Making Canned Tuna

Find innovative production technology for making canned tuna and connect directly with world-leading specialists

Canned tuna, a staple in millions of kitchens around the world, was first manufactured in 1904 by Albert P. Halfhill in California. It has since become a reliable source of protein and omega-3 fatty acids for people around the world. Canned tuna production process consists of multiple stages including thawing, cutting, steaming, deboning and sterilizing, all of which ensure the product quality and long shelf life.

Technology picks for tuna production

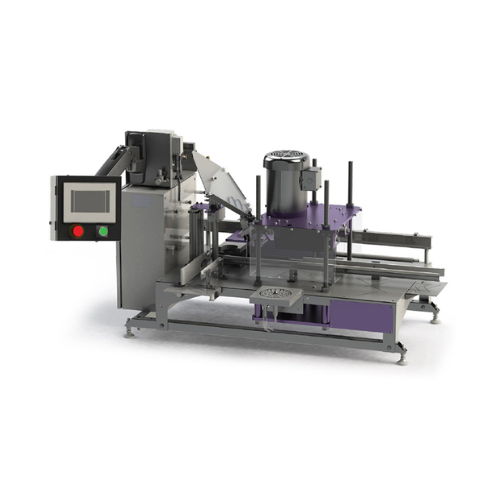

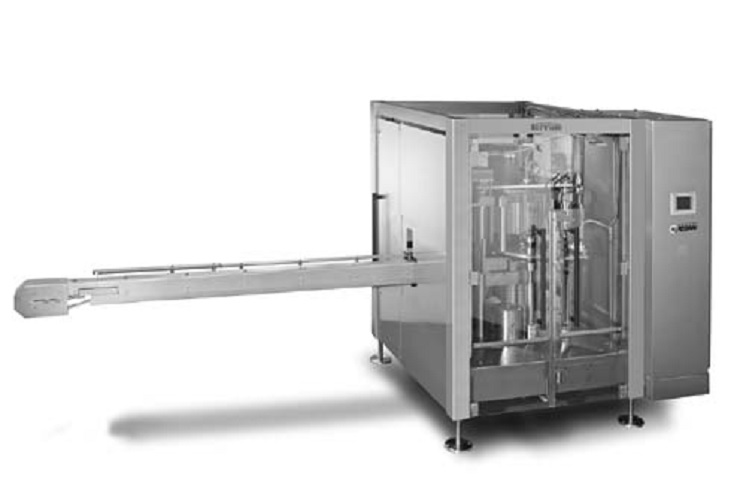

Automatic tuna can filler

Streamline your high-speed canning operations with precision-engineered fillers that maintain opti...

Tuna precooking optimization software

Optimize your tuna precooking process to maximize yield and enhance product quality b...

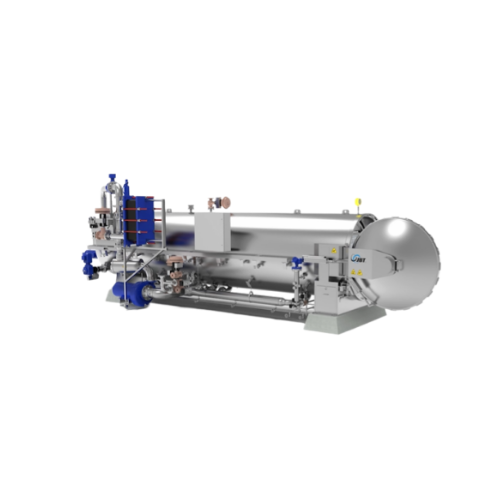

Tuna vacuum pre-cooker cooler

Optimize your tuna and seafood processing with precise thawing, cooking, and cooling under vac...

Can seamer for food products

Flexible can seaming equipment is required to adapt for product-specific variations in food can...

Tell us about your production challenge

The basics of canned tuna production process – which tuna is used for canning?

Although five different tuna species are used for commercial purposes, only three are used for canning- skipjack, yellowfin, and albacore. The canned tuna classified as light meat tuna comes from skipjack and yellowfin, while white meat tuna comes from albacore. The two differ in omega-3 content, color and taste. Light meat tuna is darker, lower in fat and omega-3s and more flavorful, while white meat tuna is lighter, with a firmer texture and high in omega-3 fatty acids.

The canned tuna production process begins with the frozen tuna arriving from the fisheries at the processing plant. There, the tuna is thawed in large water tanks, sized and sorted to minimize the weight loss from overcooking. The sorted tuna is then cut and subsequently steamed in large pressure-cooking chambers. This initial pre-cooking removes excess oils and makes it easier to separate the fillets from the rest of the meat.

