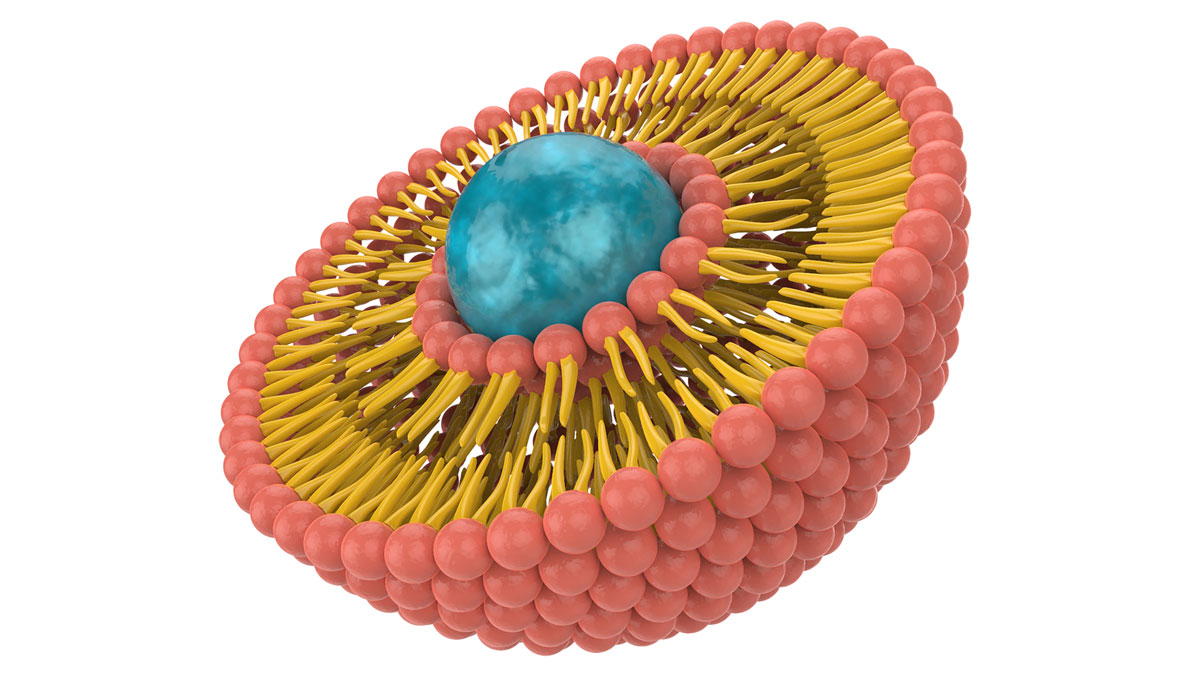

- Vaccines, Peptide drugs, Personalized medicine formulations, Monoclonal antibodies, Plasma derivatives, Enzyme preparations, Live attenuated microorganisms, Liposomal formulations, Protein therapeutics, Probiotics

- Steps before

- Formulation, Preparation, Solution mixing

- Steps after

- Sterilization, Packaging, Quality control

- Input ingredients

- water vapor, biologics, vials

- Output ingredients

- real-time monitoring data, product temperature, resistance to vapor flow, heat transfer coefficients (Kv)

- Market info

- SP Scientific is known for manufacturing high-quality freeze dryers, laboratory thermal control systems, and aseptic processing equipment, catering primarily to the pharmaceutical, biotech, and life sciences sectors with reputation for precision engineering and reliable performance.

- Sensor Type

- TDLAS (Tunable Diode Laser Absorption Spectroscopy)

- Measurement Range

- Water vapor mass flow

- Installation

- Compact

- Fits various sizes of freeze dryers

- Non-invasive Measurement

- Yes

- Application Scale

- Laboratory, Pilot, Production Scale

- Process Monitoring

- Real-time, Continuous Monitoring

- Heat Transfer Coefficient Measurement

- Yes

- Product Attribute Monitoring

- Temperature, Resistance

- Monitoring type

- Non-invasive

- Installation

- Simple and Compact

- Real-time monitoring

- Yes

- Automation level

- Continuous monitoring

- Application flexibility

- Laboratory to Production Scale

- Operation environment

- Aseptic

- Biological compatibility

- Aseptic / Sterile

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Non-invasive measurement

- Density/particle size

- Compatible with pharmaceutical forms

- Aseptic Environment

- Maintained

- Scale-Up Capability

- From laboratory to production scale

- Compact footprint

- Yes

- Discharge method

- Non-invasive

- Control panel type

- Compatible with various scales

- Installation flexibility

- Various freeze dryer sizes

- Integration capabilities

- PAT tool, near-infrared (NIR)

- Non-invasive measurement

- Yes

- Control panel type

- Not specified

- Compact footprint

- Yes