Making Synthetic Resins

Find innovative production technology for making synthetic resin and connect directly with world-leading specialists

Unlike natural resins, synthetic resins produced in the industry make up 30 to 60% of plastic composition. Silicone resins, gum arabic, epoxy resins, acrylic resin and carrageenan are some of the different types of synthetic resins that exist. You manufacture them using the chemical polymerization process. Synthetic resin making equipment can help you with that.

Select your synthetic resin process

Tell us about your production challenge

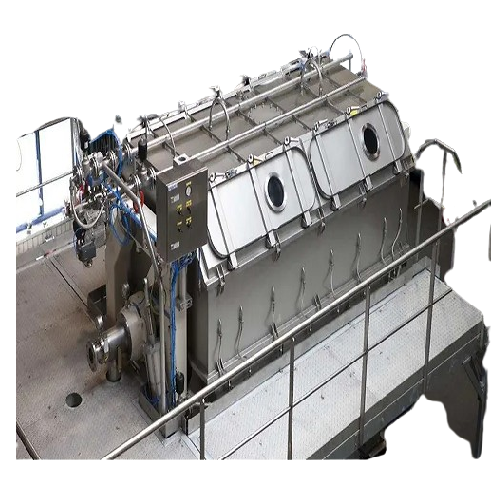

Automating chemical polymerization with synthetic resin making equipment

Even though some synthetic resins have the same physical features as natural resins, they are chemically different. You can produce them by polymerization process. To produce epoxy resins with synthetic resin making equipment, mix bisphenol A (BPA) and epichlorohydrin (ECH) to form an epoxy resin monomer. Then heat at 24-30 ºC (75.2 to 86 ºF) using a disc dryer, as it helps heat the mixture gently to give quality to the end-product.

Production of synthetic resin with a synthetic resin making machine involves different kinds of chemical reactions. You can use condensation polymerization process or addition polymerization depending on your product. The former produces larger molecules and releases water or methanol as a byproduct, in nylon production, for instance. The latter occurs in presence of a catalyst, such as ziegler-natta, and doesn’t form byproducts, such as in the production of acrylics.

From paint to roads: applications of synthetic resins

The plastic industry commonly uses synthetic resins. You can also use it to produce paint, polish and coating, paper, printing ink, leather, adhesive, and coatings, to mention a few. The construction industry uses resins to build roads and industrial floor coverings. For each product type, use different resin, depending on the different compounds they are made and their different functional groups. For example, acrylic resin can be thermosetting or thermoplastic; they have different functional groups and as such helps make different end products. Synthetic resin manufacturing equipment ensures processes’ repeatability.

The effect of heat on thermoplastics and thermosetting resins

Based on their reaction when exposed to heat, thermoplastic and thermo-setting resins act differently. The former softens when heated and hardens when it’s cool, while the latter retains its form when you apply heat. Thermoplastics are highly recyclable because they retain their chemical properties, unlike thermo-setting resins. Yet, thermosetting resins have strong structural integrity and greater heat resistance. A significant disadvantage of thermoplastic resin is that you can’t use it in certain industries because of its ability to readily melt when you apply heat. For example, you can’t make some heavy construction equipment and motor vehicle parts with thermoplastics. This is because the change in temperature alters the product.

The environmental impact of resins

Most natural resins are extracted from crude oil and the refining process is harmful to the environment and to human health. Most synthetic resins take time to biodegrade. To reduce the effect of these harmful chemicals, manufacturers are now using more environmental-friendly resins, such as eco-resin (plant based) and silicone resin. If you are looking for a nontoxic durable synthetic resin, consider using silicone resin. It has different manufacturing instructions and is used in coating, kitchen utensils, and woodworking, to name a few.

You can also use plaster of Paris and clear UV- glue for coating as sustainable options for resin. Have in mind that they don’t act like resin, though, as they have different drying times and conditions, as well as chemical and physical properties.

Processing steps involved in synthetic resin making

Which synthetic resin technology do you need?

Chub packer for resin bolt packages

Optimize high-speed packaging of liquid resin products with precise filling and wrappin...