Canning and sterilizing tuna: the crucial steps

After the initial steaming, the meat is cooled down and deboned, separating the loins from the bones and the skin. Then, the meat is transferred into cans by a filling machine. Manufacturers can add salt, water, oil, or marinade to the can, then hermetically sealed.

The filled cans are then cooked and sterilized at a temperature of 121°C for 20 minutes to eliminate harmful microorganisms but still retain tuna’s nutrients.

Sterilization is crucial for canned tuna production. Canned tuna is a low acid food, which supports the growth of microorganisms such as Clostridium botulinum. Clostridium botulinum is found in the intestines of fish, animals, birds, insects and the soil.

Being a heat-tolerant microorganism, it can produce a neurotoxin if the canned fish is underprocessed. Spores, if present in unprocessed canned tuna or if they enter the can after processing, can create issues. The processing time depends on the can size.

Mercury in canned tuna - How much of it is allowed?

Another hazard with seafood consumption is mercury poisoning. Mercury is naturally present in seafood, most often in sharks, swordfish, bluefin, and albacore tuna. Of the two tuna species used for canning, albacore contains more mercury than skipjack due to its larger size; however, both species are considered to have low mercury content.

Canned white albacore tuna typically contains about 0.32 parts per million of mercury. Canned light tuna contains about 0.12 parts per million of mercury. The FDA and the EU allow products that contain 1 part of mercury per million, and have recommended intakes of tuna for children and adults.

Environmental impact of tuna production process

With the increasing public outcry for environmentalist policies and practices, the canned tuna production process has adapted well. A study by The Environmental Working Group determined that canned tuna production produces 6.1 kg of CO2 a day, which is lower than any other meat industry. Most of the produced carbon, 68% total, comes from the fuel used for fishing, while the rest is attributed to subsequent transportation, factory processing and storing.

The way tuna is fished also contributes to the industry’s carbon footprint. With purse seine fishing, the fisheries use a cylindrical net that surrounds a school of tuna and closes the bottom. Purse seine fishing has the lowest carbon footprint per kilogram of caught fish. This fishing technique’s efficiency could potentially lower the number of fishing boats and the fuel needed to support larger fleets.

Tuna waste repurposed: byproduct to pet food

To reduce waste, tuna canning industry repurposes the remaining byproduct. The cannery produces 50 to 70% of solid waste after tuna processing, including heads, guts, gills, red tuna meat, and bones that must be discarded or repurposed.

Only white tuna meat, or loins, is used for human consumption and the remaining red meat is separated and used for animal or pet food. Sometimes, even the other discarded parts of tuna, such as the skin, fat, and organs, are added to pet food, which is especially beneficial for cats in moderation as it is a source of protein, omega-3s, and low-carb.

Moreover, the leftover meat, bones and skin from the tuna canning process can be used to produce fish oil, fish meal, gelatin and fertilizer, which significantly minimizes the amount of waste.

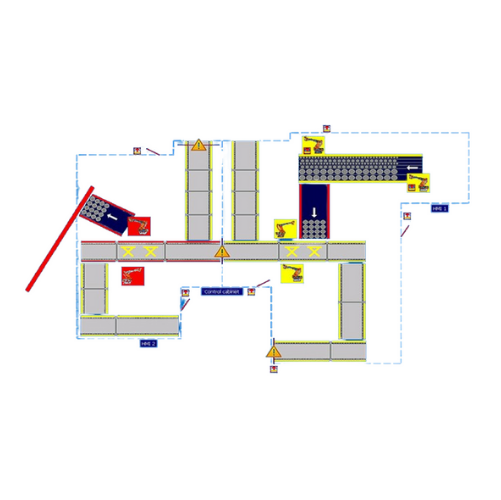

Processing steps involved in canned tuna making

Which canned tuna technology do you need?

