Cheese Blocks

Find innovative production technology for making cheese blocks and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Technology picks for cheese blocks

Cheese block cutting solution for small to medium batches

Efficiently divide large cheese blocks into precise bars or po...

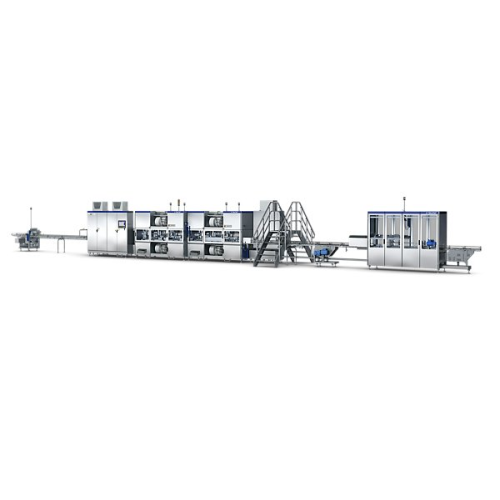

Cheese blockformer for dairy industry

Achieve consistent cheese block quality and seamless curd fusion through precision en...

Cheese cutting solution for large round cheeses and blocks

Efficiently segment and portion diverse cheese types, whether...

Block cutter for dividing cheese into bars

Effortlessly transform blocks of semi-hard cheese into uniform bars, ensuring o...

Tell us about your production challenge

Which cheese blocks technology do you need?

Stacked block mold tipping solution

Efficiently manage block molds with this tipping solution designed to streamline cheese...

Box weight checkweigher for bulk bag-in-box applications

Ensure precise weight control in bulk packaging lines with this ...

Mbs belt systems for seamless packaging integration

Optimize your packaging line with a system that seamlessly merges mul...

High-speed portion cutter with preforming option

Achieve precision and efficiency in portioning with high-speed cutting an...

Flake ice production system for direct ammonia refrigeration

Optimize your cooling processes with a highly efficient ice...

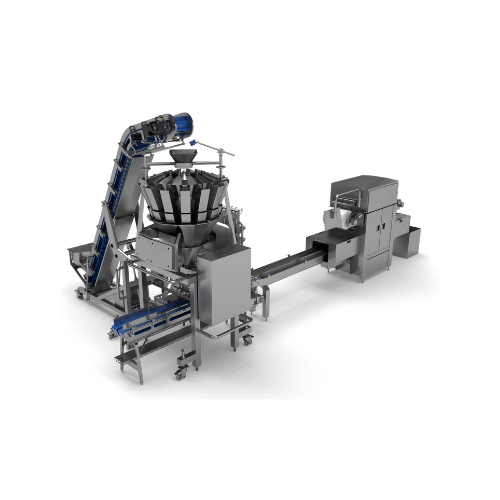

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

High-care food processing combination system with metal detection

Optimize your high-care food environment with a robus...

Cheese blockformer for dairy industry

Achieve consistent cheese block quality and seamless curd fusion through precision en...

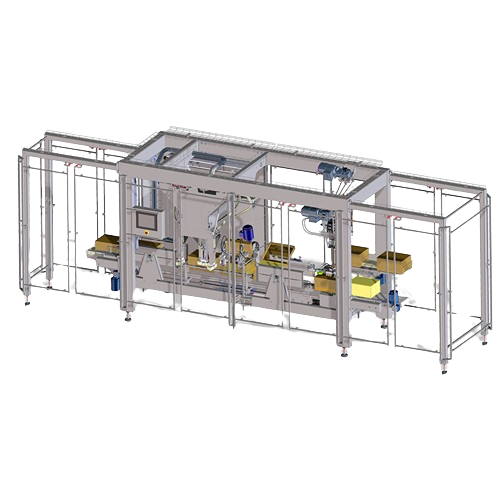

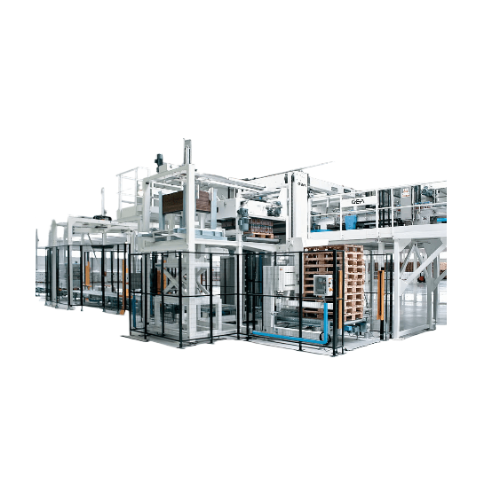

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

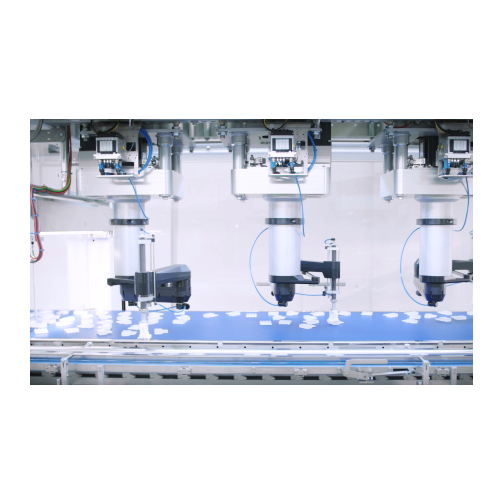

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

Vertical cheese portioning system

Achieve precise and customizable cheese portioning with a system that adapts to various s...

