Making Frozen Fruit

Find innovative production technology for making frozen fruit and connect directly with world-leading specialists

A juicy piece of fruit evokes images of sunlight and warmth. But manufacturers take the reverse route and freeze the harvested products to keep their nutritious mix of minerals, fibers, and vitamins intact. Frozen fruit processing equipment takes temperatures down to around -18 °C, giving the foods an extended lease of life. Many smoothies, jams, and purees we consume are the fruit of frozen labor.

Select your frozen fruit process

Tell us about your production challenge

Precool the materials before the fruit freezing process

Fruits are typically stored and delivered at ambient temperature or slightly refrigerated. To prepare the material for freezing, reduce the sensible heat of the foods. This energy is absorbed through direct sunlight or warm molecules in the air.

Precooling halts the post-harvesting deterioration and retains the water content of the fruit. Precooling methods depend on the sensitivity of the product. Forced air cooling, for example, adapts well to delicate foods like berries, while more robust fruits like citrus can sustain water cooling techniques.

Apply fast temperature reduction for frozen fruit processing equipment

When the products are subjected to supercooling, temperatures, drop gradually to freezing. Around this stage, the first change in phase starts occurring, and ice crystals form.

As fruits are processed through freezing technology, the molecules in the liquid content begin to collide and aggregate. This nucleation process affects the quality of the end product and depends on the freezing time. Fast freezing creates smaller ice crystals and distributes them more evenly. Conversely, a slow process leads to larger crystals that deform and puncture the cell membrane of the foods.

Peel and cut products before the freezing stage

Larger frozen fruits such as bananas or mangos are often shipped peeled and sliced. These activities, however, accelerate the degradation of products if performed after freezing and thawing.

Cut the items before freezing to retain their maximum nutritional and sensory properties. Peeling should also be done pre-freezing. To remove the skin, scald the fruits in hot water or lye solution or by steaming.

Pretreat fruits in syrup to prevent damage from ice crystals

Oxidation poses a significant challenge to the appearance and texture of frozen fruits. Soak the food in a sugar and water mixture before the precooling step. The sugars absorb moisture from the cells, reducing freezing within the membrane and protecting its structure.

The sugar ratio in the syrup ranges between 30% and 60%, depending on the natural sugar content in the fruit. For example, Kiwi, guava, and grapes require a lower sugar concentration than grapefruit, apples, and raspberries.

Processing steps involved in frozen fruit making

Which frozen fruit technology do you need?

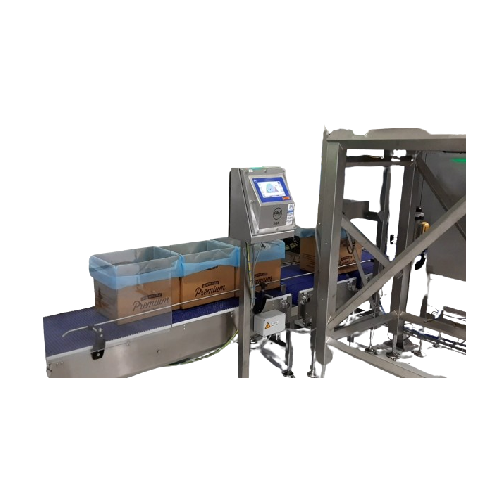

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

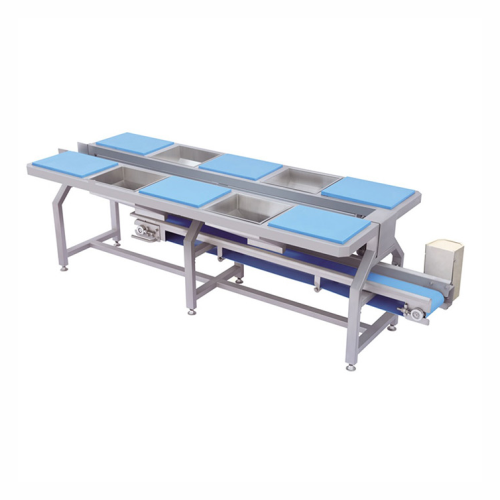

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

Vegetable and fruit cutting solution for slices, segments, and sticks

Streamline your pre-processing with a versatile c...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Optical sorter for food processing