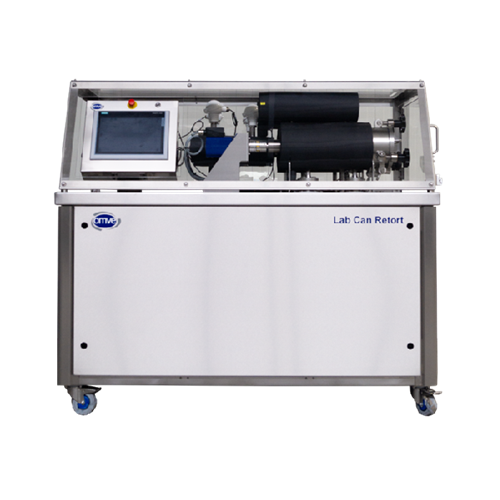

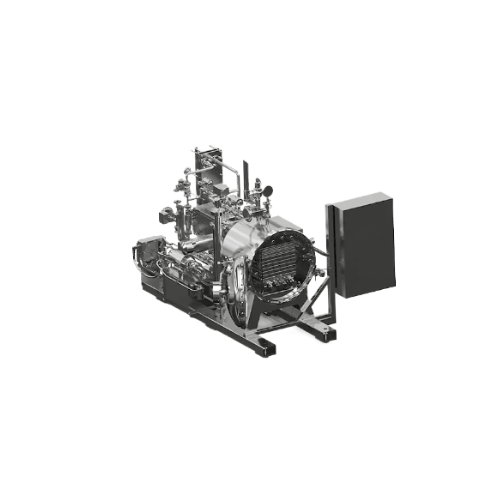

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

High infeed palletizer for varied product types

Optimize your production line with high infeed palletizers, ensuring seaml...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

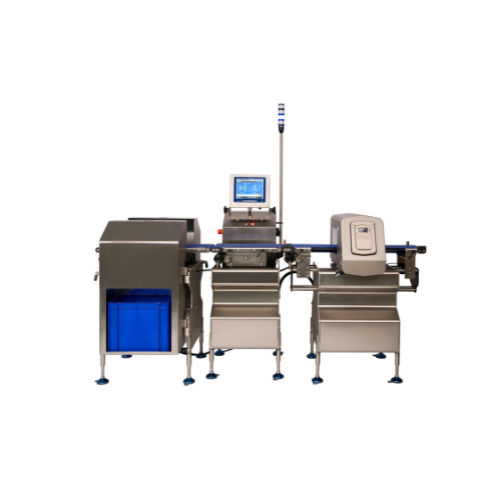

Checkweigher for food processing compliance

Ensure accurate package weights while preventing underweight or overweight pro...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

High-capacity checkweigher for heavy products

Ensure compliance and precision in weighing large and heavy packaged product...

Heavy-duty palletizing robot for production lines

Effortlessly streamline your production with this robust palletizing ro...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

Top loading case packer for automated box sealing

Streamline your packaging line with a top-loading case packer that effi...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tra...

Servo-driven dosing and portioning system

Optimally dose and portion a wide range of food products with precise weight acc...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

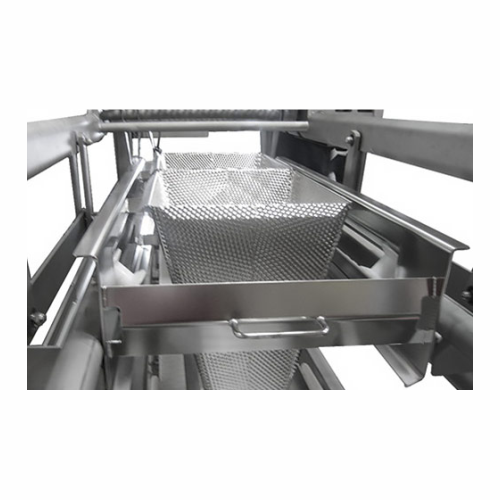

Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a sy...

Tuna vacuum pre-cooker cooler

Optimize your tuna and seafood processing with precise thawing, cooking, and cooling under vac...

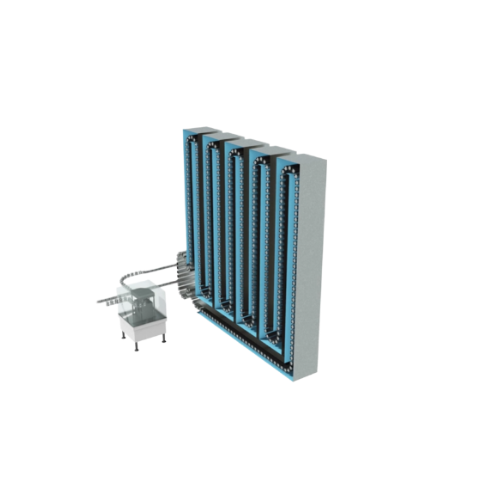

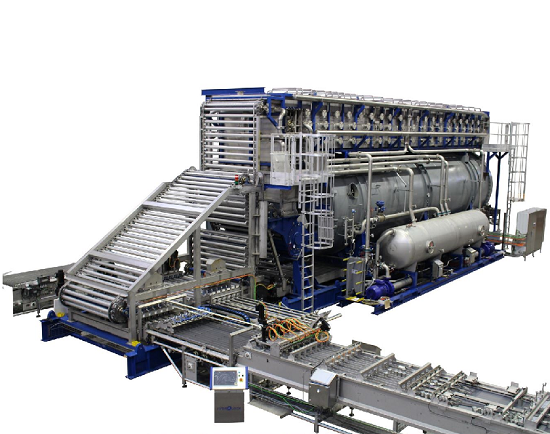

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous ...