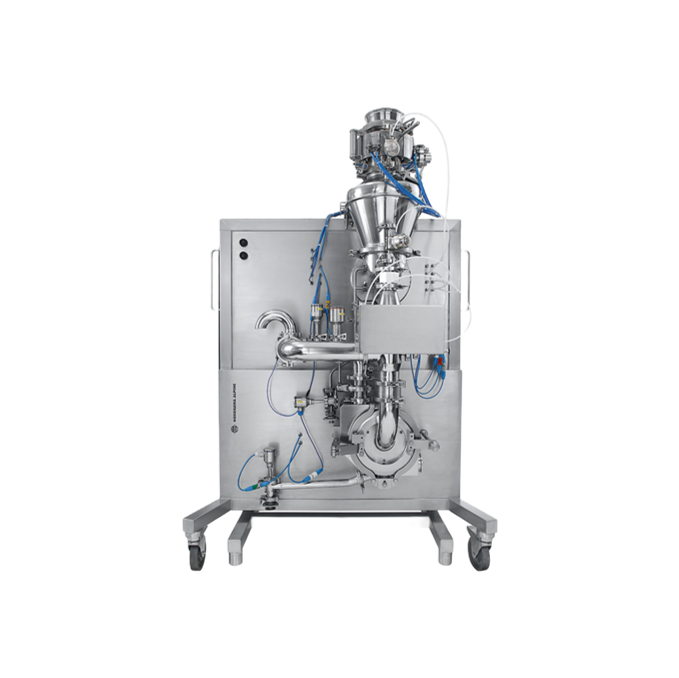

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

Laboratory mortar grinder for wet and dry grinding

Ensure precise blending of fine powders, pastes, and creams with contr...

Discontinuous screen changer for low viscosity melts

Optimize your filtration process with a discontinuous screen changer...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Solidification drum for chemical and pharmaceutical products

Convert molten materials into easily manageable flakes effi...

50l jacketed glass reactor for synthetic reactions

Achieve precise control over chemical reactions and material synthesis...

10l glass reactor system for synthetic reactions

Achieve consistent reaction control with efficient temperature and vacuum...

150l jacketed glass reactor for chemical synthesis

Achieve precise control over complex chemical processes with this sing...

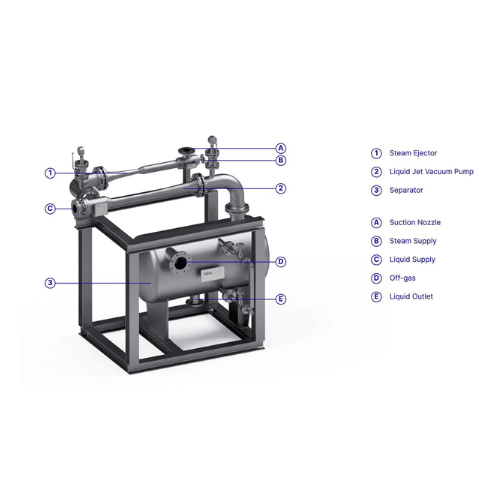

Steam jet liquid ejector vacuum system for chemical applications

Achieve reliable vacuum under challenging conditions wi...

Industrial refrigeration screw compressor

Maximize cooling efficiency and ensure precise temperature control in your opera...

Explosion protection vents for spray dryers

Optimize safety and hygiene in your spray drying operations with advanced expl...

Automated process controllers for industrial plants

Enhance your production line’s efficiency and adaptability with...

Storage silo with long base skirt for processing industry

Optimize your bulk material storage with a silo that offers du...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