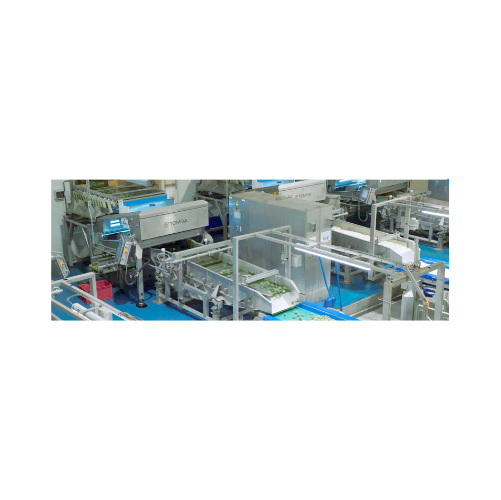

Enhance your production line with advanced sorting technology that meticulously inspects...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

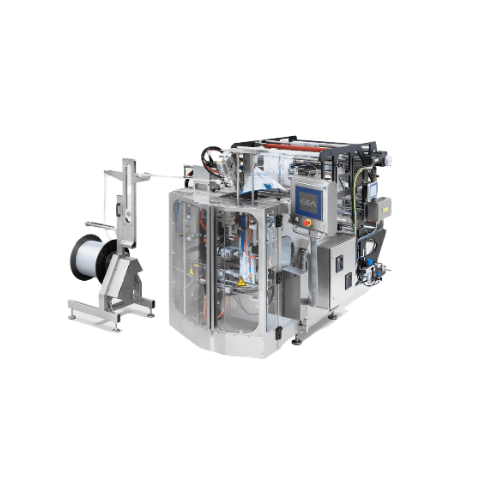

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

Food drying system for diverse products

Achieve precise moisture control and versatile drying for your diverse product line...

Extruded ice cream with large inclusions

Streamline your ice cream production with an innovative extrusion solution, allowi...

Flat-belt slicer for fruits and vegetables

Optimize your slicing process with a solution that delivers precision cuts whil...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

Large capacity cryogenic spiral freezer

Ensure consistent freezing quality and high yield in your continuous production lin...

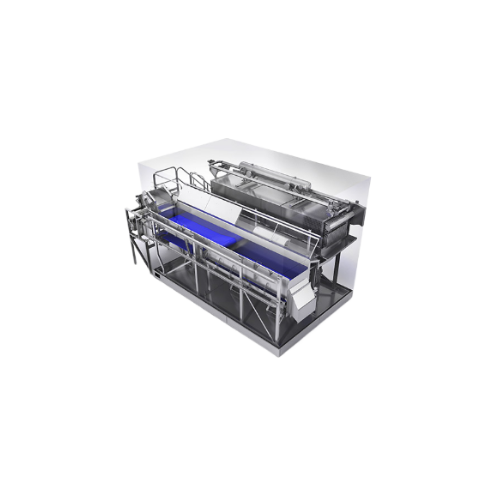

Fluidized bed freezer for fruits and vegetables

Efficiently freeze fruits and vegetables without clumping, thanks to advan...

Pre-cleaning system for Iqf berries

Ensure the purity of your IQF berries with advanced pre-cleaning technology that expert...