Gentle can handling ejector for rotary cooker

Achieve seamless can transfer and sterilization with reduced damage during h...

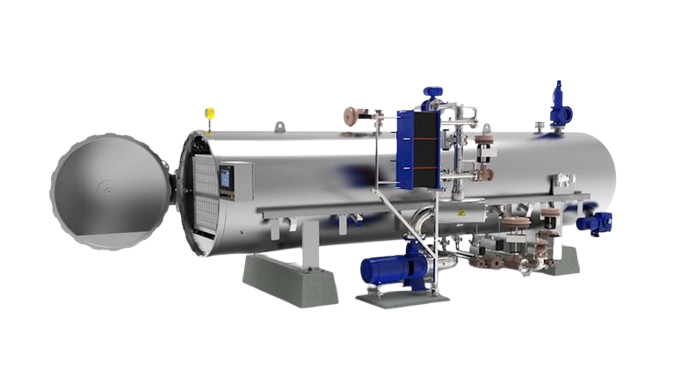

Steam water spray retort for shelf-stable food processing

Ensure uniform heat distribution and precision control in ster...

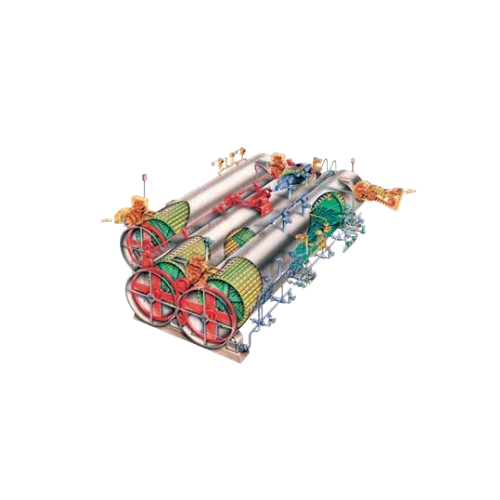

Agitating batch retort for food sterilization

Ensure superior heat distribution and precise control in your sterilization ...

Industrial retort for food sterilization

Achieve uniform sterilization and cooling in your batch production processes while...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

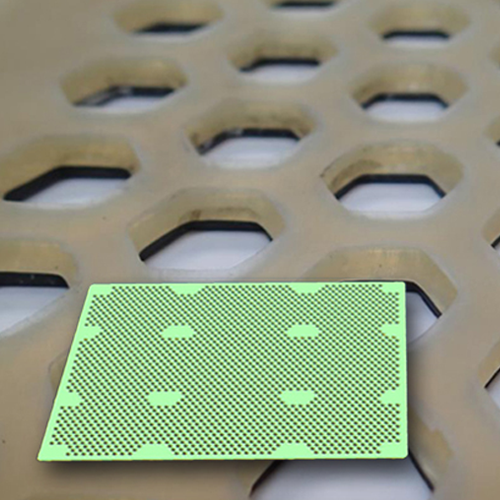

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Tuna precooking optimization software

Optimize your tuna precooking process to maximize yield and enhance product quality b...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Automatic tuna can filler

Streamline your high-speed canning operations with precision-engineered fillers that maintain opti...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Granular filler for wide mouth containers

Ensure precise filling and minimize product loss with this granular filler, expe...

High capacity volumetric filler for pumpable products

When you need high-speed, precise filling for diverse liquid and sl...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Filling and seaming groups for aluminium and tin plate cans

Smoothly synchronize filling and seaming of liquid and dense...

Automatic can seamers for food and beverage industry

Ensure airtight sealing of canned goods with precision seamers desig...

Dual view x-ray inspection for canned goods

Enhance your production line with advanced dual-view X-ray inspection, ensurin...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Industrial pickle injector for precise brine injection

Achieve unparalleled brine distribution and consistency in meat an...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Industrial autoclave food sterilizer for retort pouch and canning

Preserve the integrity and shelf life of your food pr...

Laboratory pilot sterilizers for food packaging

Optimize your R&D with precise sterilization and heat treatment capab...

Cascading water autoclave for food sterilization

Streamline your food sterilization process with an energy-efficient autoc...

Mayonnaise production line

Streamline your high-capacity mayonnaise production with precise mixing, emulsifying, and pasteur...

