Let's make potato wedges

Find innovative production technology for making potato wedges and connect directly with world-leading specialists

They can be eaten with a sauce of choice, seasoned with various spices, even battered and deep-fried again, served for lunch or as bar food, but one is for sure - everyone is a fan of potato wedges! But how does a plain potato become a delicious wedge? Potato wedges are processed with the help of standard potato processing equipment and undergo processes of washing, peeling, slicing, and cooking.

Tell us about your production challenge

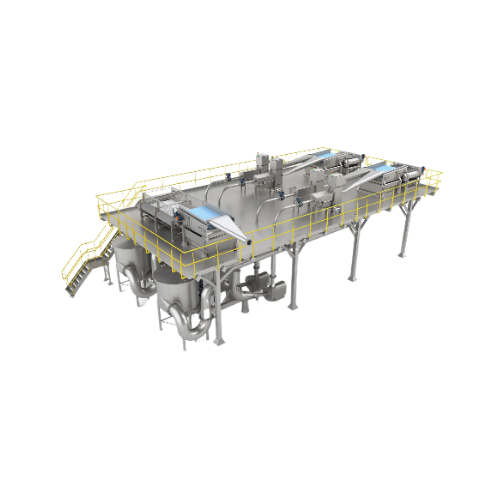

Industrial production and potato processing equipment

Potato processing is a large industry that caters to various end products, from chips over fries to wedges. Preparations and potato processing equipment in the early stages do not differ depending on the final product. Namely, once they reach the factory, potatoes must be washed from soil residues and debris before being peeled in a rotating drum with rough surfaces to remove the skin.

Peeled potatoes pass along a conveyor belt to be visually inspected and removed if substandard, and only the best quality potatoes are sliced in a potato wedges cutting machine to achieve the desired size and shape. The raw potato wedges are blanched, which plays a a vital role in color, texture, shortening find time, and enzyme inactivation.

The dried wedges are then seasoned as desired, for instance, with salt, pepper, paprika, garlic powder, etc., in a rotating flavor drum, as well as partially cooked before cooling and freezing at -18°C. Finally, the frozen wedges are bagged by an automatic food packing machine.

Deep-friend, air-fried, or baked? What is the choice?

Deep-fried food is always some of the most satisfying, comforting, and popular choices, and potato wedges are no different. The reasons why deep-fried food is so delicious are the sensual stimulation we feel due to its crunchy but melty texture, as well as the enhanced flavors and quick cooking time. While deep-frying results in a popularly crispy texture, air-frying, on the other hand, is a healthier alternative as it achieves similar results with significantly less oil. Since the method is based on hot air circulation, up to 400°C degrees, it requires less preheating time than a conventional oven.

Finally, baked wedges might be the healthiest option as oven baking tends to preserve nutrients and filter out the bad ones, in addition to requiring no oil at all. Prepared wedges are placed on baking trays before being inserted into large industrial ovens.

Times flies when potato fries: deep-frying as a cooking method

On large industrial-scale production, factories use continuous fryers that take in raw products from one side and take out the cooked product on the other, which then automatically moves onto the next production station. An adjustable conveyor belt transports pre-processed potatoes through the heated oil. In contrast, the scraper belt runs along the bottom of the fryer to take the submersed residues out, and a built-in slotted screen removes the floating debris from the oil. Ensuring clean and fresh oil is the key to a high-quality end product, therefore, adequate, frequent turnover time is also crucial. Thus, the cleaners, temperature, and internal oil circulation are always monitored and ensured. The best results are achieved by combining a high belt capacity and a high belt speed with a high but uniform oil temperature.

A healthier deep frying process? Yep, it’s possible!

Due to diet trends, food industries must find a way to make their beloved deep-fry products healthier. One option is to swap traditionally used oils with healthier and more environment-friendly alternatives such as rapeseed, cottonseed, and coconut oils. It is crucial to filter and change oil frequently to avoid burnt debris. Furthermore, the ideal oil temperature is between 176–190°C, as it cooks the potato’s surface instantly, preventing further penetration of fats. In addition, manufacturers use pre-processing as a way to minimize unhealthy fat absorption during deep-frying, such as blanching and hot washing or PEF (Pulsed Electric Field) technology to reduce sugar before frying. Moreover, alternative cooking methods such as multi-stage or vacuum frying that rely on low-temperature and low-pressure conditions are another possible solution for healthier deep-frying, as the low temperatures preserve heat-sensitive nutrients and oil does not breaks down into its carcinogenic components.