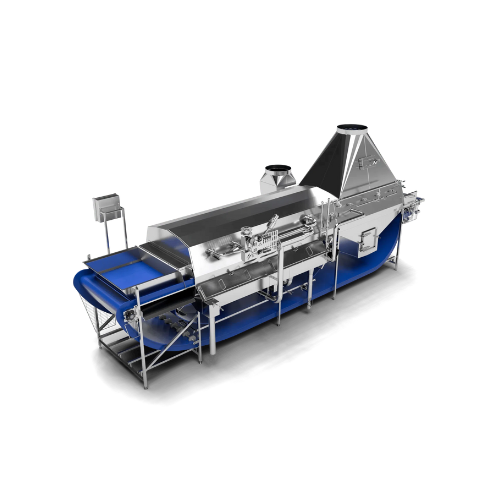

Evaporative blancher for fruits and vegetables

Achieve significant water savings and reduce wastewater generation in your ...

Fruit strigger for Iqf berries

When processing IQF berries, achieving precise stem and flower removal ensures superior quali...

Optical sorter for frozen fruit and vegetable processing

Enhance your processing line’s efficiency with high-speed ...

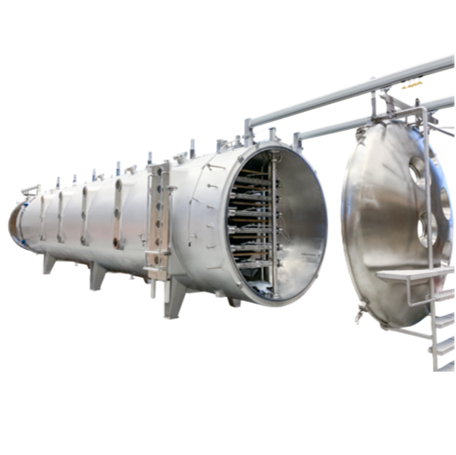

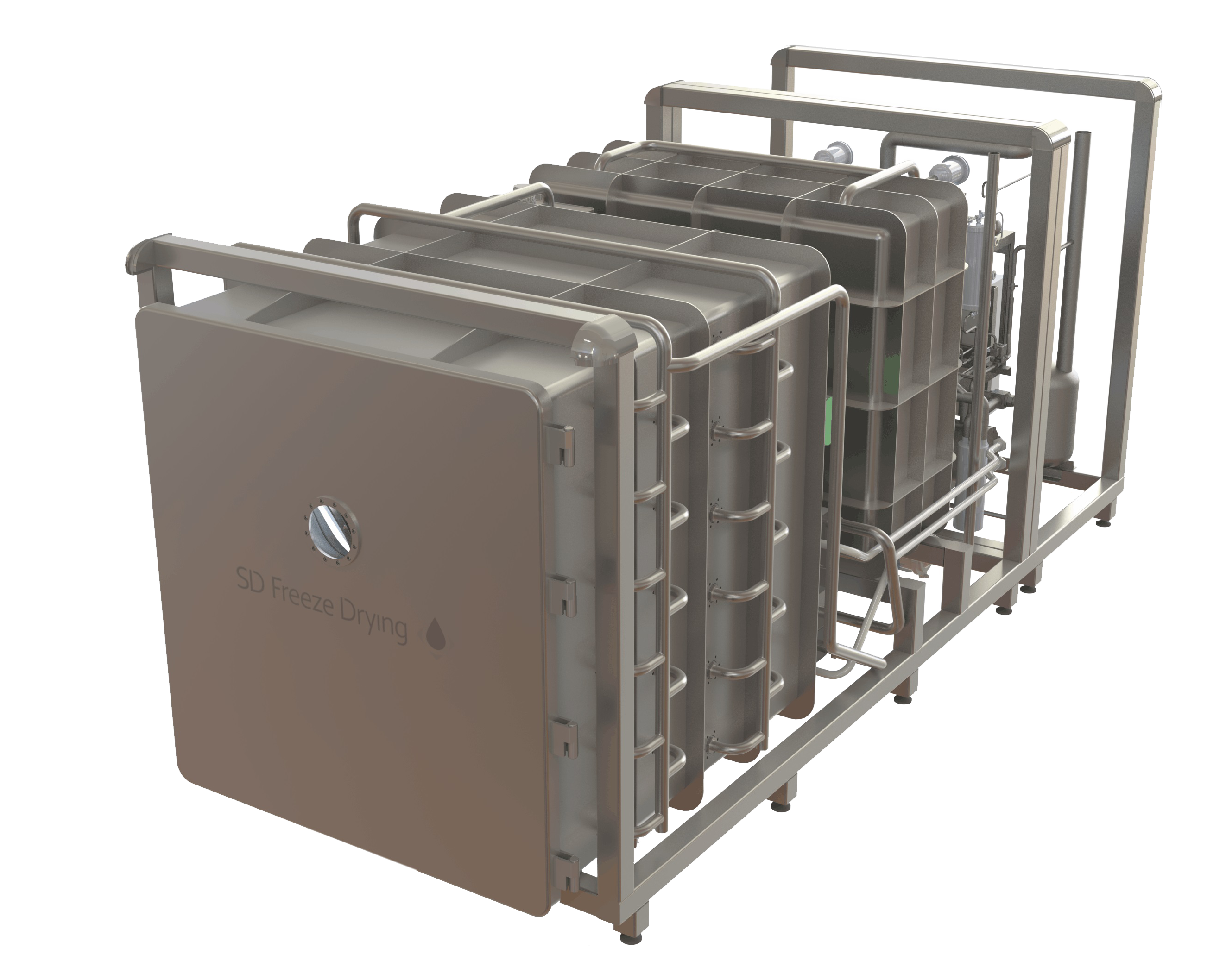

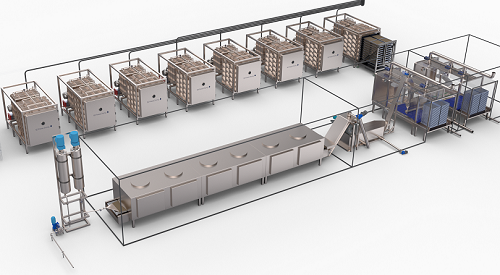

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products...

Frozen product cleaning and sizing system