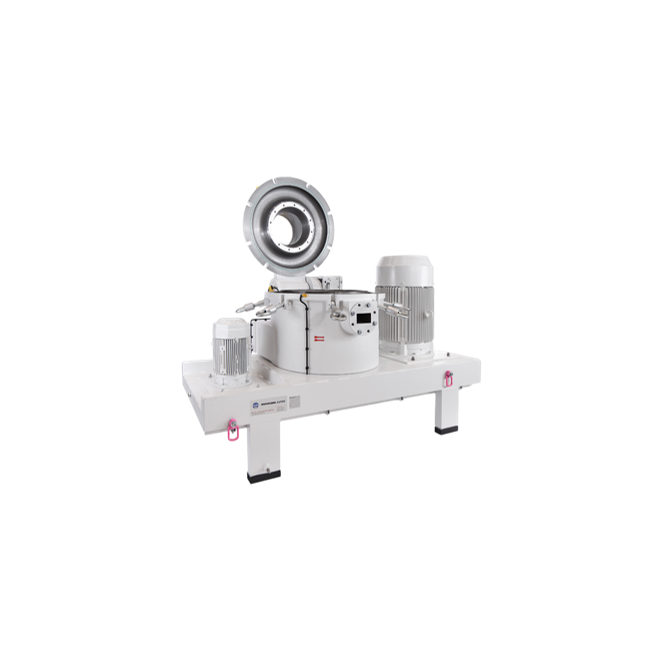

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Laboratory GMP cooler for hot melt extrusion

Pharmaceutical R&D and laboratory extrusion of viscous hot melt masses re...

GMP cooler for hot melt extrusion

Pharmaceutical production of extruded hot melt masses requires a GMP designed, FDA approv...

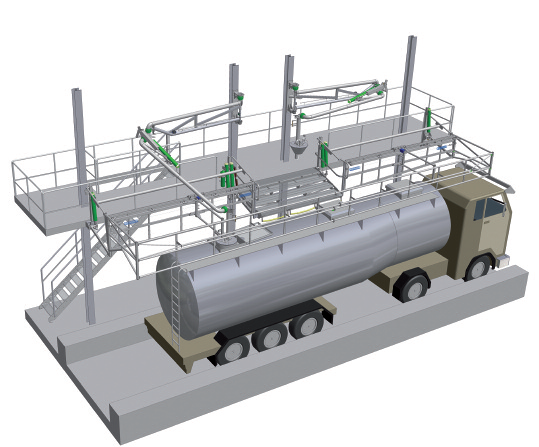

Top loading arm

Load or unload liquids from the top of the tanks safely and securely for trucks, railcars, small or big contai...

Folding stairs and safety cages

To ensure the safety of operator while working between a loading platform and road or rail t...