A new edge of potato wedge: innovations in the industry

Since wedges are a traditional, uncomplicated, and globally loved product, there is not much need for innovations in aspects other than taking advantage of technology to achieve as healthy a product as possible. One of the most interesting innovations in the potato processing industry is the aforementioned PEF technology, which can replace some food industry processes, such as blanching or pasteurization. Namely, PEF technology uses pulses of electricity to puncture cell membranes to extract water and sugar content which reduces acrylamide formation during cooking. It is a gentler process than blanching but achieves the same result: absorbing up to 50% less oil during deep frying. It also ensures more uniform cooking, color, and texture.

Processing steps involved in potato wedges making

Which potato wedges technology do you need?

Washer and peeler for carrots and potatoes

Enhance your food processing efficiency by integrating advanced solutions for w...

Accurate batching system for prepared foods

Streamline your food production with high-accuracy batching, minimizing rework...

Water reuse system for poultry plants

Optimize your water usage and reduce operating costs with an efficient system that re...

Vegetable and fruit cutting solution for slices, segments, and sticks

Streamline your pre-processing with a versatile c...

Industrial potato peeler for tuber vegetables

Streamline your vegetable processing with a machine that handles peeling and...

Stiffening system for meat products

Achieve uniform cooling and extend the shelf life of various food products with precisi...

Industrial thawing systems for meat products

Optimize your food production line with advanced thawing systems designed to ...

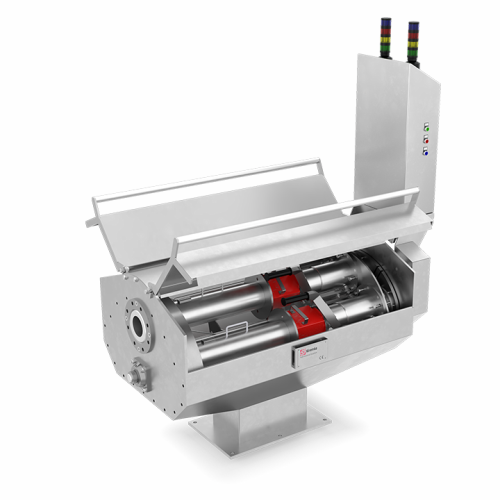

Industrial potato cutting system

Optimize your potato processing with precision slicing and cutting solutions designed for a...

Cyclone destoner for removing stones and clods

Ensure optimal pre-cleaning by removing stones and clods from potatoes effi...

French fry length grader

Efficiently sort and standardize your potato products by length, optimizing your french fry producti...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Automatic defect removal for french fries

Maximize yield and enhance quality in potato strip production with precision cut...

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Truck dumping system for unloading bulk potatoes

Optimize unloading with precision-tilted truck dumping, reducing product ...

Vertical screw elevator for potato processing

Efficiently elevate and separate your produce while minimizing space with ou...

Potato product surface oil removal system

Efficiently remove excess surface oil from fried potato products, enhancing prod...

Oil cooling module for industrial fryers

Quickly cool frying oil to prevent thermal shock and maintain oil quality, allowin...

Industrial oil mist eliminator

Optimize your frying operations with efficient oil mist control, minimizing emissions and vir...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Gentle-flo storage and handling system for fresh produce

Ensure gentle handling and precise control of fresh produce stor...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Crate dumper for potatoes and fresh produce

Ensure consistent produce flow with a robust hydraulic tilt system that stream...

Electroporation system for potato products

Optimize your potato and snack food production with an electroporation system t...

Batch peeler for potatoes and root vegetables

Optimize your vegetable processing with precise peeling and polishing, ensur...

Batter coating preparation system for potato products

Achieve consistent batter quality with a high-capacity, continuous ...

Cheese dicer for precision cuts

Streamline your cheese processing with unparalleled precision and versatility, ensuring clea...