Achieve precise cleaning and sizing of frozen goods effortlessly, enhancing prod...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

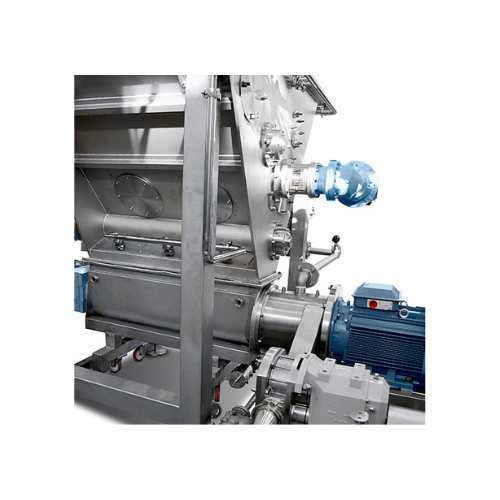

Continuous cooker for vegetables and fruits

Optimize your production line with a continuous cooker designed to defreeze an...

Shelling mill for Iqf and frozen fruit lumps

Effortlessly process frozen fruit and vegetable conglomerations into shelled ...

Shelling mill for Iqf and frozen lumps

Precision-engineered for the seamless transition from frozen state to process-ready ...

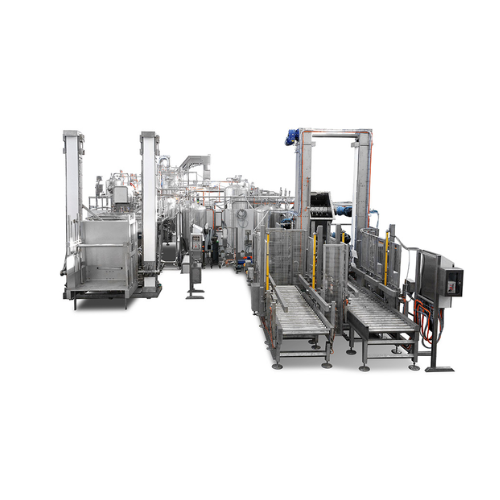

Smoothies production line for fruits and vegetables

Optimize your smoothie production with a line designed for efficient ...

