Making Extruded Cereals

Find innovative production technology for making extruded cereal and connect directly with world-leading specialists

Children love them, and adults love them too. Extruded cereal is a typical ready-to-eat cereal with different flavors and shapes. You pour cold milk into a bowl of extruded cereal and eat them for breakfast or sometimes as a dessert. These shapes of cereals are refined by thermo-mechanical cereal extruder machines. Typically, extruded cereal can be categorized into three kinds: direct expanded cereal, co-extruded cereal, and extruded flakes. Depending on which kind of extruded cereal you are making among these three kinds, your choice of processing line will differ.

Select your extruded cereal process

Tell us about your production challenge

Manufacturing processes for direct expanded cereal, co-extruded cereal, and extruded flakes

As it is mentioned above, the cereal processing lines of three types of extruded cereal vary slightly. Firstly, direct expanded cereal – cereal in diverse shapes such as loops, curls, alphabets, and stars – starts out with an extrusion process. Once the batter for the extrusion is prepared, this dough is inserted into the extrusion machine. Using a twin-screw extrusion machine, the ax in the machine cuts the batter into the shape of choice. Heat and moisture are controlled within this machine, depending on the type of direct expanded cereal you are making. Once they are extruded, they go under the syrup coating system and drying process. As the end product, you will be able to make multigrain and fruit loops, bran sticks, alphabet cereal, cocoa balls and curls, cinnamon squares, and so on.

Co-extruded cereal processing line also starts out with an extruder machine, the same twin-screw extrusion machine that can be used for the direct expanded cereal. The machine creates the square-shaped pillows that are hollow in the middle. The special feature of co-extruded cereal is that inside square-shaped pillows, there is filling inserted in the center. To make this composition, the hollow pillows go through the filling process with cream feed and pillow crimper. These stuffed pillows then go into the dryer. At the end chocolate or cream-filled pillows, fruit-filled pillows, and stringy pillows.

Lastly, extruded flakes – such as extruded bran and wheat or corn flakes – are manufactured without any preparation of dough like the two kinds of cereal above. Flour or powdered form of grains or corn can directly go into the twin-screw extruder machine connected to a barrel. Here, in this machine, heating, cooling, mixing and shearing processes are conducted, and pellets are formed through this process. The pellets are now fed to the flaking roll to turn into flakes. Then, the flakes go into the toaster where extra moisture is removed and the color and the flavor of the flakes are improved. Depending on the preference, these flakes then go to the syrup coating machine, then drying and cooling processes are followed.

Benefits of twin-screw extrusion and extrusion process itself

The extrusion process is the essential process in making extruded cereal. But, what are the benefits of the extrusion process other than it can create diverse fun shapes of cereal? The extrusion process can improve the water binding and also accelerate its speed. Also, it enhances the taste and aroma of the cereal and provides better hygienic quality with a longer shelf-life.

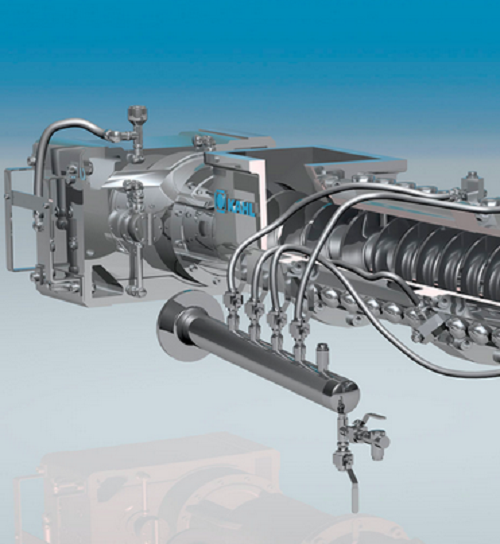

For this extrusion process, it is quite common to see twin screw extrusion machines being used. A twin-screw extrusion machine is a device with co-rotating two screws intermeshing simultaneously, eliminating inactive zones in the length of the process. Twin screw extrusion machine is often selected over single screw extruder due its ability to handle sticky, oily or highly wet ingredients. It is also easy to clean as it has a self-wiping feature, and it can be used for a wide range of ingredients of particle sizes – fine powder to grain.