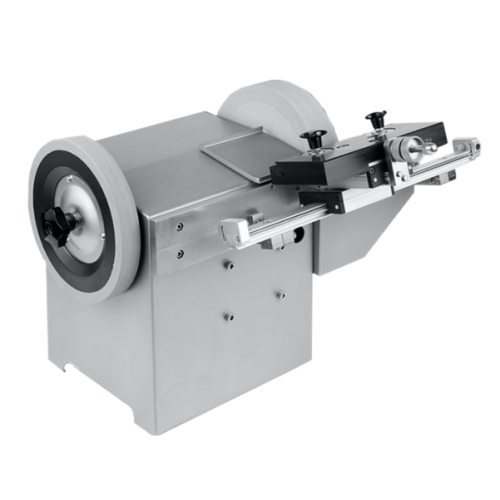

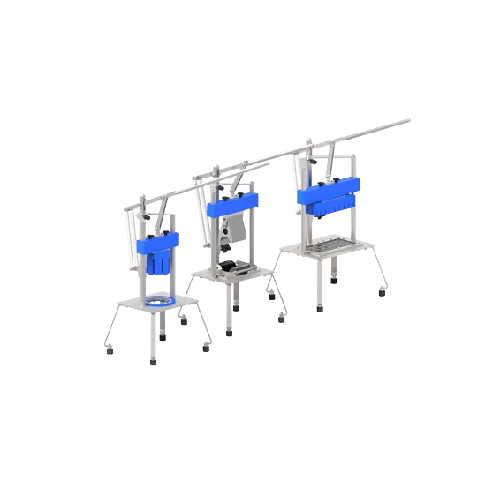

Knife honing equipment for industrial use

Enhance blade precision with minimal effort and cost, ensuring your cutting tool...

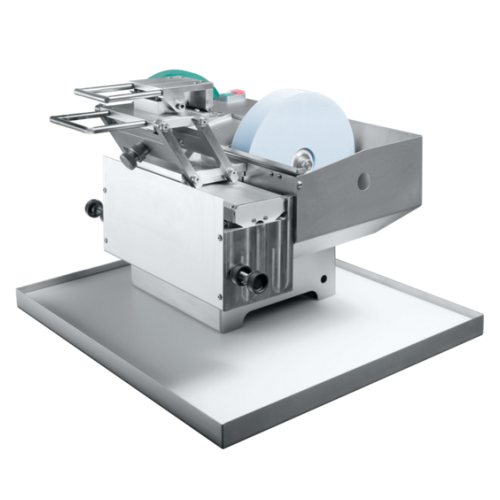

Honing tool for hydrocutting blades

Maintain the sharpness and precision of your hydrocutting blades effortlessly with this...

Potato slicer with dual rotation technology

Revolutionize your slicing process with dual rotation technology, ensuring gen...

High-capacity shredder for cheese processing

Achieve impeccable cut accuracy and consistent shred dimensions for high-volu...

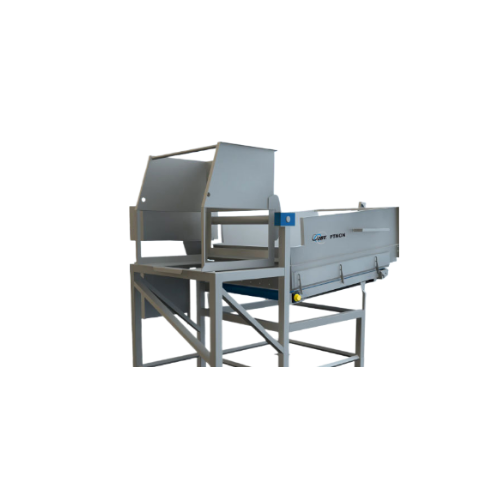

Ibc blancher with forced steam for vegetables

Optimize your blanching process with advanced steam control, reducing steam ...