Cheese cubing solution for further processing

Optimize your cheese processing efficiency by transforming whole cheese bloc...

Square and rectangular cheese cutter for bars and halves

Perfect for cheese processors needing precision, this machine ef...

Fully automatic slicer feeder for cheese bars

Enhance your cheese processing efficiency with high-speed slicing and sortin...

Automatic slicer feeder for large cheeses

Streamline your cheese processing with a system designed to seamlessly transform...

Cheese portion cutting solution

Achieve precise weight-based portions for cheese products, enhancing product consistency and...

Cheese snack cutter for various shapes and sizes

Streamline your cheese production with precision cutting for a variety of...

Automatic cheese derinding system for rectangular cheeses

For cheese processors seeking effortless precision, this machi...

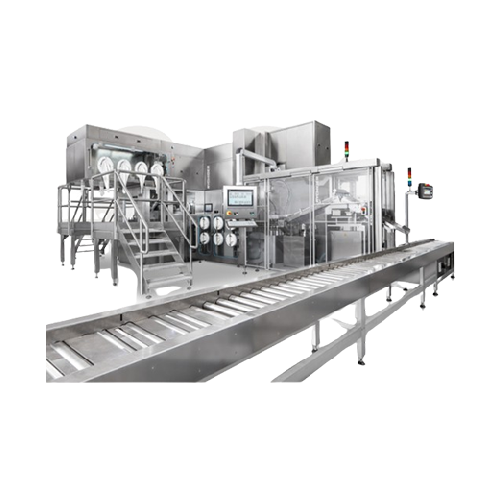

Automated cheese unpacking and cutting line

Streamline your cheese production process with a fully automated system capabl...

Inclined screw loader for food processing

Optimize your food processing line with an inclined screw loader, designed for e...

Robotic palletizer for material handling

Experience seamless and efficient palletizing with advanced robotic solutions desi...

High-speed weighing system for large batch sizes

Maximize yield and minimize waste with a high-speed batching solution des...

Optimization solution for weighing processes

Achieve precise weight compliance with minimal give-away using advanced monit...

Flexible weighing and packaging solution for small batch producers

Streamline your packaging line with a mobile solutio...

Vertical packing pattern case packer

Optimize your packaging efficiency with this high-speed case packer designed for seaml...

Wrap around case packer for horizontal and vertical packing patterns

Optimize your palletizing and distribution with a ...

Automated retail ready case closer

Optimize your retail packaging process with a solution that seamlessly seals and closes ...

High-speed vertical and horizontal case packer

Enhance your packaging line efficiency with a versatile case packing soluti...

Horizontal case packing and tray loading

Enhance your packaging line efficiency with a highly adaptive system that seamless...

Tray erecting system for various tray styles

Effortlessly configure diverse tray styles with an efficient system designed ...

Stainless steel molds for shaping meat products

Enhance product consistency and hygiene with custom-designed stainless ste...

Cheese cutting solution for large round cheeses and blocks

Efficiently segment and portion diverse cheese types, whether...

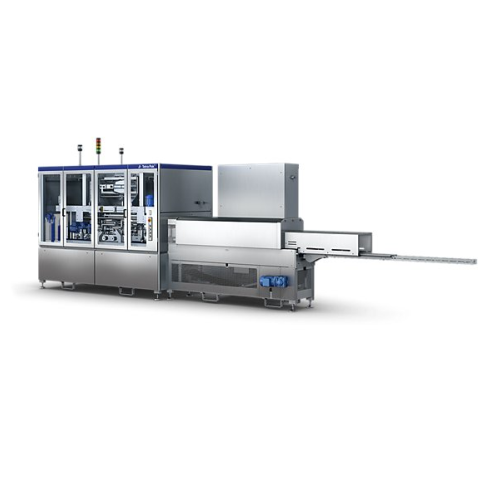

De-boxing system for cheddar blocks

Streamline your cheddar cheese production with efficient de-boxing, ensuring seamless i...

Hydraulic cutter for semi-hard cheese

Efficiently portion and cut semi-hard cheese and mozzarella into precise blocks, whee...

Hydraulic cheese cutter for round and block cheese

Optimize your cheese production with precise cutting for various chees...

Shrink-bag poultry bagger

Optimize your poultry and meat packaging with a high-speed bagger designed for precision and effic...