More colors makes extruded cereal more fun! - coloring extruded cereals with natural colorings

You can’t deny that the colorfulness of extruded cereal makes them more fun than other cereals, besides their chocolatey, fruity, and sweet taste. How can you color these extruded cereals with natural colorings? First, you comprehend that the natural colorings are heat sensitive and the colors can change due to pH levels during the extrusion process. Also, the base color of cereal dough is never white, but rather yellowish or brownish color.

Keeping these in mind, you can explore all the natural coloring options. For instance, you can use coloring made out of turmeric to get bright yellow color, and you can use carrots (beta carotene) or a blend of vegetable juice for a bright orange shade. A reddish or dark purple can be attained from the anthocyanin fruit or vegetable extract. Beetroot juice is used for bluish or bright red, and paprika extract can make a reddish-orange hue.

Processing steps involved in extruded cereal making

Which extruded cereal technology do you need?

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

Single-screw cooking extruder for snack production

Optimize your snack production with a versatile extruder designed to h...

Cooling drum for seasoned extrudates

Ensure consistent texture and quality in your extruded snacks by effectively cooling s...

Seasoning drum for extruded snack products

Achieve consistent seasoning and mixing for extruded snacks with precision and ...

Seasoning mixing system for extruded snacks

Achieve consistent flavor profiles in your extruded snacks with this high-spee...

Laboratory twin screw extruder for small batch processing

Efficiently develop formulations and conduct precise research ...

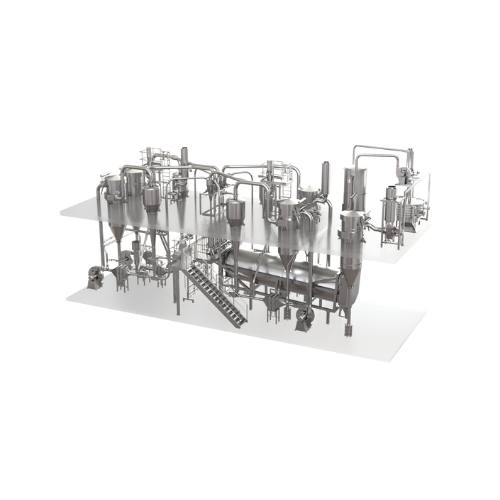

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

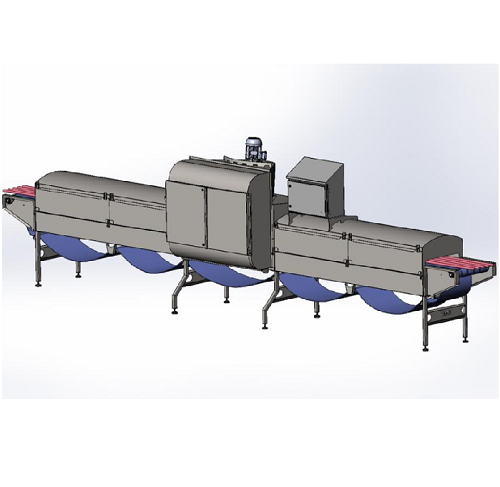

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

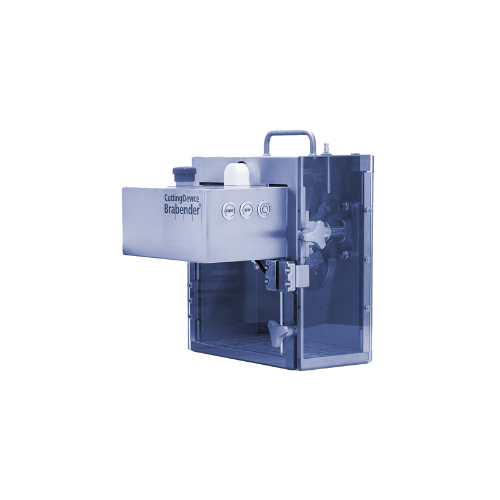

Laboratory cutting device for extrudates

For precise shaping of snack or feed extrudates, this compact cutting solution ens...