Industrial liquefying and crunching solution for frozen fruits and vegetables

Efficiently transform frozen produce int...

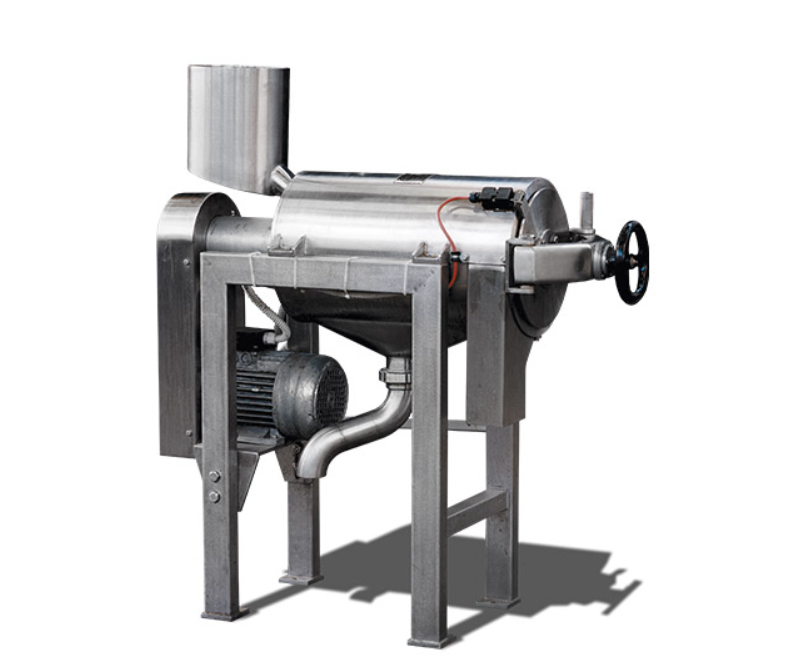

Frozen extraction turbo extractor for fruit and vegetable purees

Efficiently transform frozen fruits and vegetables into...

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expert...

Crunching and dosing solution for frozen fruits and vegetables

Streamline your processing line with a versatile system d...

Automatic top sealing for frozen food packaging

Streamline your food packaging operations with a top sealing machine desig...

Industrial bin scrubbing system for fresh produce

Enhance food safety and operational efficiency with a bin scrubbing sys...

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, o...

Iqf freezer for fruits and vegetables

Achieve perfect individual quick freezing with fluidization technology, ensuring deli...