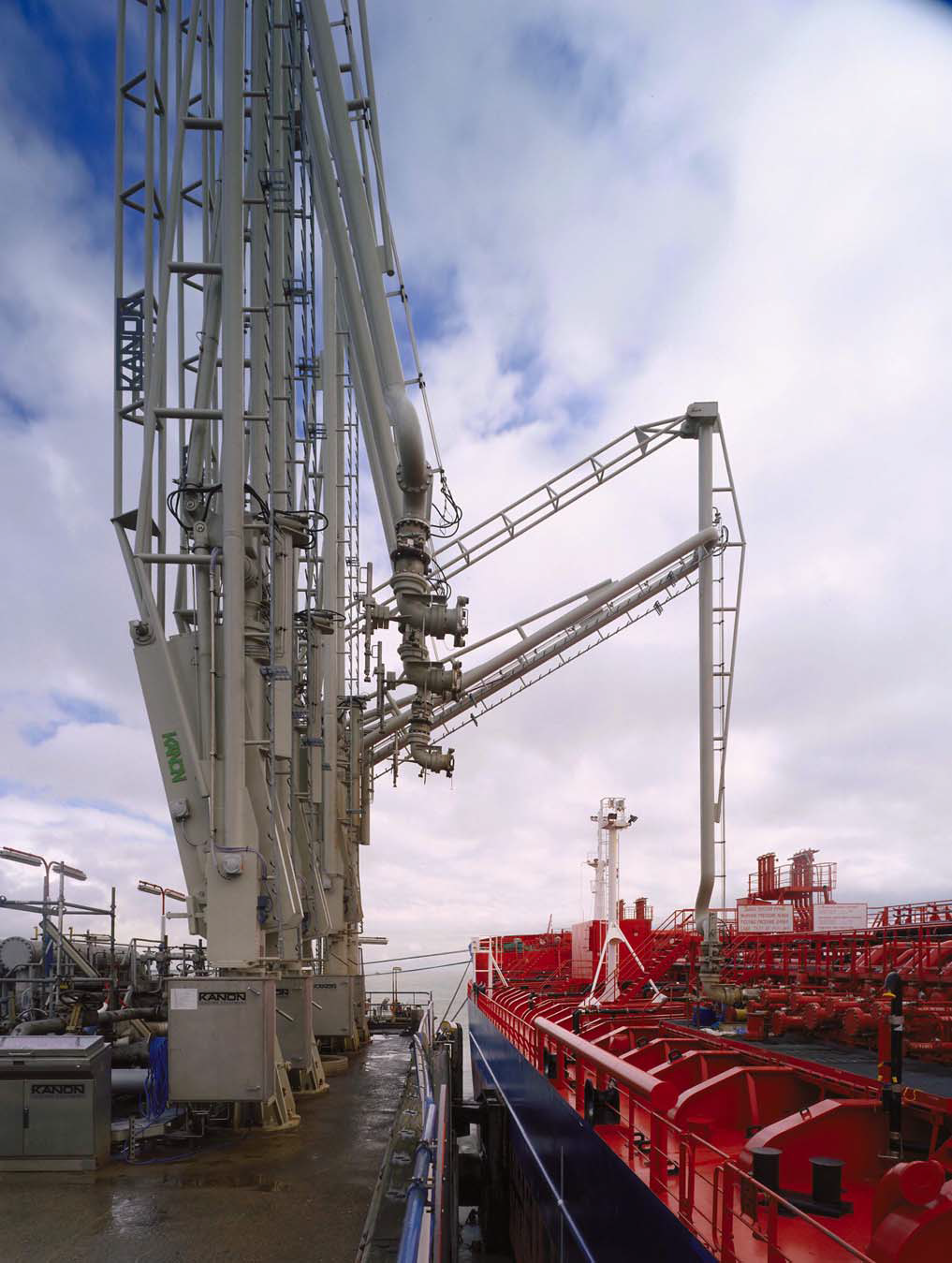

Marine loading arm

A hose or loading arm is needed when you load or unload fluids from a ship or transfer fluids between vess...

Bottom loading arm

Bottom loading/unloading arms are designed to be connected on the side or on the rear of the tanker and so...

Bagger for open mouth bags

Where a stand-alone bagger is required for filling large, open mouth bags, a delivery method is n...

Automatic bagging machine for open mouth bags

Open mouth bags allow for a variety of different products to be packaged, wi...

Special duty horizontal metering valve

Occasionally, there is no suitable standard valve available for a particular conveyi...

2-way diverter valves for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

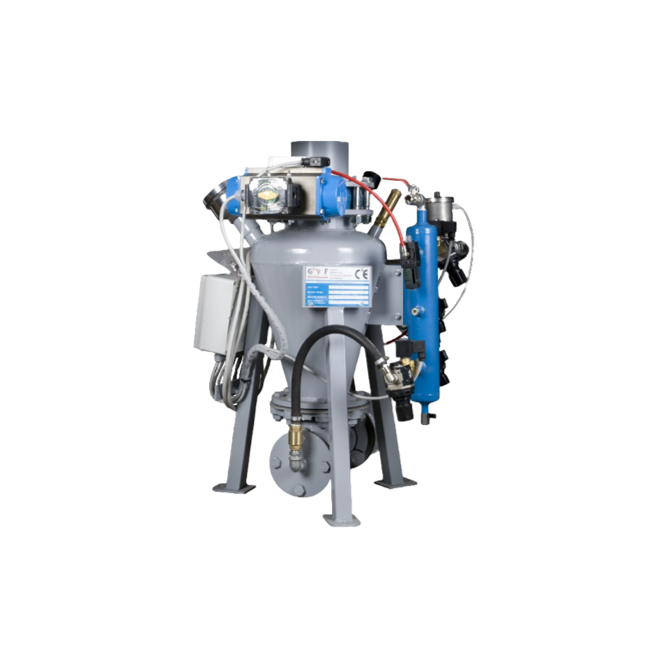

Dense phase conveyor for normal wearing materials

Dense phase pneumatic conveying is used for powders, granules, and grai...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

Hygienic open-mouth bottom-up baggers

Here are the open-mouth baggers that are specially designed for hygienic bagging of p...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....