Continuous steam cooking and cooling for fish processing

Achieve unparalleled consistency and efficiency in fish processi...

Industrial weighfeeder for hygienic applications

Achieve precise mass flow control with a hygienic design, ideal for appli...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

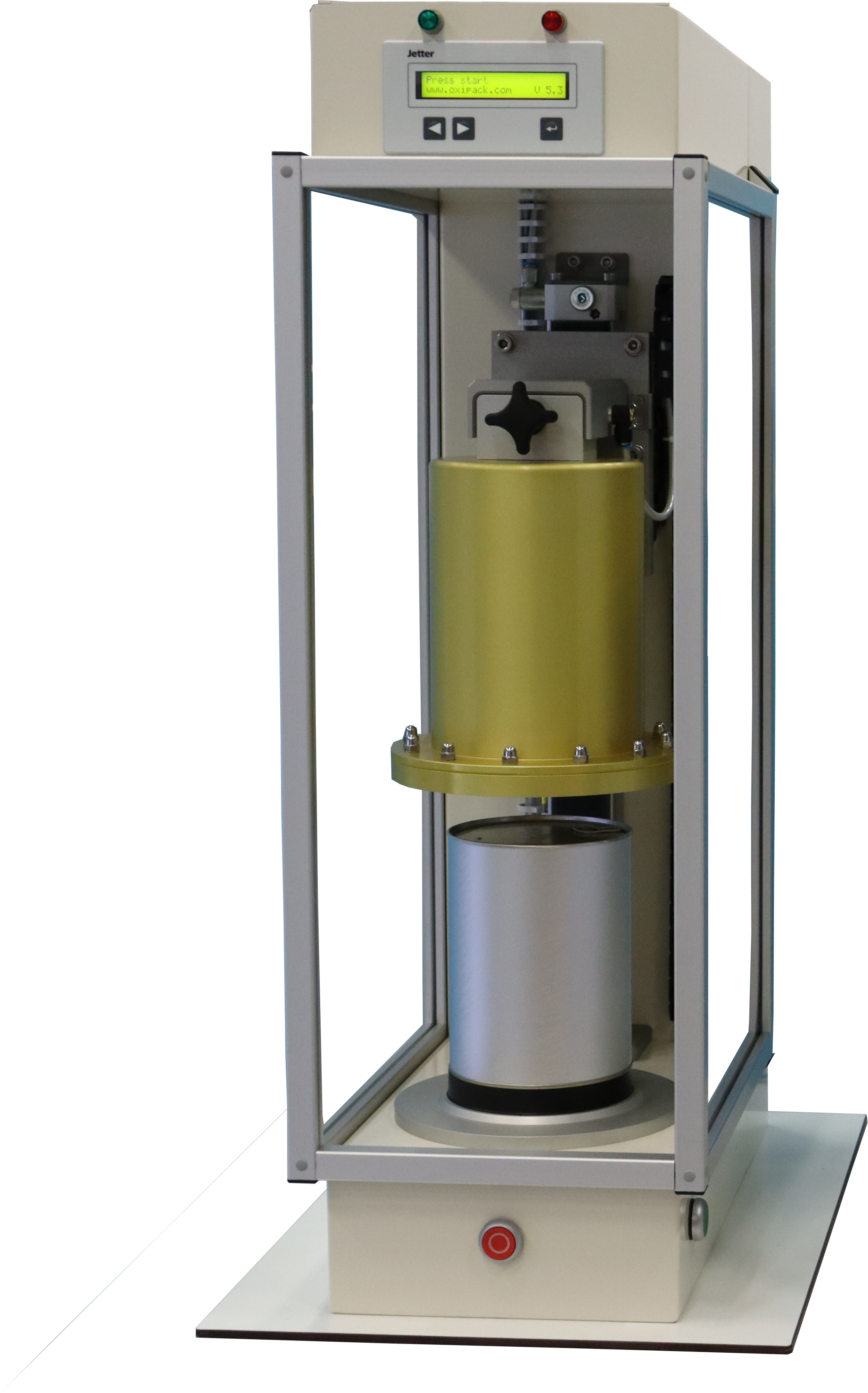

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

Irregular can seamer

Quite some time can be lost adjusting the seaming process to different can sizes when orders keep follow...

Continuous sterilizer for canned products

Sterilization is a critical operation in the manufacturing of canned vegetables ...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Autoclave for canned food

Sealing and cooking products in cans, pouches or other containers is a very popular method of pres...

High performance can seamers for the food industry

The wide variation of materials and dimensions used in the food cannin...