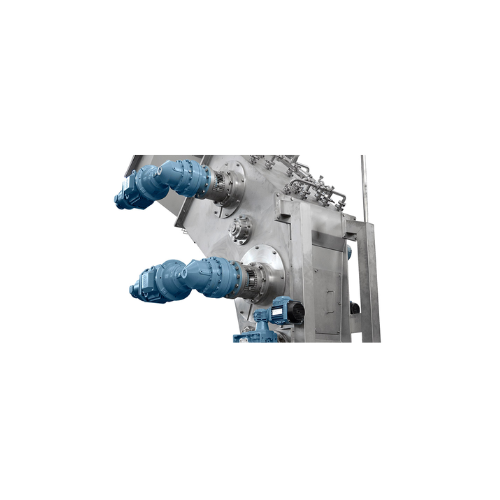

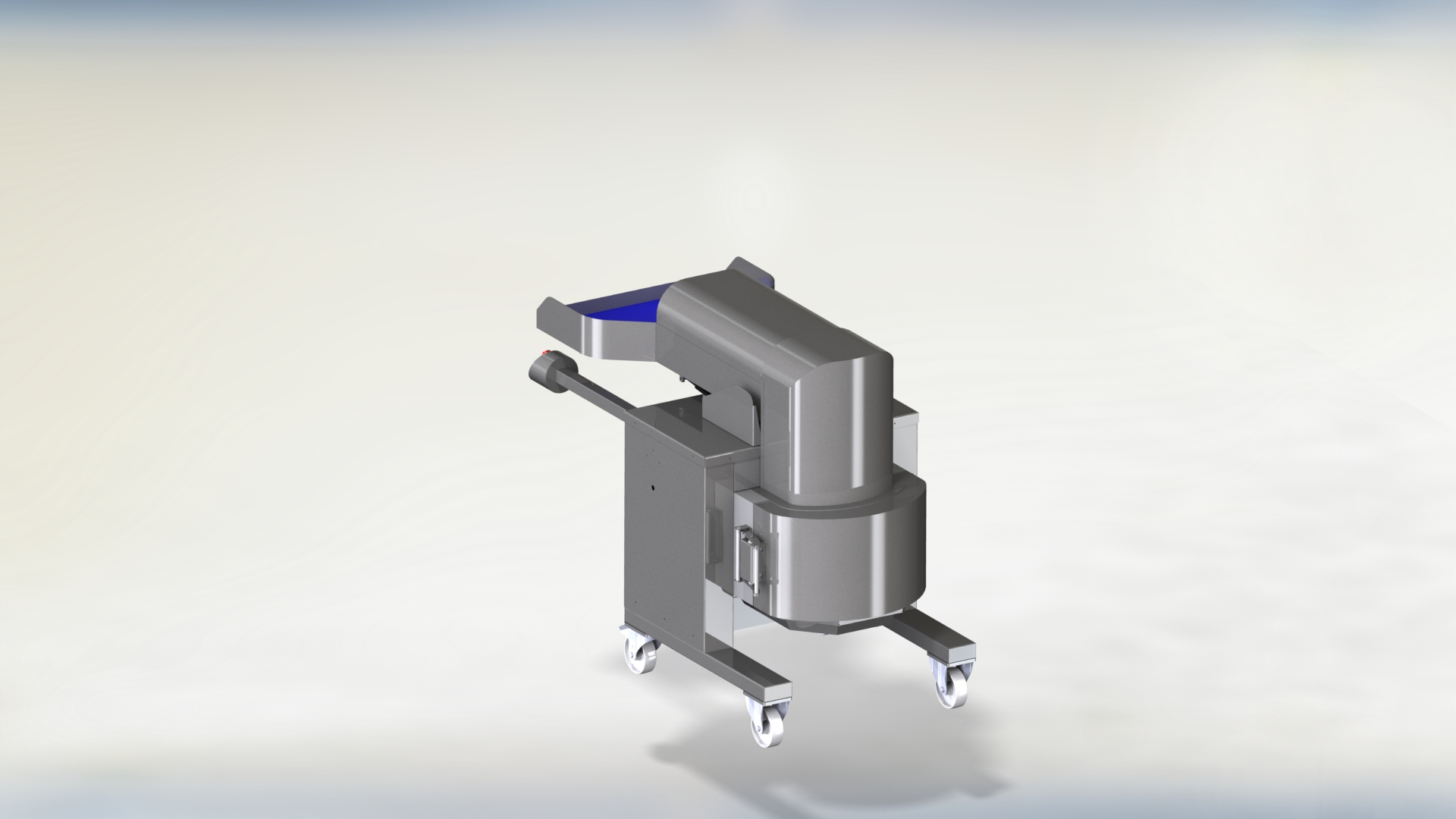

Industrial chopper/blender for frozen fruit processing

Efficiently transition frozen fruits and concentrates into a manag...