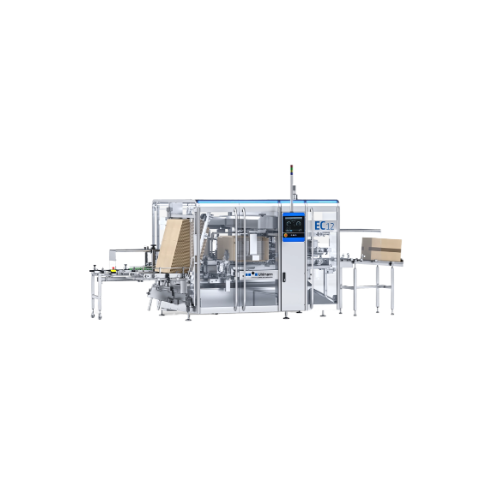

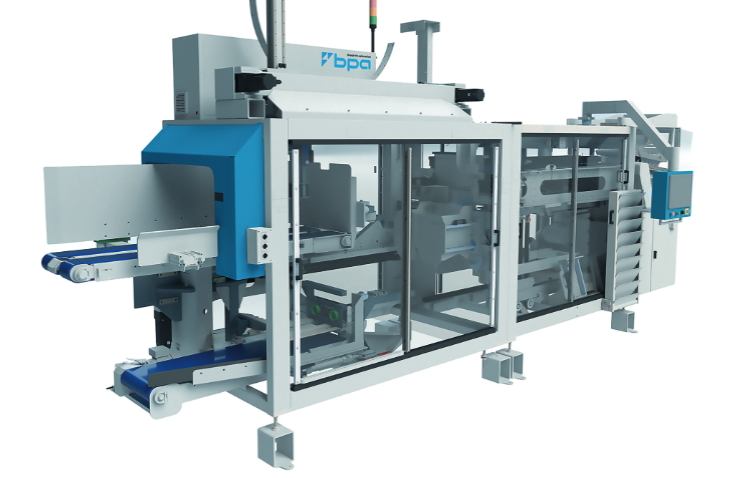

Automatic case packer for frozen potato products

Efficiently pack frozen and delicate products with precision side-loading...

Product in tote/crate washer for fresh produce

Enhance the cleanliness of your production line by ensuring that crates and...

Electric bin tipper system for food processing

Achieve consistent product flow and minimize manual handling with this adva...

Spiral oven for cooking and browning products with steam and hot air

Optimize your cooking line with a compact spiral o...

Fruit and vegetable shelf life extender

Extend the freshness and appeal of your produce with our innovative dipping solutio...

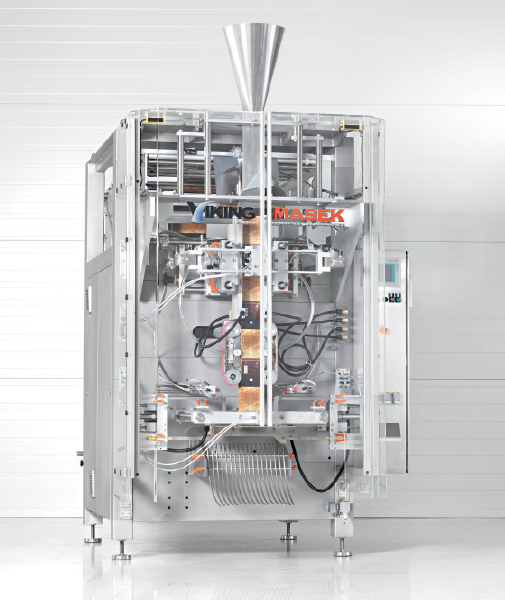

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

Industrial tunnel freezers for french fries

Ensure optimal freezing performance for high-capacity potato products, minimiz...

Segment cutter for potatoes and carrots

Achieve precise cuts on vegetables like carrots and potatoes with minimal featherin...

Potato cutting line for high-quality potato products

Achieve precise cuts and optimized yields in potato processing with ...