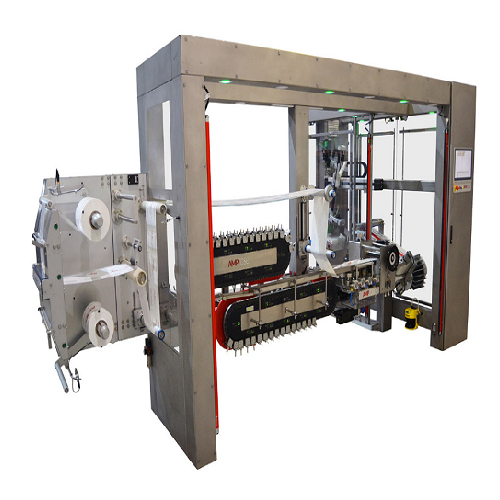

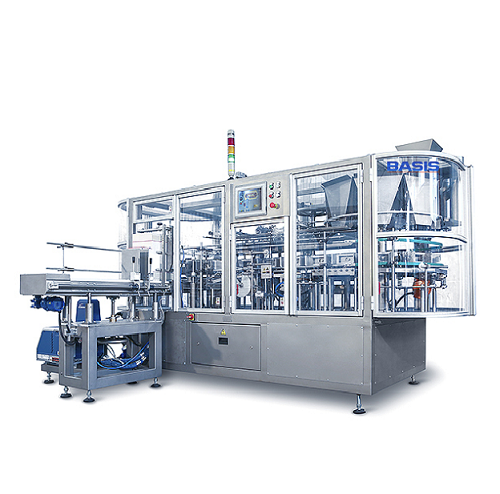

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

Forming extruders for flaked cereals

Optimize your production line with versatile forming extruders designed for precision ...

Hybrid laboratory extruders for reproducible scale-up applications

Easily switch between screw diameters to enhance fle...

Stuffing feeding device for extruders

Efficiently feed cohesive or lightweight powders into extruders to enhance product qu...

Cooling bath for efficient extrudate processing

Ensure optimal cooling for extrudates to maintain product integrity and en...

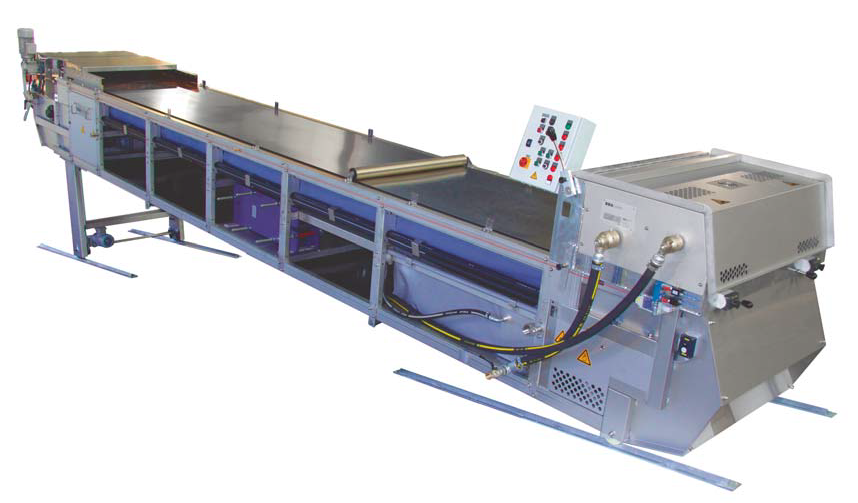

Conveyor belt laboratory for cooling extrudates

Achieve precise temperature control for high-temperature extrudates with a...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

Batch mixers for raw material preparation in extrusion processes

Optimize your extrusion process with precise raw materi...

Food product extruder for low to high capacity production

Optimize your snack production with versatile extruders that e...

Industrial guillotine machine for extruded foods

Textured vegetable proteins made from soy, wheat, and oats are extruded i...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Robotic case packing machine for snack bags

Automated packing with robotic suction arms can quickly pickup packaged produc...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Licorice cooling tunnel

Licorice and other extruded food products like vegan meats can be tricky to cool in the production pr...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

Continuous pellet cooler

Cooling is a very important and critical process for feed hygiene and pellet durability index. Pelle...

Gravity feed cooler

The food and feed industry has high food safety requirements making frequent cleaning and inspection nece...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Extruder for large-scale production of breakfast cereals

Shaped and filled extruded breakfast and snack products are extr...

Pilot extruder for cereals and snacks

Small batches of product using high value ingredients are not economical or practical...

Steel belt cooler for hot melt extrusion

For producing high volumes of extruded hot melt product a flexible, high capacity ...

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...