Industrial-scale chopper and blender for frozen juice processing

Eliminate lengthy thaw times for frozen concentrates wi...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

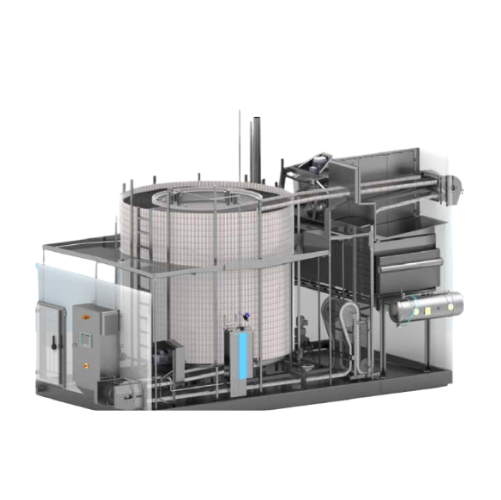

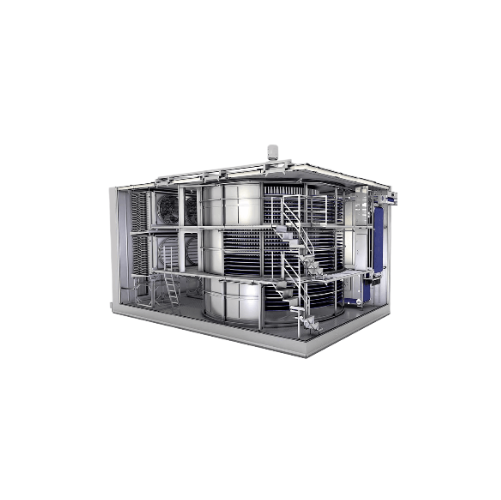

Customized spiral freezer solution for food industry

Designed to enhance your freezing efficiency, our spiral solution ha...

Frozen food products control system

Ensure optimal freezing precision with a system that continuously monitors product crys...

Iqf tunnel freezers for berries

Maximize product quality with advanced fluidization technology, ensuring consistent freezing...

Granulator for nut meats and cookies

Optimize your processing line with precision granulation, slitting, and scarifying of ...

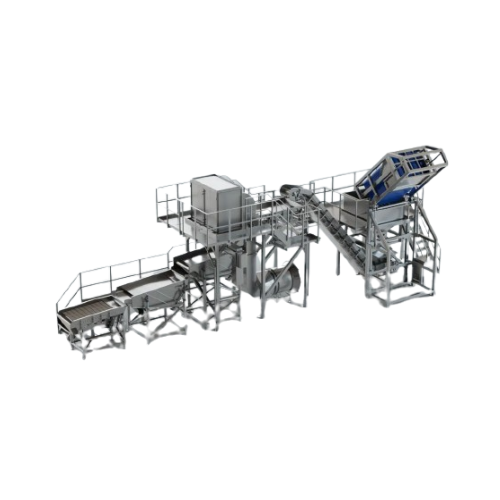

Acai berry processing line

Enhance your acai berry production efficiency with an automated line that transforms traditional ...

Slow masticating juicer for twin gear pressing

Effortlessly create nutrient-rich juices and culinary delights with precisi...

Blizzard sorter for Iqf fruits and vegetables

Optimize your frozen food production with a compact sorter that seamlessly r...

Twin product multihead weighing system for mixing and sorting

Optimize your production line with precision mixing and hi...

Vegetable and fruit air drying production line

Efficiently dry fruits, vegetables, and vacuum-packed goods while maintaini...

Semi-automatic fruit and vegetable slicer

Optimize your fruit and vegetable processing with precise cutting capabilities, ...

Washdown Cartoner For Frozen Foods

When packing frozen foods into cartons, your packaging system should be cleaned by wash-...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Entry-level vertical cartoner for frozen food

When it comes to frozen food, selecting quality packaging is fundamental for...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Declumping machine for dried fruit or frozen vegetables

Breaking up dried fruit neatly, without damage, requires gentle a...