Extruded cereals cooling Equipment

Find innovative extruded cereals cooling equipment and connect directly with world-leading technology suppliers

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Which extruded cereals cooling technology do you need?

Cooling drum for seasoned extrudates

Ensure consistent texture and quality in your extruded snacks by effectively cooling s...

Cooling bath for efficient extrudate processing

Ensure optimal cooling for extrudates to maintain product integrity and en...

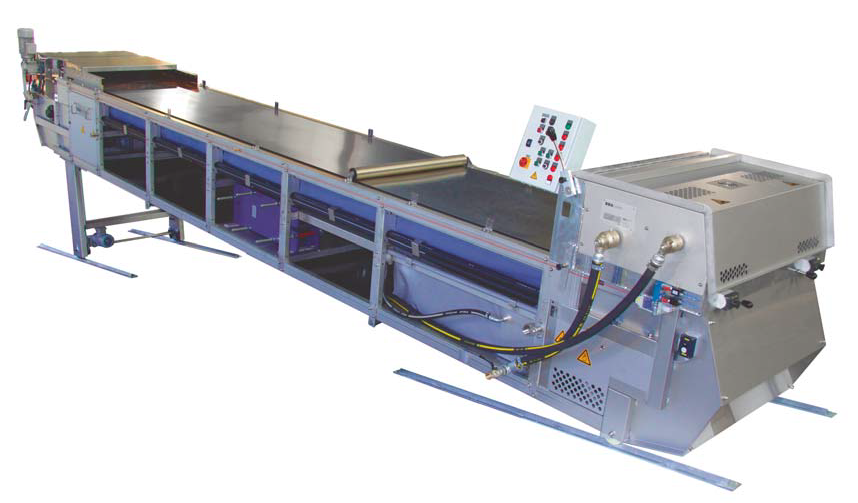

Conveyor belt laboratory for cooling extrudates

Achieve precise temperature control for high-temperature extrudates with a...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

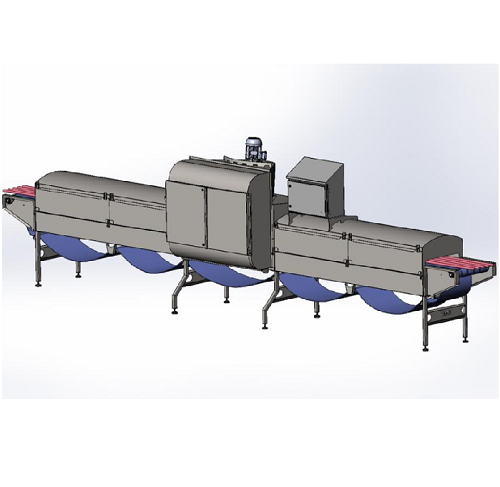

Licorice cooling tunnel

Licorice and other extruded food products like vegan meats can be tricky to cool in the production pr...

Continuous pellet cooler

Cooling is a very important and critical process for feed hygiene and pellet durability index. Pelle...

Gravity feed cooler

The food and feed industry has high food safety requirements making frequent cleaning and inspection nece...

Steel belt cooler for hot melt extrusion

For producing high volumes of extruded hot melt product a flexible, high capacity ...

Single-screw cooking extruder for snack production

Optimize your snack production with a versatile extruder designed to h...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Forming extruders for flaked cereals

Optimize your production line with versatile forming extruders designed for precision ...

Hybrid laboratory extruders for reproducible scale-up applications

Easily switch between screw diameters to enhance fle...