Industrial labeling system for precise product traceability

Enhance your production line with a state-of-the-art system ...

Vacuum packaging system for whole birds and meat products

Optimize your packaging line with this high-speed vacuum syste...

Industrial slicer for cooked ham and calibrated products

Achieve precision slicing and flexible portioning of meats and c...

3a certified product recovery system for food and pharmaceuticals

Optimize your production line with a system designed ...

Industrial depalletizer for high-speed operations

Optimize your production line efficiency with a high-speed depalletizin...

High level infeed palletizer system

Optimize your production line with a high-speed palletizing solution that seamlessly in...

Air-conditioning curing for raw sausage production

Enhance your meat processing line with precise climate management for ...

Industrial pressing system for convenience food

Optimize your production line with a versatile pressing system, designed t...

Stainless steel trolley for industrial use

Streamline material handling and storage in food processing operations with a v...

Steam cooker and stretcher for cheese production

Easily integrate versatile steam cooking and stretching to enhance your c...

Horizontal flow wrapper for vacuum packaging

Enhance your food packaging line with a solution designed for precision vacuu...

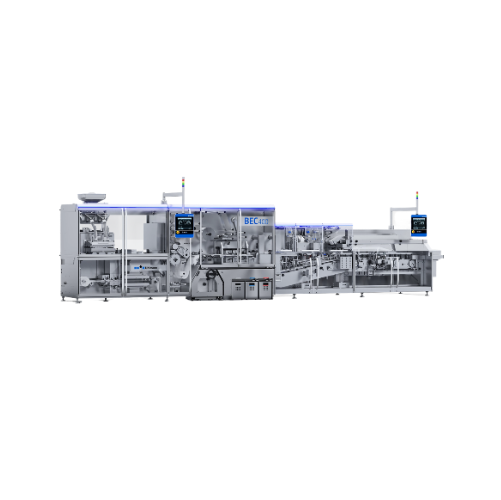

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Combined metal detector and checkweigher for food production

Ensure compliance and safety in food production with this i...

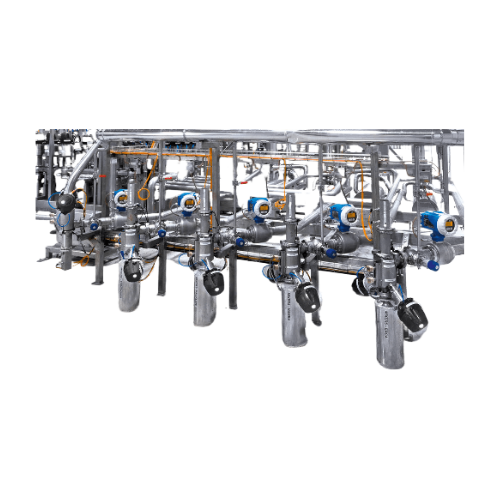

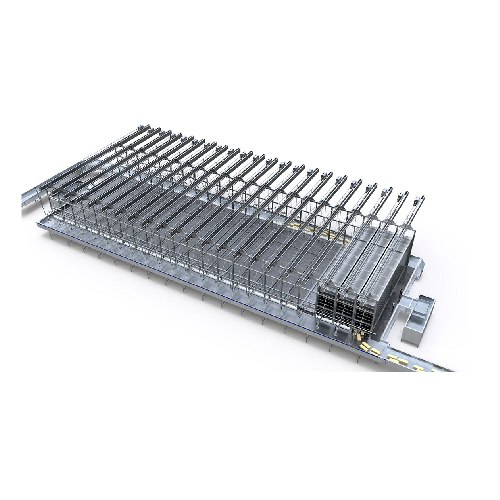

Efficient brining system for cheese production

Ensure precise temperature control and consistent quality in your cheese pr...

Filling solution for tetra brik® packages

Optimize your filling and packaging process with a system that seamlessly switch...

Vertical package accumulator for food and beverage production

Ensure seamless flow and precise order tracking of package...

Shrink wrapping system for flex portion packages

Optimize your packaging line with a high-speed shrink wrapping system des...

High-speed shrink wrapping system

Enhance your packaging efficiency with a high-speed shrink wrapping system that ensures s...

High-speed case packer for crates and boxes

Streamline high-speed packaging with advanced robotics, placing over 140 packs...

Automated production line for ground meat products

Enhance your meat processing efficiency by seamlessly integrating grin...

Compact carton packing solution for standardized tasks

Streamline your packaging workflow with a preconfigured solution d...

Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried...

Manual burger former for food production

Streamline your food product shaping process with manual precision, ensuring unifo...

Organized component storage for vacuum fillers

Prevent equipment damage and streamline cleaning operations with a storage ...

High-speed sausage production system with synchronized hanging

Enhance your high-speed sausage production with precision...

Portioner for ground meat production

Effortlessly streamline your high-volume meat processing with a versatile system desig...

Metal detection system for twisted sausages production

Ensure the safety of your twisted sausage production line by detec...