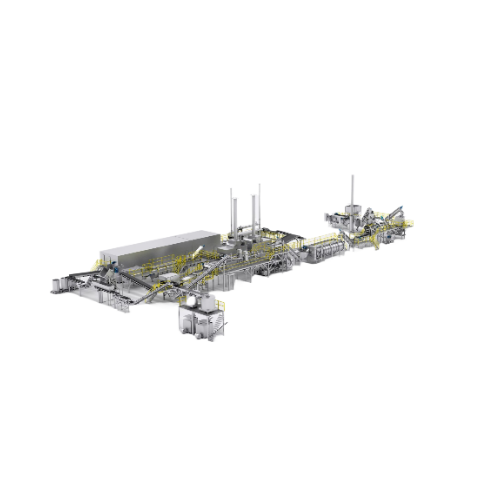

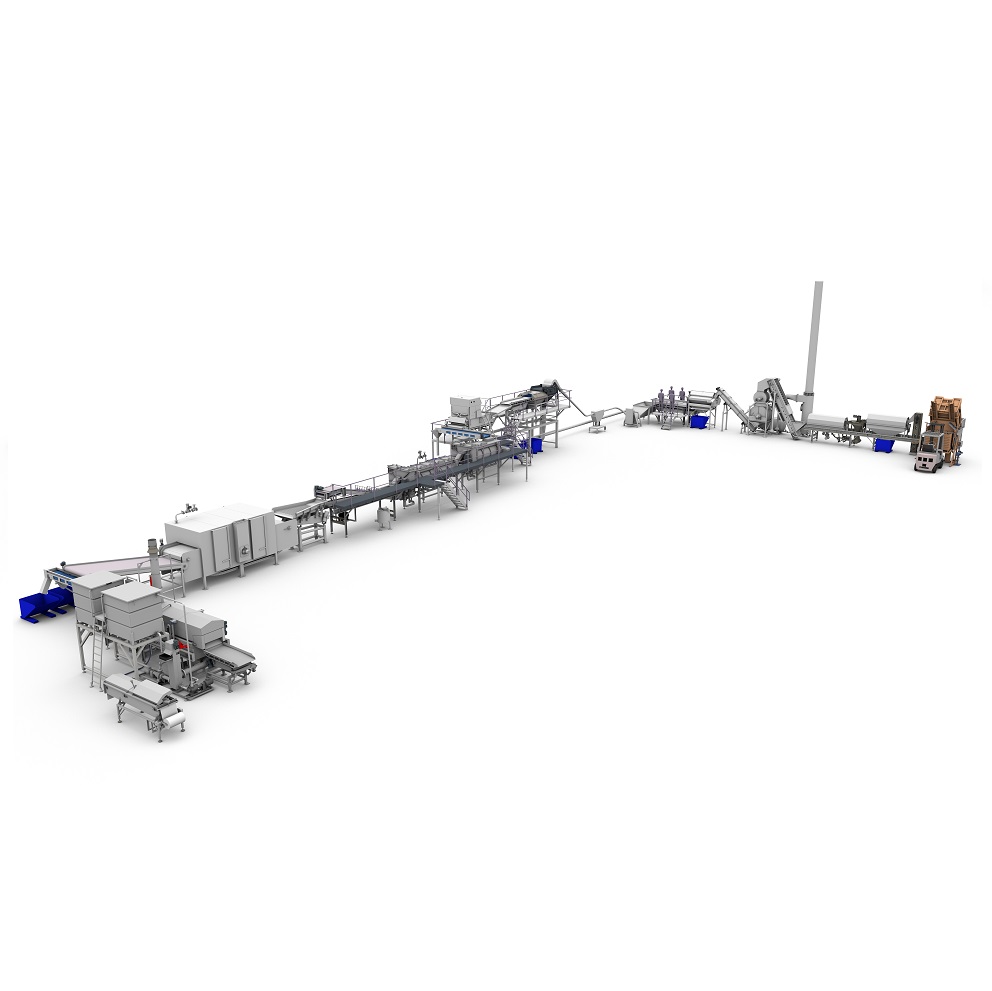

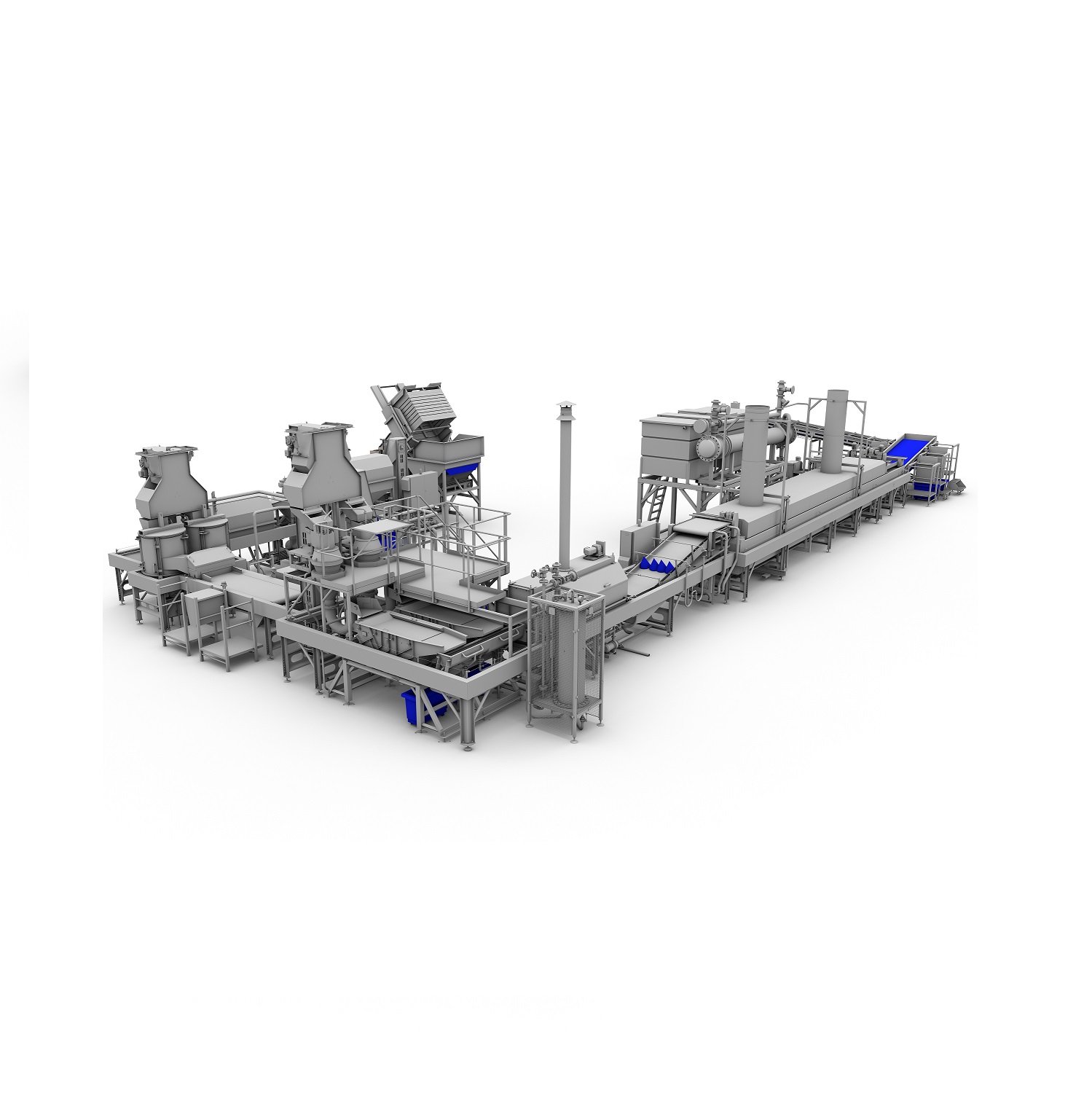

French fry production line

Optimize your French fry production with a seamless line that ensures precise cutting, consistent...

Pneumatic potato cutter for precise slicing

Achieve consistent and precise cuts for high-volume potato processing with pne...

Multi-function vegetable cutting machine

Effortlessly transform a variety of fruits and vegetables into precise shapes and ...

Fast chicken plucker for meat processing plants

Eliminate the manual hassle of poultry depilation and ensure pristine qual...

Wet bunker for potato buffering

Efficiently buffer and rinse pre-peeled potatoes and other potato products using a wet bunke...

Continuous roller peeler for root vegetables

Optimize peeling efficiency with precision-controlled roller systems engineer...

Semi-automatic fruit and vegetable slicer

Optimize your fruit and vegetable processing with precise cutting capabilities, ...

Spiral roller grader for peeled potatoes

Achieve precise size grading for peeled potatoes with a spiral roller system that ...

Manual slice and wedge cutter for fruits and vegetables

Achieve precise fruit and vegetable cuts with ease using a robust...

Potato halving and quartering solution

Enhance efficiency in potato processing with a machine engineered to precisely halve...

Potato halving system

Ensure precise halving of potatoes and root vegetables at high speed with seamless integration into you...

Energy recovery unit for potato chips production line

Manufacturers of French fries and potato chips require a lot of ene...

French fries processing line

Mass-producing french fries from raw potatoes requires a series of steps and various equipment ...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

Flavouring system for healthy rice cakes and snacks

Being active on the market for healthy popped snacks asks for a flexi...

Industrial washing machine for fruits and vegetables

The effective fruit and vegetables’ initial preparation for producti...

Potato chips production line

The key to making a flavorful and crispy bag of potato chips is the frying temperature within t...

Frozen food automatic case packer

Adequately packaged frozen fries retain their original color, taste, and texture. And bec...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Industrial potato washer

Washing potatoes or other vegetables can be a time consuming task for large restaurants or other foo...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...